How Vacuum Pumps Facilitate Novel Battery Technologies

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution

Vacuum pump technology has undergone significant evolution since its inception, playing a crucial role in the development of novel battery technologies. The journey of vacuum pumps began in the 17th century with the invention of the first mechanical vacuum pump by Otto von Guericke. This early device laid the foundation for future advancements in vacuum technology.

In the 19th century, the introduction of the mercury displacement pump marked a significant milestone. This pump type offered improved vacuum levels and reliability, enabling more sophisticated scientific experiments and industrial applications. The early 20th century saw the development of rotary vane pumps and diffusion pumps, which further enhanced vacuum capabilities and expanded the range of potential applications.

The mid-20th century brought about a revolution in vacuum pump technology with the invention of turbomolecular pumps. These high-speed rotary pumps could achieve much higher vacuum levels, opening new possibilities for scientific research and industrial processes. Concurrently, the development of cryogenic pumps provided an alternative method for achieving ultra-high vacuums, particularly useful in specialized applications.

As the demand for cleaner and more efficient vacuum systems grew, oil-free pump technologies emerged. Scroll pumps and diaphragm pumps gained popularity in applications requiring contamination-free environments, such as semiconductor manufacturing and advanced battery production. These oil-free pumps eliminated the risk of oil backstreaming, a critical factor in maintaining the purity of battery materials during production.

The late 20th and early 21st centuries saw the integration of smart technologies into vacuum pumps. Computerized control systems, remote monitoring capabilities, and predictive maintenance features have significantly improved the efficiency and reliability of vacuum systems. This evolution has been particularly beneficial in the production of advanced batteries, where precise control of the manufacturing environment is crucial.

In recent years, the focus has shifted towards developing more energy-efficient and environmentally friendly vacuum pumps. Variable speed drives, improved motor designs, and advanced materials have contributed to reducing the energy consumption of vacuum systems. This trend aligns well with the goals of sustainable battery production, supporting the overall objective of creating greener energy storage solutions.

The evolution of vacuum pump technology continues to be driven by the demands of emerging industries, including advanced battery manufacturing. Current developments are focused on further improving vacuum levels, enhancing pump reliability, and reducing operational costs. These advancements are expected to play a vital role in enabling the production of next-generation batteries with improved performance and longevity.

In the 19th century, the introduction of the mercury displacement pump marked a significant milestone. This pump type offered improved vacuum levels and reliability, enabling more sophisticated scientific experiments and industrial applications. The early 20th century saw the development of rotary vane pumps and diffusion pumps, which further enhanced vacuum capabilities and expanded the range of potential applications.

The mid-20th century brought about a revolution in vacuum pump technology with the invention of turbomolecular pumps. These high-speed rotary pumps could achieve much higher vacuum levels, opening new possibilities for scientific research and industrial processes. Concurrently, the development of cryogenic pumps provided an alternative method for achieving ultra-high vacuums, particularly useful in specialized applications.

As the demand for cleaner and more efficient vacuum systems grew, oil-free pump technologies emerged. Scroll pumps and diaphragm pumps gained popularity in applications requiring contamination-free environments, such as semiconductor manufacturing and advanced battery production. These oil-free pumps eliminated the risk of oil backstreaming, a critical factor in maintaining the purity of battery materials during production.

The late 20th and early 21st centuries saw the integration of smart technologies into vacuum pumps. Computerized control systems, remote monitoring capabilities, and predictive maintenance features have significantly improved the efficiency and reliability of vacuum systems. This evolution has been particularly beneficial in the production of advanced batteries, where precise control of the manufacturing environment is crucial.

In recent years, the focus has shifted towards developing more energy-efficient and environmentally friendly vacuum pumps. Variable speed drives, improved motor designs, and advanced materials have contributed to reducing the energy consumption of vacuum systems. This trend aligns well with the goals of sustainable battery production, supporting the overall objective of creating greener energy storage solutions.

