How Vacuum Pumps Aid Advanced Material Deposition Techniques

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Objectives

Vacuum pumps have played a pivotal role in the evolution of advanced material deposition techniques, with their development closely intertwined with the progress in thin film technology and semiconductor manufacturing. The journey of vacuum pump technology began in the early 20th century with the invention of mechanical pumps, which laid the foundation for creating controlled low-pressure environments essential for material deposition processes.

As the demands of the semiconductor industry grew in the mid-20th century, so did the need for more sophisticated vacuum systems. This led to the development of diffusion pumps and turbomolecular pumps, which could achieve higher vacuum levels and cleaner environments. These advancements were crucial in enabling the production of increasingly complex integrated circuits and the exploration of new materials for electronic devices.

The late 20th century saw a paradigm shift with the introduction of dry pumps, addressing the environmental concerns associated with oil-based pumps. This innovation not only improved the cleanliness of vacuum systems but also enhanced the reliability and efficiency of material deposition processes. Concurrently, the development of cryogenic pumps opened new possibilities for ultra-high vacuum applications, further expanding the capabilities of material deposition techniques.

In recent years, the focus has shifted towards developing smart, energy-efficient vacuum pumps that can integrate seamlessly with Industry 4.0 principles. These modern pumps incorporate advanced sensors and control systems, allowing for real-time monitoring and optimization of deposition processes. The objective is to achieve precise control over vacuum conditions, which is critical for depositing materials with specific properties and structures at the nanoscale level.

Looking ahead, the goals for vacuum pump technology in advanced material deposition are multifaceted. There is a strong emphasis on developing pumps that can maintain stable ultra-high vacuum conditions for extended periods, crucial for the deposition of novel 2D materials and complex heterostructures. Additionally, there is a push towards miniaturization and integration, aiming to create compact vacuum systems that can be incorporated into portable deposition equipment for on-site manufacturing and research applications.

Another key objective is to enhance the energy efficiency of vacuum pumps, reducing the overall environmental impact of material deposition processes. This aligns with the broader industry trend towards sustainable manufacturing practices. Researchers are also exploring new pump designs that can handle a wider range of process gases and byproducts, accommodating the diverse requirements of emerging deposition techniques such as atomic layer deposition and plasma-enhanced chemical vapor deposition.

In conclusion, the evolution of vacuum pump technology has been instrumental in advancing material deposition techniques, and its continued development remains crucial for future innovations in this field. The objectives moving forward are centered on achieving higher vacuum levels, greater process control, improved energy efficiency, and enhanced versatility to meet the ever-expanding demands of advanced material science and nanotechnology.

As the demands of the semiconductor industry grew in the mid-20th century, so did the need for more sophisticated vacuum systems. This led to the development of diffusion pumps and turbomolecular pumps, which could achieve higher vacuum levels and cleaner environments. These advancements were crucial in enabling the production of increasingly complex integrated circuits and the exploration of new materials for electronic devices.

The late 20th century saw a paradigm shift with the introduction of dry pumps, addressing the environmental concerns associated with oil-based pumps. This innovation not only improved the cleanliness of vacuum systems but also enhanced the reliability and efficiency of material deposition processes. Concurrently, the development of cryogenic pumps opened new possibilities for ultra-high vacuum applications, further expanding the capabilities of material deposition techniques.

In recent years, the focus has shifted towards developing smart, energy-efficient vacuum pumps that can integrate seamlessly with Industry 4.0 principles. These modern pumps incorporate advanced sensors and control systems, allowing for real-time monitoring and optimization of deposition processes. The objective is to achieve precise control over vacuum conditions, which is critical for depositing materials with specific properties and structures at the nanoscale level.

Looking ahead, the goals for vacuum pump technology in advanced material deposition are multifaceted. There is a strong emphasis on developing pumps that can maintain stable ultra-high vacuum conditions for extended periods, crucial for the deposition of novel 2D materials and complex heterostructures. Additionally, there is a push towards miniaturization and integration, aiming to create compact vacuum systems that can be incorporated into portable deposition equipment for on-site manufacturing and research applications.

Another key objective is to enhance the energy efficiency of vacuum pumps, reducing the overall environmental impact of material deposition processes. This aligns with the broader industry trend towards sustainable manufacturing practices. Researchers are also exploring new pump designs that can handle a wider range of process gases and byproducts, accommodating the diverse requirements of emerging deposition techniques such as atomic layer deposition and plasma-enhanced chemical vapor deposition.

In conclusion, the evolution of vacuum pump technology has been instrumental in advancing material deposition techniques, and its continued development remains crucial for future innovations in this field. The objectives moving forward are centered on achieving higher vacuum levels, greater process control, improved energy efficiency, and enhanced versatility to meet the ever-expanding demands of advanced material science and nanotechnology.

