How Vacuum Pumps Influence Advanced Composite Material Curing

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech in Composites

Vacuum pump technology plays a crucial role in the curing process of advanced composite materials, significantly influencing the quality and performance of the final product. The application of vacuum pressure during the curing cycle serves multiple purposes, each contributing to the overall enhancement of the composite's properties.

Primarily, vacuum pumps facilitate the removal of air and volatile compounds from the composite layup. This process, known as degassing, is essential for minimizing voids and air pockets within the material structure. By creating a low-pressure environment, vacuum pumps encourage the escape of trapped gases, resulting in a more uniform and dense composite. The reduction of voids leads to improved mechanical properties, including higher strength, better fatigue resistance, and enhanced durability.

Furthermore, vacuum pressure aids in the consolidation of composite layers. As the pump evacuates air from between the layers, it generates compressive forces that promote intimate contact between the reinforcing fibers and the resin matrix. This increased contact area ensures better fiber wet-out and impregnation, leading to stronger interfacial bonding and improved load transfer capabilities within the composite structure.

The influence of vacuum pumps extends to the distribution of resin throughout the composite. By applying consistent pressure across the entire surface area, vacuum pumps help to achieve a more uniform resin distribution. This uniformity is crucial for maintaining consistent material properties and minimizing areas of resin-rich or resin-starved regions, which could otherwise become potential weak points in the finished product.

In the context of autoclave curing, vacuum pumps work in conjunction with positive pressure to further enhance the consolidation process. The combination of vacuum and autoclave pressure creates a significant pressure differential, which aids in removing any remaining air or volatiles and ensures thorough compaction of the composite layers. This synergistic effect results in composites with superior fiber volume fractions and reduced porosity.

Vacuum pump technology also contributes to the dimensional accuracy of cured composite parts. By maintaining consistent pressure throughout the curing cycle, it helps to minimize part distortion and warpage that can occur due to uneven resin flow or thermal stresses. This aspect is particularly important for complex geometries or large-scale composite structures where maintaining tight tolerances is critical.

Moreover, the use of vacuum pumps in composite curing processes enables better control over the resin-to-fiber ratio. By regulating the amount of resin that remains in the composite after excess resin is removed, vacuum pumps help achieve the optimal balance between strength and weight – a key consideration in many high-performance applications such as aerospace and automotive industries.

Primarily, vacuum pumps facilitate the removal of air and volatile compounds from the composite layup. This process, known as degassing, is essential for minimizing voids and air pockets within the material structure. By creating a low-pressure environment, vacuum pumps encourage the escape of trapped gases, resulting in a more uniform and dense composite. The reduction of voids leads to improved mechanical properties, including higher strength, better fatigue resistance, and enhanced durability.

Furthermore, vacuum pressure aids in the consolidation of composite layers. As the pump evacuates air from between the layers, it generates compressive forces that promote intimate contact between the reinforcing fibers and the resin matrix. This increased contact area ensures better fiber wet-out and impregnation, leading to stronger interfacial bonding and improved load transfer capabilities within the composite structure.

The influence of vacuum pumps extends to the distribution of resin throughout the composite. By applying consistent pressure across the entire surface area, vacuum pumps help to achieve a more uniform resin distribution. This uniformity is crucial for maintaining consistent material properties and minimizing areas of resin-rich or resin-starved regions, which could otherwise become potential weak points in the finished product.

In the context of autoclave curing, vacuum pumps work in conjunction with positive pressure to further enhance the consolidation process. The combination of vacuum and autoclave pressure creates a significant pressure differential, which aids in removing any remaining air or volatiles and ensures thorough compaction of the composite layers. This synergistic effect results in composites with superior fiber volume fractions and reduced porosity.

Vacuum pump technology also contributes to the dimensional accuracy of cured composite parts. By maintaining consistent pressure throughout the curing cycle, it helps to minimize part distortion and warpage that can occur due to uneven resin flow or thermal stresses. This aspect is particularly important for complex geometries or large-scale composite structures where maintaining tight tolerances is critical.

