How to Use Predictive Models to Optimize Heat Exchanger Design

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Predictive Modeling Background and Objectives

Heat exchanger technology has evolved significantly since its inception in the early 20th century. Initially designed as simple devices for transferring heat between fluids, modern heat exchangers have become sophisticated systems critical to numerous industries including power generation, chemical processing, HVAC, and refrigeration. The technological trajectory has moved from basic shell-and-tube designs to complex plate, spiral, and microchannel configurations, each optimized for specific applications and operating conditions.

Recent advancements in computational fluid dynamics (CFD) and finite element analysis (FEA) have revolutionized heat exchanger design methodologies. These computational tools have gradually replaced traditional empirical approaches, allowing engineers to simulate and predict thermal-hydraulic performance with increasing accuracy. However, the integration of machine learning and artificial intelligence represents the next frontier in heat exchanger optimization.

The primary objective of predictive modeling in heat exchanger design is to develop robust computational frameworks that can accurately forecast performance parameters under varying operational conditions while minimizing design iterations and physical prototyping. This approach aims to reduce development costs, accelerate time-to-market, and enhance overall system efficiency and reliability.

Current predictive modeling techniques incorporate multiple physical phenomena including heat transfer coefficients, pressure drops, flow distribution, fouling behavior, and material degradation. The challenge lies in creating models that balance computational efficiency with predictive accuracy across diverse operating regimes and geometric configurations.

Industry trends indicate a growing emphasis on sustainability and energy efficiency, driving the need for heat exchangers with minimal environmental impact. This has accelerated research into novel materials, compact designs, and enhanced heat transfer surfaces that can be optimized through predictive modeling techniques.

The convergence of big data analytics with traditional thermal-hydraulic modeling presents unprecedented opportunities for developing self-learning systems capable of continuous optimization. These systems can potentially adapt to changing operational parameters and environmental conditions, representing a paradigm shift from static to dynamic design methodologies.

Looking forward, the integration of predictive models with digital twin technology and Internet of Things (IoT) infrastructure will enable real-time monitoring and optimization of heat exchanger performance throughout the operational lifecycle, further enhancing efficiency and reliability while reducing maintenance requirements and operational costs.

Recent advancements in computational fluid dynamics (CFD) and finite element analysis (FEA) have revolutionized heat exchanger design methodologies. These computational tools have gradually replaced traditional empirical approaches, allowing engineers to simulate and predict thermal-hydraulic performance with increasing accuracy. However, the integration of machine learning and artificial intelligence represents the next frontier in heat exchanger optimization.

The primary objective of predictive modeling in heat exchanger design is to develop robust computational frameworks that can accurately forecast performance parameters under varying operational conditions while minimizing design iterations and physical prototyping. This approach aims to reduce development costs, accelerate time-to-market, and enhance overall system efficiency and reliability.

Current predictive modeling techniques incorporate multiple physical phenomena including heat transfer coefficients, pressure drops, flow distribution, fouling behavior, and material degradation. The challenge lies in creating models that balance computational efficiency with predictive accuracy across diverse operating regimes and geometric configurations.

Industry trends indicate a growing emphasis on sustainability and energy efficiency, driving the need for heat exchangers with minimal environmental impact. This has accelerated research into novel materials, compact designs, and enhanced heat transfer surfaces that can be optimized through predictive modeling techniques.

The convergence of big data analytics with traditional thermal-hydraulic modeling presents unprecedented opportunities for developing self-learning systems capable of continuous optimization. These systems can potentially adapt to changing operational parameters and environmental conditions, representing a paradigm shift from static to dynamic design methodologies.

Looking forward, the integration of predictive models with digital twin technology and Internet of Things (IoT) infrastructure will enable real-time monitoring and optimization of heat exchanger performance throughout the operational lifecycle, further enhancing efficiency and reliability while reducing maintenance requirements and operational costs.

Market Analysis for Advanced Heat Exchanger Design Solutions

The global heat exchanger market is experiencing robust growth, valued at approximately $17.86 billion in 2022 and projected to reach $28.3 billion by 2030, growing at a CAGR of 5.9%. This expansion is primarily driven by increasing industrialization, stringent energy efficiency regulations, and growing demand for sustainable thermal management solutions across multiple sectors.

Energy-intensive industries such as oil and gas, chemical processing, power generation, and HVAC systems represent the largest market segments for advanced heat exchanger technologies. The oil and gas sector alone accounts for nearly 23% of the global heat exchanger market, where optimized designs can significantly reduce operational costs and environmental impact.

Regionally, Asia-Pacific dominates the market with approximately 35% share, fueled by rapid industrialization in China and India. North America and Europe follow closely, with their markets increasingly focused on energy-efficient and environmentally sustainable solutions. The Middle East is emerging as a significant growth region due to extensive oil and gas operations requiring sophisticated heat transfer equipment.