Market Demand Analysis

The market demand for advanced material deposition techniques aided by vacuum pumps has been experiencing significant growth across various industries. This surge is primarily driven by the increasing need for high-performance materials in sectors such as semiconductors, optics, and nanotechnology. The global semiconductor industry, in particular, has been a major contributor to this demand, with the market size projected to reach $726 billion by 2027, according to recent industry reports.

Vacuum pumps play a crucial role in enabling precise and controlled deposition of materials at the atomic level, which is essential for manufacturing advanced electronic components, optical coatings, and nanomaterials. The demand for these pumps is closely tied to the growth of industries that require ultra-clean and high-vacuum environments for their production processes.

In the semiconductor industry, the push towards smaller and more powerful chips has led to increased adoption of advanced deposition techniques such as atomic layer deposition (ALD) and chemical vapor deposition (CVD). These processes rely heavily on vacuum pumps to create the necessary low-pressure environments. As the industry continues to advance towards 3nm and 2nm process nodes, the demand for more sophisticated vacuum pump technologies is expected to rise.

The optical coating industry is another significant driver of market demand for vacuum pump-assisted deposition techniques. With the growing popularity of augmented reality (AR) and virtual reality (VR) technologies, there is an increased need for high-quality optical coatings on lenses and displays. This trend is further supported by the expanding market for smartphones and other consumer electronics that require advanced optical components.

In the field of nanotechnology, vacuum pumps are essential for creating and manipulating materials at the nanoscale. The global nanotechnology market is expected to grow at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026, indicating a strong potential for increased demand in vacuum pump technologies for material deposition.

The aerospace and defense sectors also contribute significantly to the market demand for advanced material deposition techniques. These industries require high-performance materials for applications such as thermal barrier coatings, wear-resistant surfaces, and advanced sensors. The use of vacuum pumps in these applications ensures the production of materials with superior properties and performance characteristics.

As sustainability becomes a key focus across industries, there is a growing demand for more energy-efficient and environmentally friendly vacuum pump technologies. This trend is driving innovation in pump design and operation, with manufacturers developing new solutions that offer improved performance while reducing energy consumption and environmental impact.

Vacuum pumps play a crucial role in enabling precise and controlled deposition of materials at the atomic level, which is essential for manufacturing advanced electronic components, optical coatings, and nanomaterials. The demand for these pumps is closely tied to the growth of industries that require ultra-clean and high-vacuum environments for their production processes.

In the semiconductor industry, the push towards smaller and more powerful chips has led to increased adoption of advanced deposition techniques such as atomic layer deposition (ALD) and chemical vapor deposition (CVD). These processes rely heavily on vacuum pumps to create the necessary low-pressure environments. As the industry continues to advance towards 3nm and 2nm process nodes, the demand for more sophisticated vacuum pump technologies is expected to rise.

The optical coating industry is another significant driver of market demand for vacuum pump-assisted deposition techniques. With the growing popularity of augmented reality (AR) and virtual reality (VR) technologies, there is an increased need for high-quality optical coatings on lenses and displays. This trend is further supported by the expanding market for smartphones and other consumer electronics that require advanced optical components.

In the field of nanotechnology, vacuum pumps are essential for creating and manipulating materials at the nanoscale. The global nanotechnology market is expected to grow at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026, indicating a strong potential for increased demand in vacuum pump technologies for material deposition.

The aerospace and defense sectors also contribute significantly to the market demand for advanced material deposition techniques. These industries require high-performance materials for applications such as thermal barrier coatings, wear-resistant surfaces, and advanced sensors. The use of vacuum pumps in these applications ensures the production of materials with superior properties and performance characteristics.

As sustainability becomes a key focus across industries, there is a growing demand for more energy-efficient and environmentally friendly vacuum pump technologies. This trend is driving innovation in pump design and operation, with manufacturers developing new solutions that offer improved performance while reducing energy consumption and environmental impact.

Current Challenges

The current challenges in advanced material deposition techniques using vacuum pumps are multifaceted and complex. One of the primary issues is achieving and maintaining ultra-high vacuum levels required for precise material deposition. As materials become more sophisticated and applications demand higher purity levels, even minute contaminations can significantly impact the quality of the deposited layers.

Another significant challenge lies in the scalability of vacuum-based deposition processes. While these techniques are well-established for small-scale production and research applications, scaling up to industrial levels while maintaining the same level of precision and uniformity presents considerable difficulties. This is particularly evident in the production of large-area thin films for applications such as solar panels and display technologies.

The energy efficiency of vacuum pumps in material deposition systems is also a growing concern. High-performance vacuum pumps often consume substantial amounts of energy, which can contribute significantly to the overall cost and environmental impact of the production process. Balancing the need for high vacuum levels with energy efficiency remains a critical challenge for the industry.

Furthermore, the integration of vacuum pumps with other components of advanced deposition systems poses technical hurdles. Ensuring seamless operation and communication between vacuum pumps, deposition sources, and control systems is crucial for achieving precise and reproducible results. This integration becomes even more complex as deposition processes become more sophisticated, often requiring real-time adjustments based on in-situ measurements.

