How Vacuum Pumps Influence Laser Ablation Techniques

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump-Laser Ablation Synergy

The synergy between vacuum pumps and laser ablation techniques represents a critical intersection in advanced materials processing and scientific research. Vacuum pumps play a pivotal role in creating and maintaining the controlled environment necessary for precise laser ablation processes. This symbiotic relationship enhances the efficiency, accuracy, and reproducibility of laser ablation techniques across various applications.

Vacuum pumps contribute to laser ablation by establishing a low-pressure environment that minimizes interference from atmospheric particles. This reduction in background gas molecules allows for more direct and unimpeded interaction between the laser beam and the target material. Consequently, the ablation process becomes more controlled and predictable, leading to improved material removal rates and surface quality.

The vacuum environment created by these pumps also significantly reduces the likelihood of unwanted chemical reactions during the ablation process. In atmospheric conditions, ablated material can react with oxygen or other gases, potentially altering the composition or properties of the processed surface. By eliminating these reactive species, vacuum pumps ensure that the laser ablation results are more representative of the true material properties.

Furthermore, the use of vacuum pumps in laser ablation setups enhances the collection and analysis of ablated material. In a vacuum, the ejected particles follow more predictable trajectories, facilitating their capture for subsequent analysis or deposition. This is particularly crucial in applications such as thin film deposition, where precise control over the ablated material's path is essential for achieving uniform and high-quality coatings.

The integration of vacuum technology also extends the capabilities of laser ablation techniques to a broader range of materials. Some substances that would otherwise react unfavorably or degrade in atmospheric conditions can be successfully processed under vacuum. This expansion of treatable materials opens up new possibilities in fields such as semiconductor manufacturing, nanotechnology, and advanced materials research.

Moreover, the vacuum environment contributes to the longevity and performance of the laser ablation equipment itself. By reducing the presence of airborne contaminants, vacuum pumps help prevent damage to sensitive optical components and maintain the cleanliness of the processing chamber. This results in more consistent performance over time and reduces the frequency of maintenance interventions.

In conclusion, the synergy between vacuum pumps and laser ablation techniques is fundamental to advancing the capabilities and applications of this technology. The controlled environment provided by vacuum systems enhances precision, expands material processing options, and improves overall process reliability. As both vacuum and laser technologies continue to evolve, their integration promises to unlock even more sophisticated and efficient material processing methods in the future.

Vacuum pumps contribute to laser ablation by establishing a low-pressure environment that minimizes interference from atmospheric particles. This reduction in background gas molecules allows for more direct and unimpeded interaction between the laser beam and the target material. Consequently, the ablation process becomes more controlled and predictable, leading to improved material removal rates and surface quality.

The vacuum environment created by these pumps also significantly reduces the likelihood of unwanted chemical reactions during the ablation process. In atmospheric conditions, ablated material can react with oxygen or other gases, potentially altering the composition or properties of the processed surface. By eliminating these reactive species, vacuum pumps ensure that the laser ablation results are more representative of the true material properties.

Furthermore, the use of vacuum pumps in laser ablation setups enhances the collection and analysis of ablated material. In a vacuum, the ejected particles follow more predictable trajectories, facilitating their capture for subsequent analysis or deposition. This is particularly crucial in applications such as thin film deposition, where precise control over the ablated material's path is essential for achieving uniform and high-quality coatings.

The integration of vacuum technology also extends the capabilities of laser ablation techniques to a broader range of materials. Some substances that would otherwise react unfavorably or degrade in atmospheric conditions can be successfully processed under vacuum. This expansion of treatable materials opens up new possibilities in fields such as semiconductor manufacturing, nanotechnology, and advanced materials research.

Moreover, the vacuum environment contributes to the longevity and performance of the laser ablation equipment itself. By reducing the presence of airborne contaminants, vacuum pumps help prevent damage to sensitive optical components and maintain the cleanliness of the processing chamber. This results in more consistent performance over time and reduces the frequency of maintenance interventions.

In conclusion, the synergy between vacuum pumps and laser ablation techniques is fundamental to advancing the capabilities and applications of this technology. The controlled environment provided by vacuum systems enhances precision, expands material processing options, and improves overall process reliability. As both vacuum and laser technologies continue to evolve, their integration promises to unlock even more sophisticated and efficient material processing methods in the future.