Moreover, the use of vacuum pumps in composite curing processes enables better control over the resin-to-fiber ratio. By regulating the amount of resin that remains in the composite after excess resin is removed, vacuum pumps help achieve the optimal balance between strength and weight – a key consideration in many high-performance applications such as aerospace and automotive industries.

Market Demand Analysis

The market demand for advanced composite materials has been experiencing significant growth, driven by their superior properties such as high strength-to-weight ratio, corrosion resistance, and design flexibility. This demand has consequently increased the need for efficient and reliable curing processes, where vacuum pumps play a crucial role.

In the aerospace industry, which is a major consumer of advanced composites, the market is projected to expand substantially over the coming years. The use of composite materials in aircraft manufacturing has been steadily increasing, with modern aircraft containing up to 50% composite materials by weight. This trend is expected to continue, fueling the demand for advanced curing technologies that can ensure the quality and performance of these materials.

The automotive sector is another key driver of market demand for advanced composite materials and their associated curing processes. As automakers strive to reduce vehicle weight to improve fuel efficiency and meet stringent emissions regulations, the adoption of composite materials in car manufacturing is on the rise. This shift is creating a growing market for vacuum-assisted curing technologies that can efficiently process these materials.

The wind energy sector is also contributing significantly to the market demand. The increasing size of wind turbine blades, often exceeding 100 meters in length, requires advanced composite materials and precise curing processes to ensure structural integrity and longevity. As the global push for renewable energy continues, this sector is expected to drive further demand for vacuum pump-assisted curing technologies.

In the marine industry, the use of advanced composites in boat and ship construction is growing due to their lightweight properties and resistance to marine environments. This trend is creating additional demand for vacuum-assisted curing processes that can handle large-scale composite structures.

The electronics industry, particularly in the production of printed circuit boards (PCBs), is another significant market for vacuum pump-assisted curing. As electronic devices become more compact and complex, the demand for high-performance PCBs with precise layering and curing is increasing.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth in demand for advanced composite materials and associated curing technologies. This is primarily due to the rapid industrialization, growing aerospace and automotive sectors, and increasing investments in renewable energy in countries like China and India.

The market demand is not only focused on the quantity of composite materials produced but also on the quality and consistency of the curing process. This has led to an increased emphasis on advanced vacuum pump technologies that can provide precise control over the curing environment, ensuring optimal material properties and reducing defects.

In the aerospace industry, which is a major consumer of advanced composites, the market is projected to expand substantially over the coming years. The use of composite materials in aircraft manufacturing has been steadily increasing, with modern aircraft containing up to 50% composite materials by weight. This trend is expected to continue, fueling the demand for advanced curing technologies that can ensure the quality and performance of these materials.

The automotive sector is another key driver of market demand for advanced composite materials and their associated curing processes. As automakers strive to reduce vehicle weight to improve fuel efficiency and meet stringent emissions regulations, the adoption of composite materials in car manufacturing is on the rise. This shift is creating a growing market for vacuum-assisted curing technologies that can efficiently process these materials.

The wind energy sector is also contributing significantly to the market demand. The increasing size of wind turbine blades, often exceeding 100 meters in length, requires advanced composite materials and precise curing processes to ensure structural integrity and longevity. As the global push for renewable energy continues, this sector is expected to drive further demand for vacuum pump-assisted curing technologies.

In the marine industry, the use of advanced composites in boat and ship construction is growing due to their lightweight properties and resistance to marine environments. This trend is creating additional demand for vacuum-assisted curing processes that can handle large-scale composite structures.

The electronics industry, particularly in the production of printed circuit boards (PCBs), is another significant market for vacuum pump-assisted curing. As electronic devices become more compact and complex, the demand for high-performance PCBs with precise layering and curing is increasing.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth in demand for advanced composite materials and associated curing technologies. This is primarily due to the rapid industrialization, growing aerospace and automotive sectors, and increasing investments in renewable energy in countries like China and India.