Customer demand is shifting noticeably toward predictive model-optimized heat exchangers that offer superior performance metrics. End-users are increasingly willing to pay premium prices for designs that demonstrate 15-20% improvements in energy efficiency, 25% reductions in maintenance requirements, and extended operational lifespans. This trend is particularly pronounced in industries where heat exchangers represent critical infrastructure components.

Market research indicates that companies offering predictive modeling capabilities for heat exchanger optimization can command 12-18% higher margins compared to traditional manufacturers. The integration of AI and machine learning into design processes is becoming a key differentiator, with approximately 67% of surveyed industry professionals expressing interest in adopting such technologies within the next three years.

Regulatory pressures are further shaping market dynamics, with carbon reduction targets and energy efficiency standards creating strong incentives for optimized heat exchanger designs. The European Union's Green Deal and similar initiatives worldwide are accelerating adoption of advanced thermal management solutions that minimize environmental footprint while maximizing performance.

Competitive analysis reveals a market bifurcation between established players with extensive manufacturing capabilities but limited digital expertise, and emerging technology-focused companies offering sophisticated modeling solutions but lacking production scale. This creates significant partnership and acquisition opportunities within the industry ecosystem.

Energy-intensive industries such as oil and gas, chemical processing, power generation, and HVAC systems represent the largest market segments for advanced heat exchanger technologies. The oil and gas sector alone accounts for nearly 23% of the global heat exchanger market, where optimized designs can significantly reduce operational costs and environmental impact.

Regionally, Asia-Pacific dominates the market with approximately 35% share, fueled by rapid industrialization in China and India. North America and Europe follow closely, with their markets increasingly focused on energy-efficient and environmentally sustainable solutions. The Middle East is emerging as a significant growth region due to extensive oil and gas operations requiring sophisticated heat transfer equipment.

Customer demand is shifting noticeably toward predictive model-optimized heat exchangers that offer superior performance metrics. End-users are increasingly willing to pay premium prices for designs that demonstrate 15-20% improvements in energy efficiency, 25% reductions in maintenance requirements, and extended operational lifespans. This trend is particularly pronounced in industries where heat exchangers represent critical infrastructure components.

Market research indicates that companies offering predictive modeling capabilities for heat exchanger optimization can command 12-18% higher margins compared to traditional manufacturers. The integration of AI and machine learning into design processes is becoming a key differentiator, with approximately 67% of surveyed industry professionals expressing interest in adopting such technologies within the next three years.

Regulatory pressures are further shaping market dynamics, with carbon reduction targets and energy efficiency standards creating strong incentives for optimized heat exchanger designs. The European Union's Green Deal and similar initiatives worldwide are accelerating adoption of advanced thermal management solutions that minimize environmental footprint while maximizing performance.

Competitive analysis reveals a market bifurcation between established players with extensive manufacturing capabilities but limited digital expertise, and emerging technology-focused companies offering sophisticated modeling solutions but lacking production scale. This creates significant partnership and acquisition opportunities within the industry ecosystem.

Current Challenges in Computational Heat Transfer Modeling

Despite significant advancements in computational fluid dynamics (CFD) and heat transfer modeling, several critical challenges persist in accurately predicting heat exchanger performance. The complexity of multi-phase flows, particularly in applications involving phase changes such as condensation or evaporation, continues to pose significant computational difficulties. Current models struggle to capture the intricate interactions at liquid-vapor interfaces and the resulting heat transfer mechanisms with sufficient accuracy.

Turbulence modeling remains another substantial obstacle, especially in complex geometries typical of modern heat exchangers. While Reynolds-Averaged Navier-Stokes (RANS) models offer computational efficiency, they often fail to capture transient flow phenomena crucial for accurate heat transfer predictions. More sophisticated approaches like Large Eddy Simulation (LES) or Direct Numerical Simulation (DNS) provide better accuracy but at prohibitively high computational costs for industrial applications.

The multi-scale nature of heat transfer phenomena presents additional challenges. Heat exchangers involve processes occurring at vastly different spatial and temporal scales, from boundary layer effects at microscopic levels to overall flow patterns at the device level. Current computational methods struggle to efficiently bridge these scales without sacrificing accuracy or requiring excessive computational resources.

Material property variations with temperature and pressure further complicate modeling efforts. Many simulation approaches rely on simplified assumptions of constant properties, which can lead to significant errors in predictions, particularly in applications with large temperature gradients or near critical points of working fluids.

Fouling and scaling effects, which progressively degrade heat exchanger performance over time, remain difficult to incorporate into predictive models. Current approaches typically consider only clean surface conditions, whereas real-world performance is significantly affected by these time-dependent phenomena.

Mesh generation and quality issues continue to impact simulation reliability. Complex heat exchanger geometries often require compromises between mesh resolution and computational feasibility, leading to potential inaccuracies in critical regions such as near-wall areas where heat transfer is most intense.

Validation challenges persist due to the difficulty in obtaining comprehensive experimental data across various operating conditions. This limits the confidence in computational models, particularly when extrapolating beyond tested conditions or when designing novel heat exchanger configurations.