Market Demand Analysis

The market demand for laser ablation techniques has been steadily growing across various industries, driven by the increasing need for precise material processing and surface modification. The integration of vacuum pumps in laser ablation systems has further expanded the market potential, as it enables enhanced control over the ablation process and improved quality of the final products.

In the semiconductor industry, laser ablation techniques coupled with vacuum pumps have become essential for the fabrication of microelectronic devices. The demand for smaller, more efficient electronic components has led to a surge in the adoption of these advanced manufacturing processes. Market analysts project a compound annual growth rate (CAGR) of over 7% for the semiconductor laser ablation equipment market over the next five years.

The medical device industry has also emerged as a significant driver of market demand for vacuum pump-assisted laser ablation techniques. These technologies are increasingly used in the production of implantable devices, surgical instruments, and diagnostic equipment. The precision offered by laser ablation under vacuum conditions allows for the creation of intricate surface patterns and textures that enhance biocompatibility and functionality.

In the aerospace sector, the demand for laser ablation techniques with vacuum pump integration is rising due to the need for lightweight, high-performance materials. The ability to precisely remove material layers and create complex surface structures is crucial for improving the aerodynamic properties of aircraft components. This market segment is expected to show substantial growth as manufacturers seek innovative solutions to enhance fuel efficiency and reduce emissions.

The automotive industry represents another significant market for laser ablation technologies incorporating vacuum pumps. As vehicle manufacturers strive to meet stringent environmental regulations and improve fuel economy, there is an increasing focus on lightweight materials and advanced surface treatments. Laser ablation techniques are being employed to create specialized surface textures that reduce friction and improve wear resistance in engine components.

Research institutions and academic laboratories continue to drive demand for advanced laser ablation systems with vacuum capabilities. These organizations require cutting-edge equipment for materials research, analytical chemistry, and the development of new manufacturing processes. The ability to conduct experiments under controlled vacuum conditions expands the scope of research possibilities and enhances the accuracy of results.

The global market for laser ablation systems with integrated vacuum pumps is characterized by a mix of established players and innovative start-ups. Competition is fierce, with companies investing heavily in research and development to gain a technological edge. As the technology matures and becomes more accessible, there is potential for market expansion into new industries and applications, further driving demand for these sophisticated systems.

In the semiconductor industry, laser ablation techniques coupled with vacuum pumps have become essential for the fabrication of microelectronic devices. The demand for smaller, more efficient electronic components has led to a surge in the adoption of these advanced manufacturing processes. Market analysts project a compound annual growth rate (CAGR) of over 7% for the semiconductor laser ablation equipment market over the next five years.

The medical device industry has also emerged as a significant driver of market demand for vacuum pump-assisted laser ablation techniques. These technologies are increasingly used in the production of implantable devices, surgical instruments, and diagnostic equipment. The precision offered by laser ablation under vacuum conditions allows for the creation of intricate surface patterns and textures that enhance biocompatibility and functionality.

In the aerospace sector, the demand for laser ablation techniques with vacuum pump integration is rising due to the need for lightweight, high-performance materials. The ability to precisely remove material layers and create complex surface structures is crucial for improving the aerodynamic properties of aircraft components. This market segment is expected to show substantial growth as manufacturers seek innovative solutions to enhance fuel efficiency and reduce emissions.

The automotive industry represents another significant market for laser ablation technologies incorporating vacuum pumps. As vehicle manufacturers strive to meet stringent environmental regulations and improve fuel economy, there is an increasing focus on lightweight materials and advanced surface treatments. Laser ablation techniques are being employed to create specialized surface textures that reduce friction and improve wear resistance in engine components.

Research institutions and academic laboratories continue to drive demand for advanced laser ablation systems with vacuum capabilities. These organizations require cutting-edge equipment for materials research, analytical chemistry, and the development of new manufacturing processes. The ability to conduct experiments under controlled vacuum conditions expands the scope of research possibilities and enhances the accuracy of results.

The global market for laser ablation systems with integrated vacuum pumps is characterized by a mix of established players and innovative start-ups. Competition is fierce, with companies investing heavily in research and development to gain a technological edge. As the technology matures and becomes more accessible, there is potential for market expansion into new industries and applications, further driving demand for these sophisticated systems.