The reliability and maintenance of vacuum pumps in continuous operation scenarios is another area of concern. Advanced material deposition often requires long, uninterrupted processing times, and any failure or performance degradation of the vacuum system can lead to significant production losses. Developing pumps with longer mean time between failures and easier maintenance protocols is an ongoing challenge.

Lastly, the industry faces challenges in adapting vacuum pump technologies to emerging deposition techniques. As new methods such as atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD) gain prominence, vacuum pump designs need to evolve to meet the specific requirements of these processes, including rapid pressure changes and compatibility with reactive gases.

Another significant challenge lies in the scalability of vacuum-based deposition processes. While these techniques are well-established for small-scale production and research applications, scaling up to industrial levels while maintaining the same level of precision and uniformity presents considerable difficulties. This is particularly evident in the production of large-area thin films for applications such as solar panels and display technologies.

The energy efficiency of vacuum pumps in material deposition systems is also a growing concern. High-performance vacuum pumps often consume substantial amounts of energy, which can contribute significantly to the overall cost and environmental impact of the production process. Balancing the need for high vacuum levels with energy efficiency remains a critical challenge for the industry.

Furthermore, the integration of vacuum pumps with other components of advanced deposition systems poses technical hurdles. Ensuring seamless operation and communication between vacuum pumps, deposition sources, and control systems is crucial for achieving precise and reproducible results. This integration becomes even more complex as deposition processes become more sophisticated, often requiring real-time adjustments based on in-situ measurements.

The reliability and maintenance of vacuum pumps in continuous operation scenarios is another area of concern. Advanced material deposition often requires long, uninterrupted processing times, and any failure or performance degradation of the vacuum system can lead to significant production losses. Developing pumps with longer mean time between failures and easier maintenance protocols is an ongoing challenge.

Lastly, the industry faces challenges in adapting vacuum pump technologies to emerging deposition techniques. As new methods such as atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD) gain prominence, vacuum pump designs need to evolve to meet the specific requirements of these processes, including rapid pressure changes and compatibility with reactive gases.

Existing Vacuum Solutions

01 Rotary vacuum pump designs

Various designs of rotary vacuum pumps have been developed to improve efficiency and performance. These include innovations in rotor configurations, sealing mechanisms, and chamber designs to enhance suction and reduce friction. Some designs focus on compact arrangements for specific applications, while others aim to increase durability and reduce maintenance needs.- Rotary vacuum pump designs: Various designs of rotary vacuum pumps have been developed to improve efficiency and performance. These include innovations in rotor configurations, sealing mechanisms, and chamber designs to enhance suction power and reduce friction. Some designs focus on compact arrangements for specific applications, while others aim to optimize flow patterns within the pump.

- Vacuum pump control systems: Advanced control systems have been implemented in vacuum pumps to optimize their operation. These systems may include electronic controllers, sensors, and feedback mechanisms to regulate pump speed, pressure, and power consumption. Some designs incorporate adaptive control algorithms to maintain optimal performance under varying conditions.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed. These pumps are designed to handle specific gases and maintain ultra-high vacuum levels required in semiconductor fabrication. Features may include corrosion-resistant materials, contamination control mechanisms, and integration with process control systems.

- Energy-efficient vacuum pump technologies: Innovations in vacuum pump design have focused on improving energy efficiency. These developments include the use of advanced materials, optimized motor designs, and innovative compression techniques. Some pumps incorporate energy recovery systems or variable speed drives to reduce power consumption while maintaining performance.

- Multi-stage and combination vacuum pump systems: Complex vacuum systems have been developed that combine multiple pump stages or different pump types to achieve specific performance characteristics. These systems may integrate rotary pumps, diffusion pumps, or turbomolecular pumps in various configurations to optimize vacuum levels, pumping speed, and overall efficiency for specialized applications.

02 Vacuum pump control systems

Advanced control systems have been implemented in vacuum pumps to optimize operation and energy efficiency. These systems may include sensors, electronic controllers, and variable speed drives to adjust pump performance based on demand. Some designs incorporate intelligent algorithms for predictive maintenance and automatic adjustment of operating parameters.Expand Specific Solutions03 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of this industry. These pumps often feature ultra-clean designs, high pumping speeds, and resistance to corrosive gases. Some innovations focus on reducing particle generation and improving pump longevity in harsh environments.Expand Specific Solutions04 Multi-stage vacuum pump systems

Multi-stage vacuum pump systems have been designed to achieve higher vacuum levels and improved efficiency. These systems often combine different types of pumps, such as rotary vane pumps with turbomolecular or diffusion pumps, to cover a wide range of pressure regimes. Some designs focus on optimizing the interaction between stages and reducing overall system size.Expand Specific Solutions05 Vacuum pump sealing and lubrication innovations

Advancements in sealing and lubrication technologies for vacuum pumps have been made to improve performance and reliability. These include novel seal designs, dry-running pumps, and specialized lubricants for high-vacuum applications. Some innovations focus on reducing oil contamination in the pumped gases and extending the operational life of pump components.Expand Specific Solutions

