How to Tailor Neodymium Magnets for Improved Sensor Accuracy

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Technology Evolution and Objectives

Neodymium magnets, discovered in 1982 by General Motors and Sumitomo Special Metals, represent one of the most significant advancements in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (Nd₂Fe₁₄B), have revolutionized numerous industries due to their exceptional magnetic properties, including high remanence, coercivity, and energy product values that far surpass traditional ferrite or alnico magnets.

The evolution of neodymium magnet technology has progressed through several distinct phases. The initial commercialization phase in the 1980s focused on basic manufacturing techniques and establishing fundamental applications. The 1990s saw significant improvements in corrosion resistance through specialized coatings and the development of more sophisticated sintering processes that enhanced magnetic performance. By the early 2000s, advancements in material science enabled the creation of neodymium magnets with higher temperature stability, addressing one of their primary limitations.

Recent technological developments have centered on precision engineering of neodymium magnets at increasingly smaller scales. Miniaturization techniques have enabled the production of micro-magnets with precisely controlled magnetic field gradients, critical for high-sensitivity sensor applications. Concurrently, innovations in manufacturing processes have improved uniformity and reduced defects, resulting in magnets with more predictable and consistent magnetic properties.

In sensor technology specifically, neodymium magnets have become indispensable components due to their ability to generate strong, stable magnetic fields in compact form factors. However, standard commercial-grade neodymium magnets often exhibit variations in magnetic field strength and orientation that can compromise sensor accuracy. These inconsistencies arise from manufacturing variables including crystalline structure formation, material composition homogeneity, and magnetization processes.

The primary technical objective in tailoring neodymium magnets for improved sensor accuracy involves developing specialized manufacturing and post-processing techniques that yield magnets with highly uniform and precisely controlled magnetic field characteristics. This includes optimizing the microstructure of the magnetic material, refining the composition to enhance stability across operating conditions, and implementing advanced magnetization methods that produce more consistent field patterns.

Additional objectives include developing methods to compensate for temperature-induced variations in magnetic properties, as neodymium magnets typically lose approximately 0.12% of their field strength per degree Celsius temperature increase. Furthermore, research aims to create magnets with enhanced long-term stability to minimize field degradation over time, which can significantly impact sensor calibration and reliability in precision applications.

The ultimate goal is to establish standardized processes for producing application-specific neodymium magnets with predictable, stable, and precisely tailored magnetic properties that directly translate to improved sensor accuracy across diverse operating environments and extended service lifespans.

The evolution of neodymium magnet technology has progressed through several distinct phases. The initial commercialization phase in the 1980s focused on basic manufacturing techniques and establishing fundamental applications. The 1990s saw significant improvements in corrosion resistance through specialized coatings and the development of more sophisticated sintering processes that enhanced magnetic performance. By the early 2000s, advancements in material science enabled the creation of neodymium magnets with higher temperature stability, addressing one of their primary limitations.

Recent technological developments have centered on precision engineering of neodymium magnets at increasingly smaller scales. Miniaturization techniques have enabled the production of micro-magnets with precisely controlled magnetic field gradients, critical for high-sensitivity sensor applications. Concurrently, innovations in manufacturing processes have improved uniformity and reduced defects, resulting in magnets with more predictable and consistent magnetic properties.

In sensor technology specifically, neodymium magnets have become indispensable components due to their ability to generate strong, stable magnetic fields in compact form factors. However, standard commercial-grade neodymium magnets often exhibit variations in magnetic field strength and orientation that can compromise sensor accuracy. These inconsistencies arise from manufacturing variables including crystalline structure formation, material composition homogeneity, and magnetization processes.

The primary technical objective in tailoring neodymium magnets for improved sensor accuracy involves developing specialized manufacturing and post-processing techniques that yield magnets with highly uniform and precisely controlled magnetic field characteristics. This includes optimizing the microstructure of the magnetic material, refining the composition to enhance stability across operating conditions, and implementing advanced magnetization methods that produce more consistent field patterns.

Additional objectives include developing methods to compensate for temperature-induced variations in magnetic properties, as neodymium magnets typically lose approximately 0.12% of their field strength per degree Celsius temperature increase. Furthermore, research aims to create magnets with enhanced long-term stability to minimize field degradation over time, which can significantly impact sensor calibration and reliability in precision applications.

