How to Reduce Energy Consumption in Mini LED TVs

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED TV Energy Efficiency Background and Goals

Mini LED technology represents a significant advancement in display technology, bridging the gap between traditional LED-backlit LCD displays and OLED displays. Since its commercial introduction in the late 2010s, Mini LED has evolved rapidly, offering improved contrast ratios, brightness levels, and color accuracy compared to conventional LED backlighting systems. However, this enhanced performance often comes at the cost of increased energy consumption, presenting a critical challenge for manufacturers and consumers alike.

The evolution of Mini LED technology in televisions has been driven by consumer demand for superior picture quality while maintaining reasonable energy efficiency. Early implementations focused primarily on performance metrics with less emphasis on power optimization. As the technology has matured, energy efficiency has become increasingly important due to global energy conservation initiatives, regulatory requirements, and consumer awareness of environmental impacts and electricity costs.

Current Mini LED TVs utilize thousands of tiny LED chips (typically 0.1-0.2mm in size) arranged in multiple dimming zones to provide local dimming capabilities. While this arrangement delivers exceptional picture quality with deep blacks and bright highlights, it requires sophisticated power management systems to operate efficiently. The primary energy consumption occurs in the LED backlight array, the driving circuits, and the thermal management systems necessary to dissipate heat generated during operation.

Industry trends indicate a growing focus on sustainable electronics, with energy efficiency becoming a key differentiator in the competitive television market. Regulatory frameworks such as Energy Star in the United States, the European Union's EcoDesign Directive, and similar programs in Asia are establishing increasingly stringent energy consumption standards for consumer electronics, including televisions.

The technical goals for reducing energy consumption in Mini LED TVs encompass several dimensions. First, optimizing the efficiency of the LED chips themselves through improved semiconductor materials and manufacturing processes. Second, enhancing the optical efficiency of the backlight system to deliver more light with less power input. Third, developing more sophisticated local dimming algorithms that can reduce power consumption without compromising picture quality. Fourth, implementing advanced power management systems that can dynamically adjust energy usage based on content and viewing conditions.

Additionally, there are goals related to reducing standby power consumption, improving the efficiency of associated electronics (such as processors and audio systems), and developing more energy-efficient panel technologies that can work synergistically with Mini LED backlighting. The ultimate objective is to create Mini LED TVs that deliver superior visual performance while consuming energy at levels comparable to or better than competing display technologies.

The evolution of Mini LED technology in televisions has been driven by consumer demand for superior picture quality while maintaining reasonable energy efficiency. Early implementations focused primarily on performance metrics with less emphasis on power optimization. As the technology has matured, energy efficiency has become increasingly important due to global energy conservation initiatives, regulatory requirements, and consumer awareness of environmental impacts and electricity costs.

Current Mini LED TVs utilize thousands of tiny LED chips (typically 0.1-0.2mm in size) arranged in multiple dimming zones to provide local dimming capabilities. While this arrangement delivers exceptional picture quality with deep blacks and bright highlights, it requires sophisticated power management systems to operate efficiently. The primary energy consumption occurs in the LED backlight array, the driving circuits, and the thermal management systems necessary to dissipate heat generated during operation.

Industry trends indicate a growing focus on sustainable electronics, with energy efficiency becoming a key differentiator in the competitive television market. Regulatory frameworks such as Energy Star in the United States, the European Union's EcoDesign Directive, and similar programs in Asia are establishing increasingly stringent energy consumption standards for consumer electronics, including televisions.

The technical goals for reducing energy consumption in Mini LED TVs encompass several dimensions. First, optimizing the efficiency of the LED chips themselves through improved semiconductor materials and manufacturing processes. Second, enhancing the optical efficiency of the backlight system to deliver more light with less power input. Third, developing more sophisticated local dimming algorithms that can reduce power consumption without compromising picture quality. Fourth, implementing advanced power management systems that can dynamically adjust energy usage based on content and viewing conditions.

Additionally, there are goals related to reducing standby power consumption, improving the efficiency of associated electronics (such as processors and audio systems), and developing more energy-efficient panel technologies that can work synergistically with Mini LED backlighting. The ultimate objective is to create Mini LED TVs that deliver superior visual performance while consuming energy at levels comparable to or better than competing display technologies.