Key Industry Players

The vacuum pump market for advanced material deposition techniques is in a mature growth phase, with a global market size expected to reach several billion dollars by 2025. The technology has become increasingly sophisticated, with major players like Edwards Ltd., Applied Materials, Inc., and Tokyo Electron Ltd. leading innovation in high-performance vacuum systems for semiconductor and display manufacturing. These companies, along with others like ULVAC, Inc. and Pfeiffer Vacuum GmbH, are driving advancements in precision, efficiency, and integration of vacuum technologies with deposition processes. The competitive landscape is characterized by a mix of established industrial giants and specialized equipment manufacturers, all vying to meet the demanding requirements of next-generation materials and devices.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for material deposition processes. Their iXH series of dry pumps offers high pumping speeds up to 4200 m³/h and ultimate pressures down to 5 x 10⁻⁴ mbar[1]. These pumps utilize a unique screw mechanism that provides excellent performance in harsh coating environments. Edwards has also introduced the nEXT turbomolecular pump series, which can achieve rotation speeds up to 90,000 rpm and pumping speeds of 3000 L/s for N₂[2]. These pumps are designed with advanced rotor designs and magnetic bearings to minimize vibration and maximize uptime in sensitive deposition processes.

Strengths: High pumping speeds, low ultimate pressures, and robust design for harsh environments. Weaknesses: Higher initial cost compared to conventional pumps, and potential complexity in maintenance for advanced models.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed the Endura® platform, which integrates advanced vacuum pump technology with their PVD (Physical Vapor Deposition) systems. The platform utilizes a combination of turbomolecular and cryogenic pumps to achieve ultra-high vacuum conditions necessary for precise material deposition[3]. Their systems can maintain pressures as low as 10⁻⁹ Torr during deposition processes. Applied Materials has also introduced the Producer® platform for CVD (Chemical Vapor Deposition) applications, which incorporates specialized vacuum pumps designed to handle corrosive and particulate-laden process gases[4]. These pumps feature advanced sealing technologies and corrosion-resistant materials to ensure long-term reliability in aggressive chemical environments.

Strengths: Integrated systems with optimized vacuum performance for specific deposition processes. Weaknesses: High system complexity and cost, potentially limiting accessibility for smaller manufacturers.

