How Vacuum Pumps Support Green Chemistry Processes

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution

Vacuum pump technology has undergone significant evolution since its inception, playing a crucial role in supporting green chemistry processes. The journey of vacuum pump development can be traced back to the 17th century, with Otto von Guericke's pioneering work on the first mechanical vacuum pump. However, it wasn't until the industrial revolution that vacuum pumps began to see widespread application in various industries.

In the early 20th century, the introduction of rotary vane pumps marked a significant milestone in vacuum technology. These pumps offered improved efficiency and reliability compared to their predecessors, making them suitable for a wide range of industrial applications. As the demand for higher vacuum levels grew, particularly in the semiconductor industry, turbomolecular pumps emerged in the 1950s, capable of achieving ultra-high vacuum conditions.

The late 20th century saw the development of dry vacuum pumps, which eliminated the need for oil in the pumping mechanism. This innovation was particularly significant for green chemistry processes, as it reduced the risk of contamination and minimized environmental impact. Scroll pumps and claw pumps are examples of dry vacuum technologies that have gained popularity in recent decades.

In recent years, the focus has shifted towards improving energy efficiency and reducing the environmental footprint of vacuum pumps. Variable speed drive technology has been integrated into pump designs, allowing for optimized performance and reduced energy consumption. Additionally, advancements in materials science have led to the development of more durable and corrosion-resistant components, extending the lifespan of vacuum pumps and reducing maintenance requirements.

The advent of Industry 4.0 has brought about smart vacuum pumps equipped with sensors and connectivity features. These intelligent systems can monitor their own performance, predict maintenance needs, and adjust operating parameters in real-time, further enhancing efficiency and reliability. This integration of digital technology has opened up new possibilities for process optimization in green chemistry applications.

Looking towards the future, vacuum pump evolution is likely to continue focusing on sustainability and efficiency. Research is ongoing into novel pump designs that can achieve higher vacuum levels with lower energy consumption. Additionally, the development of pumps specifically tailored for green chemistry processes, capable of handling aggressive chemicals and supporting solvent recovery systems, is an area of active innovation.

As environmental regulations become more stringent, vacuum pump manufacturers are also exploring the use of eco-friendly materials and manufacturing processes. This holistic approach to sustainability encompasses not only the pump's operation but also its entire lifecycle, from production to disposal.

In the early 20th century, the introduction of rotary vane pumps marked a significant milestone in vacuum technology. These pumps offered improved efficiency and reliability compared to their predecessors, making them suitable for a wide range of industrial applications. As the demand for higher vacuum levels grew, particularly in the semiconductor industry, turbomolecular pumps emerged in the 1950s, capable of achieving ultra-high vacuum conditions.

The late 20th century saw the development of dry vacuum pumps, which eliminated the need for oil in the pumping mechanism. This innovation was particularly significant for green chemistry processes, as it reduced the risk of contamination and minimized environmental impact. Scroll pumps and claw pumps are examples of dry vacuum technologies that have gained popularity in recent decades.

In recent years, the focus has shifted towards improving energy efficiency and reducing the environmental footprint of vacuum pumps. Variable speed drive technology has been integrated into pump designs, allowing for optimized performance and reduced energy consumption. Additionally, advancements in materials science have led to the development of more durable and corrosion-resistant components, extending the lifespan of vacuum pumps and reducing maintenance requirements.

The advent of Industry 4.0 has brought about smart vacuum pumps equipped with sensors and connectivity features. These intelligent systems can monitor their own performance, predict maintenance needs, and adjust operating parameters in real-time, further enhancing efficiency and reliability. This integration of digital technology has opened up new possibilities for process optimization in green chemistry applications.

Looking towards the future, vacuum pump evolution is likely to continue focusing on sustainability and efficiency. Research is ongoing into novel pump designs that can achieve higher vacuum levels with lower energy consumption. Additionally, the development of pumps specifically tailored for green chemistry processes, capable of handling aggressive chemicals and supporting solvent recovery systems, is an area of active innovation.

As environmental regulations become more stringent, vacuum pump manufacturers are also exploring the use of eco-friendly materials and manufacturing processes. This holistic approach to sustainability encompasses not only the pump's operation but also its entire lifecycle, from production to disposal.

Green Chemistry Market

The green chemistry market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations aimed at reducing the environmental impact of chemical processes. This market encompasses a wide range of products, technologies, and services that promote sustainable and eco-friendly chemical production methods. The demand for green chemistry solutions has been particularly strong in industries such as pharmaceuticals, agrochemicals, and consumer goods.

One of the key factors driving the growth of the green chemistry market is the rising adoption of sustainable practices by major chemical manufacturers. These companies are increasingly investing in research and development to create more environmentally friendly processes and products. This shift is not only driven by regulatory pressures but also by consumer demand for greener alternatives and the potential for cost savings through improved efficiency and reduced waste.

The market for green chemistry solutions is expected to continue its upward trajectory in the coming years. Analysts project a compound annual growth rate (CAGR) of over 6% for the global green chemistry market through 2025. This growth is attributed to several factors, including the increasing focus on circular economy principles, the development of bio-based chemicals, and the implementation of green chemistry practices in emerging economies.

In terms of regional distribution, North America and Europe currently lead the green chemistry market, with well-established regulatory frameworks and a strong emphasis on sustainability. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, growing environmental concerns, and government initiatives to promote sustainable development.

The green chemistry market is characterized by a diverse range of products and technologies. These include bio-based solvents, catalysts for more efficient reactions, renewable feedstocks, and process intensification technologies. Among these, vacuum pumps play a crucial role in supporting green chemistry processes by enabling more efficient separations, reducing energy consumption, and minimizing waste generation.

