How to Reduce Galvanized Steel’s Environmental Impact

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanization Environmental Challenges and Objectives

Galvanized steel has been a cornerstone material in construction, automotive, and infrastructure industries for decades due to its exceptional corrosion resistance and durability. However, the environmental footprint of galvanization processes has become increasingly concerning as global sustainability standards evolve. The galvanization industry faces significant environmental challenges, primarily stemming from zinc mining, energy-intensive production processes, and the release of harmful emissions.

The zinc coating process typically involves hot-dip galvanization, where steel is immersed in molten zinc at temperatures exceeding 450°C. This energy-intensive procedure contributes substantially to carbon emissions, with traditional galvanizing facilities consuming between 300-600 kWh of energy per ton of processed steel. Additionally, the process generates zinc ash, dross, and spent acid solutions containing heavy metals that require careful management to prevent environmental contamination.

Zinc mining and refining operations present another layer of environmental concern. Open-pit mining for zinc ore disrupts ecosystems, while refining processes generate sulfur dioxide emissions and solid waste. The global zinc supply chain's carbon footprint is estimated at 2.3 tons of CO2 equivalent per ton of refined zinc, highlighting the upstream environmental impact of galvanized steel production.

Water pollution represents a critical challenge, as galvanizing operations traditionally use acid pickling baths that generate wastewater containing dissolved metals, acids, and other contaminants. Without proper treatment, these effluents can contaminate groundwater and aquatic ecosystems, causing long-term environmental damage and potential public health issues.

The primary objective of environmental improvement initiatives in galvanization is to develop cleaner production technologies that maintain or enhance steel's corrosion protection while minimizing ecological impact. This includes reducing energy consumption by at least 30% through process optimization and equipment modernization, as well as decreasing freshwater usage by implementing closed-loop water systems and advanced filtration technologies.

Another key goal is minimizing hazardous waste generation through improved zinc recovery systems and alternative pre-treatment methods that reduce or eliminate the need for harsh chemicals. The industry aims to achieve a 50% reduction in landfill waste by 2030 through enhanced recycling protocols and circular economy approaches.

Emissions reduction represents a critical objective, with targets focusing on decreasing volatile organic compounds (VOCs), particulate matter, and greenhouse gas emissions. This includes transitioning to lower-temperature processes, implementing advanced air pollution control systems, and exploring renewable energy integration to power galvanizing operations.

The ultimate long-term vision involves developing next-generation galvanizing technologies that fundamentally reimagine the protection of steel while dramatically reducing environmental impact across the entire life cycle, from raw material extraction to end-of-life recycling.

The zinc coating process typically involves hot-dip galvanization, where steel is immersed in molten zinc at temperatures exceeding 450°C. This energy-intensive procedure contributes substantially to carbon emissions, with traditional galvanizing facilities consuming between 300-600 kWh of energy per ton of processed steel. Additionally, the process generates zinc ash, dross, and spent acid solutions containing heavy metals that require careful management to prevent environmental contamination.

Zinc mining and refining operations present another layer of environmental concern. Open-pit mining for zinc ore disrupts ecosystems, while refining processes generate sulfur dioxide emissions and solid waste. The global zinc supply chain's carbon footprint is estimated at 2.3 tons of CO2 equivalent per ton of refined zinc, highlighting the upstream environmental impact of galvanized steel production.

Water pollution represents a critical challenge, as galvanizing operations traditionally use acid pickling baths that generate wastewater containing dissolved metals, acids, and other contaminants. Without proper treatment, these effluents can contaminate groundwater and aquatic ecosystems, causing long-term environmental damage and potential public health issues.

The primary objective of environmental improvement initiatives in galvanization is to develop cleaner production technologies that maintain or enhance steel's corrosion protection while minimizing ecological impact. This includes reducing energy consumption by at least 30% through process optimization and equipment modernization, as well as decreasing freshwater usage by implementing closed-loop water systems and advanced filtration technologies.

Another key goal is minimizing hazardous waste generation through improved zinc recovery systems and alternative pre-treatment methods that reduce or eliminate the need for harsh chemicals. The industry aims to achieve a 50% reduction in landfill waste by 2030 through enhanced recycling protocols and circular economy approaches.