The ultimate goal is to establish standardized processes for producing application-specific neodymium magnets with predictable, stable, and precisely tailored magnetic properties that directly translate to improved sensor accuracy across diverse operating environments and extended service lifespans.

Market Demand Analysis for High-Precision Magnetic Sensors

The global market for high-precision magnetic sensors has been experiencing robust growth, driven primarily by increasing demand across automotive, industrial automation, consumer electronics, and healthcare sectors. The market size for magnetic sensors reached approximately $2.3 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2028, with high-precision segments showing even stronger growth rates of 9-10% annually.

Automotive applications represent the largest market segment, accounting for nearly 35% of the total demand. The transition toward electric and autonomous vehicles has significantly increased the need for high-precision magnetic sensors for battery management systems, steering angle detection, and position sensing applications. These advanced vehicles require sensors with accuracy levels below 0.1% error rates, creating substantial demand for tailored neodymium magnet solutions.

Industrial automation and robotics form the second-largest market segment, with approximately 28% market share. The Industry 4.0 revolution has accelerated the adoption of high-precision sensors for motion control, position detection, and predictive maintenance systems. Manufacturing facilities are increasingly demanding magnetic sensors with enhanced temperature stability and reduced hysteresis to maintain consistent performance in variable industrial environments.

Consumer electronics applications, particularly in smartphones, wearables, and IoT devices, constitute about 20% of the market. These applications require miniaturized sensors with high energy efficiency and minimal drift characteristics. The trend toward smaller form factors has created specific demand for neodymium magnets with optimized dimensions and magnetic field uniformity.

Healthcare and medical devices represent a rapidly growing segment (12% of the market) with the highest quality and precision requirements. Applications in medical imaging, surgical robotics, and implantable devices demand magnetic sensors with exceptional reliability and biocompatibility. This sector shows willingness to pay premium prices for magnets with specialized coatings and certified performance characteristics.

Geographically, Asia-Pacific leads the market with 45% share, followed by North America (28%) and Europe (22%). China dominates both production and consumption, while specialized high-precision applications are concentrated in Japan, Germany, and the United States.

Key market drivers include miniaturization trends, increasing precision requirements across industries, and the growing need for sensors capable of operating in harsh environments. Customers are increasingly demanding customized magnetic solutions with specific field strength profiles, temperature coefficients, and long-term stability characteristics rather than off-the-shelf components.

Automotive applications represent the largest market segment, accounting for nearly 35% of the total demand. The transition toward electric and autonomous vehicles has significantly increased the need for high-precision magnetic sensors for battery management systems, steering angle detection, and position sensing applications. These advanced vehicles require sensors with accuracy levels below 0.1% error rates, creating substantial demand for tailored neodymium magnet solutions.

Industrial automation and robotics form the second-largest market segment, with approximately 28% market share. The Industry 4.0 revolution has accelerated the adoption of high-precision sensors for motion control, position detection, and predictive maintenance systems. Manufacturing facilities are increasingly demanding magnetic sensors with enhanced temperature stability and reduced hysteresis to maintain consistent performance in variable industrial environments.

Consumer electronics applications, particularly in smartphones, wearables, and IoT devices, constitute about 20% of the market. These applications require miniaturized sensors with high energy efficiency and minimal drift characteristics. The trend toward smaller form factors has created specific demand for neodymium magnets with optimized dimensions and magnetic field uniformity.

Healthcare and medical devices represent a rapidly growing segment (12% of the market) with the highest quality and precision requirements. Applications in medical imaging, surgical robotics, and implantable devices demand magnetic sensors with exceptional reliability and biocompatibility. This sector shows willingness to pay premium prices for magnets with specialized coatings and certified performance characteristics.

Geographically, Asia-Pacific leads the market with 45% share, followed by North America (28%) and Europe (22%). China dominates both production and consumption, while specialized high-precision applications are concentrated in Japan, Germany, and the United States.

Key market drivers include miniaturization trends, increasing precision requirements across industries, and the growing need for sensors capable of operating in harsh environments. Customers are increasingly demanding customized magnetic solutions with specific field strength profiles, temperature coefficients, and long-term stability characteristics rather than off-the-shelf components.