The market demand is not only focused on the quantity of composite materials produced but also on the quality and consistency of the curing process. This has led to an increased emphasis on advanced vacuum pump technologies that can provide precise control over the curing environment, ensuring optimal material properties and reducing defects.

Current Challenges

The current challenges in the field of vacuum pump influence on advanced composite material curing are multifaceted and complex. One of the primary obstacles is achieving uniform pressure distribution across large composite structures. As composite parts become increasingly larger and more intricate, ensuring consistent vacuum pressure throughout the entire surface area becomes increasingly difficult. This non-uniformity can lead to variations in resin flow and curing rates, potentially resulting in defects and compromised mechanical properties.

Another significant challenge lies in the optimization of vacuum pump systems for different composite materials and geometries. Each composite material and part shape requires a specific vacuum profile for optimal curing. Developing adaptive vacuum systems that can automatically adjust to various material properties and part complexities remains a technological hurdle. This challenge is further compounded by the need to maintain precise vacuum levels throughout the entire curing cycle, which can last several hours or even days for some advanced composites.

The energy efficiency of vacuum pump systems in composite curing processes is also a pressing concern. Current systems often consume substantial amounts of energy, particularly for large-scale industrial applications. Improving the energy efficiency of these systems without compromising their performance is a critical challenge that impacts both environmental sustainability and production costs.

Vacuum leakage and seal integrity present ongoing challenges in the industry. Even minor leaks can significantly affect the curing process, leading to quality issues and increased production times. Developing more robust sealing technologies and leak detection methods, especially for complex part geometries, remains an area of active research and development.

Furthermore, the integration of vacuum pump systems with other advanced manufacturing technologies, such as in-situ monitoring and adaptive control systems, poses significant technical challenges. Creating seamless interfaces between vacuum systems and real-time process monitoring tools is crucial for achieving consistent quality in advanced composite manufacturing.

Lastly, the scalability of vacuum pump technologies for high-volume production environments is a growing concern. As the demand for advanced composite materials increases across various industries, developing vacuum systems that can maintain high performance and reliability in continuous, high-throughput production settings becomes increasingly important. This challenge involves not only scaling up the vacuum pump technology itself but also addressing issues related to maintenance, downtime reduction, and overall system robustness in industrial environments.

Another significant challenge lies in the optimization of vacuum pump systems for different composite materials and geometries. Each composite material and part shape requires a specific vacuum profile for optimal curing. Developing adaptive vacuum systems that can automatically adjust to various material properties and part complexities remains a technological hurdle. This challenge is further compounded by the need to maintain precise vacuum levels throughout the entire curing cycle, which can last several hours or even days for some advanced composites.

The energy efficiency of vacuum pump systems in composite curing processes is also a pressing concern. Current systems often consume substantial amounts of energy, particularly for large-scale industrial applications. Improving the energy efficiency of these systems without compromising their performance is a critical challenge that impacts both environmental sustainability and production costs.

Vacuum leakage and seal integrity present ongoing challenges in the industry. Even minor leaks can significantly affect the curing process, leading to quality issues and increased production times. Developing more robust sealing technologies and leak detection methods, especially for complex part geometries, remains an area of active research and development.

Furthermore, the integration of vacuum pump systems with other advanced manufacturing technologies, such as in-situ monitoring and adaptive control systems, poses significant technical challenges. Creating seamless interfaces between vacuum systems and real-time process monitoring tools is crucial for achieving consistent quality in advanced composite manufacturing.

Lastly, the scalability of vacuum pump technologies for high-volume production environments is a growing concern. As the demand for advanced composite materials increases across various industries, developing vacuum systems that can maintain high performance and reliability in continuous, high-throughput production settings becomes increasingly important. This challenge involves not only scaling up the vacuum pump technology itself but also addressing issues related to maintenance, downtime reduction, and overall system robustness in industrial environments.