Emissions reduction represents a critical objective, with targets focusing on decreasing volatile organic compounds (VOCs), particulate matter, and greenhouse gas emissions. This includes transitioning to lower-temperature processes, implementing advanced air pollution control systems, and exploring renewable energy integration to power galvanizing operations.

The ultimate long-term vision involves developing next-generation galvanizing technologies that fundamentally reimagine the protection of steel while dramatically reducing environmental impact across the entire life cycle, from raw material extraction to end-of-life recycling.

Market Demand for Sustainable Steel Coating Solutions

The global market for sustainable steel coating solutions has witnessed significant growth in recent years, driven by increasing environmental regulations, consumer awareness, and corporate sustainability commitments. The galvanized steel industry, valued at approximately $188 billion in 2022, is experiencing a paradigm shift toward greener alternatives as stakeholders across the value chain demand reduced environmental footprints.

Environmental regulations have become increasingly stringent worldwide, with the European Union's Green Deal and Carbon Border Adjustment Mechanism (CBAM) setting new standards for industrial emissions. Similarly, the United States EPA has tightened regulations on zinc and heavy metal discharge from galvanizing operations. These regulatory pressures have created an urgent market need for coating solutions that minimize environmental impact while maintaining performance characteristics.

End-user industries, particularly automotive, construction, and consumer appliances, are driving demand for sustainably produced galvanized steel. Major automotive manufacturers have established sustainability targets requiring suppliers to reduce carbon footprints by 30-50% by 2030. The construction sector, representing approximately 40% of galvanized steel consumption, has embraced green building certifications like LEED and BREEAM, which award points for environmentally responsible material selection.

Market research indicates that consumers are increasingly willing to pay premium prices for products with verified environmental credentials. A 2023 industry survey revealed that 67% of procurement professionals in manufacturing sectors now include environmental impact metrics in supplier evaluation criteria, up from 42% in 2018. This shift in purchasing behavior has created a competitive advantage for steel producers offering demonstrably sustainable coating solutions.

The circular economy concept has gained significant traction, creating market demand for galvanized steel products designed for recyclability and reduced life-cycle impacts. Steel recycling rates have improved globally, but coating materials often present challenges in the recycling process. Consequently, there is growing demand for coating technologies that maintain recyclability while reducing environmental harm during production and end-of-life phases.

Regional market variations exist, with European and North American markets showing stronger immediate demand for sustainable solutions, while emerging economies in Asia and Africa prioritize cost-effectiveness alongside gradual environmental improvements. However, the global trend is unmistakably moving toward sustainability as a core market requirement rather than a premium option.

Industry forecasts project the market for environmentally optimized galvanized steel to grow at a compound annual rate of 7.8% through 2030, significantly outpacing traditional galvanizing methods. This growth trajectory underscores the economic opportunity in developing and commercializing sustainable coating technologies that address current environmental challenges while meeting performance requirements.

Environmental regulations have become increasingly stringent worldwide, with the European Union's Green Deal and Carbon Border Adjustment Mechanism (CBAM) setting new standards for industrial emissions. Similarly, the United States EPA has tightened regulations on zinc and heavy metal discharge from galvanizing operations. These regulatory pressures have created an urgent market need for coating solutions that minimize environmental impact while maintaining performance characteristics.

End-user industries, particularly automotive, construction, and consumer appliances, are driving demand for sustainably produced galvanized steel. Major automotive manufacturers have established sustainability targets requiring suppliers to reduce carbon footprints by 30-50% by 2030. The construction sector, representing approximately 40% of galvanized steel consumption, has embraced green building certifications like LEED and BREEAM, which award points for environmentally responsible material selection.

Market research indicates that consumers are increasingly willing to pay premium prices for products with verified environmental credentials. A 2023 industry survey revealed that 67% of procurement professionals in manufacturing sectors now include environmental impact metrics in supplier evaluation criteria, up from 42% in 2018. This shift in purchasing behavior has created a competitive advantage for steel producers offering demonstrably sustainable coating solutions.

The circular economy concept has gained significant traction, creating market demand for galvanized steel products designed for recyclability and reduced life-cycle impacts. Steel recycling rates have improved globally, but coating materials often present challenges in the recycling process. Consequently, there is growing demand for coating technologies that maintain recyclability while reducing environmental harm during production and end-of-life phases.

