How to Upgrade Heat Exchangers for Better Thermal Performance

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Evolution and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, transitioning from simple shell-and-tube designs to sophisticated plate, spiral, and microchannel configurations. The fundamental principle of transferring thermal energy between fluids without mixing has remained constant, but efficiency, compactness, and material science have advanced dramatically. Early heat exchangers were primarily constructed from copper and brass, while modern variants utilize specialized alloys, ceramics, and composite materials that offer superior thermal conductivity and corrosion resistance.

The evolution of heat exchanger technology has been driven by increasing industrial demands for energy efficiency and space optimization. The 1950s-1970s saw the development of compact heat exchangers with higher surface area-to-volume ratios. The 1980s-1990s brought computational fluid dynamics (CFD) modeling, enabling more precise design optimization. Since 2000, nanotechnology has introduced enhanced surfaces and nanofluids that significantly improve heat transfer coefficients.

Current technological trends focus on sustainability and performance enhancement. Passive techniques such as extended surfaces, inserts, and surface modifications are being complemented by active methods including vibration, electrostatic fields, and ultrasonic enhancement. The integration of smart materials and self-cleaning surfaces represents the cutting edge of heat exchanger innovation, addressing fouling issues that have historically plagued thermal performance.

The primary objectives for heat exchanger upgrades center on four key parameters: increasing the overall heat transfer coefficient, reducing pressure drop, minimizing fouling, and extending operational lifespan. These improvements must be achieved while maintaining or reducing physical footprint and material costs. Specific quantitative targets typically include 15-30% enhancement in heat transfer efficiency, 10-20% reduction in pumping power requirements, and doubling of maintenance intervals.

Industry-specific objectives vary considerably. In HVAC applications, the focus is on miniaturization and noise reduction. Chemical processing prioritizes corrosion resistance and fouling mitigation. Power generation seeks ultra-high temperature capabilities and thermal cycling durability. Renewable energy applications demand cost-effective solutions for intermittent operation. Across all sectors, there is growing emphasis on modular designs that facilitate maintenance and future upgrades.

The technological roadmap for heat exchanger advancement includes near-term goals of optimizing existing geometries and materials, mid-term objectives of commercializing novel enhancement techniques, and long-term aspirations of developing self-optimizing systems with integrated sensors and adaptive control mechanisms. This progression aligns with broader industrial trends toward digitalization, sustainability, and circular economy principles.

The evolution of heat exchanger technology has been driven by increasing industrial demands for energy efficiency and space optimization. The 1950s-1970s saw the development of compact heat exchangers with higher surface area-to-volume ratios. The 1980s-1990s brought computational fluid dynamics (CFD) modeling, enabling more precise design optimization. Since 2000, nanotechnology has introduced enhanced surfaces and nanofluids that significantly improve heat transfer coefficients.

Current technological trends focus on sustainability and performance enhancement. Passive techniques such as extended surfaces, inserts, and surface modifications are being complemented by active methods including vibration, electrostatic fields, and ultrasonic enhancement. The integration of smart materials and self-cleaning surfaces represents the cutting edge of heat exchanger innovation, addressing fouling issues that have historically plagued thermal performance.

The primary objectives for heat exchanger upgrades center on four key parameters: increasing the overall heat transfer coefficient, reducing pressure drop, minimizing fouling, and extending operational lifespan. These improvements must be achieved while maintaining or reducing physical footprint and material costs. Specific quantitative targets typically include 15-30% enhancement in heat transfer efficiency, 10-20% reduction in pumping power requirements, and doubling of maintenance intervals.

Industry-specific objectives vary considerably. In HVAC applications, the focus is on miniaturization and noise reduction. Chemical processing prioritizes corrosion resistance and fouling mitigation. Power generation seeks ultra-high temperature capabilities and thermal cycling durability. Renewable energy applications demand cost-effective solutions for intermittent operation. Across all sectors, there is growing emphasis on modular designs that facilitate maintenance and future upgrades.