The evolution of vacuum pump technology continues to be driven by the demands of emerging industries, including advanced battery manufacturing. Current developments are focused on further improving vacuum levels, enhancing pump reliability, and reducing operational costs. These advancements are expected to play a vital role in enabling the production of next-generation batteries with improved performance and longevity.

Battery Market Dynamics

The battery market has experienced significant growth and transformation in recent years, driven by the increasing demand for electric vehicles, renewable energy storage, and portable electronic devices. This dynamic landscape has created a fertile ground for novel battery technologies, with vacuum pumps playing a crucial role in their development and production processes.

The global battery market is projected to reach substantial value in the coming years, with lithium-ion batteries dominating the sector. However, emerging technologies such as solid-state batteries, lithium-sulfur batteries, and sodium-ion batteries are gaining traction, promising improved performance, safety, and sustainability. These advancements are reshaping market dynamics and attracting substantial investments from both established players and startups.

Electric vehicles (EVs) represent a major driving force behind battery market growth. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance, long-range batteries continues to surge. This trend has led to increased competition among automakers and battery manufacturers, spurring innovation and cost reduction efforts.

The renewable energy sector is another key factor influencing battery market dynamics. The intermittent nature of solar and wind power generation necessitates efficient energy storage solutions, creating opportunities for large-scale battery systems. Grid-scale energy storage applications are expanding rapidly, with lithium-ion batteries currently leading the market but facing competition from emerging technologies.

Consumer electronics remain a significant segment of the battery market, with ongoing demand for longer-lasting, faster-charging batteries in smartphones, laptops, and wearable devices. This sector continues to drive innovation in miniaturization and energy density improvements.

The battery supply chain has become a critical focus for many countries, leading to efforts to establish domestic battery production capabilities and secure raw material supplies. This geopolitical aspect has further intensified market competition and influenced investment decisions.

Sustainability concerns are increasingly shaping battery market dynamics. There is growing emphasis on developing batteries with reduced environmental impact, improved recyclability, and ethical sourcing of materials. This shift is driving research into alternative battery chemistries and more sustainable production processes.

In this evolving landscape, vacuum pumps play a vital role in enabling the development and production of novel battery technologies. They are essential in creating the controlled environments necessary for manufacturing advanced battery components, such as electrode materials and electrolytes. Vacuum technology is particularly crucial in the production of solid-state batteries, where precise control of atmospheric conditions is required to achieve the desired material properties and performance characteristics.

The global battery market is projected to reach substantial value in the coming years, with lithium-ion batteries dominating the sector. However, emerging technologies such as solid-state batteries, lithium-sulfur batteries, and sodium-ion batteries are gaining traction, promising improved performance, safety, and sustainability. These advancements are reshaping market dynamics and attracting substantial investments from both established players and startups.

Electric vehicles (EVs) represent a major driving force behind battery market growth. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance, long-range batteries continues to surge. This trend has led to increased competition among automakers and battery manufacturers, spurring innovation and cost reduction efforts.

The renewable energy sector is another key factor influencing battery market dynamics. The intermittent nature of solar and wind power generation necessitates efficient energy storage solutions, creating opportunities for large-scale battery systems. Grid-scale energy storage applications are expanding rapidly, with lithium-ion batteries currently leading the market but facing competition from emerging technologies.

Consumer electronics remain a significant segment of the battery market, with ongoing demand for longer-lasting, faster-charging batteries in smartphones, laptops, and wearable devices. This sector continues to drive innovation in miniaturization and energy density improvements.

The battery supply chain has become a critical focus for many countries, leading to efforts to establish domestic battery production capabilities and secure raw material supplies. This geopolitical aspect has further intensified market competition and influenced investment decisions.

Sustainability concerns are increasingly shaping battery market dynamics. There is growing emphasis on developing batteries with reduced environmental impact, improved recyclability, and ethical sourcing of materials. This shift is driving research into alternative battery chemistries and more sustainable production processes.