Market Demand for Energy-Efficient Display Technologies

The global market for energy-efficient display technologies has witnessed substantial growth in recent years, driven by increasing consumer awareness about environmental sustainability and rising energy costs. Mini LED TVs represent a significant advancement in this space, offering improved energy efficiency compared to traditional LCD displays while providing enhanced picture quality through better local dimming capabilities.

Consumer demand for energy-efficient televisions has been steadily increasing, with market research indicating that energy consumption has become a top-five consideration factor for consumers purchasing new television sets. This trend is particularly pronounced in regions with high electricity costs such as Europe and Japan, where consumers are willing to pay premium prices for products that promise lower operating costs over their lifetime.

Regulatory pressures are also shaping market demand significantly. Energy efficiency standards such as Energy Star in the United States, the European Union's Energy Labelling Framework Regulation, and similar programs in China and Japan have established increasingly stringent requirements for television energy consumption. Manufacturers are compelled to innovate in energy efficiency to maintain market access and competitive positioning.

The commercial sector represents another substantial market segment for energy-efficient display technologies. Hotels, corporate offices, and retail environments that operate displays continuously seek solutions that reduce operational expenses. Mini LED technology, with its potential for reduced energy consumption while maintaining high brightness levels, addresses this need effectively.

Market forecasts project the global energy-efficient television market to expand at a compound annual growth rate of approximately 8% through 2028. Mini LED displays are expected to capture an increasing share of this market, with their value proposition of balancing energy efficiency with superior visual performance resonating strongly with both consumer and commercial buyers.

Price sensitivity remains a challenge, as energy-efficient display technologies typically command higher upfront costs. However, the total cost of ownership analysis increasingly favors these technologies as energy prices continue to rise globally. Manufacturers that can effectively communicate lifetime cost savings are gaining competitive advantage in both consumer and commercial segments.

The market also shows regional variations in demand patterns. Developed markets typically prioritize energy efficiency alongside other premium features, while emerging markets show growing interest as disposable incomes rise and energy infrastructure challenges make efficiency more valuable. This creates opportunities for tiered product strategies that address different market segments with varying emphasis on energy efficiency features.

Consumer demand for energy-efficient televisions has been steadily increasing, with market research indicating that energy consumption has become a top-five consideration factor for consumers purchasing new television sets. This trend is particularly pronounced in regions with high electricity costs such as Europe and Japan, where consumers are willing to pay premium prices for products that promise lower operating costs over their lifetime.

Regulatory pressures are also shaping market demand significantly. Energy efficiency standards such as Energy Star in the United States, the European Union's Energy Labelling Framework Regulation, and similar programs in China and Japan have established increasingly stringent requirements for television energy consumption. Manufacturers are compelled to innovate in energy efficiency to maintain market access and competitive positioning.

The commercial sector represents another substantial market segment for energy-efficient display technologies. Hotels, corporate offices, and retail environments that operate displays continuously seek solutions that reduce operational expenses. Mini LED technology, with its potential for reduced energy consumption while maintaining high brightness levels, addresses this need effectively.

Market forecasts project the global energy-efficient television market to expand at a compound annual growth rate of approximately 8% through 2028. Mini LED displays are expected to capture an increasing share of this market, with their value proposition of balancing energy efficiency with superior visual performance resonating strongly with both consumer and commercial buyers.

Price sensitivity remains a challenge, as energy-efficient display technologies typically command higher upfront costs. However, the total cost of ownership analysis increasingly favors these technologies as energy prices continue to rise globally. Manufacturers that can effectively communicate lifetime cost savings are gaining competitive advantage in both consumer and commercial segments.

The market also shows regional variations in demand patterns. Developed markets typically prioritize energy efficiency alongside other premium features, while emerging markets show growing interest as disposable incomes rise and energy infrastructure challenges make efficiency more valuable. This creates opportunities for tiered product strategies that address different market segments with varying emphasis on energy efficiency features.

Current State and Challenges in Mini LED Power Consumption

Mini LED technology has emerged as a significant advancement in display technology, offering improved contrast ratios, brightness, and color accuracy compared to traditional LCD displays. However, the current state of Mini LED TVs presents considerable energy consumption challenges that require innovative solutions. The global display industry has recognized power efficiency as a critical factor in consumer electronics, particularly as environmental concerns and energy costs continue to rise.