The technological roadmap for heat exchanger advancement includes near-term goals of optimizing existing geometries and materials, mid-term objectives of commercializing novel enhancement techniques, and long-term aspirations of developing self-optimizing systems with integrated sensors and adaptive control mechanisms. This progression aligns with broader industrial trends toward digitalization, sustainability, and circular economy principles.

Market Demand for Enhanced Thermal Efficiency

The global market for enhanced thermal efficiency in heat exchangers is experiencing robust growth, driven primarily by increasing energy costs and stringent environmental regulations. Industries across various sectors are actively seeking solutions to optimize thermal performance while reducing operational expenses and carbon footprints. According to recent market analyses, the global heat exchanger market is projected to reach $28.5 billion by 2025, with a significant portion of this growth attributed to demand for high-efficiency solutions.

Energy-intensive industries such as power generation, chemical processing, and oil refining represent the largest market segments seeking thermal efficiency improvements. These sectors face mounting pressure to reduce energy consumption while maintaining or increasing production capacity. For instance, the chemical processing industry alone could achieve energy savings of approximately 20-30% through implementation of advanced heat exchanger technologies.

The HVAC sector presents another substantial market opportunity, particularly as commercial and residential building standards increasingly emphasize energy efficiency. Building owners and operators are recognizing that investments in enhanced heat exchange systems typically deliver return on investment within 2-4 years through reduced energy costs. This economic incentive has accelerated adoption rates, especially in regions with high energy prices or aggressive climate policies.

Emerging economies, particularly in Asia-Pacific, are demonstrating the fastest growth in demand for enhanced thermal efficiency solutions. China and India, with their rapidly expanding industrial bases and increasing environmental consciousness, represent particularly promising markets. These regions are not merely seeking incremental improvements but are often positioned to leapfrog directly to cutting-edge thermal technologies.

Market research indicates that customers are increasingly valuing total lifecycle performance over initial acquisition costs. This shift has created opportunities for premium solutions that offer superior thermal efficiency, even at higher upfront costs. The market has responded with a proliferation of specialized heat exchanger designs optimized for specific applications and operating conditions.

Regulatory drivers are also reshaping market demand. Carbon pricing mechanisms, emissions regulations, and energy efficiency standards are creating powerful incentives for industries to invest in thermal performance upgrades. The European Union's carbon pricing system, for example, has significantly accelerated adoption of high-efficiency heat exchange technologies across multiple industries.

Technological advancements in materials science, manufacturing processes, and computational fluid dynamics are enabling new generations of heat exchangers with dramatically improved performance characteristics. These innovations are not only expanding the potential market but are also creating opportunities for substantial efficiency gains in previously underserved applications and industries.

Energy-intensive industries such as power generation, chemical processing, and oil refining represent the largest market segments seeking thermal efficiency improvements. These sectors face mounting pressure to reduce energy consumption while maintaining or increasing production capacity. For instance, the chemical processing industry alone could achieve energy savings of approximately 20-30% through implementation of advanced heat exchanger technologies.

The HVAC sector presents another substantial market opportunity, particularly as commercial and residential building standards increasingly emphasize energy efficiency. Building owners and operators are recognizing that investments in enhanced heat exchange systems typically deliver return on investment within 2-4 years through reduced energy costs. This economic incentive has accelerated adoption rates, especially in regions with high energy prices or aggressive climate policies.

Emerging economies, particularly in Asia-Pacific, are demonstrating the fastest growth in demand for enhanced thermal efficiency solutions. China and India, with their rapidly expanding industrial bases and increasing environmental consciousness, represent particularly promising markets. These regions are not merely seeking incremental improvements but are often positioned to leapfrog directly to cutting-edge thermal technologies.