Existing Vacuum Solutions

01 Vacuum pump design for curing processes

Specialized vacuum pump designs are developed for curing applications, focusing on efficient air removal and pressure control. These pumps are engineered to maintain consistent vacuum levels during curing processes, ensuring optimal results for various materials and products.- Vacuum pump design for curing processes: Specialized vacuum pump designs are developed for curing applications, focusing on efficient air removal and pressure control during the curing process. These pumps are engineered to maintain consistent vacuum levels, which is crucial for achieving uniform curing results in various industries such as composite manufacturing, rubber processing, and electronics.

- Integration of vacuum pumps in curing systems: Vacuum pumps are integrated into comprehensive curing systems, often as part of automated production lines. These integrated systems combine vacuum technology with heating elements, pressure sensors, and control mechanisms to create optimized curing environments for different materials and products.

- Energy-efficient vacuum pumping for curing applications: Advancements in vacuum pump technology focus on improving energy efficiency in curing processes. This includes the development of variable speed drives, intelligent control systems, and heat recovery mechanisms to reduce energy consumption while maintaining optimal curing conditions.

- Vacuum pump maintenance and monitoring in curing operations: Innovative approaches to vacuum pump maintenance and monitoring are implemented to ensure consistent performance in curing applications. This includes predictive maintenance systems, real-time performance monitoring, and automated diagnostics to minimize downtime and optimize curing process reliability.

- Specialized vacuum pumps for different curing materials: Vacuum pumps are tailored for specific curing applications, considering the unique requirements of different materials such as resins, adhesives, and coatings. These specialized pumps may feature corrosion-resistant components, enhanced vapor handling capabilities, or precise pressure control mechanisms to optimize the curing process for various substances.

02 Integration of vacuum systems in curing equipment

Vacuum systems are integrated into curing equipment to enhance the overall curing process. This integration allows for better control of the curing environment, improved material properties, and reduced curing times. The combined systems often include specialized controls and monitoring features.Expand Specific Solutions03 Vacuum-assisted curing for composite materials

Vacuum pumps are utilized in the curing of composite materials to remove air and volatiles, ensuring better consolidation and reducing voids. This technique is particularly important in aerospace and automotive industries where high-performance materials are crucial.Expand Specific Solutions04 Energy-efficient vacuum pumps for curing applications

Development of energy-efficient vacuum pumps specifically designed for curing processes. These pumps incorporate advanced technologies to reduce power consumption while maintaining high performance, contributing to more sustainable manufacturing practices.Expand Specific Solutions05 Vacuum pump control systems for precise curing

Advanced control systems for vacuum pumps used in curing processes, allowing for precise regulation of vacuum levels and curing parameters. These systems often include programmable features, real-time monitoring, and adaptive controls to optimize the curing process for different materials and products.Expand Specific Solutions

Key Industry Players

The vacuum pump industry for advanced composite material curing is in a mature stage, with a substantial market size driven by aerospace and automotive sectors. The technology is well-established, with key players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Leybold AG offering sophisticated solutions. These companies have developed high-performance vacuum pumps tailored for composite curing processes, demonstrating a high level of technical maturity. Major aerospace manufacturers such as The Boeing Co. and Airbus Operations GmbH are significant end-users, further driving innovation and competition in this specialized market. The industry landscape is characterized by ongoing improvements in pump efficiency, reliability, and integration with advanced curing systems.

The Boeing Co.

Technical Solution: The Boeing Co. has developed proprietary vacuum-assisted resin transfer molding (VARTM) techniques for large-scale composite structures used in aerospace applications. Their approach integrates advanced vacuum pump systems with innovative tooling designs to achieve uniform vacuum distribution across expansive composite parts, such as aircraft fuselages and wings. Boeing's vacuum curing process incorporates zoned vacuum control, allowing for differential pressure application across various sections of a composite part to optimize resin flow and minimize structural defects[6]. The company has also pioneered the use of portable, high-capacity vacuum pumps that can be easily repositioned around large composite structures during the curing process, ensuring consistent vacuum levels even in challenging geometries[7].