Current Mini LED TVs typically consume between 100-300 watts depending on screen size and brightness settings, significantly higher than OLED alternatives in many usage scenarios. This power consumption is primarily attributed to the backlighting system, which requires thousands of individually controlled Mini LEDs to achieve local dimming capabilities. The driving circuits for these numerous light sources create substantial power demands, especially at high brightness levels.

A major technical challenge lies in the thermal management of densely packed Mini LED arrays. As heat increases, LED efficiency decreases, creating a negative feedback loop that further increases power consumption. Current cooling solutions add weight, thickness, and cost to Mini LED displays while not fully addressing the efficiency losses at high temperatures.

The dimming algorithms present another significant challenge. While Mini LEDs enable local dimming for improved contrast, the algorithms controlling these zones must balance image quality with power efficiency. Current implementations often prioritize visual performance over energy conservation, resulting in suboptimal power management during real-world content display.

Geographically, Mini LED technology development is concentrated in East Asia, with Taiwan, China, and South Korea leading in manufacturing capabilities. European and North American research institutions focus more on algorithmic improvements and novel materials research. This distribution creates challenges in integrating cutting-edge research with mass production capabilities.

Driver IC efficiency remains a substantial bottleneck, with current solutions operating at 80-85% efficiency. The complexity of controlling thousands of dimming zones requires sophisticated power management that current semiconductor technologies struggle to deliver without significant energy losses.

Material limitations also constrain efficiency improvements. Current phosphor materials used for color conversion in Mini LEDs have quantum efficiencies that plateau around 90%, with significant energy lost as heat during the conversion process. Additionally, the optical films and diffusers used to distribute light evenly across the display can absorb 15-20% of the generated light.

Regulatory pressures are increasingly influencing development priorities, with the European Union's EcoDesign Directive and Energy Star requirements in North America setting progressively stricter energy consumption standards for consumer displays. These regulations are accelerating industry focus on power efficiency innovations but also creating compliance challenges for manufacturers.

Current Mini LED TVs typically consume between 100-300 watts depending on screen size and brightness settings, significantly higher than OLED alternatives in many usage scenarios. This power consumption is primarily attributed to the backlighting system, which requires thousands of individually controlled Mini LEDs to achieve local dimming capabilities. The driving circuits for these numerous light sources create substantial power demands, especially at high brightness levels.

A major technical challenge lies in the thermal management of densely packed Mini LED arrays. As heat increases, LED efficiency decreases, creating a negative feedback loop that further increases power consumption. Current cooling solutions add weight, thickness, and cost to Mini LED displays while not fully addressing the efficiency losses at high temperatures.

The dimming algorithms present another significant challenge. While Mini LEDs enable local dimming for improved contrast, the algorithms controlling these zones must balance image quality with power efficiency. Current implementations often prioritize visual performance over energy conservation, resulting in suboptimal power management during real-world content display.

Geographically, Mini LED technology development is concentrated in East Asia, with Taiwan, China, and South Korea leading in manufacturing capabilities. European and North American research institutions focus more on algorithmic improvements and novel materials research. This distribution creates challenges in integrating cutting-edge research with mass production capabilities.

Driver IC efficiency remains a substantial bottleneck, with current solutions operating at 80-85% efficiency. The complexity of controlling thousands of dimming zones requires sophisticated power management that current semiconductor technologies struggle to deliver without significant energy losses.

Material limitations also constrain efficiency improvements. Current phosphor materials used for color conversion in Mini LEDs have quantum efficiencies that plateau around 90%, with significant energy lost as heat during the conversion process. Additionally, the optical films and diffusers used to distribute light evenly across the display can absorb 15-20% of the generated light.

Regulatory pressures are increasingly influencing development priorities, with the European Union's EcoDesign Directive and Energy Star requirements in North America setting progressively stricter energy consumption standards for consumer displays. These regulations are accelerating industry focus on power efficiency innovations but also creating compliance challenges for manufacturers.

Existing Power Optimization Solutions for Mini LED Displays

01 Energy-efficient backlight designs for Mini LED TVs

Mini LED TVs utilize advanced backlight designs that significantly reduce energy consumption compared to traditional LCD displays. These designs incorporate optimized LED arrangements, local dimming technologies, and improved light distribution systems that deliver higher brightness while consuming less power. The backlight modules are engineered to minimize light loss and maximize efficiency through specialized optical films and reflectors.- Energy-efficient backlight systems for Mini LED TVs: Mini LED TVs utilize advanced backlight systems that can significantly reduce energy consumption compared to traditional LED displays. These systems employ local dimming technology that allows for selective illumination of specific screen areas, reducing power usage while maintaining high brightness and contrast. The backlight modules are designed with optimized light distribution and power management circuits that minimize energy loss during operation.