In this evolving landscape, vacuum pumps play a vital role in enabling the development and production of novel battery technologies. They are essential in creating the controlled environments necessary for manufacturing advanced battery components, such as electrode materials and electrolytes. Vacuum technology is particularly crucial in the production of solid-state batteries, where precise control of atmospheric conditions is required to achieve the desired material properties and performance characteristics.

Vacuum Tech Challenges

The development of vacuum pump technology for novel battery applications faces several significant challenges. One of the primary obstacles is achieving and maintaining ultra-high vacuum levels required for certain battery manufacturing processes. Current vacuum pump systems often struggle to reach and sustain the extreme low pressures needed for advanced battery production, particularly in large-scale industrial settings.

Material compatibility presents another major hurdle. The aggressive chemicals and materials used in battery production can corrode or degrade conventional vacuum pump components, leading to reduced performance and increased maintenance requirements. Developing pumps with corrosion-resistant materials and coatings that can withstand these harsh environments is crucial for long-term reliability and efficiency.

Energy efficiency is a growing concern in vacuum pump technology for battery applications. Many existing pump designs consume substantial amounts of power, especially when operating at high vacuum levels. This not only increases production costs but also contradicts the sustainability goals often associated with battery technology development. Improving the energy efficiency of vacuum pumps without compromising their performance is a key challenge facing researchers and engineers.

Scalability and throughput pose additional challenges, particularly as battery production volumes increase to meet growing demand. Vacuum systems must be capable of handling larger substrates and higher production rates while maintaining consistent vacuum levels across the entire process area. This requires innovations in pump design, gas flow management, and system integration.

Contamination control is critical in battery manufacturing, and vacuum pumps play a vital role in maintaining clean environments. However, conventional pump designs can introduce particulates or oil vapor into the process chamber, potentially compromising battery quality. Developing oil-free and particle-free pump technologies that can achieve high vacuum levels is essential for advancing battery production techniques.

Noise and vibration reduction represent another set of challenges in vacuum pump technology. The operation of high-performance vacuum pumps often generates significant noise and vibration, which can be disruptive in manufacturing environments and potentially affect sensitive production processes. Addressing these issues through innovative pump designs and advanced isolation techniques is crucial for improving working conditions and process stability.

Finally, the integration of smart technologies and predictive maintenance capabilities into vacuum pump systems presents both opportunities and challenges. While these advancements can potentially improve system reliability and reduce downtime, they also require the development of sophisticated sensors, data analytics, and control systems tailored to the unique demands of battery manufacturing environments.

Material compatibility presents another major hurdle. The aggressive chemicals and materials used in battery production can corrode or degrade conventional vacuum pump components, leading to reduced performance and increased maintenance requirements. Developing pumps with corrosion-resistant materials and coatings that can withstand these harsh environments is crucial for long-term reliability and efficiency.

Energy efficiency is a growing concern in vacuum pump technology for battery applications. Many existing pump designs consume substantial amounts of power, especially when operating at high vacuum levels. This not only increases production costs but also contradicts the sustainability goals often associated with battery technology development. Improving the energy efficiency of vacuum pumps without compromising their performance is a key challenge facing researchers and engineers.

Scalability and throughput pose additional challenges, particularly as battery production volumes increase to meet growing demand. Vacuum systems must be capable of handling larger substrates and higher production rates while maintaining consistent vacuum levels across the entire process area. This requires innovations in pump design, gas flow management, and system integration.

Contamination control is critical in battery manufacturing, and vacuum pumps play a vital role in maintaining clean environments. However, conventional pump designs can introduce particulates or oil vapor into the process chamber, potentially compromising battery quality. Developing oil-free and particle-free pump technologies that can achieve high vacuum levels is essential for advancing battery production techniques.

Noise and vibration reduction represent another set of challenges in vacuum pump technology. The operation of high-performance vacuum pumps often generates significant noise and vibration, which can be disruptive in manufacturing environments and potentially affect sensitive production processes. Addressing these issues through innovative pump designs and advanced isolation techniques is crucial for improving working conditions and process stability.