Regional market variations exist, with European and North American markets showing stronger immediate demand for sustainable solutions, while emerging economies in Asia and Africa prioritize cost-effectiveness alongside gradual environmental improvements. However, the global trend is unmistakably moving toward sustainability as a core market requirement rather than a premium option.

Industry forecasts project the market for environmentally optimized galvanized steel to grow at a compound annual rate of 7.8% through 2030, significantly outpacing traditional galvanizing methods. This growth trajectory underscores the economic opportunity in developing and commercializing sustainable coating technologies that address current environmental challenges while meeting performance requirements.

Current State and Limitations of Galvanization Processes

Galvanization, a process that applies a protective zinc coating to steel, has been widely adopted across industries for its corrosion resistance properties. However, current galvanization processes present significant environmental challenges that require urgent attention. The conventional hot-dip galvanizing process operates at temperatures between 445-465°C, consuming substantial energy and generating considerable greenhouse gas emissions. Industry estimates suggest that producing one ton of galvanized steel releases approximately 2.3 tons of CO2 equivalent, contributing significantly to the steel industry's carbon footprint.

The zinc mining and refining processes that supply raw materials for galvanization create additional environmental burdens. These activities result in habitat destruction, soil contamination, and water pollution through acid mine drainage and heavy metal leaching. Current extraction methods typically recover only 50-60% of available zinc, leading to resource inefficiency and increased environmental impact per unit of usable zinc.

Waste management represents another critical limitation of existing galvanization technologies. The pickling process, which prepares steel surfaces for zinc coating, generates acidic waste streams containing iron chlorides and sulfates. These hazardous byproducts require specialized treatment and disposal protocols that are often energy-intensive and costly. Additionally, spent acid solutions and zinc-containing dross from galvanizing baths pose significant environmental risks if improperly managed.

Water consumption in traditional galvanization processes is substantial, with estimates suggesting 1-3 cubic meters of water required per ton of galvanized steel. This water becomes contaminated with heavy metals and chemical agents, necessitating extensive treatment before discharge. Many facilities, particularly in developing regions, lack adequate wastewater treatment capabilities, resulting in environmental contamination.

Workplace health concerns further complicate the environmental profile of galvanization. Workers are exposed to zinc fumes, acid mists, and other hazardous substances that can cause respiratory issues and other health problems. These occupational hazards necessitate extensive ventilation systems that consume additional energy and resources.

The durability of galvanized coatings, while beneficial for product longevity, presents end-of-life recycling challenges. Zinc-coated steel requires specialized recycling processes to separate and recover both materials effectively. Current recycling technologies achieve only partial zinc recovery rates of 60-70%, with the remainder typically lost as waste or environmental discharge.

Regulatory compliance adds another layer of complexity, with increasingly stringent environmental standards being implemented globally. Many existing galvanization facilities struggle to meet these evolving requirements without significant technological upgrades or process modifications, creating economic barriers to environmental improvement.

The zinc mining and refining processes that supply raw materials for galvanization create additional environmental burdens. These activities result in habitat destruction, soil contamination, and water pollution through acid mine drainage and heavy metal leaching. Current extraction methods typically recover only 50-60% of available zinc, leading to resource inefficiency and increased environmental impact per unit of usable zinc.

Waste management represents another critical limitation of existing galvanization technologies. The pickling process, which prepares steel surfaces for zinc coating, generates acidic waste streams containing iron chlorides and sulfates. These hazardous byproducts require specialized treatment and disposal protocols that are often energy-intensive and costly. Additionally, spent acid solutions and zinc-containing dross from galvanizing baths pose significant environmental risks if improperly managed.

Water consumption in traditional galvanization processes is substantial, with estimates suggesting 1-3 cubic meters of water required per ton of galvanized steel. This water becomes contaminated with heavy metals and chemical agents, necessitating extensive treatment before discharge. Many facilities, particularly in developing regions, lack adequate wastewater treatment capabilities, resulting in environmental contamination.

Workplace health concerns further complicate the environmental profile of galvanization. Workers are exposed to zinc fumes, acid mists, and other hazardous substances that can cause respiratory issues and other health problems. These occupational hazards necessitate extensive ventilation systems that consume additional energy and resources.

The durability of galvanized coatings, while beneficial for product longevity, presents end-of-life recycling challenges. Zinc-coated steel requires specialized recycling processes to separate and recover both materials effectively. Current recycling technologies achieve only partial zinc recovery rates of 60-70%, with the remainder typically lost as waste or environmental discharge.