Integration of these computational models with optimization algorithms introduces additional complexity, as the high computational cost of each simulation iteration can make traditional optimization approaches impractical for real-world design problems.

Turbulence modeling remains another substantial obstacle, especially in complex geometries typical of modern heat exchangers. While Reynolds-Averaged Navier-Stokes (RANS) models offer computational efficiency, they often fail to capture transient flow phenomena crucial for accurate heat transfer predictions. More sophisticated approaches like Large Eddy Simulation (LES) or Direct Numerical Simulation (DNS) provide better accuracy but at prohibitively high computational costs for industrial applications.

The multi-scale nature of heat transfer phenomena presents additional challenges. Heat exchangers involve processes occurring at vastly different spatial and temporal scales, from boundary layer effects at microscopic levels to overall flow patterns at the device level. Current computational methods struggle to efficiently bridge these scales without sacrificing accuracy or requiring excessive computational resources.

Material property variations with temperature and pressure further complicate modeling efforts. Many simulation approaches rely on simplified assumptions of constant properties, which can lead to significant errors in predictions, particularly in applications with large temperature gradients or near critical points of working fluids.

Fouling and scaling effects, which progressively degrade heat exchanger performance over time, remain difficult to incorporate into predictive models. Current approaches typically consider only clean surface conditions, whereas real-world performance is significantly affected by these time-dependent phenomena.

Mesh generation and quality issues continue to impact simulation reliability. Complex heat exchanger geometries often require compromises between mesh resolution and computational feasibility, leading to potential inaccuracies in critical regions such as near-wall areas where heat transfer is most intense.

Validation challenges persist due to the difficulty in obtaining comprehensive experimental data across various operating conditions. This limits the confidence in computational models, particularly when extrapolating beyond tested conditions or when designing novel heat exchanger configurations.

Integration of these computational models with optimization algorithms introduces additional complexity, as the high computational cost of each simulation iteration can make traditional optimization approaches impractical for real-world design problems.

State-of-the-Art Predictive Modeling Approaches

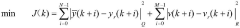

01 Machine learning models for heat exchanger optimization

Machine learning algorithms can be employed to develop predictive models for heat exchanger design optimization. These models can analyze historical performance data, identify patterns, and make predictions about optimal design parameters. By leveraging techniques such as neural networks and support vector machines, engineers can create models that accurately predict heat transfer efficiency, pressure drop, and other critical performance metrics, enabling more efficient design iterations and optimization.- Machine learning models for heat exchanger optimization: Machine learning algorithms can be applied to optimize heat exchanger designs by predicting performance under various operating conditions. These models can analyze large datasets of thermal performance metrics to identify optimal design parameters, reducing the need for extensive physical testing. Neural networks and other AI techniques enable more accurate prediction of heat transfer coefficients and pressure drops, leading to more efficient heat exchanger designs.

- Computational fluid dynamics (CFD) simulation for design prediction: CFD simulations provide detailed insights into fluid flow and heat transfer within exchangers, allowing engineers to predict performance before physical prototyping. These computational models can simulate complex geometries and flow conditions to optimize parameters such as tube arrangement, baffle placement, and flow distribution. By integrating CFD with optimization algorithms, designers can rapidly iterate through design alternatives to maximize thermal efficiency while minimizing pressure drop.

- Digital twin technology for real-time optimization: Digital twin technology creates virtual replicas of physical heat exchangers that can be used for continuous monitoring and optimization. These models incorporate real-time operational data to predict performance degradation, optimize maintenance schedules, and suggest operational adjustments. By maintaining a synchronized virtual model, engineers can test modifications virtually before implementing them in the physical system, reducing downtime and improving overall system efficiency.

- Multi-objective optimization algorithms for balanced design: Multi-objective optimization techniques help balance competing design goals such as heat transfer efficiency, pressure drop, material usage, and manufacturing costs. These algorithms can generate Pareto-optimal solution sets that represent the best possible trade-offs between different performance metrics. Advanced techniques like genetic algorithms, particle swarm optimization, and simulated annealing can efficiently explore large design spaces to identify optimal heat exchanger configurations for specific applications.

- Data-driven predictive maintenance models: Predictive models can forecast heat exchanger fouling, corrosion, and performance degradation based on operational data. These models analyze patterns in temperature differentials, pressure drops, and other parameters to detect early signs of efficiency loss. By predicting maintenance needs before critical failures occur, these systems help optimize cleaning schedules, reduce energy consumption, and extend equipment lifespan while maintaining optimal thermal performance.

