How Vacuum Pumps Support Atmospheric Simulation Chambers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Objectives

Vacuum pumps have played a crucial role in the development of atmospheric simulation chambers since the early 20th century. These chambers, designed to replicate various atmospheric conditions, rely heavily on vacuum technology to create controlled environments for scientific research and industrial testing. The evolution of vacuum pumps has been closely intertwined with the advancement of atmospheric simulation capabilities.

In the 1950s and 1960s, the space race spurred significant improvements in vacuum pump technology. Rotary vane pumps and diffusion pumps became more efficient and reliable, enabling researchers to achieve lower pressures and better simulate upper atmospheric conditions. This period saw the emergence of large-scale environmental chambers used for testing spacecraft and components under simulated space conditions.

The 1970s and 1980s witnessed the introduction of turbomolecular pumps, which revolutionized high-vacuum applications. These pumps offered cleaner, oil-free operation and higher pumping speeds, allowing for more precise control of gas composition in simulation chambers. This advancement was particularly important for atmospheric chemistry studies and climate research.

As environmental concerns grew in the 1990s and 2000s, the focus shifted towards creating more accurate simulations of Earth's atmosphere at various altitudes. Cryogenic pumps and getter pumps were refined to handle specific gases, enabling researchers to study complex atmospheric phenomena such as ozone depletion and greenhouse gas effects.

Recent developments in vacuum pump technology have aimed at improving energy efficiency, reducing noise levels, and enhancing pump longevity. Dry pumps, such as scroll pumps and multi-stage Roots pumps, have gained popularity due to their ability to maintain clean vacuum environments without oil contamination. These advancements have been crucial for long-duration experiments and sensitive measurements in atmospheric simulation chambers.

The primary objectives of vacuum pump technology in supporting atmospheric simulation chambers include achieving and maintaining precise pressure levels, from near-atmospheric conditions to high vacuum states. This capability is essential for simulating various altitudes and planetary atmospheres. Additionally, modern vacuum systems aim to provide rapid pump-down times, allowing for quick changes in experimental conditions and increased research productivity.

Another key goal is to enhance the control and repeatability of gas composition within the chambers. Advanced vacuum pumps, coupled with sophisticated gas injection systems, enable researchers to create and maintain specific atmospheric mixtures with high accuracy. This precision is vital for studying complex atmospheric chemistry and validating climate models.

Looking forward, the development of vacuum pump technology for atmospheric simulation chambers is focused on further improving pumping efficiency, reducing energy consumption, and expanding the range of achievable pressures and gas compositions. Innovations in materials science and pump design are expected to yield more compact, reliable, and versatile vacuum systems, capable of supporting increasingly complex atmospheric simulations and expanding our understanding of Earth's atmosphere and other planetary environments.

In the 1950s and 1960s, the space race spurred significant improvements in vacuum pump technology. Rotary vane pumps and diffusion pumps became more efficient and reliable, enabling researchers to achieve lower pressures and better simulate upper atmospheric conditions. This period saw the emergence of large-scale environmental chambers used for testing spacecraft and components under simulated space conditions.

The 1970s and 1980s witnessed the introduction of turbomolecular pumps, which revolutionized high-vacuum applications. These pumps offered cleaner, oil-free operation and higher pumping speeds, allowing for more precise control of gas composition in simulation chambers. This advancement was particularly important for atmospheric chemistry studies and climate research.

As environmental concerns grew in the 1990s and 2000s, the focus shifted towards creating more accurate simulations of Earth's atmosphere at various altitudes. Cryogenic pumps and getter pumps were refined to handle specific gases, enabling researchers to study complex atmospheric phenomena such as ozone depletion and greenhouse gas effects.

Recent developments in vacuum pump technology have aimed at improving energy efficiency, reducing noise levels, and enhancing pump longevity. Dry pumps, such as scroll pumps and multi-stage Roots pumps, have gained popularity due to their ability to maintain clean vacuum environments without oil contamination. These advancements have been crucial for long-duration experiments and sensitive measurements in atmospheric simulation chambers.