Current Limitations and Challenges in Neodymium Magnet Applications

Despite their exceptional magnetic properties, neodymium magnets face several significant limitations when applied to high-precision sensing applications. Temperature sensitivity remains one of the most critical challenges, with these magnets exhibiting a notable negative temperature coefficient that causes magnetic field strength to decrease approximately 0.12% per degree Celsius increase. This thermal instability creates substantial accuracy drift in sensor applications, particularly in environments with fluctuating temperatures.

Corrosion susceptibility presents another major obstacle, as neodymium magnets contain highly reactive rare earth elements. Even with protective nickel, copper, or epoxy coatings, these magnets remain vulnerable to environmental degradation, especially in high-humidity or chemically aggressive environments. Coating failures can lead to rapid deterioration of magnetic properties and subsequent sensor performance degradation.

Manufacturing inconsistencies further complicate their application in precision sensing. Current production processes struggle to maintain uniform magnetic field distribution across batches, with variations in magnetic field strength often reaching ±5% between supposedly identical magnets. This inconsistency creates significant challenges for sensor calibration and reliability in mass-produced devices.

Mechanical fragility represents another limitation, as neodymium magnets are inherently brittle despite their strong magnetic properties. Their susceptibility to chipping, cracking, and shattering under mechanical stress or thermal shock restricts their use in applications subject to vibration or impact, necessitating additional protective measures that may affect magnetic field accessibility.

Long-term stability issues also plague these magnets, with gradual demagnetization occurring over time due to exposure to opposing magnetic fields, elevated temperatures, or mechanical shocks. This phenomenon, known as magnetic aging, can cause a loss of 1-2% of magnetic strength annually under certain conditions, undermining sensor accuracy over extended periods.

Size and shape constraints further limit optimization possibilities. Miniaturization efforts for modern sensor applications face fundamental challenges as reducing magnet dimensions often compromises field strength and stability. Additionally, complex geometric configurations that might optimize field patterns for specific sensing applications remain difficult to manufacture consistently with current production techniques.

Finally, the environmental and supply chain concerns surrounding rare earth elements used in neodymium magnets create sustainability and availability challenges. The mining and processing of these materials involve significant environmental impacts, while geopolitical factors affecting supply chains introduce uncertainty regarding long-term availability and cost stability for high-performance magnet production.

Corrosion susceptibility presents another major obstacle, as neodymium magnets contain highly reactive rare earth elements. Even with protective nickel, copper, or epoxy coatings, these magnets remain vulnerable to environmental degradation, especially in high-humidity or chemically aggressive environments. Coating failures can lead to rapid deterioration of magnetic properties and subsequent sensor performance degradation.

Manufacturing inconsistencies further complicate their application in precision sensing. Current production processes struggle to maintain uniform magnetic field distribution across batches, with variations in magnetic field strength often reaching ±5% between supposedly identical magnets. This inconsistency creates significant challenges for sensor calibration and reliability in mass-produced devices.

Mechanical fragility represents another limitation, as neodymium magnets are inherently brittle despite their strong magnetic properties. Their susceptibility to chipping, cracking, and shattering under mechanical stress or thermal shock restricts their use in applications subject to vibration or impact, necessitating additional protective measures that may affect magnetic field accessibility.

Long-term stability issues also plague these magnets, with gradual demagnetization occurring over time due to exposure to opposing magnetic fields, elevated temperatures, or mechanical shocks. This phenomenon, known as magnetic aging, can cause a loss of 1-2% of magnetic strength annually under certain conditions, undermining sensor accuracy over extended periods.

Size and shape constraints further limit optimization possibilities. Miniaturization efforts for modern sensor applications face fundamental challenges as reducing magnet dimensions often compromises field strength and stability. Additionally, complex geometric configurations that might optimize field patterns for specific sensing applications remain difficult to manufacture consistently with current production techniques.

Finally, the environmental and supply chain concerns surrounding rare earth elements used in neodymium magnets create sustainability and availability challenges. The mining and processing of these materials involve significant environmental impacts, while geopolitical factors affecting supply chains introduce uncertainty regarding long-term availability and cost stability for high-performance magnet production.