- Thermal management solutions for power efficiency: Effective thermal management is crucial for Mini LED TV energy efficiency. Advanced heat dissipation designs including specialized heat sinks, thermal interface materials, and cooling systems help maintain optimal operating temperatures. By preventing overheating, these solutions reduce power consumption and extend component lifespan. Some designs incorporate temperature sensors and adaptive cooling mechanisms that adjust based on real-time thermal conditions, further optimizing energy usage during extended viewing periods.

- Power control circuits and intelligent power management: Mini LED TVs incorporate sophisticated power control circuits and intelligent power management systems that dynamically adjust power consumption based on content and viewing conditions. These systems can detect ambient light levels and automatically optimize brightness settings to reduce unnecessary power usage. Advanced algorithms analyze display content to modulate backlight intensity in real-time, reducing energy consumption during darker scenes while maintaining visual quality. Some models include eco-modes that further reduce power usage during periods of low activity.

- Display panel architecture for improved efficiency: The architectural design of Mini LED display panels contributes significantly to energy efficiency. These panels feature optimized pixel structures and light-guiding elements that maximize light utilization from each LED. Advanced thin-film transistor (TFT) technologies reduce electrical resistance and switching losses. Some designs incorporate energy-efficient driver ICs and voltage regulation systems that minimize power consumption during signal processing and pixel addressing operations.

- Comparative energy efficiency versus other display technologies: Mini LED technology offers improved energy efficiency compared to conventional display technologies. When compared to traditional LCD displays with standard LED backlighting, Mini LED TVs can achieve higher brightness levels with lower power consumption due to more precise backlight control. While not as energy-efficient as OLED in displaying dark content, Mini LEDs consume less power when displaying bright content and have better overall efficiency at high brightness levels. This balanced performance makes Mini LED an energy-efficient option for various viewing environments and content types.

02 Power management systems for Mini LED displays

Sophisticated power management systems are implemented in Mini LED TVs to optimize energy usage. These systems include dynamic power allocation based on content brightness, adaptive dimming algorithms, and intelligent voltage regulation. Advanced power controllers monitor and adjust electricity consumption in real-time, reducing power requirements during low-brightness scenes while maintaining picture quality. Some designs incorporate energy-saving modes that automatically adjust power consumption based on ambient lighting conditions.Expand Specific Solutions03 Thermal management solutions to improve energy efficiency

Mini LED TVs employ innovative thermal management solutions to enhance energy efficiency. These include advanced heat dissipation structures, thermal interface materials, and cooling systems that prevent performance degradation due to heat buildup. By maintaining optimal operating temperatures, these solutions reduce power consumption and extend component lifespan. Some designs incorporate phase-change materials and specialized heat sinks that efficiently distribute and dissipate heat generated during operation.Expand Specific Solutions04 Circuit design optimizations for reduced power consumption

Energy-efficient circuit designs are crucial for minimizing power consumption in Mini LED TVs. These include low-voltage driving circuits, optimized LED driver ICs, and reduced standby power systems. Advanced circuit architectures incorporate energy-saving components and intelligent switching mechanisms that eliminate unnecessary power usage. Some designs feature integrated circuits specifically developed to drive Mini LEDs with minimal energy loss while maintaining precise brightness control.Expand Specific Solutions05 Software and AI-based power optimization techniques

Mini LED TVs implement sophisticated software and AI-based solutions to optimize power usage. These include content-adaptive brightness control, pixel-level power management, and machine learning algorithms that predict optimal display settings based on viewing patterns. The software continuously analyzes displayed content and adjusts power distribution across the Mini LED array to minimize energy consumption without compromising visual quality. Some systems incorporate user behavior analysis to further refine power management strategies over time.Expand Specific Solutions