Market research indicates that customers are increasingly valuing total lifecycle performance over initial acquisition costs. This shift has created opportunities for premium solutions that offer superior thermal efficiency, even at higher upfront costs. The market has responded with a proliferation of specialized heat exchanger designs optimized for specific applications and operating conditions.

Regulatory drivers are also reshaping market demand. Carbon pricing mechanisms, emissions regulations, and energy efficiency standards are creating powerful incentives for industries to invest in thermal performance upgrades. The European Union's carbon pricing system, for example, has significantly accelerated adoption of high-efficiency heat exchange technologies across multiple industries.

Technological advancements in materials science, manufacturing processes, and computational fluid dynamics are enabling new generations of heat exchangers with dramatically improved performance characteristics. These innovations are not only expanding the potential market but are also creating opportunities for substantial efficiency gains in previously underserved applications and industries.

Current Limitations and Technical Barriers

Despite significant advancements in heat exchanger technology, several critical limitations and technical barriers continue to impede optimal thermal performance. The primary constraint remains fouling, which occurs when unwanted materials accumulate on heat transfer surfaces. This phenomenon creates an insulating layer that significantly reduces heat transfer efficiency, with studies indicating performance degradation of up to 30% in industrial applications. Fouling is particularly problematic in applications involving high-temperature fluids, mineral-rich water, or biological materials, requiring frequent maintenance cycles that increase operational costs.

Material limitations represent another significant barrier. Conventional materials like copper, aluminum, and stainless steel have inherent thermal conductivity ceilings that restrict maximum achievable efficiency. While copper offers excellent thermal conductivity (approximately 400 W/m·K), its susceptibility to corrosion in certain environments and high cost limit widespread application in all settings. Advanced materials like titanium alloys provide corrosion resistance but at significantly lower thermal conductivity (approximately 22 W/m·K).

Geometric constraints pose substantial challenges to heat exchanger optimization. Traditional designs often struggle with the fundamental trade-off between heat transfer area and pressure drop. Increasing surface area through fins or complex geometries enhances thermal performance but simultaneously increases fluid resistance, requiring greater pumping power and energy consumption. This relationship becomes particularly problematic in compact applications where space limitations prevent dimensional expansion.

Flow distribution inefficiencies represent another critical barrier. Non-uniform flow patterns lead to localized hot spots, thermal stress, and reduced overall efficiency. Current computational fluid dynamics models still struggle to perfectly predict complex flow behaviors in intricate geometries, making optimization challenging, especially in multi-phase flow applications.

Manufacturing limitations further restrict innovation in heat exchanger design. Complex geometries that could theoretically enhance performance often prove prohibitively expensive or technically unfeasible to produce at scale using conventional manufacturing techniques. While additive manufacturing offers promising alternatives, current limitations in material options, build size, and production speed restrict widespread industrial adoption.

Energy recovery inefficiencies remain problematic, particularly in low-temperature differential applications. When temperature differences between fluid streams fall below approximately 20°C, conventional heat exchangers struggle to achieve economically viable heat recovery rates, leaving significant potential energy unharnessed in many industrial processes.

Material limitations represent another significant barrier. Conventional materials like copper, aluminum, and stainless steel have inherent thermal conductivity ceilings that restrict maximum achievable efficiency. While copper offers excellent thermal conductivity (approximately 400 W/m·K), its susceptibility to corrosion in certain environments and high cost limit widespread application in all settings. Advanced materials like titanium alloys provide corrosion resistance but at significantly lower thermal conductivity (approximately 22 W/m·K).

Geometric constraints pose substantial challenges to heat exchanger optimization. Traditional designs often struggle with the fundamental trade-off between heat transfer area and pressure drop. Increasing surface area through fins or complex geometries enhances thermal performance but simultaneously increases fluid resistance, requiring greater pumping power and energy consumption. This relationship becomes particularly problematic in compact applications where space limitations prevent dimensional expansion.