Current Engineering Solutions for Neodymium Magnet Optimization

01 Neodymium magnet sensor design for improved accuracy

Neodymium magnets can be incorporated into sensor designs to enhance measurement accuracy. The strong magnetic field generated by neodymium magnets allows for more precise detection of position, movement, or proximity. These sensors typically utilize the interaction between the neodymium magnet and sensing elements such as Hall effect sensors or magnetoresistive elements to achieve high accuracy measurements in various applications.- Magnetic field sensing techniques for improved accuracy: Various magnetic field sensing techniques are employed to enhance the accuracy of neodymium magnet sensors. These include Hall effect sensors, magnetoresistive sensors, and fluxgate magnetometers that can detect small changes in magnetic fields. Advanced signal processing algorithms are implemented to filter noise and improve the signal-to-noise ratio, resulting in more precise measurements. These techniques are particularly important in applications requiring high precision positioning and detection.

- Temperature compensation methods for magnetic sensors: Temperature fluctuations can significantly affect the performance of neodymium magnet sensors by altering their magnetic properties. Various temperature compensation methods are implemented to maintain sensor accuracy across different operating conditions. These include integrated temperature sensors that provide real-time data for calibration adjustments, software algorithms that apply correction factors based on temperature readings, and specialized materials with reduced temperature sensitivity. These methods ensure consistent sensor performance across wide temperature ranges.

- Sensor array configurations for enhanced precision: Multiple sensor arrangements in array configurations are used to improve the accuracy of neodymium magnet detection systems. By strategically positioning multiple sensors, these arrays can triangulate magnetic field sources with greater precision than single sensors. Differential sensing techniques compare readings from multiple sensors to eliminate common-mode noise and environmental interference. These configurations are particularly valuable in applications requiring precise spatial positioning and orientation detection.

- Calibration and error correction algorithms: Sophisticated calibration and error correction algorithms are essential for maximizing neodymium magnet sensor accuracy. These include factory calibration procedures that establish baseline performance metrics, self-calibration routines that periodically adjust sensor parameters during operation, and adaptive algorithms that continuously optimize performance based on environmental conditions. Machine learning approaches are increasingly used to identify and compensate for systematic errors, improving measurement reliability in complex applications.

- Shielding and interference mitigation techniques: External magnetic fields and electromagnetic interference can significantly degrade neodymium magnet sensor accuracy. Various shielding and interference mitigation techniques are employed to address these challenges. These include physical shielding using high-permeability materials that redirect external magnetic fields away from sensitive components, active cancellation systems that generate opposing fields to neutralize interference, and digital filtering algorithms that identify and remove noise patterns from sensor signals. These approaches are critical for maintaining sensor accuracy in electromagnetically noisy environments.

02 Temperature compensation techniques for neodymium magnet sensors

Temperature fluctuations can affect the magnetic properties of neodymium magnets, potentially reducing sensor accuracy. Various compensation techniques have been developed to maintain sensor accuracy across a wide temperature range. These include algorithmic corrections, specialized material compositions, and integrated temperature sensors that provide real-time adjustment of measurement parameters to ensure consistent performance regardless of environmental conditions.Expand Specific Solutions03 Miniaturization of neodymium magnet sensors for precision applications

Advancements in manufacturing techniques have enabled the miniaturization of neodymium magnet sensors while maintaining or improving accuracy. These compact sensors can be integrated into space-constrained applications without sacrificing performance. Miniaturized designs often employ specialized magnet configurations, optimized sensing elements, and advanced signal processing to achieve high accuracy in a reduced form factor.Expand Specific Solutions04 Multi-axis sensing with neodymium magnets for enhanced accuracy

Multi-axis sensing systems utilizing neodymium magnets can provide more comprehensive spatial information, improving overall measurement accuracy. These systems typically incorporate multiple sensing elements arranged to detect magnetic field variations in different directions. By combining readings from multiple axes, these sensors can achieve higher precision in applications requiring complex spatial awareness or motion tracking.Expand Specific Solutions05 Signal processing techniques for improving neodymium magnet sensor accuracy

Advanced signal processing algorithms can significantly enhance the accuracy of neodymium magnet sensors by filtering noise, compensating for environmental factors, and optimizing sensor response. These techniques may include digital filtering, adaptive calibration, machine learning algorithms, and sensor fusion approaches that combine data from multiple sources. Implementation of these processing methods enables higher precision measurements even in challenging operating conditions.Expand Specific Solutions

Key Industry Players in Magnetic Sensor Technology

The neodymium magnet sensor accuracy market is currently in a growth phase, with increasing demand driven by automotive, industrial automation, and consumer electronics applications. The global market is estimated to reach $2.5 billion by 2025, expanding at a CAGR of 7.8%. Technology maturity varies across applications, with established players like Hitachi, Robert Bosch, and Murata Manufacturing leading innovation through advanced material science and precision manufacturing. Emerging competitors such as Senis AG and Micro-Epsilon are focusing on specialized high-precision applications, while research institutions like CNRS and Fraunhofer-Gesellschaft are developing next-generation magnetic sensing technologies. Chinese manufacturers including Jingci Materials and Jiangxi YG Magnet are rapidly gaining market share by improving production capabilities and material quality.