Regulatory compliance adds another layer of complexity, with increasingly stringent environmental standards being implemented globally. Many existing galvanization facilities struggle to meet these evolving requirements without significant technological upgrades or process modifications, creating economic barriers to environmental improvement.

Existing Eco-friendly Galvanization Methods

01 Zinc runoff and leaching concerns

Galvanized steel can release zinc into the environment through runoff and leaching processes. This zinc release occurs primarily during rainfall when water comes into contact with galvanized surfaces. The environmental impact includes potential contamination of soil and water bodies, affecting aquatic ecosystems. Various technologies have been developed to mitigate zinc leaching, including improved coating techniques and runoff management systems that can capture and treat zinc-containing water before it enters the environment.- Zinc emission reduction in galvanizing processes: Various methods have been developed to reduce zinc emissions during the galvanizing process, which can have significant environmental impacts. These include improved coating techniques, zinc recovery systems, and process optimizations that minimize zinc waste. Such innovations help reduce the environmental footprint of galvanized steel production by preventing zinc contamination in soil and water bodies while conserving valuable resources.

- Eco-friendly galvanizing compositions: Environmentally friendly galvanizing compositions have been developed to reduce the ecological impact of traditional galvanizing processes. These compositions may include alternative materials, reduced heavy metal content, or biodegradable components. By reformulating galvanizing mixtures, manufacturers can decrease harmful emissions and waste while maintaining or improving the corrosion resistance properties of galvanized steel products.

- Waste treatment and recycling in galvanizing operations: Advanced waste treatment and recycling systems have been implemented in galvanizing operations to minimize environmental impact. These systems focus on treating wastewater, recovering valuable metals, and recycling byproducts from the galvanizing process. Such approaches significantly reduce the amount of hazardous waste sent to landfills and decrease the overall environmental footprint of galvanized steel production.

- Energy-efficient galvanizing methods: Energy-efficient galvanizing methods have been developed to reduce the carbon footprint associated with traditional high-temperature galvanizing processes. These innovations include lower temperature coating techniques, improved furnace designs, and energy recovery systems. By reducing energy consumption, these methods help decrease greenhouse gas emissions and contribute to more sustainable galvanized steel production.

- Alternative corrosion protection systems with reduced environmental impact: Alternative corrosion protection systems have been developed as environmentally friendlier options to traditional hot-dip galvanizing. These include zinc-alloy coatings, thermal spray technologies, and hybrid protection systems that use less zinc or eliminate environmentally harmful chemicals. Such alternatives aim to provide comparable corrosion protection while reducing the environmental impact associated with conventional galvanizing processes.

02 Eco-friendly galvanization processes

Innovations in galvanization processes have led to more environmentally sustainable methods. These include reduced-zinc coating technologies, energy-efficient hot-dip processes, and alternative coating compositions that maintain corrosion resistance while decreasing environmental impact. Some processes eliminate harmful chemicals traditionally used in surface preparation and utilize renewable energy sources to power galvanizing operations. These eco-friendly processes significantly reduce emissions, waste generation, and resource consumption compared to conventional galvanizing methods.Expand Specific Solutions03 Recycling and end-of-life management

Galvanized steel offers significant environmental benefits through its recyclability. The material can be fully recycled at the end of its useful life, which can span decades due to its corrosion resistance. Recycling processes have been developed to separate zinc coatings from steel substrates, allowing both materials to be recovered and reused. This circular economy approach reduces the need for virgin material extraction and minimizes waste sent to landfills. Advanced sorting and processing technologies enable efficient recovery of zinc and steel from galvanized products.Expand Specific Solutions04 Emissions reduction in production

Manufacturing galvanized steel has traditionally been associated with significant air emissions, including greenhouse gases, particulate matter, and volatile organic compounds. Innovative technologies have been developed to capture and treat these emissions, including advanced filtration systems, thermal oxidizers, and closed-loop production processes. Some facilities have implemented carbon capture technologies and switched to cleaner energy sources to reduce their carbon footprint. These improvements have substantially decreased the environmental impact of galvanized steel production.Expand Specific Solutions05 Alternative corrosion protection methods