Current Challenges

Laser ablation techniques have made significant strides in recent years, but they continue to face several challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is the precise control of the ablation environment, particularly in terms of pressure and gas composition. Vacuum pumps play a crucial role in this aspect, yet their integration and optimization remain complex.

The efficiency of laser ablation is highly dependent on the ambient pressure, which directly affects the plasma plume dynamics and particle formation. Current vacuum pump systems often struggle to maintain consistent pressure levels throughout the ablation process, leading to variations in ablation rates and product quality. This inconsistency poses a significant challenge for industries requiring high-precision manufacturing or analytical processes.

Another pressing issue is the removal of ablation debris and nanoparticles generated during the process. While vacuum pumps are essential for this task, existing systems frequently fail to completely eliminate all particles, potentially causing contamination or interference with subsequent ablation cycles. This problem is particularly acute in applications such as thin film deposition or nanoparticle synthesis, where purity is paramount.

The speed of pressure adjustment is another critical factor that current vacuum pump technologies struggle to address adequately. Rapid pressure changes are often necessary for multi-step ablation processes or when transitioning between different materials. However, many existing pump systems lack the responsiveness required for these dynamic environments, limiting the flexibility and throughput of laser ablation techniques.

Energy efficiency and heat management present additional challenges in the integration of vacuum pumps with laser ablation systems. The power consumption of high-performance vacuum pumps can be substantial, contributing significantly to the overall energy footprint of the ablation process. Moreover, heat generated by both the laser and the pump can affect the stability of the vacuum environment, potentially impacting ablation precision and repeatability.

Noise and vibration from vacuum pumps also pose challenges, particularly in sensitive research environments or when working with delicate materials. These disturbances can interfere with the laser focusing mechanism or introduce unwanted artifacts in the ablation process. Developing quieter, low-vibration pump systems without compromising performance remains a significant technical hurdle.

Lastly, the scalability of vacuum pump solutions for laser ablation presents a notable challenge. As industries seek to increase production volumes or ablation areas, scaling up vacuum systems while maintaining uniform pressure distribution and efficient particle removal becomes increasingly complex. This scaling issue is particularly evident in large-area ablation applications or high-throughput manufacturing processes.

The efficiency of laser ablation is highly dependent on the ambient pressure, which directly affects the plasma plume dynamics and particle formation. Current vacuum pump systems often struggle to maintain consistent pressure levels throughout the ablation process, leading to variations in ablation rates and product quality. This inconsistency poses a significant challenge for industries requiring high-precision manufacturing or analytical processes.

Another pressing issue is the removal of ablation debris and nanoparticles generated during the process. While vacuum pumps are essential for this task, existing systems frequently fail to completely eliminate all particles, potentially causing contamination or interference with subsequent ablation cycles. This problem is particularly acute in applications such as thin film deposition or nanoparticle synthesis, where purity is paramount.

The speed of pressure adjustment is another critical factor that current vacuum pump technologies struggle to address adequately. Rapid pressure changes are often necessary for multi-step ablation processes or when transitioning between different materials. However, many existing pump systems lack the responsiveness required for these dynamic environments, limiting the flexibility and throughput of laser ablation techniques.

Energy efficiency and heat management present additional challenges in the integration of vacuum pumps with laser ablation systems. The power consumption of high-performance vacuum pumps can be substantial, contributing significantly to the overall energy footprint of the ablation process. Moreover, heat generated by both the laser and the pump can affect the stability of the vacuum environment, potentially impacting ablation precision and repeatability.

Noise and vibration from vacuum pumps also pose challenges, particularly in sensitive research environments or when working with delicate materials. These disturbances can interfere with the laser focusing mechanism or introduce unwanted artifacts in the ablation process. Developing quieter, low-vibration pump systems without compromising performance remains a significant technical hurdle.

Lastly, the scalability of vacuum pump solutions for laser ablation presents a notable challenge. As industries seek to increase production volumes or ablation areas, scaling up vacuum systems while maintaining uniform pressure distribution and efficient particle removal becomes increasingly complex. This scaling issue is particularly evident in large-area ablation applications or high-throughput manufacturing processes.