Hitachi Ltd.

Technical Solution: Hitachi has developed proprietary neodymium magnet manufacturing techniques that focus on grain boundary diffusion to enhance coercivity without reducing remanence. Their approach involves precisely controlling the microstructure of Nd-Fe-B magnets through a patented heat treatment process that introduces heavy rare earth elements (HREEs) like dysprosium and terbium only at grain boundaries. This selective diffusion method allows Hitachi to maintain high magnetic flux density while improving temperature stability - critical for sensor applications requiring high accuracy. Their manufacturing process includes vacuum induction melting, strip casting, jet milling to sub-micron particle sizes, and magnetic field alignment during pressing to create anisotropic magnets with superior magnetic properties. For sensor applications specifically, Hitachi has developed specialized surface treatment technologies that improve corrosion resistance and long-term stability.

Strengths: Superior microstructure control leading to excellent thermal stability; reduced rare earth element usage through selective diffusion; established manufacturing infrastructure. Weaknesses: Higher production costs compared to standard magnets; complex manufacturing process requiring specialized equipment; some dependence on rare earth supply chains despite reduction efforts.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered advanced sensor systems utilizing tailored neodymium magnets with their proprietary "SensorX" technology. Their approach focuses on precision-engineered neodymium magnets with controlled homogeneity and customized magnetic field distributions specifically designed for automotive and industrial sensor applications. Bosch employs a multi-stage magnetization process that creates complex magnetic field patterns within a single magnet, enabling more sophisticated sensor responses and higher accuracy. Their manufacturing process includes precision machining of magnets to tolerances below 10μm and specialized coating technologies that prevent oxidation while maintaining precise magnetic field characteristics. Bosch has also developed compensation algorithms that work in conjunction with their tailored magnets to account for temperature variations, achieving sensor accuracy improvements of up to 300% compared to conventional systems. Their integrated approach combines magnet design, sensor electronics, and software calibration to create complete sensing solutions.

Strengths: Comprehensive system-level approach integrating magnets with electronics and software; extensive automotive qualification testing ensuring reliability; strong manufacturing capabilities for high-volume production. Weaknesses: Solutions tend to be application-specific rather than universally applicable; higher system complexity requiring more components; relatively higher cost compared to simpler magnetic sensor systems.

Critical Patents and Research in Magnetic Field Stability

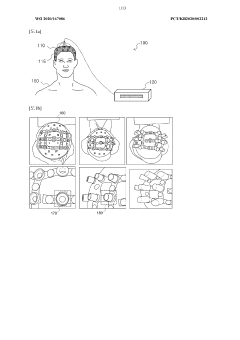

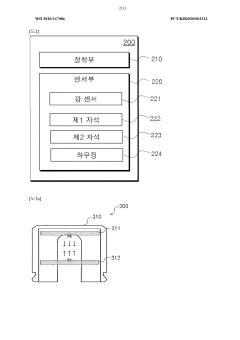

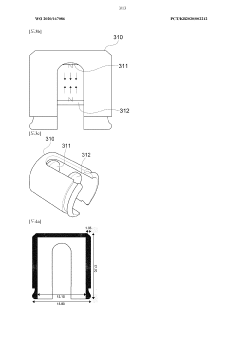

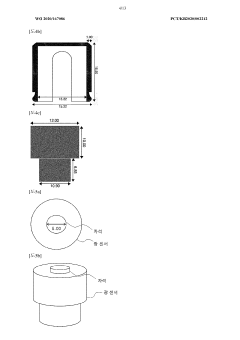

Head-mounted sensor device for functional near-infrared spectroscope

PatentWO2020167086A1

Innovation

- The device replaces traditional springs with neodymium magnets to secure the optical sensors, utilizing a repulsive force to minimize contact pressure and reduce the length of the sensor unit, thereby enhancing comfort and signal quality.