Flow distribution inefficiencies represent another critical barrier. Non-uniform flow patterns lead to localized hot spots, thermal stress, and reduced overall efficiency. Current computational fluid dynamics models still struggle to perfectly predict complex flow behaviors in intricate geometries, making optimization challenging, especially in multi-phase flow applications.

Manufacturing limitations further restrict innovation in heat exchanger design. Complex geometries that could theoretically enhance performance often prove prohibitively expensive or technically unfeasible to produce at scale using conventional manufacturing techniques. While additive manufacturing offers promising alternatives, current limitations in material options, build size, and production speed restrict widespread industrial adoption.

Energy recovery inefficiencies remain problematic, particularly in low-temperature differential applications. When temperature differences between fluid streams fall below approximately 20°C, conventional heat exchangers struggle to achieve economically viable heat recovery rates, leaving significant potential energy unharnessed in many industrial processes.

State-of-the-Art Heat Transfer Solutions

01 Enhanced heat exchanger designs for improved thermal efficiency

Various structural designs can significantly improve heat exchanger thermal performance. These include optimized fin configurations, tube arrangements, and surface modifications that increase heat transfer area while minimizing pressure drop. Advanced geometries create turbulence in fluid flow, breaking thermal boundary layers and enhancing heat transfer coefficients. These design innovations can be applied across different heat exchanger types to achieve higher thermal efficiency with reduced size and material requirements.- Enhanced heat transfer surface designs: Various surface designs can significantly improve heat exchanger thermal performance. These include specialized fins, microchannels, and textured surfaces that increase the effective heat transfer area. Such designs promote turbulence in fluid flow while minimizing pressure drop, resulting in more efficient heat exchange. Advanced manufacturing techniques allow for precise creation of these optimized surface geometries that can be tailored for specific applications.

- Performance monitoring and analysis systems: Sophisticated monitoring systems enable real-time assessment of heat exchanger thermal performance. These systems utilize sensors, data acquisition equipment, and analytical software to track key parameters such as temperature differentials, flow rates, and heat transfer coefficients. Advanced algorithms can detect performance degradation, predict maintenance needs, and optimize operating conditions. This approach allows for proactive management of heat exchanger efficiency and extends equipment lifespan.

- Novel heat exchanger configurations: Innovative heat exchanger designs move beyond traditional shell-and-tube or plate configurations to achieve superior thermal performance. These include spiral, matrix, and hybrid designs that optimize fluid flow paths and heat transfer surface area. Some configurations incorporate multiple heat exchange stages or combine different heat transfer mechanisms. These novel arrangements can significantly reduce size requirements while increasing overall thermal efficiency for specific applications.

- Advanced materials for improved conductivity: The use of advanced materials with superior thermal conductivity properties enhances heat exchanger performance. These materials include specialized metal alloys, composites, and engineered surfaces with nano-scale features. Some materials offer benefits such as corrosion resistance, fouling reduction, or weight savings in addition to improved heat transfer. Material selection can be optimized based on specific operating conditions, fluid properties, and performance requirements.

- Computational modeling and optimization techniques: Computational fluid dynamics (CFD) and other simulation tools enable detailed analysis and optimization of heat exchanger designs. These techniques allow engineers to predict thermal performance under various operating conditions, identify flow distribution issues, and optimize geometric parameters. Advanced modeling approaches can account for complex phenomena such as phase change, fouling, and thermal stress. This computational approach significantly reduces development time and costs while improving final design performance.