The primary objectives of vacuum pump technology in supporting atmospheric simulation chambers include achieving and maintaining precise pressure levels, from near-atmospheric conditions to high vacuum states. This capability is essential for simulating various altitudes and planetary atmospheres. Additionally, modern vacuum systems aim to provide rapid pump-down times, allowing for quick changes in experimental conditions and increased research productivity.

Another key goal is to enhance the control and repeatability of gas composition within the chambers. Advanced vacuum pumps, coupled with sophisticated gas injection systems, enable researchers to create and maintain specific atmospheric mixtures with high accuracy. This precision is vital for studying complex atmospheric chemistry and validating climate models.

Looking forward, the development of vacuum pump technology for atmospheric simulation chambers is focused on further improving pumping efficiency, reducing energy consumption, and expanding the range of achievable pressures and gas compositions. Innovations in materials science and pump design are expected to yield more compact, reliable, and versatile vacuum systems, capable of supporting increasingly complex atmospheric simulations and expanding our understanding of Earth's atmosphere and other planetary environments.

Atmospheric Simulation Market Analysis

The atmospheric simulation market has been experiencing significant growth in recent years, driven by increasing demand for accurate climate modeling, environmental research, and industrial applications. This market segment encompasses a wide range of products and services, including atmospheric simulation chambers, vacuum pumps, and associated equipment.

The global atmospheric simulation market is projected to expand at a steady pace, with a compound annual growth rate (CAGR) expected to remain in the high single digits over the next five years. This growth is primarily attributed to the rising awareness of climate change impacts, stringent environmental regulations, and the need for advanced testing facilities in various industries.

Key market drivers include the growing emphasis on renewable energy research, advancements in aerospace and defense technologies, and the increasing adoption of atmospheric simulation chambers in automotive testing. The automotive sector, in particular, has emerged as a significant contributor to market growth, as manufacturers seek to improve vehicle performance and emissions under diverse atmospheric conditions.

Geographically, North America and Europe currently dominate the atmospheric simulation market, owing to their well-established research infrastructure and stringent environmental policies. However, the Asia-Pacific region is anticipated to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing R&D investments, and government initiatives to address air quality concerns.

The market is characterized by the presence of both large multinational corporations and specialized niche players. Leading companies in this space are continuously investing in research and development to enhance their product offerings and maintain a competitive edge. Collaborations between academic institutions, research organizations, and industry players are becoming increasingly common, fostering innovation and driving market expansion.

Vacuum pumps play a crucial role in atmospheric simulation chambers, enabling precise control of pressure and gas composition. The demand for high-performance vacuum pumps specifically designed for atmospheric simulation applications is expected to grow in tandem with the overall market. Manufacturers are focusing on developing energy-efficient, low-maintenance vacuum pump solutions to meet the evolving needs of research facilities and industrial users.

Despite the positive outlook, the atmospheric simulation market faces certain challenges. High initial investment costs, complex operational requirements, and the need for skilled personnel can act as barriers to market entry and adoption. Additionally, the ongoing global economic uncertainties may impact research budgets and capital expenditures in some regions, potentially slowing market growth in the short term.

The global atmospheric simulation market is projected to expand at a steady pace, with a compound annual growth rate (CAGR) expected to remain in the high single digits over the next five years. This growth is primarily attributed to the rising awareness of climate change impacts, stringent environmental regulations, and the need for advanced testing facilities in various industries.

Key market drivers include the growing emphasis on renewable energy research, advancements in aerospace and defense technologies, and the increasing adoption of atmospheric simulation chambers in automotive testing. The automotive sector, in particular, has emerged as a significant contributor to market growth, as manufacturers seek to improve vehicle performance and emissions under diverse atmospheric conditions.

Geographically, North America and Europe currently dominate the atmospheric simulation market, owing to their well-established research infrastructure and stringent environmental policies. However, the Asia-Pacific region is anticipated to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing R&D investments, and government initiatives to address air quality concerns.