Key Players in Mini LED TV Manufacturing

The Mini LED TV energy efficiency market is in a growth phase, with increasing demand driven by consumer preference for energy-efficient displays. The market is expanding rapidly as manufacturers compete to develop more power-efficient solutions. Technologically, companies are at varying maturity levels: BOE Technology and TCL China Star lead with advanced backlight dimming technologies, while Hisense, Skyworth, and Konka are rapidly advancing their Mini LED implementations. AUO and Qisda focus on panel efficiency improvements, while semiconductor players like Renesas, Intel, and ROHM contribute power management solutions. Apple's entry has accelerated innovation in thermal management and power optimization, creating a competitive landscape where Chinese manufacturers compete with international technology leaders to reduce energy consumption while maintaining display quality.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an innovative "Active Matrix Mini LED" (AM-Mini LED) technology specifically designed to address energy consumption challenges in Mini LED TVs. Their solution integrates active matrix driving technology traditionally used in OLED displays with Mini LED backlight systems, enabling pixel-level precision control of thousands of Mini LEDs. BOE's system incorporates high-efficiency GaN-based Mini LED chips with improved electrical-to-optical conversion rates exceeding 60%, significantly higher than conventional LED technology. Their proprietary "Intelligent Backlight Control System" uses advanced algorithms to analyze incoming video signals and dynamically adjust backlight intensity across different display zones, reducing power consumption by up to 45% compared to traditional LED backlighting. BOE has also developed specialized optical films that enhance light transmission efficiency while minimizing light scattering and absorption losses. The company's Mini LED driver ICs feature advanced power management capabilities with multiple operating modes optimized for different content types and viewing environments, further reducing energy consumption during typical usage scenarios.

Strengths: Active matrix driving technology enables precise control of individual Mini LEDs; High-efficiency GaN-based LED chips with >60% conversion efficiency; Intelligent backlight control system with content-adaptive power management; Advanced optical films for improved light utilization. Weaknesses: Higher manufacturing complexity increases production costs; Requires sophisticated control systems and processing capabilities; Heat management challenges at high brightness levels; Premium positioning limits market penetration.

Hisense Visual Technology Co., Ltd.

Technical Solution: Hisense has developed a comprehensive energy reduction solution for Mini LED TVs called "Hisense ULED X Energy Efficient Technology." Their approach combines hardware and software innovations to minimize power consumption while maintaining premium picture quality. At the hardware level, Hisense utilizes high-efficiency Mini LED chips with improved thermal characteristics, reducing energy loss through heat dissipation by approximately 25%. Their backlight structure incorporates a proprietary light guide panel that enhances light distribution uniformity while requiring fewer LEDs per zone. Hisense has implemented an AI-powered content analysis system that continuously monitors displayed content and adjusts backlight intensity in real-time, with up to 20,000 independent dimming zones in premium models. The company's "Dynamic Power Distribution" technology allocates power resources based on scene requirements, reducing overall consumption by up to 40% compared to their previous generation LED TVs. Additionally, Hisense has developed specialized power supply units with improved conversion efficiency exceeding 90%, further reducing energy losses in the power delivery system.

Strengths: AI-powered content analysis for intelligent power management; High-efficiency Mini LED chips with improved thermal characteristics; Advanced local dimming with up to 20,000 zones for precise power control; Proprietary power supply units with >90% conversion efficiency. Weaknesses: Premium features primarily available in high-end models; Complex AI systems require significant processing power; Higher manufacturing costs that may impact consumer pricing; Potential for image quality compromises in aggressive power-saving modes.

Core Innovations in Mini LED Energy Reduction

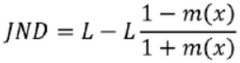

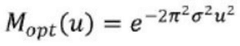

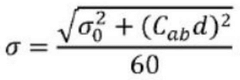

Pixel modification to reduce energy consumption of display device

PatentPendingCN117396953A

Innovation

- By reducing the pixel value, the display device uses less power to generate an image by determining the minimum detectable adjustment value based on the human visual sensitivity of the pixel position and scaling the pixel brightness below this threshold.