02 Thermal performance monitoring and analysis systems

Sophisticated monitoring and analysis systems enable real-time assessment of heat exchanger thermal performance. These systems utilize temperature sensors, flow meters, and pressure transducers to collect operational data. Advanced algorithms and computational models process this information to calculate heat transfer coefficients, thermal resistance, and overall efficiency. This allows for early detection of performance degradation, optimization of operating parameters, and predictive maintenance scheduling to maintain optimal thermal performance throughout the heat exchanger's service life.Expand Specific Solutions03 Novel materials and coatings for enhanced heat transfer

The application of advanced materials and specialized coatings can significantly improve heat exchanger thermal performance. High thermal conductivity materials like copper alloys, aluminum composites, and graphene-enhanced surfaces facilitate more efficient heat transfer. Hydrophobic or hydrophilic coatings can modify surface wettability to enhance phase-change heat transfer. Anti-fouling and corrosion-resistant coatings maintain clean heat transfer surfaces over extended periods, preventing performance degradation caused by scale formation or material deterioration.Expand Specific Solutions04 Flow optimization techniques for improved thermal performance

Optimizing fluid flow patterns within heat exchangers can substantially enhance thermal performance. Techniques include the implementation of flow distributors, baffles, and turbulators that create controlled turbulence and eliminate dead zones. Computational fluid dynamics is used to design flow paths that maximize heat transfer while minimizing pressure drop penalties. Pulsating or oscillating flows can disrupt thermal boundary layers, while multi-pass configurations ensure optimal temperature gradients throughout the heat exchanger volume.Expand Specific Solutions05 Phase-change and two-phase flow heat transfer enhancement

Utilizing phase-change phenomena and two-phase flow mechanisms can dramatically improve heat exchanger thermal performance. These systems leverage the latent heat of vaporization or condensation to transfer large amounts of thermal energy with minimal temperature differences. Specialized surface structures promote nucleate boiling or dropwise condensation, significantly increasing heat transfer coefficients. Microchannels and enhanced surfaces create controlled nucleation sites and manage vapor-liquid interactions to optimize the phase-change process and prevent flow instabilities that could reduce thermal performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The heat exchanger thermal performance upgrade market is currently in a growth phase, with increasing demand driven by energy efficiency requirements and sustainability initiatives. The global market size is estimated to exceed $20 billion, expanding at 6-8% annually as industries prioritize thermal efficiency optimization. Technologically, the field shows varying maturity levels, with companies demonstrating different specialization areas. Leading players include Danfoss with advanced refrigeration heat exchangers, Mitsubishi Electric and Daikin focusing on HVAC applications, while Sanhua and Kelvion pioneer microchannel technology. Chinese manufacturers like Midea, Gree, and Haier are rapidly advancing their capabilities, particularly in residential applications, while research institutions such as Fraunhofer-Gesellschaft and Xi'an Jiaotong University drive fundamental innovation in next-generation heat transfer technologies.

Danfoss A/S

Technical Solution: Danfoss has developed advanced Micro Plate Heat Exchanger (MPHE) technology that significantly improves thermal performance through innovative plate designs with asymmetrical patterns. Their Z-pattern flow arrangement creates turbulent flow even at low velocities, enhancing heat transfer coefficients by up to 10% compared to traditional plate designs. Danfoss also implements precise distribution systems that ensure optimal refrigerant distribution across all channels, minimizing superheat variations. Their latest innovations include specialized surface texturing techniques that increase the effective heat transfer area while maintaining manageable pressure drops. Additionally, Danfoss has pioneered low-charge systems that reduce refrigerant volume by up to 40% while maintaining thermal efficiency, particularly beneficial for systems using natural refrigerants like propane and CO2.

Strengths: Superior thermal efficiency with up to 10% higher heat transfer coefficients; reduced refrigerant charge requirements; excellent performance with natural refrigerants; compact design with smaller footprint. Weaknesses: Higher initial manufacturing costs; more complex production process; potential for increased pressure drop in some applications; may require system redesign when retrofitting.

Midea Group Co. Ltd.