Research has led to the development of alternative corrosion protection methods that aim to reduce or eliminate the environmental concerns associated with traditional galvanization. These include zinc-aluminum alloy coatings, organic and inorganic zinc-rich primers, thermal spray coatings, and environmentally benign inhibitors. Some alternatives use significantly less zinc or replace it with more environmentally friendly materials while still providing comparable or superior corrosion protection. These methods can offer reduced environmental impact throughout the product lifecycle.Expand Specific Solutions

Key Industry Players in Sustainable Galvanization

The galvanized steel environmental impact reduction market is currently in a growth phase, with increasing regulatory pressure and consumer demand driving innovation. The global market for sustainable steel solutions is expanding rapidly, estimated to reach significant scale as major players invest in green technologies. Leading steel manufacturers including ArcelorMittal, POSCO Holdings, Nippon Steel, and JFE Steel are advancing technical maturity through various approaches: developing zinc recovery systems, implementing energy-efficient galvanizing processes, utilizing renewable energy in production, and creating water-based protective coatings. European companies like voestalpine and The Coatinc Company are pioneering zero-waste galvanizing technologies, while Asian manufacturers such as Baoshan Iron & Steel and Hyundai Steel focus on reducing emissions through process optimization and alternative coating methods.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed a comprehensive environmental impact reduction strategy for galvanized steel production centered around their "Eco-Products" initiative. Their SuperDyma® technology utilizes a zinc-aluminum-magnesium alloy coating that provides superior corrosion resistance while using approximately 25% less zinc than conventional galvanized products. This directly reduces resource consumption and mining impacts associated with zinc extraction. The company has implemented advanced dry-type emission control systems that eliminate wastewater discharge from galvanizing operations while capturing zinc-containing dust for recycling. Their Zero-Discharge Water Management System recirculates process water through specialized treatment facilities, reducing freshwater consumption by up to 90% compared to conventional systems. NIPPON STEEL has also pioneered energy-efficient induction heating technology for their galvanizing lines, reducing CO2 emissions by approximately 40% compared to conventional natural gas heating systems. Additionally, their AI-controlled coating thickness optimization system ensures minimal zinc usage while maintaining product performance specifications, further reducing resource consumption and environmental footprint.

Strengths: Industry-leading coating technologies that reduce zinc consumption while improving product performance; highly efficient closed-loop resource management systems; strong integration of digital technologies for process optimization. Weaknesses: High initial capital costs for implementing advanced environmental technologies; technology implementation varies across different production facilities globally; some solutions are proprietary and not widely available to the broader industry.

POSCO Holdings, Inc.

Technical Solution: POSCO has developed a comprehensive PosMAC (POSCO Magnesium Alloy Coated) technology that significantly reduces galvanized steel's environmental footprint. This innovative coating contains 2.5-3% magnesium and 2-3% aluminum along with zinc, providing superior corrosion resistance while using less zinc overall. Their process reduces zinc consumption by approximately 20-30% compared to traditional hot-dip galvanizing while extending product lifespan by up to three times. POSCO's environmental management system includes advanced air pollution control technologies that capture over 98% of particulate emissions and volatile organic compounds from galvanizing operations. Their closed-loop water recycling system achieves near-zero wastewater discharge through multi-stage filtration and treatment processes that recover zinc and other metals for reuse. POSCO has also implemented energy-efficient induction heating technology in their galvanizing lines, reducing energy consumption by approximately 35% compared to conventional natural gas heating systems. Additionally, their Smart Factory initiative incorporates AI and IoT technologies to optimize coating thickness and minimize resource consumption while maintaining product quality specifications.

Strengths: World-class research capabilities in coating technologies; highly integrated production systems allowing for comprehensive environmental controls; strong commitment to carbon neutrality with clear implementation roadmap. Weaknesses: High implementation costs for advanced environmental technologies; some solutions are optimized for specific product lines rather than all galvanized products; regional regulatory differences affect standardization across global operations.

Core Innovations in Low-impact Zinc Application

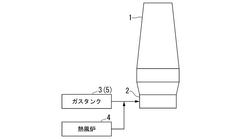

Blast furnace operation method

PatentWO2021107091A1

Innovation

- Incorporating high concentration hydrogen-containing gas, with a minimum of 80 mol% hydrogen, into the blast furnace operation to reduce the amount of carbonaceous materials needed, while maintaining stable furnace conditions by optimizing the injection temperature and amount of hydrogen gas based on specific correlations to minimize carbon consumption and emissions.