Core Vacuum Innovations

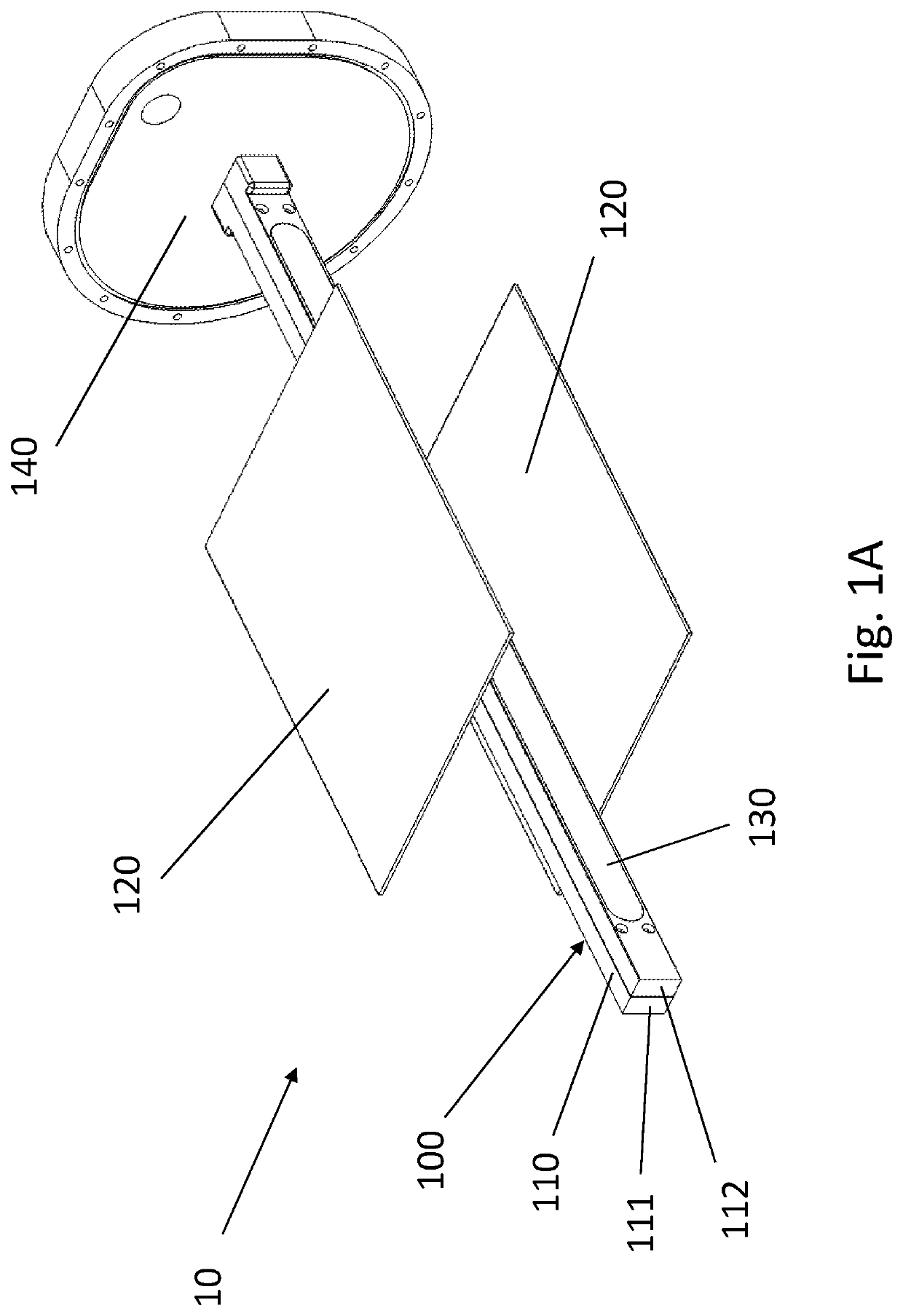

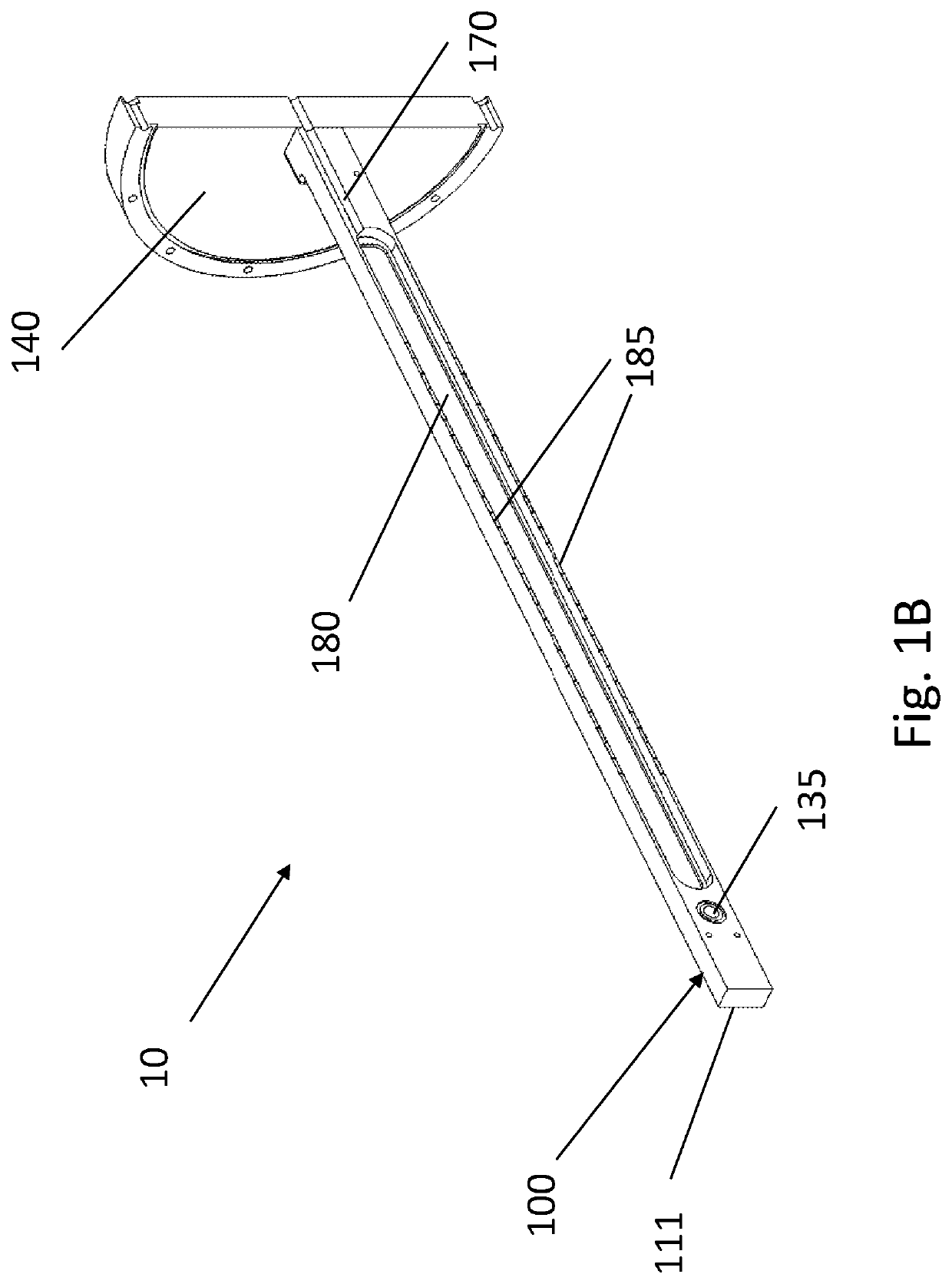

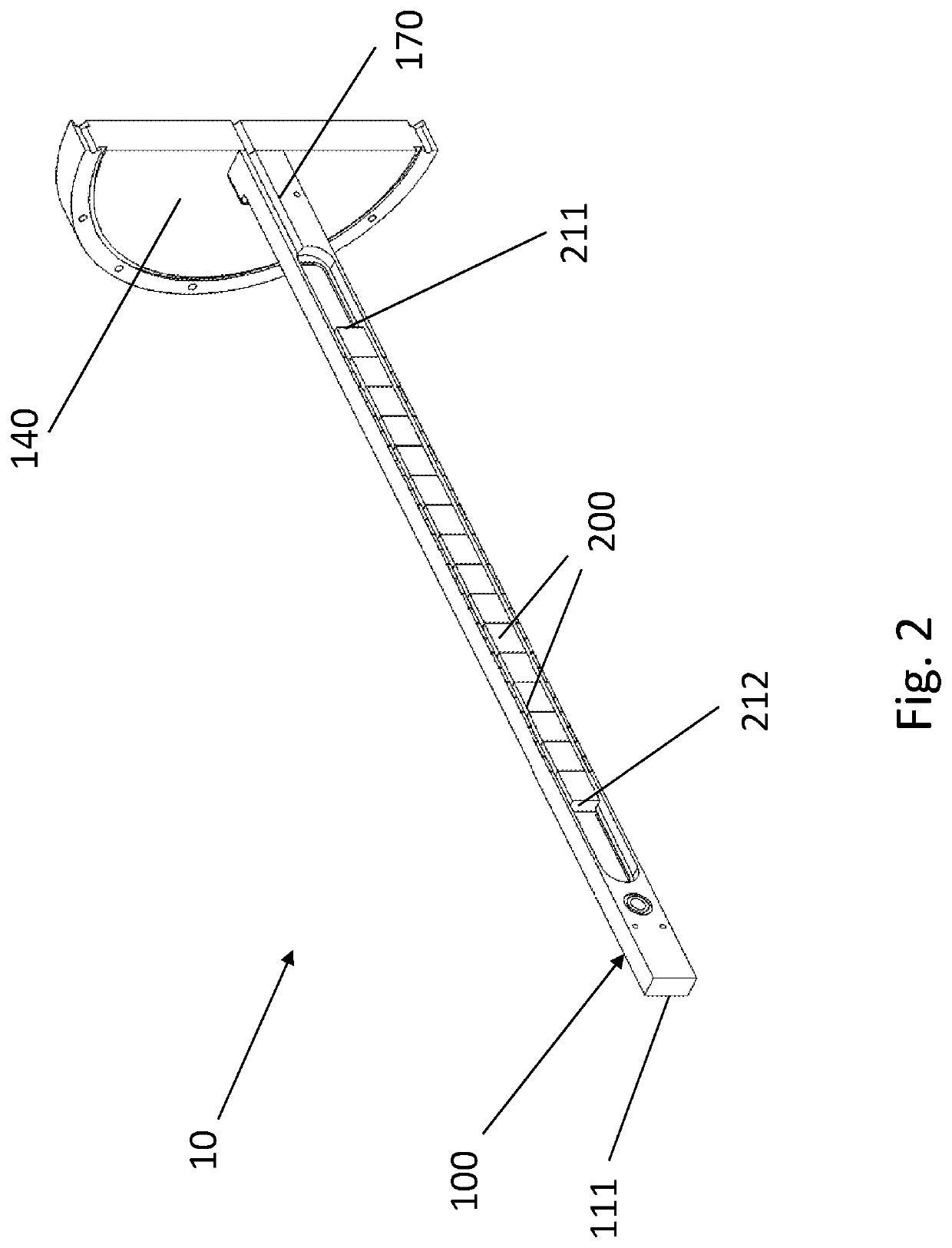

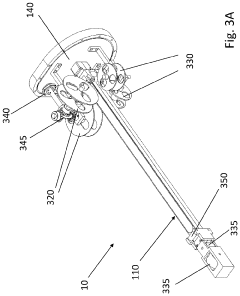

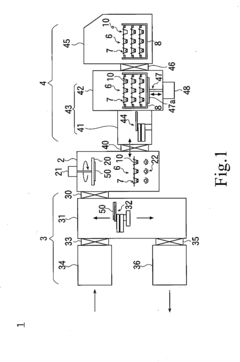

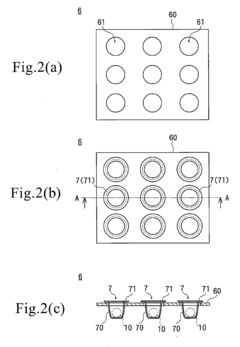

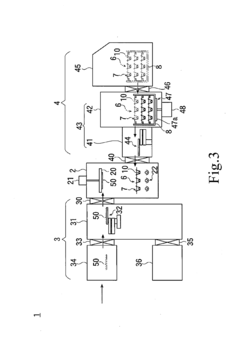

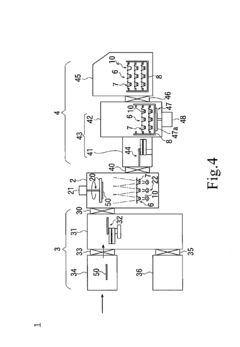

High throughput vacuum deposition sources and system thereof

PatentInactiveUS20200109473A1

Innovation

- A high throughput deposition apparatus with elongated plasma sources, magnets to confine plasma, and a web transport mechanism that minimizes contact with deposition sources, utilizing a vacuum chamber with differential pumping chambers to maintain low operating pressures and reduce gas phase reactions, and employing protective webs to prevent deposition on electrodes.

Vacuum deposition system and vacuum deposition method

PatentInactiveEP2423348A1

Innovation

- A vacuum deposition system with a substrate and material supplying/replacing system, including a material loading region in a dry atmosphere and a heating mechanism, allows for efficient and uniform film formation by preventing moisture exposure and using a simple configuration without shutters or film thickness monitors.

Environmental Impact

The environmental impact of vacuum pumps in advanced material deposition techniques is a critical consideration in the broader context of sustainable manufacturing and green technology. These pumps play a crucial role in creating the necessary conditions for precise material deposition, but their operation also has implications for energy consumption and potential emissions.

Vacuum pumps used in material deposition processes typically require significant energy input to maintain the low-pressure environments essential for high-quality deposition. This energy demand contributes to the overall carbon footprint of the manufacturing process. However, advancements in pump technology have led to more energy-efficient models, reducing the environmental impact over time. Modern vacuum pumps often incorporate variable speed drives and intelligent control systems, optimizing energy usage based on real-time process requirements.