02 Computational fluid dynamics (CFD) based predictive modeling

Computational fluid dynamics simulations can be used to create predictive models for heat exchanger design optimization. These models simulate fluid flow, heat transfer, and thermodynamic processes within the heat exchanger, allowing engineers to predict performance under various operating conditions. By integrating CFD with optimization algorithms, designers can identify optimal geometric configurations, flow arrangements, and material selections that maximize heat transfer efficiency while minimizing pressure drop and material usage.Expand Specific Solutions03 Digital twin technology for real-time optimization

Digital twin technology creates virtual replicas of physical heat exchangers that can be used for predictive modeling and optimization. These digital twins continuously update based on real-time operational data, allowing for dynamic optimization of heat exchanger performance. By simulating various scenarios and operating conditions, engineers can predict maintenance needs, optimize operating parameters, and identify potential design improvements without disrupting actual operations.Expand Specific Solutions04 Multi-objective optimization algorithms

Multi-objective optimization algorithms can be applied to heat exchanger design to balance competing performance criteria. These algorithms consider multiple objectives simultaneously, such as maximizing heat transfer, minimizing pressure drop, reducing material costs, and enhancing durability. By employing techniques like genetic algorithms, particle swarm optimization, and Bayesian optimization, engineers can identify Pareto-optimal solutions that represent the best possible trade-offs between different design objectives.Expand Specific Solutions05 Artificial intelligence for material selection and configuration

Artificial intelligence techniques can be used to predict optimal material selections and geometric configurations for heat exchangers. These AI systems analyze vast databases of material properties, heat transfer characteristics, and previous design outcomes to recommend optimal combinations for specific applications. By considering factors such as thermal conductivity, corrosion resistance, cost, and manufacturing constraints, AI-driven predictive models can significantly accelerate the design process and lead to more innovative and efficient heat exchanger designs.Expand Specific Solutions

Leading Organizations in Thermal Systems Modeling

The heat exchanger design optimization market is in a growth phase, characterized by increasing adoption of predictive modeling technologies across industries. The market is expanding due to rising energy efficiency demands and sustainability initiatives, with an estimated value exceeding $2 billion. Technologically, the field shows varying maturity levels, with academic institutions (Xi'an Jiaotong University, University of Tokyo) driving fundamental research while industrial players implement practical applications. Leading companies like Siemens AG, Johnson Controls, and Mitsubishi Electric are advancing commercial solutions, while specialized firms such as Baltimore Aircoil and Brain4energy focus on niche innovations. Energy sector organizations including Huaneng Clean Energy Research Institute and China Nuclear Power Operation Management are developing sector-specific applications, creating a competitive landscape balanced between established industrial giants and specialized technology providers.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered a predictive modeling approach for heat exchanger optimization that combines thermodynamic principles with machine learning algorithms. Their system utilizes a multi-physics simulation environment that incorporates fluid dynamics, heat transfer mechanics, and material science to create high-fidelity models of heat exchanger performance. The predictive framework employs gradient boosting algorithms to analyze the relationship between design parameters (tube geometry, fin configuration, material properties) and performance metrics (heat transfer rate, pressure drop, energy efficiency). Bosch's approach is particularly notable for its integration of manufacturing constraints directly into the optimization process, ensuring that optimized designs remain practical for production. Their models incorporate real-world operational data from automotive cooling systems, HVAC applications, and industrial processes to continuously refine prediction accuracy[2]. The system can automatically generate and evaluate thousands of design variations to identify optimal configurations for specific applications, reducing development time by up to 60% compared to traditional design methods.

Strengths: Strong integration with manufacturing processes; excellent balance between theoretical models and practical constraints; proven track record in automotive applications. Weaknesses: Models may be overly specialized for automotive/HVAC applications; requires extensive computational resources for complex simulations; proprietary nature limits academic collaboration.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed an advanced AI-driven predictive modeling system for heat exchanger optimization called "MELOPT" (Mitsubishi Electric Optimization Technology). This framework combines physics-based models with deep learning algorithms to create accurate simulations of heat exchanger performance across diverse applications. Their approach utilizes reinforcement learning techniques to navigate the complex design space, considering parameters such as tube arrangement, fin geometry, material properties, and flow distribution. Mitsubishi's models are particularly sophisticated in their ability to optimize for multiple competing objectives simultaneously, such as heat transfer efficiency, pressure drop, material usage, and manufacturing cost. The system incorporates computational fluid dynamics (CFD) simulations validated against experimental data from their extensive testing facilities, ensuring high prediction accuracy. Mitsubishi's approach is notable for its integration with their manufacturing systems, allowing the optimization algorithm to consider production capabilities and constraints[5]. Their predictive models can simulate performance under varying environmental conditions, enabling robust designs that maintain efficiency across operational ranges. The technology has demonstrated efficiency improvements of 15-22% in HVAC applications and up to 30% material reduction in certain heat exchanger designs.

Strengths: Excellent balance between theoretical optimization and practical manufacturing constraints; strong validation across diverse applications from HVAC to power generation; sophisticated multi-objective optimization capabilities. Weaknesses: Complex implementation requiring specialized expertise; significant computational requirements; optimization process may be time-intensive for highly complex designs.