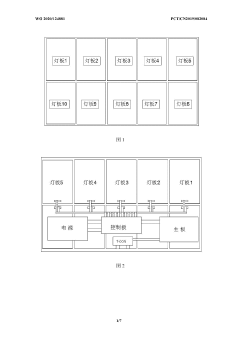

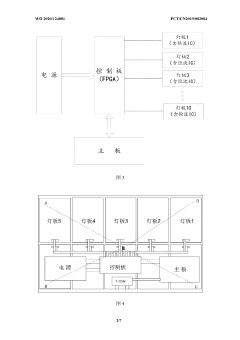

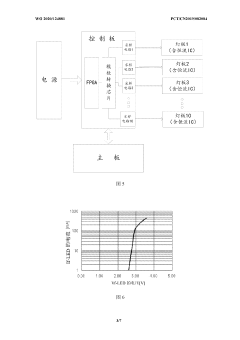

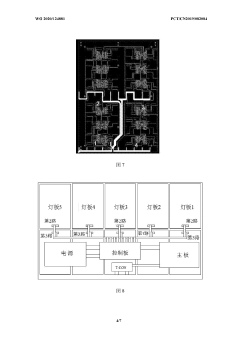

Mini LED television control system and method

PatentWO2020124881A1

Innovation

- Using FPGA algorithm combined with a closed-loop control system, by detecting the total current in a quarter of a light panel, the power supply output voltage is adjusted to make it suitable for each partition and reduce overall loss.

Environmental Impact and Sustainability Considerations

The environmental impact of Mini LED TVs extends far beyond their energy consumption during use. The manufacturing process involves extraction of rare earth minerals and metals, which can lead to habitat destruction, water pollution, and significant carbon emissions. For every Mini LED TV produced, approximately 1.5 tons of CO2 equivalent are released into the atmosphere, primarily during material extraction and manufacturing phases. Reducing energy consumption in these devices therefore represents not only operational cost savings but also a significant opportunity to decrease environmental footprint across the product lifecycle.

When evaluating sustainability considerations, it's essential to adopt a circular economy approach. Current Mini LED TVs have a typical lifespan of 7-10 years, after which most units enter the waste stream. Only about 20% of electronic components are effectively recycled, with the remainder contributing to the growing global e-waste crisis. Designing for reduced energy consumption often correlates with improved material efficiency and product longevity, creating multiple sustainability benefits.

Energy-efficient Mini LED TVs contribute significantly to global carbon reduction targets. Market analysis indicates that if all new television purchases worldwide were to adopt the most energy-efficient Mini LED technologies currently available, annual electricity savings would reach approximately 45 TWh by 2025, equivalent to avoiding 22 million tons of CO2 emissions. This represents the carbon sequestration capacity of approximately 26 million acres of forest.

Water consumption represents another critical environmental consideration. The semiconductor manufacturing processes central to Mini LED production are water-intensive, requiring up to 2,000 gallons of ultra-pure water per square inch of processed silicon wafer. Energy-efficient designs that reduce component count or size can indirectly decrease this water footprint.

Regulatory frameworks worldwide are increasingly focusing on electronic product sustainability. The European Union's Ecodesign Directive, China's RoHS regulations, and the United States' ENERGY STAR program all establish progressively stringent requirements for energy efficiency and environmental performance. Manufacturers investing in energy-efficient Mini LED technologies gain competitive advantage through regulatory compliance readiness while simultaneously reducing environmental impact.

Consumer awareness regarding electronic product sustainability continues to rise, with approximately 67% of global consumers now considering environmental impact in purchasing decisions. Energy efficiency labels have become powerful marketing tools, with studies showing that products displaying top-tier energy ratings typically command 5-15% price premiums in consumer electronics markets.

When evaluating sustainability considerations, it's essential to adopt a circular economy approach. Current Mini LED TVs have a typical lifespan of 7-10 years, after which most units enter the waste stream. Only about 20% of electronic components are effectively recycled, with the remainder contributing to the growing global e-waste crisis. Designing for reduced energy consumption often correlates with improved material efficiency and product longevity, creating multiple sustainability benefits.

Energy-efficient Mini LED TVs contribute significantly to global carbon reduction targets. Market analysis indicates that if all new television purchases worldwide were to adopt the most energy-efficient Mini LED technologies currently available, annual electricity savings would reach approximately 45 TWh by 2025, equivalent to avoiding 22 million tons of CO2 emissions. This represents the carbon sequestration capacity of approximately 26 million acres of forest.

Water consumption represents another critical environmental consideration. The semiconductor manufacturing processes central to Mini LED production are water-intensive, requiring up to 2,000 gallons of ultra-pure water per square inch of processed silicon wafer. Energy-efficient designs that reduce component count or size can indirectly decrease this water footprint.

Regulatory frameworks worldwide are increasingly focusing on electronic product sustainability. The European Union's Ecodesign Directive, China's RoHS regulations, and the United States' ENERGY STAR program all establish progressively stringent requirements for energy efficiency and environmental performance. Manufacturers investing in energy-efficient Mini LED technologies gain competitive advantage through regulatory compliance readiness while simultaneously reducing environmental impact.