Existing Technical Solutions

01 Vacuum pump design and efficiency

Vacuum pumps are designed to improve efficiency and performance in various applications. This includes optimizing the pump's internal structure, enhancing sealing mechanisms, and incorporating advanced materials to reduce friction and wear. These improvements lead to better vacuum generation and maintenance, as well as increased energy efficiency.- Vacuum pump design and efficiency: Vacuum pump design plays a crucial role in determining its efficiency and performance. Innovations in pump design focus on improving suction capacity, reducing power consumption, and enhancing overall efficiency. These advancements may include optimized rotor configurations, improved sealing mechanisms, and innovative valve designs.

- Application in semiconductor manufacturing: Vacuum pumps are essential in semiconductor manufacturing processes, particularly in creating and maintaining clean, low-pressure environments. Their influence extends to various stages of chip production, including etching, deposition, and ion implantation. Specialized vacuum pumps are designed to handle specific gases and contaminants encountered in these processes.

- Vacuum pump control and monitoring systems: Advanced control and monitoring systems enhance the performance and reliability of vacuum pumps. These systems may include sensors for pressure, temperature, and flow rate monitoring, as well as intelligent control algorithms for optimizing pump operation. Such systems can improve energy efficiency, extend pump lifespan, and enable predictive maintenance.

- Vacuum pump noise reduction: Noise reduction is a significant concern in vacuum pump design and operation. Various techniques are employed to minimize noise levels, including vibration isolation, acoustic enclosures, and advanced muffler designs. These improvements not only enhance the working environment but also comply with increasingly stringent noise regulations.

- Vacuum pump applications in automotive industry: Vacuum pumps play a crucial role in various automotive systems, including brake boosters, emissions control, and turbocharger regulation. The influence of vacuum pumps in this sector focuses on improving vehicle performance, fuel efficiency, and emissions reduction. Innovations in this area include electric vacuum pumps and integrated pump designs for hybrid and electric vehicles.

02 Vacuum pump applications in semiconductor manufacturing

Vacuum pumps play a crucial role in semiconductor manufacturing processes. They are used in various stages, including wafer processing, thin film deposition, and etching. The influence of vacuum pumps in this industry is significant, as they help maintain the clean, controlled environments necessary for producing high-quality semiconductor devices.Expand Specific Solutions03 Vacuum pump noise reduction techniques

Reducing noise generated by vacuum pumps is an important consideration in many applications. Various techniques are employed to minimize noise levels, including the use of sound-absorbing materials, redesigning pump components to reduce vibration, and implementing advanced control systems to optimize pump operation. These methods help improve the working environment and reduce overall noise pollution.Expand Specific Solutions04 Vacuum pump integration in automotive systems

Vacuum pumps are increasingly integrated into automotive systems to enhance vehicle performance and efficiency. They are used in various applications, such as brake boosters, emission control systems, and turbocharger systems. The influence of vacuum pumps in automotive design contributes to improved fuel efficiency, reduced emissions, and enhanced overall vehicle performance.Expand Specific Solutions05 Vacuum pump maintenance and monitoring

Proper maintenance and monitoring of vacuum pumps are essential for ensuring their long-term performance and reliability. This includes regular inspections, lubrication, and replacement of worn components. Advanced monitoring systems are also employed to track pump performance, predict potential failures, and optimize maintenance schedules, thereby reducing downtime and improving overall system efficiency.Expand Specific Solutions

Key Industry Players

The laser ablation techniques market, influenced by vacuum pump technology, is in a growth phase characterized by increasing applications across industries. The global market size is expanding, driven by advancements in materials processing and analytical sciences. Technologically, the field is maturing, with companies like FEI Co., Rolls-Royce Plc, and Rofin-Sinar Technologies LLC leading innovation. Research institutions such as CNRS, Ghent University, and NTU are contributing to technological advancements. The competitive landscape is diverse, with established players and emerging companies like Eximo Medical Ltd. and AquaBeam LLC entering the market, indicating a dynamic and evolving industry.