Strengths: Expertise in large-scale composite manufacturing, integrated approach combining vacuum technology with tooling design. Weaknesses: Solutions may be highly specialized for aerospace applications, potentially less adaptable to other industries.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for composite material curing processes. Their innovative approach includes the use of dry pumps with variable speed drives, which allow for precise control of vacuum levels throughout the curing cycle. These pumps are designed to maintain consistent vacuum pressure, crucial for ensuring uniform resin distribution and minimizing void formation in composite materials. Edwards' systems also incorporate intelligent control algorithms that adjust pump performance based on real-time feedback from the curing process, optimizing energy efficiency and curing quality[1][3]. The company has introduced oil-free vacuum solutions that prevent potential contamination of composite materials during curing, a critical factor in aerospace and high-performance applications[2].

Strengths: Precise vacuum control, energy efficiency, and contamination-free operation. Weaknesses: Potentially higher initial cost compared to traditional vacuum systems, may require specialized training for operators.

Core Vacuum Innovations

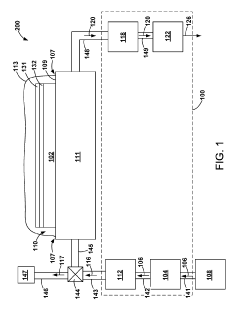

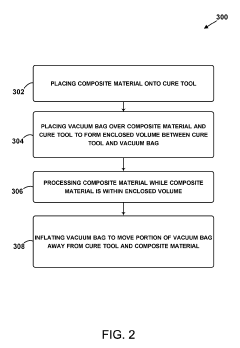

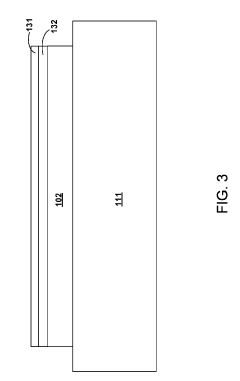

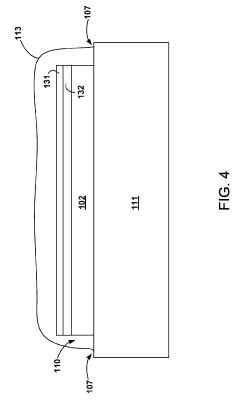

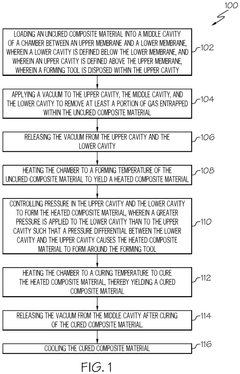

System and method for processing composite material

PatentActiveUS20190255786A1

Innovation

- A system and method that includes inflating the vacuum bag using pressurized gas, with an ionizer to neutralize static electricity and a gas filter to remove particulates and vapors, allowing easier removal of the vacuum bag while minimizing exposure to harmful substances.

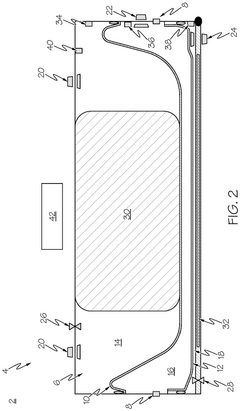

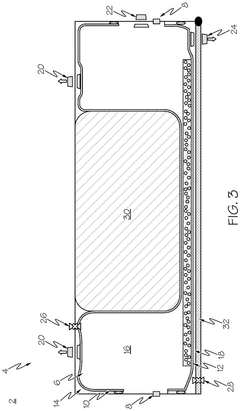

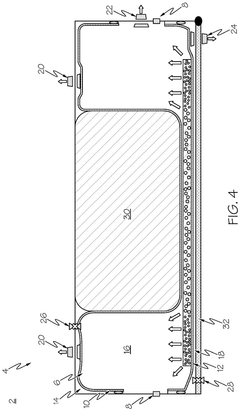

Methods and systems for forming composite parts

PatentPendingEP4530051A1

Innovation

- A method involving vacuum application, differential pressure control, and controlled heating to form and cure composite materials within a chamber segmented by membranes, minimizing contact with membranes to prevent compression and void formation, and using a system with controlled vacuum and pressure ports to facilitate uniform shaping and curing.