Regulatory Framework for Metal Coating Industries

The regulatory landscape governing galvanized steel production continues to evolve globally, with increasingly stringent environmental standards being implemented across major manufacturing regions. In the European Union, the Industrial Emissions Directive (IED) establishes strict emission limits for zinc and other heavy metals, requiring galvanizing facilities to implement Best Available Techniques (BAT) as outlined in the BAT Reference Documents. These regulations mandate comprehensive environmental management systems, regular monitoring of emissions, and implementation of pollution prevention technologies.

In North America, the U.S. Environmental Protection Agency regulates galvanizing operations under the Clean Air Act and Clean Water Act, with specific National Emission Standards for Hazardous Air Pollutants (NESHAP) addressing zinc emissions from hot-dip galvanizing processes. Additionally, the EPA's Effluent Guidelines establish limitations on wastewater discharges from metal finishing operations, including strict parameters for zinc, iron, and acidic compounds.

Asian markets demonstrate varying regulatory approaches, with China's recent environmental reforms under the Blue Sky Defense initiative imposing stricter controls on metal coating industries. Japan maintains comprehensive regulations through its Air Pollution Control Law and Water Pollution Control Law, emphasizing advanced treatment technologies and continuous emissions monitoring.

Emerging regulatory trends include the implementation of Extended Producer Responsibility (EPR) frameworks, which hold manufacturers accountable for the environmental impacts of their products throughout the entire lifecycle. Carbon pricing mechanisms are increasingly affecting galvanizing operations, with emissions trading schemes and carbon taxes creating financial incentives for reducing greenhouse gas emissions associated with high-energy galvanizing processes.

Chemical management regulations, such as the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and similar frameworks in other regions, are imposing additional compliance requirements on the substances used in galvanizing processes. These regulations necessitate substitution of hazardous chemicals with safer alternatives and comprehensive documentation of chemical usage and risk management measures.

International standards like ISO 14001 for environmental management systems and ISO 50001 for energy management are becoming de facto requirements for galvanizing facilities seeking to demonstrate environmental compliance and gain market access. Industry-specific certifications, such as the American Galvanizers Association's Sustainable Galvanizing Practices program, are also emerging as important benchmarks for environmental performance in the sector.

Compliance costs represent a significant consideration for galvanizing operations, with investments in pollution control equipment, monitoring systems, and administrative resources necessary to meet regulatory requirements. However, proactive regulatory compliance strategies can yield competitive advantages through improved operational efficiency, reduced liability risks, and enhanced market positioning as environmentally responsible suppliers.

In North America, the U.S. Environmental Protection Agency regulates galvanizing operations under the Clean Air Act and Clean Water Act, with specific National Emission Standards for Hazardous Air Pollutants (NESHAP) addressing zinc emissions from hot-dip galvanizing processes. Additionally, the EPA's Effluent Guidelines establish limitations on wastewater discharges from metal finishing operations, including strict parameters for zinc, iron, and acidic compounds.

Asian markets demonstrate varying regulatory approaches, with China's recent environmental reforms under the Blue Sky Defense initiative imposing stricter controls on metal coating industries. Japan maintains comprehensive regulations through its Air Pollution Control Law and Water Pollution Control Law, emphasizing advanced treatment technologies and continuous emissions monitoring.

Emerging regulatory trends include the implementation of Extended Producer Responsibility (EPR) frameworks, which hold manufacturers accountable for the environmental impacts of their products throughout the entire lifecycle. Carbon pricing mechanisms are increasingly affecting galvanizing operations, with emissions trading schemes and carbon taxes creating financial incentives for reducing greenhouse gas emissions associated with high-energy galvanizing processes.

Chemical management regulations, such as the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and similar frameworks in other regions, are imposing additional compliance requirements on the substances used in galvanizing processes. These regulations necessitate substitution of hazardous chemicals with safer alternatives and comprehensive documentation of chemical usage and risk management measures.

International standards like ISO 14001 for environmental management systems and ISO 50001 for energy management are becoming de facto requirements for galvanizing facilities seeking to demonstrate environmental compliance and gain market access. Industry-specific certifications, such as the American Galvanizers Association's Sustainable Galvanizing Practices program, are also emerging as important benchmarks for environmental performance in the sector.