Key Algorithms and Mathematical Frameworks

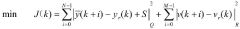

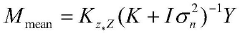

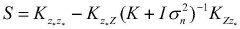

Heat exchange system temperature regulation and control method based on Gaussian process model predictive control

PatentPendingCN117168222A

Innovation

- Using a predictive control method based on the Gaussian process model, by obtaining the operating state parameters and mechanism model of the heat exchange system, constructing a state space model and Gaussian process model, designing a model predictive controller, optimizing the control input to achieve temperature control, and through Kalman The filter matrix and feedback correction mechanism improve the robustness of the control system.

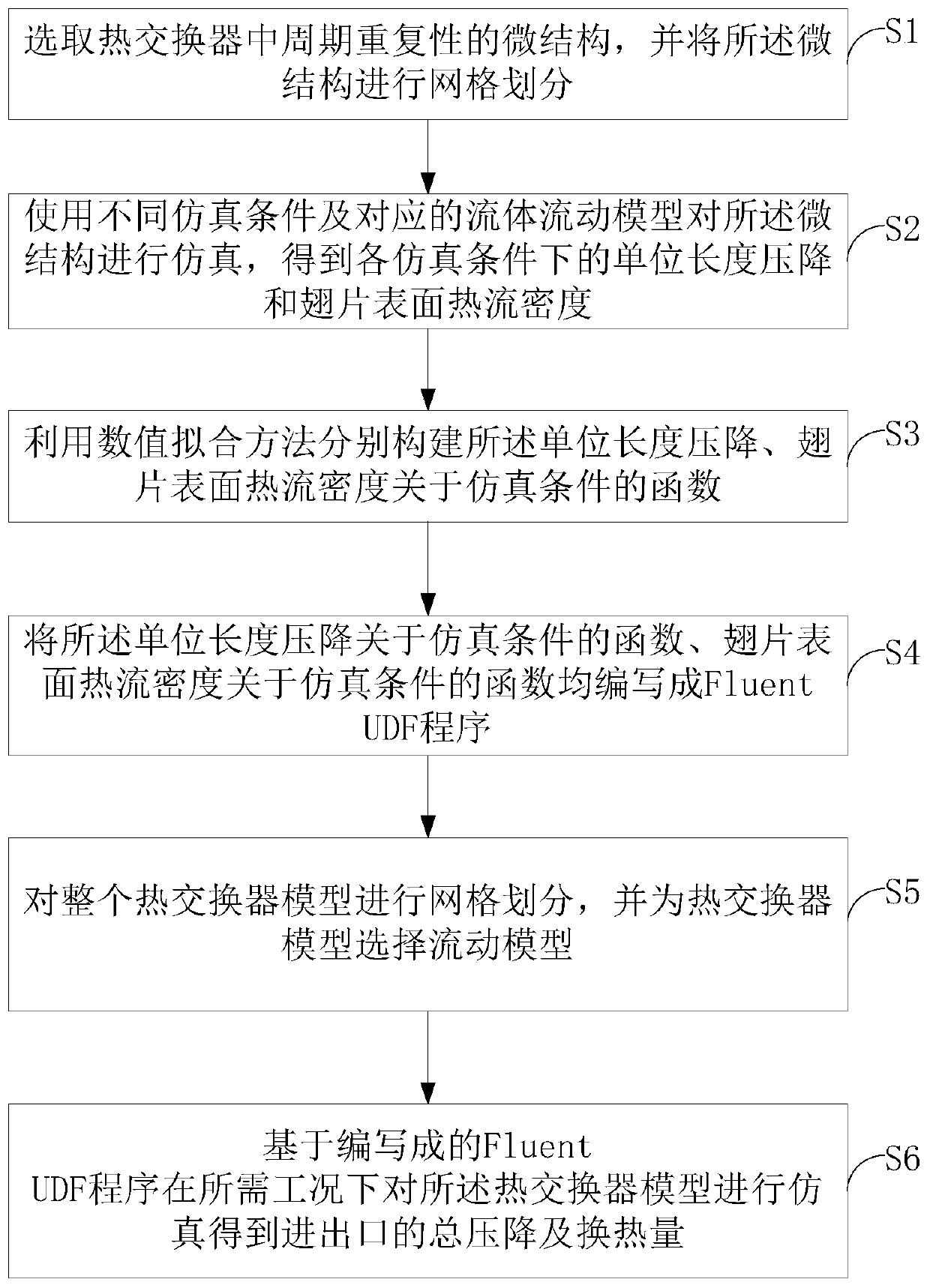

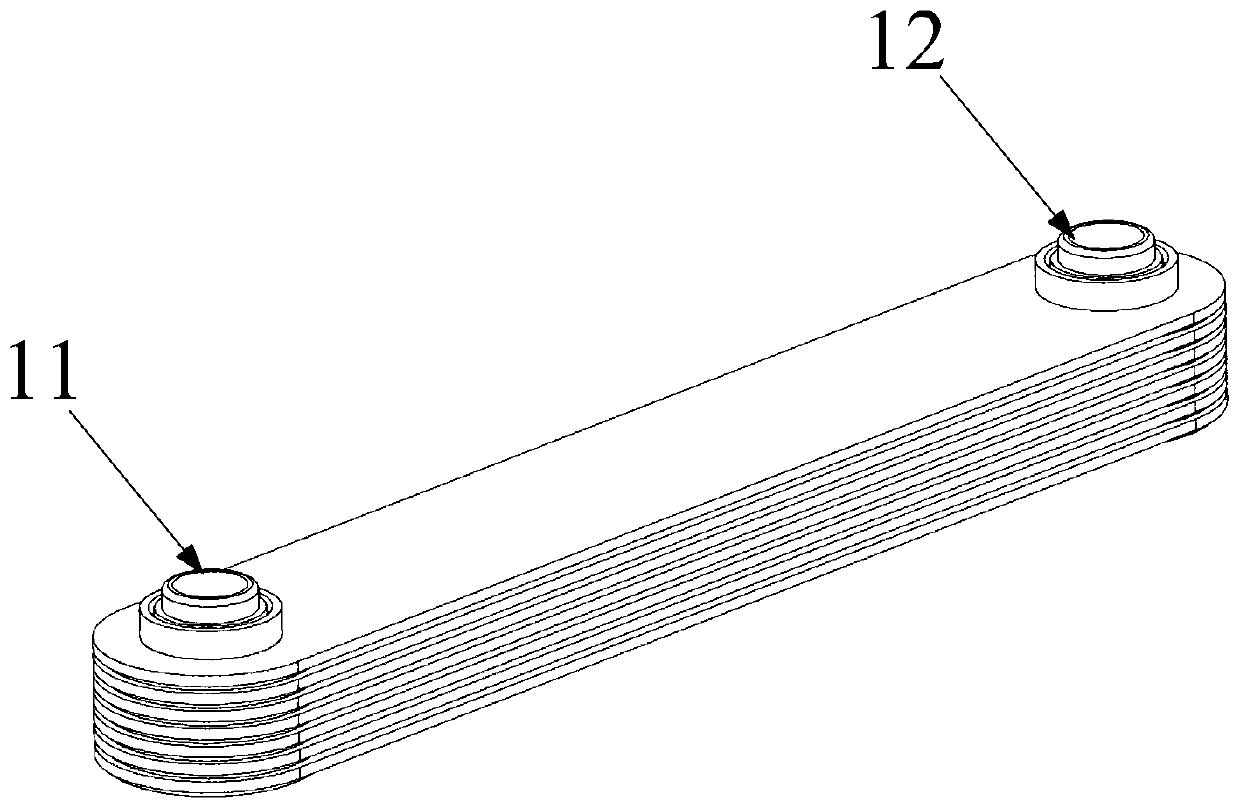

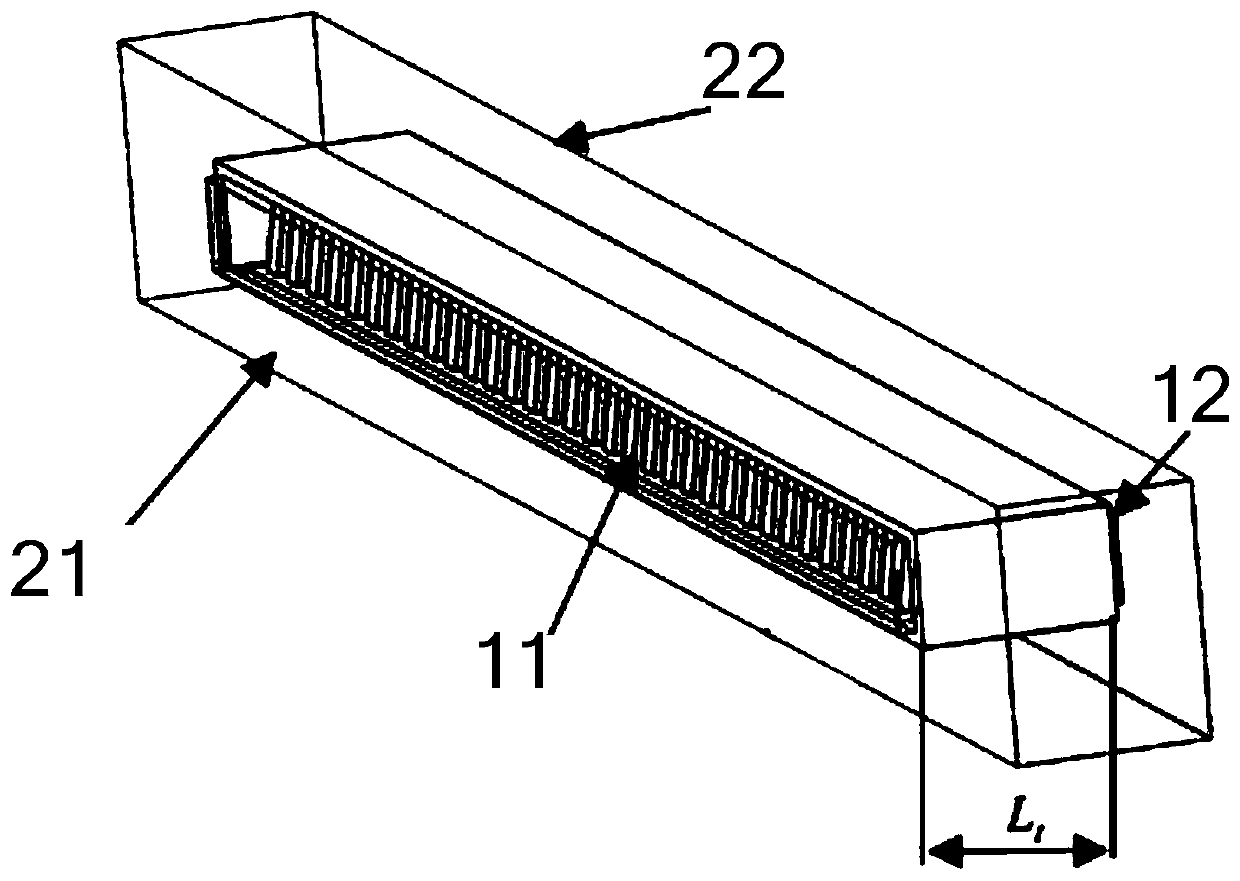

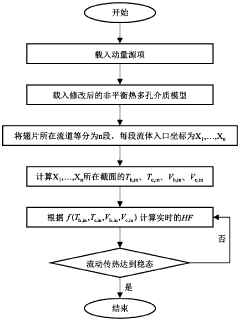

Simulation method of plate-fin heat exchanger

PatentActiveCN111310391A

Innovation

- By selecting the periodic repetitive microstructure in the heat exchanger for mesh division, using different simulation conditions to simulate the fluid flow model, constructing the functions of unit length pressure drop and fin surface heat flow density with respect to the simulation conditions, and writing them into a Fluent UDF program , used to simulate the entire heat exchanger model under different working conditions, accurately considering changes in fluid flow rate and temperature.

Energy Efficiency and Sustainability Implications