The market is characterized by the presence of both large multinational corporations and specialized niche players. Leading companies in this space are continuously investing in research and development to enhance their product offerings and maintain a competitive edge. Collaborations between academic institutions, research organizations, and industry players are becoming increasingly common, fostering innovation and driving market expansion.

Vacuum pumps play a crucial role in atmospheric simulation chambers, enabling precise control of pressure and gas composition. The demand for high-performance vacuum pumps specifically designed for atmospheric simulation applications is expected to grow in tandem with the overall market. Manufacturers are focusing on developing energy-efficient, low-maintenance vacuum pump solutions to meet the evolving needs of research facilities and industrial users.

Despite the positive outlook, the atmospheric simulation market faces certain challenges. High initial investment costs, complex operational requirements, and the need for skilled personnel can act as barriers to market entry and adoption. Additionally, the ongoing global economic uncertainties may impact research budgets and capital expenditures in some regions, potentially slowing market growth in the short term.

Vacuum Technology Challenges

Vacuum technology plays a crucial role in atmospheric simulation chambers, yet it faces several significant challenges. One of the primary issues is achieving and maintaining ultra-high vacuum levels required for accurate atmospheric simulations. As the demand for more precise environmental modeling increases, the need for vacuum pumps capable of reaching pressures as low as 10^-10 mbar becomes paramount. However, attaining such extreme vacuum conditions poses substantial technical difficulties.

The contamination of vacuum systems presents another major challenge. Even minute amounts of residual gases or particles can significantly affect the accuracy of atmospheric simulations. This necessitates the development of advanced cleaning and degassing techniques, as well as the use of specialized materials that minimize outgassing. The implementation of these measures often increases the complexity and cost of vacuum systems.

Vacuum pump reliability and longevity are also critical concerns in atmospheric simulation chambers. These facilities often require continuous operation for extended periods, placing considerable stress on vacuum equipment. The development of pumps with improved durability, reduced maintenance requirements, and enhanced resistance to corrosive gases is essential for ensuring consistent performance in long-term experiments.

Energy efficiency represents another significant challenge in vacuum technology for atmospheric simulation chambers. High-performance vacuum pumps typically consume substantial amounts of energy, contributing to increased operational costs and environmental impact. Balancing the need for powerful pumping capabilities with energy conservation goals requires innovative approaches to pump design and operation.

The integration of vacuum systems with other components of atmospheric simulation chambers poses additional challenges. Ensuring seamless communication and coordination between vacuum pumps, sensors, and control systems is crucial for maintaining precise atmospheric conditions. This integration often requires sophisticated software and hardware interfaces, adding another layer of complexity to the overall system design.

Scalability is an emerging challenge as researchers seek to conduct experiments on varying scales. Vacuum systems must be adaptable to different chamber sizes and configurations, from small laboratory setups to large-scale environmental simulators. This flexibility demands modular pump designs and scalable vacuum solutions that can maintain consistent performance across different experimental scales.

As atmospheric research advances, there is an increasing need for vacuum systems capable of handling a wider range of gases and environmental conditions. This includes the ability to work with corrosive or reactive gases, as well as to rapidly adjust to changing pressure and composition requirements. Developing versatile vacuum technologies that can adapt to these diverse experimental needs remains a significant technical hurdle.

The contamination of vacuum systems presents another major challenge. Even minute amounts of residual gases or particles can significantly affect the accuracy of atmospheric simulations. This necessitates the development of advanced cleaning and degassing techniques, as well as the use of specialized materials that minimize outgassing. The implementation of these measures often increases the complexity and cost of vacuum systems.

Vacuum pump reliability and longevity are also critical concerns in atmospheric simulation chambers. These facilities often require continuous operation for extended periods, placing considerable stress on vacuum equipment. The development of pumps with improved durability, reduced maintenance requirements, and enhanced resistance to corrosive gases is essential for ensuring consistent performance in long-term experiments.