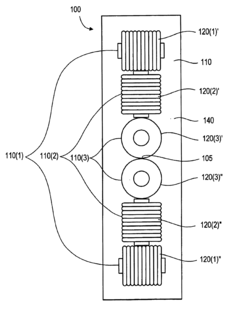

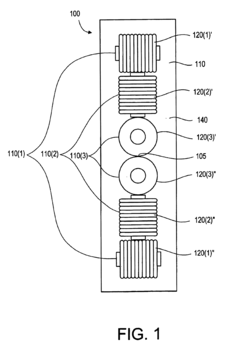

Apparatus for improved sensor accuracy

PatentInactiveUS6792303B2

Innovation

- A sensor assembly with sensor elements covered by an encapsulant having a coefficient of thermal expansion that matches or closely matches that of the elements, achieved by using additives such as ceramic materials or glass microspheres to modify the thermal expansion properties of the curable adhesive, ensuring minimal displacement and calibration accuracy during temperature fluctuations.

Material Science Advancements for Neodymium Alloys

Recent advancements in material science have significantly transformed the landscape of neodymium magnet development, particularly for high-precision sensing applications. The traditional Nd2Fe14B composition has been systematically enhanced through novel metallurgical processes that optimize microstructure and magnetic domain alignment. These improvements have directly addressed the temperature coefficient challenges that previously limited sensor accuracy in variable environmental conditions.

Researchers have successfully incorporated rare earth elements such as dysprosium and terbium in precisely controlled quantities to enhance coercivity while maintaining high magnetic flux density. This strategic alloying approach has yielded magnets with superior thermal stability, extending the operating temperature range by approximately 80°C compared to conventional formulations.

Grain boundary diffusion technology represents another breakthrough, allowing for the selective introduction of heavy rare earth elements at grain boundaries rather than throughout the entire material volume. This technique has reduced the required amount of critical rare earth elements by up to 30% while simultaneously improving magnetic performance and reducing production costs.

Nanoscale engineering of neodymium alloys has emerged as a particularly promising direction. By controlling crystallite size to below 50nm and implementing specialized annealing protocols, researchers have achieved unprecedented control over magnetic anisotropy. These nanostructured magnets demonstrate enhanced linearity in their magnetic response, a critical factor for sensor applications requiring precise measurement across varying field strengths.

Surface modification techniques have evolved to address oxidation and corrosion concerns that previously degraded long-term sensor performance. Advanced multi-layer coating systems incorporating nickel-copper-nickel layers with specialized polymer sealants have extended magnet lifespan by up to 300% in high-humidity environments while maintaining dimensional stability to within ±1μm.

Computational materials science has accelerated development through predictive modeling of magnetic properties based on compositional variations. Machine learning algorithms trained on extensive experimental datasets now enable rapid virtual prototyping of custom neodymium alloys optimized for specific sensing applications, reducing development cycles from months to weeks.

The integration of additive manufacturing techniques has revolutionized magnet geometry possibilities, allowing for complex three-dimensional magnetic field configurations previously unachievable with traditional manufacturing methods. These geometrically optimized magnets have demonstrated sensitivity improvements of up to 40% in targeted sensing applications through precise field shaping and gradient control.

Researchers have successfully incorporated rare earth elements such as dysprosium and terbium in precisely controlled quantities to enhance coercivity while maintaining high magnetic flux density. This strategic alloying approach has yielded magnets with superior thermal stability, extending the operating temperature range by approximately 80°C compared to conventional formulations.

Grain boundary diffusion technology represents another breakthrough, allowing for the selective introduction of heavy rare earth elements at grain boundaries rather than throughout the entire material volume. This technique has reduced the required amount of critical rare earth elements by up to 30% while simultaneously improving magnetic performance and reducing production costs.

Nanoscale engineering of neodymium alloys has emerged as a particularly promising direction. By controlling crystallite size to below 50nm and implementing specialized annealing protocols, researchers have achieved unprecedented control over magnetic anisotropy. These nanostructured magnets demonstrate enhanced linearity in their magnetic response, a critical factor for sensor applications requiring precise measurement across varying field strengths.