Rofin-Sinar Technologies LLC

Technical Solution: Rofin-Sinar Technologies LLC has developed advanced vacuum-assisted laser ablation systems for precise material removal. Their technology utilizes high-power pulsed lasers in conjunction with optimized vacuum pumps to enhance ablation efficiency and control. The vacuum system helps to remove debris and vapors generated during the ablation process, reducing redeposition and improving overall quality [1]. They have implemented a closed-loop feedback system that dynamically adjusts laser parameters and vacuum pressure based on real-time monitoring of the ablation process, ensuring consistent results across different materials and geometries [3]. Additionally, Rofin-Sinar has integrated specialized nozzle designs that create localized high-vacuum zones directly at the ablation site, further improving material removal and reducing thermal effects on surrounding areas [5].

Strengths: Precise control over ablation process, reduced contamination, and improved efficiency. Weaknesses: Complexity of system integration and potential for increased operational costs.

Elemental Scientific Lasers, LLC.

Technical Solution: Elemental Scientific Lasers, LLC. has pioneered a novel approach to vacuum-enhanced laser ablation for analytical applications. Their technology combines ultra-fast laser pulses with a high-efficiency vacuum extraction system to improve sample introduction in mass spectrometry and other analytical techniques. The company has developed a proprietary vacuum chamber design that maximizes the collection of ablated particles while minimizing sample loss [2]. Their system incorporates a multi-stage vacuum pump configuration that allows for precise control of pressure gradients, optimizing particle transport from the ablation site to the analytical instrument [4]. ESL has also implemented advanced software algorithms for real-time adjustment of laser and vacuum parameters based on sample characteristics and analytical requirements, ensuring optimal performance across a wide range of materials [6].

Strengths: High-efficiency sample collection, versatility across different analytical applications. Weaknesses: Potentially higher initial investment and specialized training requirements for operators.

Core Innovations

Ablation device

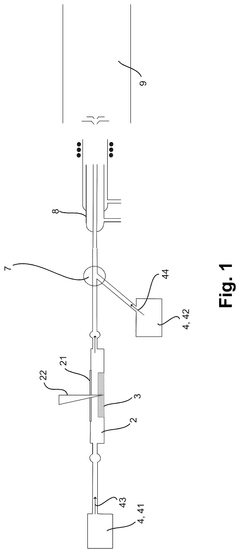

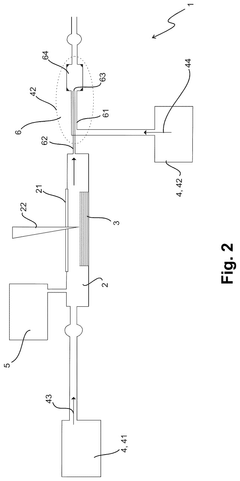

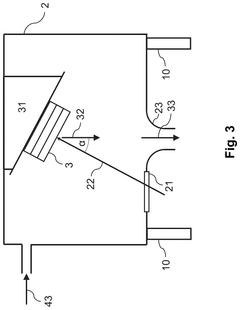

PatentPendingUS20250157807A1

Innovation

- A negative pressure ablation chamber gas flow vacuum pump arrangement is introduced, comprising an ablation chamber with a laser, a feedback controllable gas feed for cell and mixed gases, and a pressure measuring device. This setup uses a gas flow vacuum pump with an inner tube for sample gas and an outer tube for mixed gas, allowing active pumping without particle traps.

Controlled separation of laser ablation sample gas for direction to multiple analytic detectors

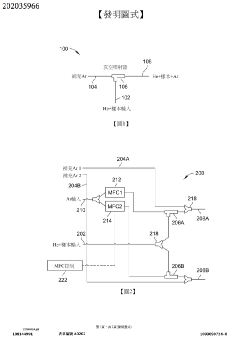

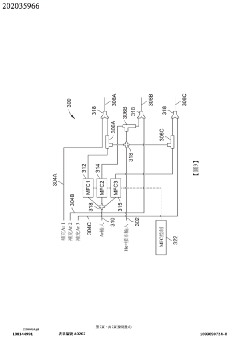

PatentPendingTW202035966A

Innovation

- Integration of a vacuum pump to create negative pressure in the sample transport gas, allowing for controlled flow and improved sample delivery.

- Incorporation of a make-up gas input to supplement the laser-ablated sample and carrier gas, enabling better control over gas composition and flow rates.