Energy efficiency represents another significant challenge in vacuum technology for atmospheric simulation chambers. High-performance vacuum pumps typically consume substantial amounts of energy, contributing to increased operational costs and environmental impact. Balancing the need for powerful pumping capabilities with energy conservation goals requires innovative approaches to pump design and operation.

The integration of vacuum systems with other components of atmospheric simulation chambers poses additional challenges. Ensuring seamless communication and coordination between vacuum pumps, sensors, and control systems is crucial for maintaining precise atmospheric conditions. This integration often requires sophisticated software and hardware interfaces, adding another layer of complexity to the overall system design.

Scalability is an emerging challenge as researchers seek to conduct experiments on varying scales. Vacuum systems must be adaptable to different chamber sizes and configurations, from small laboratory setups to large-scale environmental simulators. This flexibility demands modular pump designs and scalable vacuum solutions that can maintain consistent performance across different experimental scales.

As atmospheric research advances, there is an increasing need for vacuum systems capable of handling a wider range of gases and environmental conditions. This includes the ability to work with corrosive or reactive gases, as well as to rapidly adjust to changing pressure and composition requirements. Developing versatile vacuum technologies that can adapt to these diverse experimental needs remains a significant technical hurdle.

Current Vacuum Pump Solutions

01 Vacuum pump design for atmospheric pressure applications

Vacuum pumps designed specifically for operation at or near atmospheric pressure. These pumps are engineered to efficiently handle the challenges of pumping gases at higher pressures, incorporating features such as improved sealing mechanisms and optimized compression ratios to maintain performance in atmospheric conditions.- Vacuum pump design for atmospheric pressure applications: Vacuum pumps designed specifically for operation at or near atmospheric pressure, incorporating features to enhance efficiency and performance in these conditions. These pumps may include specialized sealing mechanisms, optimized flow paths, or unique impeller designs to handle the challenges of pumping at higher pressures.

- Pressure control systems in vacuum pumps: Systems and methods for controlling and maintaining specific pressure levels in vacuum pumps, particularly when operating near atmospheric pressure. These may include pressure sensors, feedback loops, and adaptive control mechanisms to adjust pump operation based on ambient conditions and desired vacuum levels.

- Energy efficiency improvements in atmospheric pressure vacuum pumps: Innovations focused on improving the energy efficiency of vacuum pumps operating at or near atmospheric pressure. This may involve advanced motor designs, power management systems, or novel pump geometries that reduce energy consumption while maintaining performance.

- Multi-stage vacuum pump systems for atmospheric pressure applications: Vacuum pump systems that utilize multiple stages or combinations of different pump types to effectively handle atmospheric pressure conditions. These systems may incorporate both mechanical and diffusion pumps, or use a series of pumps with different operating characteristics to achieve desired vacuum levels efficiently.

- Specialized materials and coatings for atmospheric pressure vacuum pumps: Use of advanced materials and surface treatments in vacuum pump components to enhance performance and durability when operating at atmospheric pressure. This may include corrosion-resistant alloys, low-friction coatings, or materials with specific thermal properties to manage heat generation and dissipation.

02 Pressure control systems in vacuum pumps

Advanced pressure control systems integrated into vacuum pumps to maintain stable operation at varying atmospheric pressures. These systems may include pressure sensors, feedback loops, and adaptive control algorithms to adjust pump performance based on ambient conditions, ensuring consistent vacuum levels across different atmospheric pressures.Expand Specific Solutions03 Energy-efficient vacuum pumping at atmospheric pressure

Innovative approaches to improve the energy efficiency of vacuum pumps operating at or near atmospheric pressure. These may include novel motor designs, improved fluid dynamics, and smart control systems that optimize power consumption based on the current atmospheric pressure and required vacuum level.Expand Specific Solutions04 Multi-stage vacuum pumps for atmospheric pressure applications

Multi-stage vacuum pump designs tailored for efficient operation across a wide range of pressures, from atmospheric to high vacuum. These pumps utilize a series of compression stages, each optimized for a specific pressure range, to achieve high performance and reliability when starting from atmospheric pressure.Expand Specific Solutions05 Vacuum pump sealing technologies for atmospheric pressure