Surface modification techniques have evolved to address oxidation and corrosion concerns that previously degraded long-term sensor performance. Advanced multi-layer coating systems incorporating nickel-copper-nickel layers with specialized polymer sealants have extended magnet lifespan by up to 300% in high-humidity environments while maintaining dimensional stability to within ±1μm.

Computational materials science has accelerated development through predictive modeling of magnetic properties based on compositional variations. Machine learning algorithms trained on extensive experimental datasets now enable rapid virtual prototyping of custom neodymium alloys optimized for specific sensing applications, reducing development cycles from months to weeks.

The integration of additive manufacturing techniques has revolutionized magnet geometry possibilities, allowing for complex three-dimensional magnetic field configurations previously unachievable with traditional manufacturing methods. These geometrically optimized magnets have demonstrated sensitivity improvements of up to 40% in targeted sensing applications through precise field shaping and gradient control.

Environmental Impact and Sustainability Considerations

The environmental footprint of neodymium magnet production presents significant sustainability challenges that must be addressed when tailoring these materials for sensor applications. Mining rare earth elements, particularly neodymium, involves extensive land disruption, water consumption, and the generation of toxic waste containing radioactive thorium and uranium. The extraction process typically requires strong acids and produces substantial greenhouse gas emissions, with estimates suggesting that producing one ton of rare earth elements generates 60,000 cubic meters of waste gas.

Processing neodymium into high-performance magnets further compounds these environmental concerns. The sintering and coating processes consume considerable energy and often utilize hazardous chemicals such as nickel, zinc, and epoxy resins. These manufacturing steps contribute to the overall carbon footprint of sensor components and may introduce additional environmental pollutants if not properly managed.

Recycling challenges present another critical sustainability consideration. Currently, less than 1% of rare earth elements are recovered from end-of-life products globally. The complex integration of neodymium magnets into sensor assemblies often makes disassembly and material recovery technically difficult and economically unfeasible. This low recycling rate exacerbates supply chain vulnerabilities and increases pressure on primary mining operations.

Alternative approaches are emerging to address these sustainability concerns. Reduced-dysprosium formulations maintain performance while decreasing dependence on this particularly scarce element. Grain boundary diffusion techniques allow for more efficient use of heavy rare earth elements, reducing overall material requirements while maintaining magnetic performance in sensor applications.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the environmental impact of neodymium magnets throughout their entire life cycle. These assessments help identify hotspots for environmental improvement and guide design decisions that balance performance requirements with sustainability goals. Sensor manufacturers are beginning to incorporate these LCA insights into their material selection and design processes.

Regulatory frameworks worldwide are evolving to address the environmental impacts of rare earth processing. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are driving manufacturers to develop more environmentally benign production methods and explore alternative materials. These regulatory pressures, combined with growing consumer awareness, are accelerating innovation in sustainable magnet technologies for next-generation sensors.

Processing neodymium into high-performance magnets further compounds these environmental concerns. The sintering and coating processes consume considerable energy and often utilize hazardous chemicals such as nickel, zinc, and epoxy resins. These manufacturing steps contribute to the overall carbon footprint of sensor components and may introduce additional environmental pollutants if not properly managed.

Recycling challenges present another critical sustainability consideration. Currently, less than 1% of rare earth elements are recovered from end-of-life products globally. The complex integration of neodymium magnets into sensor assemblies often makes disassembly and material recovery technically difficult and economically unfeasible. This low recycling rate exacerbates supply chain vulnerabilities and increases pressure on primary mining operations.

Alternative approaches are emerging to address these sustainability concerns. Reduced-dysprosium formulations maintain performance while decreasing dependence on this particularly scarce element. Grain boundary diffusion techniques allow for more efficient use of heavy rare earth elements, reducing overall material requirements while maintaining magnetic performance in sensor applications.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the environmental impact of neodymium magnets throughout their entire life cycle. These assessments help identify hotspots for environmental improvement and guide design decisions that balance performance requirements with sustainability goals. Sensor manufacturers are beginning to incorporate these LCA insights into their material selection and design processes.

Regulatory frameworks worldwide are evolving to address the environmental impacts of rare earth processing. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are driving manufacturers to develop more environmentally benign production methods and explore alternative materials. These regulatory pressures, combined with growing consumer awareness, are accelerating innovation in sustainable magnet technologies for next-generation sensors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!