Compliance costs represent a significant consideration for galvanizing operations, with investments in pollution control equipment, monitoring systems, and administrative resources necessary to meet regulatory requirements. However, proactive regulatory compliance strategies can yield competitive advantages through improved operational efficiency, reduced liability risks, and enhanced market positioning as environmentally responsible suppliers.

Life Cycle Assessment of Galvanized Products

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of galvanized steel products throughout their entire lifecycle. This methodology examines impacts from raw material extraction through manufacturing, use, and end-of-life disposal or recycling. For galvanized steel, the assessment typically begins with zinc and iron ore mining operations, considering energy consumption, water usage, and emissions associated with extraction processes.

The production phase analysis reveals that traditional hot-dip galvanizing processes contribute significantly to environmental burdens, primarily through energy-intensive heating requirements and zinc bath operations. Studies indicate that approximately 40-50% of the total environmental impact occurs during this manufacturing stage, with greenhouse gas emissions ranging from 2.0 to 2.8 kg CO2-equivalent per kilogram of galvanized product, depending on process efficiency and energy sources.

Transportation impacts vary considerably based on supply chain logistics but generally contribute 5-15% of the total environmental footprint. The use phase demonstrates galvanized steel's environmental advantages, as its corrosion resistance typically extends product lifespan by 1.5 to 2.5 times compared to uncoated alternatives, thereby reducing replacement frequency and associated impacts.

End-of-life assessment reveals promising opportunities, as galvanized steel maintains high recyclability rates of 90-98% in many markets. However, the zinc coating presents separation challenges during recycling processes, potentially increasing energy requirements or reducing recovery efficiency.

Recent comparative LCAs demonstrate that galvanized steel generally outperforms alternative materials like aluminum or certain polymers when considering full lifecycle impacts, particularly when accounting for durability and recyclability benefits. However, these advantages are partially offset by the initial production impacts.

Sensitivity analyses within these assessments highlight critical improvement opportunities, particularly in manufacturing energy efficiency, zinc application optimization, and development of more environmentally friendly fluxing agents. The most significant potential for impact reduction lies in transitioning to renewable energy sources for production processes, which could reduce carbon footprints by 30-45%.

Standardized LCA methodologies such as ISO 14040/14044 provide the framework for these assessments, though industry-specific protocols have emerged to address unique aspects of metal coating processes. These assessments increasingly incorporate water footprint analysis and toxicity potential evaluations to provide more comprehensive environmental profiles of galvanized products.

The production phase analysis reveals that traditional hot-dip galvanizing processes contribute significantly to environmental burdens, primarily through energy-intensive heating requirements and zinc bath operations. Studies indicate that approximately 40-50% of the total environmental impact occurs during this manufacturing stage, with greenhouse gas emissions ranging from 2.0 to 2.8 kg CO2-equivalent per kilogram of galvanized product, depending on process efficiency and energy sources.

Transportation impacts vary considerably based on supply chain logistics but generally contribute 5-15% of the total environmental footprint. The use phase demonstrates galvanized steel's environmental advantages, as its corrosion resistance typically extends product lifespan by 1.5 to 2.5 times compared to uncoated alternatives, thereby reducing replacement frequency and associated impacts.

End-of-life assessment reveals promising opportunities, as galvanized steel maintains high recyclability rates of 90-98% in many markets. However, the zinc coating presents separation challenges during recycling processes, potentially increasing energy requirements or reducing recovery efficiency.

Recent comparative LCAs demonstrate that galvanized steel generally outperforms alternative materials like aluminum or certain polymers when considering full lifecycle impacts, particularly when accounting for durability and recyclability benefits. However, these advantages are partially offset by the initial production impacts.

Sensitivity analyses within these assessments highlight critical improvement opportunities, particularly in manufacturing energy efficiency, zinc application optimization, and development of more environmentally friendly fluxing agents. The most significant potential for impact reduction lies in transitioning to renewable energy sources for production processes, which could reduce carbon footprints by 30-45%.

Standardized LCA methodologies such as ISO 14040/14044 provide the framework for these assessments, though industry-specific protocols have emerged to address unique aspects of metal coating processes. These assessments increasingly incorporate water footprint analysis and toxicity potential evaluations to provide more comprehensive environmental profiles of galvanized products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!