The optimization of heat exchanger design through predictive modeling offers significant energy efficiency and sustainability benefits across multiple industrial sectors. Predictive models enable engineers to minimize energy consumption by identifying optimal operating parameters and design configurations that reduce thermal losses and maximize heat transfer efficiency. Studies indicate that optimized heat exchangers can achieve energy savings of 15-30% compared to conventional designs, directly translating to reduced fossil fuel consumption and greenhouse gas emissions.

From a lifecycle perspective, predictive modeling contributes to sustainability by extending equipment lifespan through more accurate prediction of thermal stresses and material fatigue. This approach reduces the frequency of replacements and associated environmental impacts from manufacturing new components. Additionally, optimized designs typically require less raw material while maintaining or improving performance, further reducing the embodied carbon footprint of heat exchange systems.

The water-energy nexus represents another critical sustainability dimension. Advanced heat exchanger designs can significantly reduce cooling water requirements in industrial processes, addressing water scarcity concerns in manufacturing and power generation sectors. Predictive models that incorporate water consumption metrics alongside thermal performance can identify designs that balance these competing sustainability objectives.

Regulatory compliance and carbon reduction initiatives are increasingly driving industry adoption of energy-efficient technologies. Predictive modeling provides quantifiable evidence of sustainability improvements, supporting carbon accounting and environmental reporting requirements. Organizations can leverage these models to demonstrate compliance with energy efficiency standards and qualify for green certification programs or sustainability-linked financing.

Economic sustainability benefits are equally compelling. The initial investment in advanced modeling capabilities typically yields returns through reduced operational costs over equipment lifetime. Analysis shows that energy-optimized heat exchangers often achieve payback periods of 1-3 years in energy-intensive industries, with cumulative savings continuing to accrue throughout the operational life of the equipment.

Looking forward, the integration of predictive modeling with circular economy principles presents opportunities for designing heat exchangers with improved recyclability and remanufacturing potential. Models that incorporate end-of-life considerations alongside performance metrics can guide material selection and design choices that facilitate future resource recovery while maintaining optimal thermal performance.

From a lifecycle perspective, predictive modeling contributes to sustainability by extending equipment lifespan through more accurate prediction of thermal stresses and material fatigue. This approach reduces the frequency of replacements and associated environmental impacts from manufacturing new components. Additionally, optimized designs typically require less raw material while maintaining or improving performance, further reducing the embodied carbon footprint of heat exchange systems.

The water-energy nexus represents another critical sustainability dimension. Advanced heat exchanger designs can significantly reduce cooling water requirements in industrial processes, addressing water scarcity concerns in manufacturing and power generation sectors. Predictive models that incorporate water consumption metrics alongside thermal performance can identify designs that balance these competing sustainability objectives.