- Design of a system that allows for direction of the sample transport gas to multiple analytic detectors, increasing analytical capabilities and flexibility.

Vacuum Technology Advancements

Vacuum technology has undergone significant advancements in recent years, revolutionizing various industries, including laser ablation techniques. The evolution of vacuum pumps has played a crucial role in enhancing the efficiency and precision of laser ablation processes.

One of the key developments in vacuum technology is the improvement in pump designs. Modern vacuum pumps offer higher pumping speeds and lower ultimate pressures, allowing for faster evacuation of chambers and maintenance of more stable vacuum environments. This is particularly beneficial for laser ablation techniques, as it enables better control over the ablation process and reduces contamination risks.

The introduction of oil-free vacuum pumps has been a game-changer for laser ablation applications. These pumps eliminate the risk of oil contamination, which is critical for maintaining the purity of ablated materials and ensuring consistent results. Dry scroll pumps and turbomolecular pumps are increasingly being used in laser ablation setups, providing clean and reliable vacuum conditions.

Another significant advancement is the development of intelligent vacuum systems. These systems incorporate sensors and control algorithms that can automatically adjust pumping parameters based on real-time pressure measurements. This level of automation enhances the stability of vacuum conditions during laser ablation processes, leading to more reproducible results and improved overall efficiency.

The miniaturization of vacuum pumps has also contributed to the advancement of portable laser ablation systems. Compact, high-performance pumps now allow for the development of mobile laser ablation units, expanding the range of applications and enabling in-situ analysis in fields such as archaeology and environmental science.

Furthermore, the integration of vacuum technology with other cutting-edge technologies has opened up new possibilities in laser ablation techniques. For instance, the combination of advanced vacuum systems with in-situ mass spectrometry has enabled real-time analysis of ablated materials, providing valuable insights into sample composition and reaction dynamics.

The ongoing research in vacuum technology continues to push the boundaries of what is possible in laser ablation. Current efforts focus on developing ultra-high vacuum systems capable of achieving even lower pressures, which could potentially unlock new applications in nanomaterial fabrication and quantum technology research.

As vacuum technology continues to evolve, it is expected to further enhance the capabilities of laser ablation techniques, enabling more precise material removal, improved analysis of ablated particles, and the exploration of new scientific frontiers. The synergy between vacuum technology and laser ablation promises to drive innovation across various fields, from materials science to biomedical research.

One of the key developments in vacuum technology is the improvement in pump designs. Modern vacuum pumps offer higher pumping speeds and lower ultimate pressures, allowing for faster evacuation of chambers and maintenance of more stable vacuum environments. This is particularly beneficial for laser ablation techniques, as it enables better control over the ablation process and reduces contamination risks.

The introduction of oil-free vacuum pumps has been a game-changer for laser ablation applications. These pumps eliminate the risk of oil contamination, which is critical for maintaining the purity of ablated materials and ensuring consistent results. Dry scroll pumps and turbomolecular pumps are increasingly being used in laser ablation setups, providing clean and reliable vacuum conditions.

Another significant advancement is the development of intelligent vacuum systems. These systems incorporate sensors and control algorithms that can automatically adjust pumping parameters based on real-time pressure measurements. This level of automation enhances the stability of vacuum conditions during laser ablation processes, leading to more reproducible results and improved overall efficiency.

The miniaturization of vacuum pumps has also contributed to the advancement of portable laser ablation systems. Compact, high-performance pumps now allow for the development of mobile laser ablation units, expanding the range of applications and enabling in-situ analysis in fields such as archaeology and environmental science.

Furthermore, the integration of vacuum technology with other cutting-edge technologies has opened up new possibilities in laser ablation techniques. For instance, the combination of advanced vacuum systems with in-situ mass spectrometry has enabled real-time analysis of ablated materials, providing valuable insights into sample composition and reaction dynamics.

The ongoing research in vacuum technology continues to push the boundaries of what is possible in laser ablation. Current efforts focus on developing ultra-high vacuum systems capable of achieving even lower pressures, which could potentially unlock new applications in nanomaterial fabrication and quantum technology research.