Finally, the integration of smart technologies and predictive maintenance capabilities into vacuum pump systems presents both opportunities and challenges. While these advancements can potentially improve system reliability and reduce downtime, they also require the development of sophisticated sensors, data analytics, and control systems tailored to the unique demands of battery manufacturing environments.

Current Vacuum Solutions

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping capacity, reduced power consumption, and improved reliability in vacuum systems.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.

- Vacuum pumps for semiconductor manufacturing: Specialized vacuum pumps have been developed for use in semiconductor manufacturing processes. These pumps are designed to handle the unique requirements of semiconductor fabrication, including high cleanliness standards, corrosive gas compatibility, and precise pressure control. The pumps incorporate features to minimize particle generation and maintain stable vacuum conditions in sensitive manufacturing environments.

- Historical developments in vacuum pump technology: The evolution of vacuum pump technology spans several decades, with numerous innovations and design iterations. Early patents showcase fundamental concepts and mechanisms that laid the foundation for modern vacuum pumps. These historical developments include various types of displacement pumps, improvements in sealing techniques, and advancements in materials used for pump construction.

- Vacuum pumps for automotive applications: Vacuum pumps play a crucial role in automotive systems, particularly in brake boosters and engine management. Specialized designs have been developed to meet the specific requirements of automotive applications, including compact size, durability under harsh conditions, and integration with other vehicle systems. These pumps often incorporate features to enhance fuel efficiency and reduce emissions.

- Energy-efficient vacuum pump systems: Recent innovations focus on improving the energy efficiency of vacuum pump systems. These developments include advanced control algorithms, variable speed drives, and heat recovery mechanisms. Energy-efficient designs aim to reduce power consumption, minimize operating costs, and lower the environmental impact of vacuum pump operations across various industries.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high vacuum levels, and minimize particle contamination. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.Expand Specific Solutions03 Integration of vacuum pumps in automotive systems

Vacuum pumps have been incorporated into various automotive systems to enhance vehicle performance and efficiency. Applications include brake boosters, engine management systems, and emissions control devices. These pumps are designed to be compact, durable, and capable of operating under varying conditions encountered in automotive environments.Expand Specific Solutions04 Energy-efficient vacuum pump technologies

Advancements in vacuum pump technologies have focused on improving energy efficiency to reduce operational costs and environmental impact. These developments include the use of variable speed drives, optimized motor designs, and intelligent control systems. Such innovations allow for better matching of pump output to system demands, resulting in significant energy savings.Expand Specific Solutions05 Historical developments in vacuum pump technology

The evolution of vacuum pump technology spans several decades, with numerous innovations contributing to improved performance and reliability. Historical developments include advancements in rotary vane pumps, diffusion pumps, and turbomolecular pumps. These innovations have led to the creation of more efficient and versatile vacuum pumps suitable for a wide range of applications.Expand Specific Solutions

Key Industry Players

The vacuum pump industry for novel battery technologies is in a growth phase, driven by increasing demand for advanced energy storage solutions. The market size is expanding rapidly, with major players like LEYBOLD AG, Edwards Ltd., and Pfeiffer Vacuum GmbH leading the way. These companies are investing heavily in R&D to improve vacuum pump efficiency and performance for battery manufacturing processes. The technology is maturing, with innovations focusing on enhancing precision, reducing energy consumption, and increasing pump longevity. Emerging players such as Milwaukee Electric Tool Corp. are also entering the market, bringing new perspectives and potentially disruptive technologies to this evolving sector.

LEYBOLD AG

Technical Solution: LEYBOLD AG has developed advanced vacuum pump technologies specifically tailored for battery manufacturing processes. Their SCREWLINE series of dry screw vacuum pumps offer high pumping speeds and ultimate pressures suitable for various battery production stages[1]. These pumps utilize a unique screw rotor design that ensures efficient gas handling and minimal maintenance requirements. LEYBOLD's vacuum systems are particularly effective in electrode drying processes, where precise moisture removal is critical for battery performance and longevity[2]. The company has also introduced smart vacuum solutions with integrated sensors and control systems, allowing real-time monitoring and optimization of vacuum levels throughout the battery production line[3].