Advanced sealing technologies developed to maintain vacuum integrity in pumps operating at or near atmospheric pressure. These may include innovative materials, dynamic sealing mechanisms, and pressure-responsive seal designs that adapt to changing atmospheric conditions to prevent leakage and maintain pump efficiency.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump industry supporting atmospheric simulation chambers is in a mature stage, with a global market size estimated in the billions of dollars. The technology is well-established, with key players like Edwards Ltd., Pfeiffer Vacuum GmbH, and ULVAC, Inc. leading innovation. These companies offer advanced solutions for precise atmospheric control, crucial for research and industrial applications. The competitive landscape is characterized by continuous improvements in pump efficiency, reliability, and integration with digital control systems. Emerging trends include the development of more compact, energy-efficient pumps and the incorporation of smart technologies for remote monitoring and predictive maintenance.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pumps specifically designed for atmospheric simulation chambers. Their GXS dry screw pump series offers high pumping speeds up to 3400 m³/h and ultimate pressures down to 5x10^-4 mbar[1]. These pumps utilize a unique screw mechanism that provides efficient gas handling and compression, enabling precise control of atmospheric conditions. Edwards' pumps incorporate intelligent control systems that allow for real-time monitoring and adjustment of pump parameters, ensuring stable and reproducible atmospheric simulations[2]. The company has also implemented energy-efficient technologies, such as variable speed drives, which optimize power consumption based on the chamber's requirements[3].

Strengths: High pumping speeds, precise pressure control, and energy efficiency. Weaknesses: May require specialized maintenance and higher initial investment compared to simpler pump designs.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed the HiPace turbomolecular pump series specifically for atmospheric simulation applications. These pumps achieve high compression ratios for light gases, enabling the creation of ultra-high vacuum conditions essential for accurate atmospheric simulations[4]. Pfeiffer's pumps feature advanced rotor designs with multiple stages, allowing for efficient pumping across a wide pressure range. The company has also implemented hybrid bearing technology, combining ceramic ball bearings and permanent magnetic bearings, which reduces friction and extends the pump's lifespan[5]. Pfeiffer's pumps are equipped with integrated controllers that offer precise speed control and monitoring capabilities, ensuring stable performance during long-duration simulations[6].

Strengths: High compression ratios, wide operating pressure range, and long-lasting bearing technology. Weaknesses: May have higher costs associated with advanced technologies and potential complexity in maintenance.

Innovative Vacuum Pump Designs

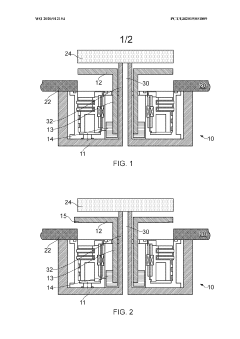

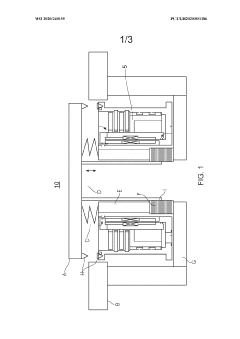

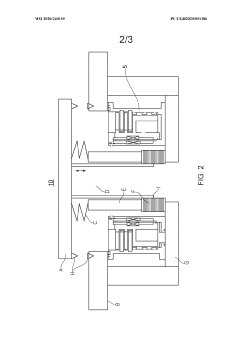

Vacuum pump with through channel and vacuum chamber

PatentWO2020012154A1

Innovation

- A vacuum pump design featuring a rotor, stator, and a controllable valve plate with an axial passage for central substrate mounting and power connections, allowing for uniform gas flow and fast pressure control, along with the option of magnetic levitation for rotor positioning and actuator-controlled axial movement of the valve plate to optimize inlet conductance.