The use of vacuum pumps in material deposition also raises concerns about potential emissions. While the primary function of these pumps is to remove gases from the deposition chamber, they may inadvertently release trace amounts of process gases or particulates into the atmosphere. To mitigate this, many advanced systems now incorporate sophisticated filtration and abatement technologies. These systems capture and neutralize potentially harmful emissions before they can enter the environment.

Water consumption is another environmental factor to consider. Some vacuum pump systems, particularly those using liquid ring technology, require water for cooling and sealing. This can lead to significant water usage in industrial settings. However, the development of dry vacuum pumps has helped address this issue by eliminating the need for sealing fluids, thereby reducing water consumption and the associated environmental impact.

The materials used in the construction of vacuum pumps themselves also have environmental implications. Many pumps contain metals and alloys that require energy-intensive mining and refining processes. However, the longevity of high-quality vacuum pumps can offset this initial environmental cost over time. Additionally, manufacturers are increasingly focusing on designing pumps with recyclable components and exploring the use of more sustainable materials.

In the context of lifecycle assessment, the environmental impact of vacuum pumps extends beyond their operational phase. The production, transportation, and eventual disposal or recycling of these pumps all contribute to their overall environmental footprint. As such, there is a growing emphasis on designing pumps with longer operational lifespans and easier maintenance, reducing the frequency of replacement and the associated environmental costs.