Strengths: High efficiency in moisture removal, low maintenance requirements, and smart integration capabilities. Weaknesses: Potentially higher initial cost compared to traditional pump technologies, and may require specialized training for operators.

Edwards Ltd.

Technical Solution: Edwards Ltd. has pioneered vacuum solutions specifically designed for lithium-ion battery production. Their GXS dry screw pump series offers high pumping speeds and low ultimate pressures, crucial for various stages of battery manufacturing[1]. Edwards has developed specialized vacuum systems for electrode drying processes, which are critical in removing residual solvents and moisture from battery components[2]. Their pumps incorporate advanced temperature management systems to handle the volatile organic compounds (VOCs) often present in battery production environments. Additionally, Edwards has introduced the iXM series of intelligent vacuum pumps, which feature predictive maintenance capabilities and can be integrated into Industry 4.0 manufacturing systems[3]. These pumps use machine learning algorithms to optimize performance and energy efficiency in real-time, adapting to the specific requirements of different battery production processes.

Strengths: Specialized solutions for lithium-ion battery production, advanced VOC handling capabilities, and intelligent pump systems with predictive maintenance. Weaknesses: Potentially higher upfront costs and may require more complex integration into existing manufacturing lines.

Pump Innovation Patents

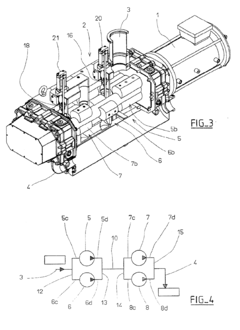

Pumping system for rapid evacuation of a containment and having a low energy consumption

PatentInactiveEP1746287A1

Innovation

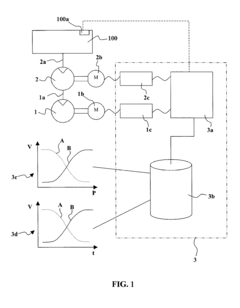

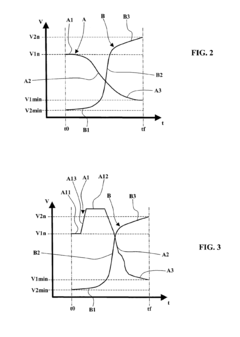

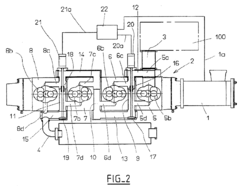

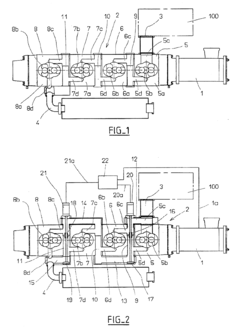

- A vacuum pumping device with a primary and secondary pump connected in series, driven by electric motors controlled by an electronic module that adjusts their speeds according to specific laws to optimize energy consumption, with the secondary pump speed increasing and primary pump speed decreasing as pressure decreases, allowing for efficient energy use by leveraging the low energy compression zone and maintaining flow rate.

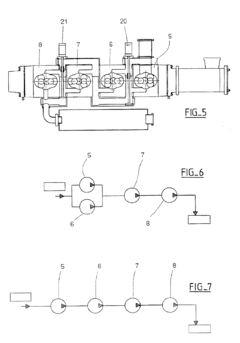

Vacuum pumping with energy limitation

PatentInactiveEP1710440A2

Innovation

- A vacuum pumping device with variable geometry and a multi-stage dry mechanical pump that adjusts its configuration based on pressure and power consumption to optimize flow rate, using intelligent connection modes and electronic control to switch between parallel and series configurations, allowing a smaller pump to achieve faster pumping with reduced energy use.