Technical Solution: Midea Group has developed proprietary heat exchanger technology focusing on enhanced surface treatments and innovative tube designs. Their R-Evolution heat exchanger system incorporates hydrophilic aluminum fin coatings that improve condensate drainage by up to 30%, significantly enhancing heat transfer efficiency in high-humidity environments. Midea's technology also features variable-pitch tube arrangements that optimize airflow distribution and reduce pressure drops across the heat exchanger. Their latest innovation includes multi-path refrigerant circuits with electronic expansion valve control that dynamically adjusts refrigerant flow based on load conditions, improving part-load efficiency by up to 15%. Additionally, Midea has implemented advanced manufacturing techniques including precision brazing and automated assembly processes that ensure consistent quality and performance across their heat exchanger product line.

Strengths: Excellent performance in variable humidity conditions; optimized for residential and commercial HVAC applications; good balance between cost and performance; strong manufacturing capabilities for mass production. Weaknesses: Less specialized for industrial high-pressure applications; moderate improvements in extreme temperature conditions; some designs prioritize cost-effectiveness over maximum possible efficiency.

Critical Patents in Heat Exchange Technology

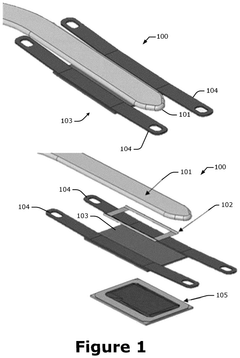

Corrosion-resistant composition of matter having enhanced thermal conductivity, heat exchangers made therefrom, and method of making same

PatentInactiveUS6465561B1

Innovation

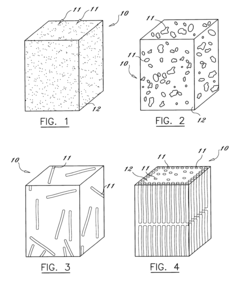

- A composition combining liquid crystal polymers (LCPs) with thermally conductive particles, such as carbonaceous materials like graphite, is used to create an anisotropic material with enhanced thermal conductivity, allowing for directional heat transfer and improved corrosion resistance, manufactured through methods like injection molding and lost-core molding.

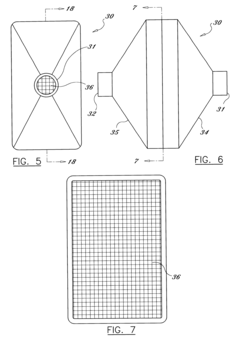

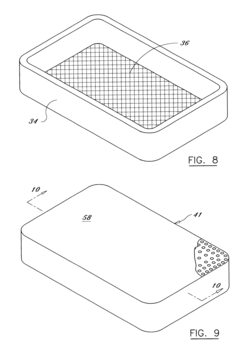

Heat pipe for improved thermal performance at cold plate interface

PatentPendingUS20250142778A1

Innovation

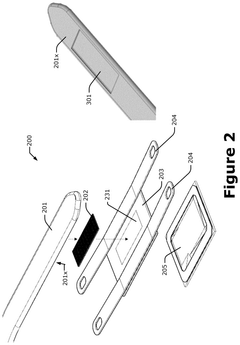

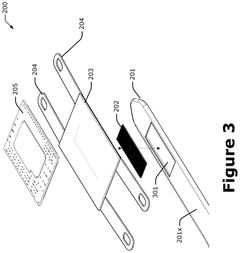

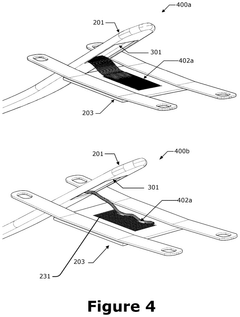

- The proposed solution involves creating a cavity or window on the inner surface of the heat pipe and/or the cold plate, increasing the thermal transfer area, and eliminating the solder layer between the heat pipe and the cold plate to enhance heat transfer and reduce thermal resistance.

Materials Science Advancements for Heat Exchangers

Recent advancements in materials science have revolutionized heat exchanger technology, offering unprecedented opportunities for thermal performance enhancement. Traditional materials like copper, aluminum, and stainless steel are being supplemented or replaced by innovative alternatives with superior thermal conductivity properties. Nanomaterials, particularly carbon nanotubes and graphene, demonstrate thermal conductivity values up to 3000-5000 W/m·K, significantly outperforming conventional copper (400 W/m·K).