Despite these challenges, the use of vacuum pumps in advanced material deposition techniques often results in net positive environmental outcomes. By enabling the production of more efficient and durable materials, these processes contribute to the development of technologies that can significantly reduce energy consumption and emissions in various applications, from solar panels to energy-efficient electronics.

Vacuum pumps used in material deposition processes typically require significant energy input to maintain the low-pressure environments essential for high-quality deposition. This energy demand contributes to the overall carbon footprint of the manufacturing process. However, advancements in pump technology have led to more energy-efficient models, reducing the environmental impact over time. Modern vacuum pumps often incorporate variable speed drives and intelligent control systems, optimizing energy usage based on real-time process requirements.

The use of vacuum pumps in material deposition also raises concerns about potential emissions. While the primary function of these pumps is to remove gases from the deposition chamber, they may inadvertently release trace amounts of process gases or particulates into the atmosphere. To mitigate this, many advanced systems now incorporate sophisticated filtration and abatement technologies. These systems capture and neutralize potentially harmful emissions before they can enter the environment.

Water consumption is another environmental factor to consider. Some vacuum pump systems, particularly those using liquid ring technology, require water for cooling and sealing. This can lead to significant water usage in industrial settings. However, the development of dry vacuum pumps has helped address this issue by eliminating the need for sealing fluids, thereby reducing water consumption and the associated environmental impact.