As vacuum technology continues to evolve, it is expected to further enhance the capabilities of laser ablation techniques, enabling more precise material removal, improved analysis of ablated particles, and the exploration of new scientific frontiers. The synergy between vacuum technology and laser ablation promises to drive innovation across various fields, from materials science to biomedical research.

Environmental Impact Assessment

The environmental impact of laser ablation techniques influenced by vacuum pumps is a critical consideration in the adoption and development of this technology. Vacuum pumps play a crucial role in creating the low-pressure environment necessary for efficient laser ablation processes. However, their operation can have both direct and indirect environmental consequences that must be carefully assessed and mitigated.

One of the primary environmental concerns associated with vacuum pumps in laser ablation is energy consumption. These pumps often require significant electrical power to maintain the necessary vacuum levels, contributing to increased energy demand and potentially higher carbon emissions depending on the energy source. The continuous operation of vacuum pumps during laser ablation processes can lead to substantial energy usage over time, impacting the overall carbon footprint of the technology.

Noise pollution is another environmental factor to consider. Vacuum pumps, especially larger industrial models, can generate considerable noise during operation. This may have implications for workplace environments and surrounding areas, potentially affecting local ecosystems and human well-being. Implementing noise reduction measures and proper insulation becomes essential to minimize this impact.

The use of working fluids in certain types of vacuum pumps, such as oil-sealed rotary vane pumps, presents potential environmental risks. These fluids can become contaminated during the pumping process and may require periodic replacement and disposal. Proper handling and disposal of these fluids are crucial to prevent soil and water contamination.

Vacuum pumps also influence the management of ablation byproducts. While the vacuum environment helps contain and control the material removed during laser ablation, the pumps play a role in the collection and filtration of these particles. Efficient filtration systems integrated with the vacuum pumps are necessary to prevent the release of potentially harmful particulates into the atmosphere.

The manufacturing and disposal of vacuum pumps themselves have environmental implications. The production of pump components often involves resource-intensive processes and the use of various materials, including metals and plastics. Ensuring sustainable manufacturing practices and implementing effective recycling and disposal programs for end-of-life pumps are important considerations in minimizing the overall environmental impact.

In conclusion, while vacuum pumps are essential for enhancing the efficiency and precision of laser ablation techniques, their environmental impact must be carefully managed. Strategies such as improving energy efficiency, reducing noise emissions, implementing proper waste management protocols, and adopting sustainable manufacturing and disposal practices are crucial for minimizing the environmental footprint of this technology.

One of the primary environmental concerns associated with vacuum pumps in laser ablation is energy consumption. These pumps often require significant electrical power to maintain the necessary vacuum levels, contributing to increased energy demand and potentially higher carbon emissions depending on the energy source. The continuous operation of vacuum pumps during laser ablation processes can lead to substantial energy usage over time, impacting the overall carbon footprint of the technology.

Noise pollution is another environmental factor to consider. Vacuum pumps, especially larger industrial models, can generate considerable noise during operation. This may have implications for workplace environments and surrounding areas, potentially affecting local ecosystems and human well-being. Implementing noise reduction measures and proper insulation becomes essential to minimize this impact.

The use of working fluids in certain types of vacuum pumps, such as oil-sealed rotary vane pumps, presents potential environmental risks. These fluids can become contaminated during the pumping process and may require periodic replacement and disposal. Proper handling and disposal of these fluids are crucial to prevent soil and water contamination.

Vacuum pumps also influence the management of ablation byproducts. While the vacuum environment helps contain and control the material removed during laser ablation, the pumps play a role in the collection and filtration of these particles. Efficient filtration systems integrated with the vacuum pumps are necessary to prevent the release of potentially harmful particulates into the atmosphere.

The manufacturing and disposal of vacuum pumps themselves have environmental implications. The production of pump components often involves resource-intensive processes and the use of various materials, including metals and plastics. Ensuring sustainable manufacturing practices and implementing effective recycling and disposal programs for end-of-life pumps are important considerations in minimizing the overall environmental impact.

In conclusion, while vacuum pumps are essential for enhancing the efficiency and precision of laser ablation techniques, their environmental impact must be carefully managed. Strategies such as improving energy efficiency, reducing noise emissions, implementing proper waste management protocols, and adopting sustainable manufacturing and disposal practices are crucial for minimizing the environmental footprint of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!