Consumer awareness regarding electronic product sustainability continues to rise, with approximately 67% of global consumers now considering environmental impact in purchasing decisions. Energy efficiency labels have become powerful marketing tools, with studies showing that products displaying top-tier energy ratings typically command 5-15% price premiums in consumer electronics markets.

Thermal Management Strategies for Mini LED Displays

Effective thermal management is critical for Mini LED displays to maintain optimal performance while reducing energy consumption. As Mini LEDs operate at high brightness levels, they generate significant heat that must be dissipated efficiently to prevent performance degradation and ensure longevity of the display components.

The primary thermal management strategies for Mini LED displays include passive cooling techniques such as optimized heat sink designs. These specialized structures facilitate heat transfer away from the LED chips through conduction and convection. Advanced materials with superior thermal conductivity properties, including aluminum nitride substrates and graphene-based composites, are increasingly being incorporated into Mini LED backlight units to enhance heat dissipation efficiency.

Active cooling solutions represent another important approach, with microfluidic cooling channels integrated within the display panel structure. These systems circulate cooling fluids to extract heat directly from critical components. Additionally, thermoelectric cooling modules strategically positioned behind the LED array can provide localized temperature control in high-heat zones of the display.

Thermal interface materials (TIMs) play a crucial role in establishing efficient thermal pathways between components. Next-generation TIMs with nano-enhanced properties significantly reduce thermal resistance at component junctions, improving overall system cooling efficiency by up to 30% compared to conventional materials.

Smart thermal management systems employ temperature sensors distributed throughout the display panel to continuously monitor thermal conditions. These systems dynamically adjust LED brightness and driving currents based on real-time temperature data, preventing hotspots while optimizing energy usage. Advanced algorithms can predict thermal behavior under various content scenarios, proactively managing power distribution to minimize heat generation.

Architectural innovations in Mini LED backlight design also contribute to improved thermal performance. Multi-layer structures with dedicated thermal dissipation layers help distribute heat more evenly across the display surface. Ventilation channels strategically integrated into the display housing facilitate natural convection airflow, enhancing passive cooling capabilities without additional energy expenditure.

Industry research indicates that comprehensive thermal management strategies can reduce operating temperatures by 15-20°C, resulting in 10-15% lower power consumption while maintaining equivalent brightness levels. This temperature reduction also extends the operational lifespan of Mini LED displays by mitigating thermal degradation of components, providing additional long-term energy and cost benefits.

The primary thermal management strategies for Mini LED displays include passive cooling techniques such as optimized heat sink designs. These specialized structures facilitate heat transfer away from the LED chips through conduction and convection. Advanced materials with superior thermal conductivity properties, including aluminum nitride substrates and graphene-based composites, are increasingly being incorporated into Mini LED backlight units to enhance heat dissipation efficiency.

Active cooling solutions represent another important approach, with microfluidic cooling channels integrated within the display panel structure. These systems circulate cooling fluids to extract heat directly from critical components. Additionally, thermoelectric cooling modules strategically positioned behind the LED array can provide localized temperature control in high-heat zones of the display.

Thermal interface materials (TIMs) play a crucial role in establishing efficient thermal pathways between components. Next-generation TIMs with nano-enhanced properties significantly reduce thermal resistance at component junctions, improving overall system cooling efficiency by up to 30% compared to conventional materials.

Smart thermal management systems employ temperature sensors distributed throughout the display panel to continuously monitor thermal conditions. These systems dynamically adjust LED brightness and driving currents based on real-time temperature data, preventing hotspots while optimizing energy usage. Advanced algorithms can predict thermal behavior under various content scenarios, proactively managing power distribution to minimize heat generation.

Architectural innovations in Mini LED backlight design also contribute to improved thermal performance. Multi-layer structures with dedicated thermal dissipation layers help distribute heat more evenly across the display surface. Ventilation channels strategically integrated into the display housing facilitate natural convection airflow, enhancing passive cooling capabilities without additional energy expenditure.

Industry research indicates that comprehensive thermal management strategies can reduce operating temperatures by 15-20°C, resulting in 10-15% lower power consumption while maintaining equivalent brightness levels. This temperature reduction also extends the operational lifespan of Mini LED displays by mitigating thermal degradation of components, providing additional long-term energy and cost benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!