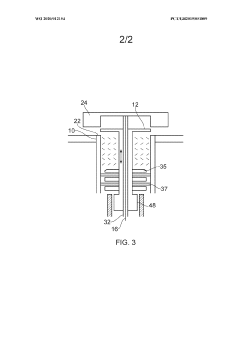

Vacuum assembly and vacuum pump with an axial through passage

PatentWO2020240155A1

Innovation

- A vacuum pump with a hollow shaft defining an axial passage that extends through the pump, allowing the cathode plate to be powered and sealed without disrupting gas flow, eliminating the need for a poppet valve and reducing hardware requirements by using a movable cathode plate for sealing and power supply access.

Vacuum Pump Energy Efficiency

Vacuum pump energy efficiency is a critical factor in the operation of atmospheric simulation chambers. These chambers rely heavily on vacuum pumps to create and maintain the desired atmospheric conditions, making the energy consumption of these pumps a significant consideration. In recent years, there has been a growing focus on improving the energy efficiency of vacuum pumps used in atmospheric simulation applications.

One of the primary approaches to enhancing vacuum pump energy efficiency is through the development of advanced pump designs. Modern vacuum pumps incorporate innovative technologies such as variable speed drives, which allow the pump to adjust its operating speed based on the required vacuum level. This adaptive functionality significantly reduces energy consumption during periods of lower demand, resulting in overall improved efficiency.

Another key area of improvement is in the materials used in pump construction. High-performance materials with lower friction coefficients and improved thermal properties contribute to reduced energy losses and enhanced pump efficiency. Additionally, the integration of advanced lubricants and sealing technologies further minimizes energy waste due to friction and leakage.

The implementation of intelligent control systems has also played a crucial role in optimizing vacuum pump energy efficiency. These systems utilize sensors and algorithms to monitor and adjust pump performance in real-time, ensuring optimal operation under varying conditions. By continuously optimizing pump parameters, such as speed and pressure, these control systems can achieve substantial energy savings without compromising the performance of the atmospheric simulation chamber.

Heat recovery systems have emerged as an innovative approach to improving overall energy efficiency in vacuum pump applications. By capturing and repurposing the heat generated during pump operation, these systems can provide supplementary heating for other processes or facilities, effectively reducing the net energy consumption of the entire system.

Manufacturers are increasingly focusing on the development of oil-free vacuum pump technologies, which not only offer environmental benefits but also contribute to improved energy efficiency. These pumps eliminate the need for oil changes and reduce friction-related energy losses, resulting in lower operational costs and enhanced sustainability.

The integration of vacuum pumps with energy management systems has become a standard practice in many atmospheric simulation facilities. These systems provide comprehensive monitoring and analysis of energy consumption patterns, enabling operators to identify opportunities for further efficiency improvements and implement targeted energy-saving strategies.

As the demand for more sophisticated atmospheric simulation capabilities continues to grow, the importance of vacuum pump energy efficiency will only increase. Ongoing research and development efforts are focused on pushing the boundaries of pump technology, exploring novel materials, and refining control algorithms to achieve even greater energy savings in the future.

One of the primary approaches to enhancing vacuum pump energy efficiency is through the development of advanced pump designs. Modern vacuum pumps incorporate innovative technologies such as variable speed drives, which allow the pump to adjust its operating speed based on the required vacuum level. This adaptive functionality significantly reduces energy consumption during periods of lower demand, resulting in overall improved efficiency.

Another key area of improvement is in the materials used in pump construction. High-performance materials with lower friction coefficients and improved thermal properties contribute to reduced energy losses and enhanced pump efficiency. Additionally, the integration of advanced lubricants and sealing technologies further minimizes energy waste due to friction and leakage.

The implementation of intelligent control systems has also played a crucial role in optimizing vacuum pump energy efficiency. These systems utilize sensors and algorithms to monitor and adjust pump performance in real-time, ensuring optimal operation under varying conditions. By continuously optimizing pump parameters, such as speed and pressure, these control systems can achieve substantial energy savings without compromising the performance of the atmospheric simulation chamber.

Heat recovery systems have emerged as an innovative approach to improving overall energy efficiency in vacuum pump applications. By capturing and repurposing the heat generated during pump operation, these systems can provide supplementary heating for other processes or facilities, effectively reducing the net energy consumption of the entire system.