Advanced ceramic composites represent another frontier, with silicon carbide and aluminum nitride offering excellent thermal conductivity while maintaining corrosion resistance in aggressive environments. These materials enable heat exchangers to operate efficiently in previously challenging applications such as chemical processing and high-temperature industrial processes.

Metal matrix composites (MMCs) combining aluminum or copper matrices with reinforcing particles like silicon carbide or diamond particles have emerged as promising candidates for next-generation heat exchangers. These composites offer tailored thermal expansion coefficients, reducing thermal stress during operational cycles while maintaining enhanced thermal conductivity.

Surface engineering techniques have evolved to complement material selection. Hydrophobic and hydrophilic coatings can significantly alter surface wettability, affecting condensation and evaporation processes. Superhydrophobic surfaces promote dropwise condensation rather than film condensation, potentially increasing heat transfer coefficients by 5-7 times in certain applications.

Additive manufacturing has transformed heat exchanger design possibilities by enabling complex geometries impossible with traditional manufacturing methods. 3D printing allows for the creation of lattice structures and topology-optimized designs that maximize surface area while minimizing material usage and pressure drop. Materials specifically developed for additive manufacturing, such as high-performance metal powders with tailored particle size distributions, further enhance thermal performance.

Phase change materials (PCMs) incorporated into heat exchanger designs offer thermal energy storage capabilities, smoothing load variations and improving overall system efficiency. Novel microencapsulation techniques have addressed previous limitations regarding PCM containment and thermal cycling stability.

Self-healing materials represent an emerging frontier, with embedded microcapsules containing healing agents that can repair microcracks before they propagate into system failures. This technology promises to extend heat exchanger operational lifetimes while maintaining consistent thermal performance over time.

Advanced ceramic composites represent another frontier, with silicon carbide and aluminum nitride offering excellent thermal conductivity while maintaining corrosion resistance in aggressive environments. These materials enable heat exchangers to operate efficiently in previously challenging applications such as chemical processing and high-temperature industrial processes.

Metal matrix composites (MMCs) combining aluminum or copper matrices with reinforcing particles like silicon carbide or diamond particles have emerged as promising candidates for next-generation heat exchangers. These composites offer tailored thermal expansion coefficients, reducing thermal stress during operational cycles while maintaining enhanced thermal conductivity.

Surface engineering techniques have evolved to complement material selection. Hydrophobic and hydrophilic coatings can significantly alter surface wettability, affecting condensation and evaporation processes. Superhydrophobic surfaces promote dropwise condensation rather than film condensation, potentially increasing heat transfer coefficients by 5-7 times in certain applications.

Additive manufacturing has transformed heat exchanger design possibilities by enabling complex geometries impossible with traditional manufacturing methods. 3D printing allows for the creation of lattice structures and topology-optimized designs that maximize surface area while minimizing material usage and pressure drop. Materials specifically developed for additive manufacturing, such as high-performance metal powders with tailored particle size distributions, further enhance thermal performance.

Phase change materials (PCMs) incorporated into heat exchanger designs offer thermal energy storage capabilities, smoothing load variations and improving overall system efficiency. Novel microencapsulation techniques have addressed previous limitations regarding PCM containment and thermal cycling stability.

Self-healing materials represent an emerging frontier, with embedded microcapsules containing healing agents that can repair microcracks before they propagate into system failures. This technology promises to extend heat exchanger operational lifetimes while maintaining consistent thermal performance over time.

Energy Efficiency and Environmental Impact Assessment

Enhancing heat exchanger performance directly correlates with significant improvements in energy efficiency across industrial applications. Modern heat exchangers operating at optimal efficiency can reduce energy consumption by 15-30% compared to outdated or poorly maintained systems. This reduction translates to substantial cost savings and decreased carbon emissions, particularly in energy-intensive industries such as power generation, chemical processing, and HVAC systems.