The materials used in the construction of vacuum pumps themselves also have environmental implications. Many pumps contain metals and alloys that require energy-intensive mining and refining processes. However, the longevity of high-quality vacuum pumps can offset this initial environmental cost over time. Additionally, manufacturers are increasingly focusing on designing pumps with recyclable components and exploring the use of more sustainable materials.

In the context of lifecycle assessment, the environmental impact of vacuum pumps extends beyond their operational phase. The production, transportation, and eventual disposal or recycling of these pumps all contribute to their overall environmental footprint. As such, there is a growing emphasis on designing pumps with longer operational lifespans and easier maintenance, reducing the frequency of replacement and the associated environmental costs.

Despite these challenges, the use of vacuum pumps in advanced material deposition techniques often results in net positive environmental outcomes. By enabling the production of more efficient and durable materials, these processes contribute to the development of technologies that can significantly reduce energy consumption and emissions in various applications, from solar panels to energy-efficient electronics.

Material Compatibility

Material compatibility is a critical factor in advanced material deposition techniques, particularly when utilizing vacuum pumps. The interaction between the materials being deposited and the components of the vacuum system can significantly impact the quality and efficiency of the deposition process. Different materials exhibit varying levels of compatibility with vacuum environments and pump components, necessitating careful consideration in system design and operation.

Vacuum pumps used in material deposition must be constructed from materials that can withstand the potentially corrosive or reactive nature of the deposited substances. Stainless steel is commonly employed due to its excellent resistance to corrosion and chemical inertness. However, for more aggressive materials, specialized alloys or coatings may be required to ensure longevity and prevent contamination of the deposition process.

The choice of sealing materials in vacuum pumps is equally crucial. Elastomers used in seals and gaskets must be compatible with both the deposited materials and any process gases. Fluoroelastomers, such as Viton, are often preferred for their broad chemical resistance and low outgassing properties. In more demanding applications, metal seals or all-metal pump designs may be necessary to eliminate potential contamination sources.

Lubricants used in vacuum pumps must also be carefully selected to avoid interference with the deposition process. Perfluoropolyether (PFPE) lubricants are frequently used due to their low vapor pressure and chemical stability. For ultra-high vacuum applications or when dealing with highly reactive materials, dry-running pumps may be employed to eliminate the risk of lubricant contamination entirely.

The materials used in the vacuum chamber and substrate holders must also be considered. These components should not outgas or react with the deposited materials, as this could introduce impurities or alter the composition of the deposited layer. Materials such as high-purity aluminum, electropolished stainless steel, or specialized ceramics are often used to ensure compatibility and maintain vacuum integrity.

In some cases, the deposited materials themselves may pose challenges to pump operation. For instance, certain metals or compounds may condense or solidify within the pump, potentially causing damage or reduced performance. To mitigate this, pump heating systems or specialized traps may be implemented to prevent material accumulation in sensitive areas.

Understanding the material compatibility requirements for specific deposition processes is essential for optimizing system performance and ensuring the quality of deposited layers. This knowledge informs the selection of appropriate pump technologies, materials, and system configurations, ultimately contributing to the advancement of material deposition techniques across various industries and applications.

Vacuum pumps used in material deposition must be constructed from materials that can withstand the potentially corrosive or reactive nature of the deposited substances. Stainless steel is commonly employed due to its excellent resistance to corrosion and chemical inertness. However, for more aggressive materials, specialized alloys or coatings may be required to ensure longevity and prevent contamination of the deposition process.

The choice of sealing materials in vacuum pumps is equally crucial. Elastomers used in seals and gaskets must be compatible with both the deposited materials and any process gases. Fluoroelastomers, such as Viton, are often preferred for their broad chemical resistance and low outgassing properties. In more demanding applications, metal seals or all-metal pump designs may be necessary to eliminate potential contamination sources.

Lubricants used in vacuum pumps must also be carefully selected to avoid interference with the deposition process. Perfluoropolyether (PFPE) lubricants are frequently used due to their low vapor pressure and chemical stability. For ultra-high vacuum applications or when dealing with highly reactive materials, dry-running pumps may be employed to eliminate the risk of lubricant contamination entirely.

The materials used in the vacuum chamber and substrate holders must also be considered. These components should not outgas or react with the deposited materials, as this could introduce impurities or alter the composition of the deposited layer. Materials such as high-purity aluminum, electropolished stainless steel, or specialized ceramics are often used to ensure compatibility and maintain vacuum integrity.

In some cases, the deposited materials themselves may pose challenges to pump operation. For instance, certain metals or compounds may condense or solidify within the pump, potentially causing damage or reduced performance. To mitigate this, pump heating systems or specialized traps may be implemented to prevent material accumulation in sensitive areas.

Understanding the material compatibility requirements for specific deposition processes is essential for optimizing system performance and ensuring the quality of deposited layers. This knowledge informs the selection of appropriate pump technologies, materials, and system configurations, ultimately contributing to the advancement of material deposition techniques across various industries and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!