Manufacturers are increasingly focusing on the development of oil-free vacuum pump technologies, which not only offer environmental benefits but also contribute to improved energy efficiency. These pumps eliminate the need for oil changes and reduce friction-related energy losses, resulting in lower operational costs and enhanced sustainability.

The integration of vacuum pumps with energy management systems has become a standard practice in many atmospheric simulation facilities. These systems provide comprehensive monitoring and analysis of energy consumption patterns, enabling operators to identify opportunities for further efficiency improvements and implement targeted energy-saving strategies.

As the demand for more sophisticated atmospheric simulation capabilities continues to grow, the importance of vacuum pump energy efficiency will only increase. Ongoing research and development efforts are focused on pushing the boundaries of pump technology, exploring novel materials, and refining control algorithms to achieve even greater energy savings in the future.

Environmental Impact of Vacuum Systems

Vacuum systems, while essential for atmospheric simulation chambers, have significant environmental implications that warrant careful consideration. The production, operation, and disposal of vacuum pumps and associated equipment contribute to various environmental impacts throughout their lifecycle. During manufacturing, the extraction and processing of raw materials for pump components, such as metals and plastics, consume energy and resources while potentially releasing pollutants into the environment.

The operational phase of vacuum systems presents notable environmental challenges. Energy consumption is a primary concern, as vacuum pumps often require substantial electrical power to maintain low-pressure environments. This energy demand contributes to greenhouse gas emissions when sourced from non-renewable energy grids. Additionally, the use of lubricants and coolants in vacuum pumps can lead to potential environmental contamination if not properly managed or disposed of.

Noise pollution is another environmental factor associated with vacuum systems. High-performance pumps used in atmospheric simulation chambers can generate significant noise levels, potentially affecting the surrounding ecosystem and human work environments. Implementing sound insulation measures and selecting quieter pump technologies can help mitigate this impact.

The disposal of vacuum system components at the end of their lifecycle presents further environmental challenges. Electronic components, specialized materials, and potentially hazardous substances used in vacuum pumps require proper recycling or disposal procedures to prevent soil and water contamination. Implementing effective recycling programs and designing pumps with easily separable components can significantly reduce the environmental footprint of these systems.

To address these environmental concerns, the vacuum pump industry is increasingly focusing on developing more sustainable technologies. This includes the design of energy-efficient pumps, the use of environmentally friendly materials and lubricants, and the implementation of noise reduction technologies. Furthermore, the adoption of lifecycle assessment approaches in the development and operation of vacuum systems can help identify and mitigate environmental impacts across all stages of their use in atmospheric simulation chambers.

The operational phase of vacuum systems presents notable environmental challenges. Energy consumption is a primary concern, as vacuum pumps often require substantial electrical power to maintain low-pressure environments. This energy demand contributes to greenhouse gas emissions when sourced from non-renewable energy grids. Additionally, the use of lubricants and coolants in vacuum pumps can lead to potential environmental contamination if not properly managed or disposed of.

Noise pollution is another environmental factor associated with vacuum systems. High-performance pumps used in atmospheric simulation chambers can generate significant noise levels, potentially affecting the surrounding ecosystem and human work environments. Implementing sound insulation measures and selecting quieter pump technologies can help mitigate this impact.

The disposal of vacuum system components at the end of their lifecycle presents further environmental challenges. Electronic components, specialized materials, and potentially hazardous substances used in vacuum pumps require proper recycling or disposal procedures to prevent soil and water contamination. Implementing effective recycling programs and designing pumps with easily separable components can significantly reduce the environmental footprint of these systems.

To address these environmental concerns, the vacuum pump industry is increasingly focusing on developing more sustainable technologies. This includes the design of energy-efficient pumps, the use of environmentally friendly materials and lubricants, and the implementation of noise reduction technologies. Furthermore, the adoption of lifecycle assessment approaches in the development and operation of vacuum systems can help identify and mitigate environmental impacts across all stages of their use in atmospheric simulation chambers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!