Energy Efficiency Impact

Vacuum pumps play a crucial role in enhancing the energy efficiency of novel battery technologies. By creating and maintaining low-pressure environments, these pumps contribute significantly to the overall performance and sustainability of advanced battery systems. The impact of vacuum pumps on energy efficiency in battery production and operation is multifaceted and far-reaching.

In the manufacturing process of batteries, vacuum pumps are essential for creating clean, controlled environments. This ensures the removal of contaminants and moisture, which can significantly degrade battery performance and lifespan. By maintaining a high-purity atmosphere during production, vacuum pumps help minimize defects and increase the overall quality of battery cells. This results in batteries with higher energy density and improved cycle life, directly translating to enhanced energy efficiency in the final product.

Moreover, vacuum pumps are instrumental in the development of solid-state batteries, a promising technology for next-generation energy storage. These pumps facilitate the deposition of thin-film electrolytes and electrodes, enabling the creation of compact, high-performance battery structures. The precise control over layer thickness and composition afforded by vacuum-based deposition techniques leads to batteries with superior energy density and reduced internal resistance, further improving energy efficiency.

In the realm of lithium-ion battery production, vacuum pumps contribute to the critical process of electrolyte filling. By evacuating air from battery cells before introducing the electrolyte, these pumps ensure complete and uniform filling. This process minimizes the formation of voids or gas pockets within the cell, which can lead to reduced capacity and increased internal resistance. The result is a more efficient battery with improved energy transfer characteristics and longer operational life.

Vacuum technology also plays a vital role in battery recycling processes, contributing to the overall energy efficiency of the battery lifecycle. Advanced recycling techniques utilizing vacuum systems allow for the efficient recovery of valuable materials from spent batteries. This not only reduces the energy required for raw material extraction but also minimizes the environmental impact of battery production, creating a more sustainable and energy-efficient cycle of battery use and reuse.

Furthermore, vacuum pumps are essential in the development of novel electrode materials and structures. By enabling the creation of porous electrodes with high surface area, these pumps facilitate the design of batteries with enhanced charge/discharge rates and improved energy storage capacity. This advancement directly impacts the energy efficiency of batteries in high-power applications, such as electric vehicles and grid-scale energy storage systems.

In the manufacturing process of batteries, vacuum pumps are essential for creating clean, controlled environments. This ensures the removal of contaminants and moisture, which can significantly degrade battery performance and lifespan. By maintaining a high-purity atmosphere during production, vacuum pumps help minimize defects and increase the overall quality of battery cells. This results in batteries with higher energy density and improved cycle life, directly translating to enhanced energy efficiency in the final product.

Moreover, vacuum pumps are instrumental in the development of solid-state batteries, a promising technology for next-generation energy storage. These pumps facilitate the deposition of thin-film electrolytes and electrodes, enabling the creation of compact, high-performance battery structures. The precise control over layer thickness and composition afforded by vacuum-based deposition techniques leads to batteries with superior energy density and reduced internal resistance, further improving energy efficiency.

In the realm of lithium-ion battery production, vacuum pumps contribute to the critical process of electrolyte filling. By evacuating air from battery cells before introducing the electrolyte, these pumps ensure complete and uniform filling. This process minimizes the formation of voids or gas pockets within the cell, which can lead to reduced capacity and increased internal resistance. The result is a more efficient battery with improved energy transfer characteristics and longer operational life.

Vacuum technology also plays a vital role in battery recycling processes, contributing to the overall energy efficiency of the battery lifecycle. Advanced recycling techniques utilizing vacuum systems allow for the efficient recovery of valuable materials from spent batteries. This not only reduces the energy required for raw material extraction but also minimizes the environmental impact of battery production, creating a more sustainable and energy-efficient cycle of battery use and reuse.

Furthermore, vacuum pumps are essential in the development of novel electrode materials and structures. By enabling the creation of porous electrodes with high surface area, these pumps facilitate the design of batteries with enhanced charge/discharge rates and improved energy storage capacity. This advancement directly impacts the energy efficiency of batteries in high-power applications, such as electric vehicles and grid-scale energy storage systems.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and adoption of novel battery technologies facilitated by vacuum pumps. As governments worldwide increasingly focus on reducing carbon emissions and promoting sustainable energy solutions, the regulatory landscape for battery manufacturing and disposal has become more stringent.