The environmental impact of heat exchanger upgrades extends beyond energy savings. Enhanced thermal performance reduces the overall carbon footprint of industrial operations, with studies indicating that optimized heat exchange systems can decrease greenhouse gas emissions by up to 25% in certain applications. Additionally, more efficient heat transfer reduces the demand for primary energy resources, contributing to conservation efforts and sustainability goals.

Water consumption represents another critical environmental consideration. Advanced heat exchanger designs with improved thermal performance often require less cooling water, addressing water scarcity concerns in water-stressed regions. Some next-generation heat exchangers demonstrate water usage reductions of 20-40% compared to conventional designs, while maintaining or improving thermal performance.

Material efficiency also improves with enhanced heat exchanger performance. More effective heat transfer surfaces require less material for construction while achieving the same or better results. This efficiency reduces the environmental impact associated with raw material extraction, processing, and manufacturing. Furthermore, advanced materials with superior thermal properties often exhibit longer operational lifespans, reducing waste generation and replacement frequency.

Lifecycle assessment studies indicate that the environmental benefits of heat exchanger upgrades significantly outweigh the environmental costs of manufacturing and installing new components. The payback period for environmental impact typically ranges from 6 months to 3 years, depending on application specifics and operational intensity.

Regulatory compliance represents an increasingly important driver for heat exchanger upgrades. Stringent emissions regulations and energy efficiency standards worldwide are pushing industries toward more efficient thermal management solutions. Organizations that proactively upgrade their heat exchange systems often find themselves better positioned to meet future regulatory requirements without disruptive operational changes.

The circular economy perspective further enhances the environmental case for heat exchanger upgrades. Many modern heat exchanger components are designed for recyclability and remanufacturing, reducing end-of-life waste. Some manufacturers now offer take-back programs that recover and refurbish components, creating closed-loop material cycles that minimize environmental impact throughout the product lifecycle.

The environmental impact of heat exchanger upgrades extends beyond energy savings. Enhanced thermal performance reduces the overall carbon footprint of industrial operations, with studies indicating that optimized heat exchange systems can decrease greenhouse gas emissions by up to 25% in certain applications. Additionally, more efficient heat transfer reduces the demand for primary energy resources, contributing to conservation efforts and sustainability goals.

Water consumption represents another critical environmental consideration. Advanced heat exchanger designs with improved thermal performance often require less cooling water, addressing water scarcity concerns in water-stressed regions. Some next-generation heat exchangers demonstrate water usage reductions of 20-40% compared to conventional designs, while maintaining or improving thermal performance.

Material efficiency also improves with enhanced heat exchanger performance. More effective heat transfer surfaces require less material for construction while achieving the same or better results. This efficiency reduces the environmental impact associated with raw material extraction, processing, and manufacturing. Furthermore, advanced materials with superior thermal properties often exhibit longer operational lifespans, reducing waste generation and replacement frequency.

Lifecycle assessment studies indicate that the environmental benefits of heat exchanger upgrades significantly outweigh the environmental costs of manufacturing and installing new components. The payback period for environmental impact typically ranges from 6 months to 3 years, depending on application specifics and operational intensity.

Regulatory compliance represents an increasingly important driver for heat exchanger upgrades. Stringent emissions regulations and energy efficiency standards worldwide are pushing industries toward more efficient thermal management solutions. Organizations that proactively upgrade their heat exchange systems often find themselves better positioned to meet future regulatory requirements without disruptive operational changes.

The circular economy perspective further enhances the environmental case for heat exchanger upgrades. Many modern heat exchanger components are designed for recyclability and remanufacturing, reducing end-of-life waste. Some manufacturers now offer take-back programs that recover and refurbish components, creating closed-loop material cycles that minimize environmental impact throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!