Environmental Impact

The environmental impact of vacuum pumps in advanced composite material curing processes is a critical consideration for manufacturers and environmental regulators alike. These pumps play a crucial role in creating the necessary conditions for optimal curing, but their operation can have significant environmental implications.

Energy consumption is a primary concern when assessing the environmental footprint of vacuum pumps in composite curing. The continuous operation of these pumps during the curing process requires substantial electrical power, contributing to increased energy demand and associated greenhouse gas emissions. The extent of this impact varies depending on the energy source, with renewable energy sources mitigating some of the environmental concerns.

Noise pollution is another environmental factor to consider. Vacuum pumps, especially larger industrial models, can generate considerable noise during operation. This can affect the local environment and potentially impact wildlife in surrounding areas. Manufacturers are increasingly focusing on developing quieter pump technologies to address this issue.

The use of lubricants and coolants in vacuum pumps also presents environmental challenges. These substances, often petroleum-based, can pose risks if not properly managed. Leaks or improper disposal can lead to soil and water contamination. As a result, there is a growing trend towards using more environmentally friendly, biodegradable lubricants and implementing stringent waste management protocols.

Air quality is another area of environmental concern. While vacuum pumps are designed to remove air and create a low-pressure environment, they can potentially release particulates or vapors into the atmosphere. This is particularly relevant in composite curing processes where volatile organic compounds (VOCs) may be present. Advanced filtration systems and proper ventilation are essential to mitigate these air quality impacts.

Water usage is an often-overlooked aspect of vacuum pump operation in composite curing. Some pump systems require water for cooling, and the treatment and disposal of this water can have environmental implications. Water-free cooling systems are being developed to address this issue, reducing the overall water footprint of the curing process.

The lifecycle of vacuum pumps themselves also contributes to their environmental impact. The manufacturing of these pumps involves resource extraction and energy-intensive processes. Additionally, the disposal or recycling of pumps at the end of their operational life presents challenges in terms of waste management and resource recovery.

As the composite materials industry continues to grow, there is an increasing focus on developing more environmentally friendly vacuum pump technologies. This includes the use of more efficient motors, improved pump designs that reduce energy consumption, and the integration of smart control systems that optimize pump operation based on real-time curing requirements. These advancements not only reduce the environmental impact but also offer cost savings to manufacturers through improved energy efficiency.

Energy consumption is a primary concern when assessing the environmental footprint of vacuum pumps in composite curing. The continuous operation of these pumps during the curing process requires substantial electrical power, contributing to increased energy demand and associated greenhouse gas emissions. The extent of this impact varies depending on the energy source, with renewable energy sources mitigating some of the environmental concerns.

Noise pollution is another environmental factor to consider. Vacuum pumps, especially larger industrial models, can generate considerable noise during operation. This can affect the local environment and potentially impact wildlife in surrounding areas. Manufacturers are increasingly focusing on developing quieter pump technologies to address this issue.

The use of lubricants and coolants in vacuum pumps also presents environmental challenges. These substances, often petroleum-based, can pose risks if not properly managed. Leaks or improper disposal can lead to soil and water contamination. As a result, there is a growing trend towards using more environmentally friendly, biodegradable lubricants and implementing stringent waste management protocols.

Air quality is another area of environmental concern. While vacuum pumps are designed to remove air and create a low-pressure environment, they can potentially release particulates or vapors into the atmosphere. This is particularly relevant in composite curing processes where volatile organic compounds (VOCs) may be present. Advanced filtration systems and proper ventilation are essential to mitigate these air quality impacts.

Water usage is an often-overlooked aspect of vacuum pump operation in composite curing. Some pump systems require water for cooling, and the treatment and disposal of this water can have environmental implications. Water-free cooling systems are being developed to address this issue, reducing the overall water footprint of the curing process.

The lifecycle of vacuum pumps themselves also contributes to their environmental impact. The manufacturing of these pumps involves resource extraction and energy-intensive processes. Additionally, the disposal or recycling of pumps at the end of their operational life presents challenges in terms of waste management and resource recovery.