In many countries, regulations now mandate the reduction of harmful emissions during battery production processes. Vacuum pumps, which are essential in creating controlled environments for battery manufacturing, must adhere to strict guidelines regarding energy efficiency and noise pollution. Manufacturers are required to implement best available techniques (BAT) to minimize environmental impact, often necessitating the use of advanced vacuum pump technologies with lower energy consumption and reduced emissions.

The disposal and recycling of batteries have also come under increased scrutiny. Regulations such as the EU's Battery Directive and similar laws in other regions require manufacturers to implement take-back programs and ensure proper recycling of used batteries. Vacuum pumps play a vital role in the recycling process, enabling the safe extraction and separation of battery components, including potentially hazardous materials.

Furthermore, environmental regulations are driving innovation in battery chemistry and design. As traditional lithium-ion batteries face scrutiny due to their environmental impact, novel battery technologies that utilize vacuum pumps in their production, such as solid-state batteries, are gaining attention. These new technologies often promise improved safety profiles and reduced environmental footprint, aligning with regulatory goals.

The push for cleaner energy storage solutions has also led to increased funding and support for research and development in the battery sector. Many governments offer incentives for companies developing environmentally friendly battery technologies, indirectly boosting the demand for advanced vacuum pump solutions in research laboratories and pilot production facilities.

As the global focus on climate change intensifies, it is likely that environmental regulations will continue to evolve, potentially leading to even stricter standards for battery production and recycling. This trend is expected to further drive innovation in vacuum pump technology, pushing for more efficient, cleaner, and environmentally friendly solutions in the battery industry.

In conclusion, environmental regulations are significantly influencing the intersection of vacuum pump technology and novel battery development. As the regulatory landscape continues to evolve, it will remain a key driver for technological advancements and sustainable practices in the battery industry, ensuring that vacuum pump applications in this field align with global environmental goals.

In many countries, regulations now mandate the reduction of harmful emissions during battery production processes. Vacuum pumps, which are essential in creating controlled environments for battery manufacturing, must adhere to strict guidelines regarding energy efficiency and noise pollution. Manufacturers are required to implement best available techniques (BAT) to minimize environmental impact, often necessitating the use of advanced vacuum pump technologies with lower energy consumption and reduced emissions.

The disposal and recycling of batteries have also come under increased scrutiny. Regulations such as the EU's Battery Directive and similar laws in other regions require manufacturers to implement take-back programs and ensure proper recycling of used batteries. Vacuum pumps play a vital role in the recycling process, enabling the safe extraction and separation of battery components, including potentially hazardous materials.

Furthermore, environmental regulations are driving innovation in battery chemistry and design. As traditional lithium-ion batteries face scrutiny due to their environmental impact, novel battery technologies that utilize vacuum pumps in their production, such as solid-state batteries, are gaining attention. These new technologies often promise improved safety profiles and reduced environmental footprint, aligning with regulatory goals.

The push for cleaner energy storage solutions has also led to increased funding and support for research and development in the battery sector. Many governments offer incentives for companies developing environmentally friendly battery technologies, indirectly boosting the demand for advanced vacuum pump solutions in research laboratories and pilot production facilities.

As the global focus on climate change intensifies, it is likely that environmental regulations will continue to evolve, potentially leading to even stricter standards for battery production and recycling. This trend is expected to further drive innovation in vacuum pump technology, pushing for more efficient, cleaner, and environmentally friendly solutions in the battery industry.

In conclusion, environmental regulations are significantly influencing the intersection of vacuum pump technology and novel battery development. As the regulatory landscape continues to evolve, it will remain a key driver for technological advancements and sustainable practices in the battery industry, ensuring that vacuum pump applications in this field align with global environmental goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!