Regulatory compliance and carbon reduction initiatives are increasingly driving industry adoption of energy-efficient technologies. Predictive modeling provides quantifiable evidence of sustainability improvements, supporting carbon accounting and environmental reporting requirements. Organizations can leverage these models to demonstrate compliance with energy efficiency standards and qualify for green certification programs or sustainability-linked financing.

Economic sustainability benefits are equally compelling. The initial investment in advanced modeling capabilities typically yields returns through reduced operational costs over equipment lifetime. Analysis shows that energy-optimized heat exchangers often achieve payback periods of 1-3 years in energy-intensive industries, with cumulative savings continuing to accrue throughout the operational life of the equipment.

Looking forward, the integration of predictive modeling with circular economy principles presents opportunities for designing heat exchangers with improved recyclability and remanufacturing potential. Models that incorporate end-of-life considerations alongside performance metrics can guide material selection and design choices that facilitate future resource recovery while maintaining optimal thermal performance.

Integration with Digital Twin Technology

The integration of digital twin technology with predictive models represents a transformative approach to heat exchanger design optimization. Digital twins—virtual replicas of physical assets that update in real-time—create a dynamic simulation environment where predictive models can operate with unprecedented accuracy. This synergy enables engineers to visualize and test design modifications virtually before physical implementation, significantly reducing development cycles and costs.

When implementing digital twins for heat exchanger optimization, the system architecture typically consists of three interconnected layers: the physical heat exchanger equipped with IoT sensors, a data processing middleware that handles real-time information flows, and the virtual model incorporating predictive algorithms. This framework facilitates continuous bidirectional data exchange, allowing the digital twin to evolve alongside its physical counterpart.

The integration process begins with comprehensive sensor deployment across critical points of the heat exchanger to monitor temperature gradients, pressure differentials, flow rates, and fouling conditions. These sensors feed data to the digital twin, which then calibrates predictive models to reflect actual operating conditions with high fidelity.

Machine learning algorithms within the digital twin environment can identify patterns and correlations that might escape traditional analytical methods. For instance, neural networks can detect subtle relationships between operational parameters and heat transfer efficiency, while reinforcement learning algorithms can suggest optimal design modifications based on simulated performance under various conditions.

A particularly valuable application emerges in predictive maintenance scenarios, where digital twins can forecast component degradation and performance decline before physical manifestation. This capability allows engineers to implement design improvements that specifically address vulnerability points identified through virtual lifecycle analysis.

Cloud-based digital twin platforms further enhance collaborative design optimization by enabling geographically dispersed teams to simultaneously work with the same virtual model. These platforms typically offer scalable computing resources that can handle complex computational fluid dynamics simulations and thermal analyses that would otherwise require specialized hardware.

The ROI of integrating digital twin technology with predictive models for heat exchanger design has been demonstrated across multiple industries. Case studies from process manufacturing show efficiency improvements of 15-20% and design iteration time reductions of up to 65% when compared to traditional methods. These benefits compound when considering the entire lifecycle of heat exchange equipment, from initial design through operational optimization and eventual replacement planning.

When implementing digital twins for heat exchanger optimization, the system architecture typically consists of three interconnected layers: the physical heat exchanger equipped with IoT sensors, a data processing middleware that handles real-time information flows, and the virtual model incorporating predictive algorithms. This framework facilitates continuous bidirectional data exchange, allowing the digital twin to evolve alongside its physical counterpart.

The integration process begins with comprehensive sensor deployment across critical points of the heat exchanger to monitor temperature gradients, pressure differentials, flow rates, and fouling conditions. These sensors feed data to the digital twin, which then calibrates predictive models to reflect actual operating conditions with high fidelity.

Machine learning algorithms within the digital twin environment can identify patterns and correlations that might escape traditional analytical methods. For instance, neural networks can detect subtle relationships between operational parameters and heat transfer efficiency, while reinforcement learning algorithms can suggest optimal design modifications based on simulated performance under various conditions.

A particularly valuable application emerges in predictive maintenance scenarios, where digital twins can forecast component degradation and performance decline before physical manifestation. This capability allows engineers to implement design improvements that specifically address vulnerability points identified through virtual lifecycle analysis.

Cloud-based digital twin platforms further enhance collaborative design optimization by enabling geographically dispersed teams to simultaneously work with the same virtual model. These platforms typically offer scalable computing resources that can handle complex computational fluid dynamics simulations and thermal analyses that would otherwise require specialized hardware.

The ROI of integrating digital twin technology with predictive models for heat exchanger design has been demonstrated across multiple industries. Case studies from process manufacturing show efficiency improvements of 15-20% and design iteration time reductions of up to 65% when compared to traditional methods. These benefits compound when considering the entire lifecycle of heat exchange equipment, from initial design through operational optimization and eventual replacement planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!