As the composite materials industry continues to grow, there is an increasing focus on developing more environmentally friendly vacuum pump technologies. This includes the use of more efficient motors, improved pump designs that reduce energy consumption, and the integration of smart control systems that optimize pump operation based on real-time curing requirements. These advancements not only reduce the environmental impact but also offer cost savings to manufacturers through improved energy efficiency.

Quality Control Measures

Quality control measures play a crucial role in ensuring the effectiveness of vacuum pumps in advanced composite material curing processes. These measures are designed to maintain consistent performance, prevent defects, and optimize the overall curing process. One of the primary quality control measures involves regular calibration and maintenance of vacuum pumps. This includes checking and adjusting pump settings, inspecting seals and gaskets, and verifying the accuracy of pressure gauges. Proper calibration ensures that the vacuum levels achieved during the curing process are precise and consistent, which is essential for producing high-quality composite materials.

Another important quality control measure is the implementation of real-time monitoring systems. These systems continuously track vacuum levels, temperature, and other critical parameters throughout the curing process. By utilizing sensors and data logging equipment, operators can detect any deviations from the desired specifications immediately. This allows for prompt corrective actions to be taken, minimizing the risk of defects and ensuring that the curing process remains within optimal parameters.

Standardized operating procedures (SOPs) are also a key component of quality control in vacuum pump-assisted composite curing. These procedures outline step-by-step instructions for equipment setup, operation, and shutdown, as well as guidelines for troubleshooting common issues. By following these SOPs, operators can maintain consistency in the curing process across different batches and production runs, reducing variability and improving overall product quality.

Regular testing and validation of the cured composite materials are essential quality control measures. This includes destructive and non-destructive testing methods to assess the mechanical properties, void content, and overall integrity of the cured composites. By analyzing these test results, manufacturers can identify any issues related to vacuum pump performance and make necessary adjustments to the curing process.

Training and certification programs for operators and technicians form another critical aspect of quality control. These programs ensure that personnel have the necessary knowledge and skills to operate vacuum pumps effectively and troubleshoot any issues that may arise during the curing process. Ongoing training also keeps staff updated on the latest advancements in vacuum pump technology and best practices in composite material curing.

Lastly, implementing a robust documentation and traceability system is vital for quality control. This system should record all relevant data, including vacuum pump settings, curing parameters, and test results for each production batch. Such documentation allows for easy identification of any deviations or issues, facilitates root cause analysis, and supports continuous improvement efforts in the composite material curing process.

Another important quality control measure is the implementation of real-time monitoring systems. These systems continuously track vacuum levels, temperature, and other critical parameters throughout the curing process. By utilizing sensors and data logging equipment, operators can detect any deviations from the desired specifications immediately. This allows for prompt corrective actions to be taken, minimizing the risk of defects and ensuring that the curing process remains within optimal parameters.

Standardized operating procedures (SOPs) are also a key component of quality control in vacuum pump-assisted composite curing. These procedures outline step-by-step instructions for equipment setup, operation, and shutdown, as well as guidelines for troubleshooting common issues. By following these SOPs, operators can maintain consistency in the curing process across different batches and production runs, reducing variability and improving overall product quality.

Regular testing and validation of the cured composite materials are essential quality control measures. This includes destructive and non-destructive testing methods to assess the mechanical properties, void content, and overall integrity of the cured composites. By analyzing these test results, manufacturers can identify any issues related to vacuum pump performance and make necessary adjustments to the curing process.

Training and certification programs for operators and technicians form another critical aspect of quality control. These programs ensure that personnel have the necessary knowledge and skills to operate vacuum pumps effectively and troubleshoot any issues that may arise during the curing process. Ongoing training also keeps staff updated on the latest advancements in vacuum pump technology and best practices in composite material curing.

Lastly, implementing a robust documentation and traceability system is vital for quality control. This system should record all relevant data, including vacuum pump settings, curing parameters, and test results for each production batch. Such documentation allows for easy identification of any deviations or issues, facilitates root cause analysis, and supports continuous improvement efforts in the composite material curing process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!