As the green chemistry market continues to evolve, several trends are shaping its future. These include the increasing integration of artificial intelligence and machine learning in process optimization, the development of novel catalysts for more selective and efficient reactions, and the growing emphasis on water conservation and treatment in chemical processes. Additionally, there is a rising focus on the development of green chemistry solutions for emerging fields such as nanotechnology and advanced materials.

One of the key factors driving the growth of the green chemistry market is the rising adoption of sustainable practices by major chemical manufacturers. These companies are increasingly investing in research and development to create more environmentally friendly processes and products. This shift is not only driven by regulatory pressures but also by consumer demand for greener alternatives and the potential for cost savings through improved efficiency and reduced waste.

The market for green chemistry solutions is expected to continue its upward trajectory in the coming years. Analysts project a compound annual growth rate (CAGR) of over 6% for the global green chemistry market through 2025. This growth is attributed to several factors, including the increasing focus on circular economy principles, the development of bio-based chemicals, and the implementation of green chemistry practices in emerging economies.

In terms of regional distribution, North America and Europe currently lead the green chemistry market, with well-established regulatory frameworks and a strong emphasis on sustainability. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, growing environmental concerns, and government initiatives to promote sustainable development.

The green chemistry market is characterized by a diverse range of products and technologies. These include bio-based solvents, catalysts for more efficient reactions, renewable feedstocks, and process intensification technologies. Among these, vacuum pumps play a crucial role in supporting green chemistry processes by enabling more efficient separations, reducing energy consumption, and minimizing waste generation.

As the green chemistry market continues to evolve, several trends are shaping its future. These include the increasing integration of artificial intelligence and machine learning in process optimization, the development of novel catalysts for more selective and efficient reactions, and the growing emphasis on water conservation and treatment in chemical processes. Additionally, there is a rising focus on the development of green chemistry solutions for emerging fields such as nanotechnology and advanced materials.

Vacuum Tech Challenges

Vacuum technology plays a crucial role in green chemistry processes, but it also faces several significant challenges. One of the primary issues is energy efficiency. Traditional vacuum pumps consume substantial amounts of electricity, which can offset the environmental benefits of green chemistry applications. Improving the energy efficiency of vacuum systems without compromising their performance remains a key challenge for manufacturers and researchers.

Another major hurdle is the maintenance and reliability of vacuum pumps in harsh chemical environments. Green chemistry often involves corrosive or reactive substances that can damage pump components, leading to frequent maintenance or replacement. This not only increases operational costs but also creates potential environmental hazards due to the disposal of contaminated parts.

Contamination control presents another significant challenge. In many green chemistry processes, maintaining a clean vacuum environment is critical for product quality and process efficiency. However, oil-based vacuum pumps can introduce hydrocarbon contaminants into the system, necessitating the use of oil-free technologies. While dry pumps address this issue, they often come with trade-offs in terms of cost, efficiency, or pumping speed.

Scaling vacuum technology for industrial applications is also a considerable challenge. As green chemistry processes move from laboratory scale to industrial production, vacuum systems must be scaled up accordingly. This scaling often reveals unforeseen issues related to heat management, pressure control, and system integration that were not apparent at smaller scales.

The need for precise pressure control across a wide range of operating conditions poses another technical challenge. Many green chemistry processes require specific pressure environments that must be maintained consistently. Achieving this level of control, especially in large-scale operations or when dealing with varying gas loads, demands sophisticated pump designs and control systems.

Noise and vibration reduction is an often-overlooked challenge in vacuum technology. As environmental regulations become stricter, the need for quieter and low-vibration vacuum systems increases. This is particularly important in laboratory settings and in industries where precision processes are sensitive to mechanical disturbances.

Lastly, the development of smart and connected vacuum systems presents both opportunities and challenges. Integrating sensors, data analytics, and remote monitoring capabilities can greatly enhance the efficiency and reliability of vacuum pumps. However, this integration also introduces complexities in terms of cybersecurity, data management, and the need for specialized skills in operation and maintenance.

Another major hurdle is the maintenance and reliability of vacuum pumps in harsh chemical environments. Green chemistry often involves corrosive or reactive substances that can damage pump components, leading to frequent maintenance or replacement. This not only increases operational costs but also creates potential environmental hazards due to the disposal of contaminated parts.

Contamination control presents another significant challenge. In many green chemistry processes, maintaining a clean vacuum environment is critical for product quality and process efficiency. However, oil-based vacuum pumps can introduce hydrocarbon contaminants into the system, necessitating the use of oil-free technologies. While dry pumps address this issue, they often come with trade-offs in terms of cost, efficiency, or pumping speed.

Scaling vacuum technology for industrial applications is also a considerable challenge. As green chemistry processes move from laboratory scale to industrial production, vacuum systems must be scaled up accordingly. This scaling often reveals unforeseen issues related to heat management, pressure control, and system integration that were not apparent at smaller scales.

The need for precise pressure control across a wide range of operating conditions poses another technical challenge. Many green chemistry processes require specific pressure environments that must be maintained consistently. Achieving this level of control, especially in large-scale operations or when dealing with varying gas loads, demands sophisticated pump designs and control systems.

Noise and vibration reduction is an often-overlooked challenge in vacuum technology. As environmental regulations become stricter, the need for quieter and low-vibration vacuum systems increases. This is particularly important in laboratory settings and in industries where precision processes are sensitive to mechanical disturbances.

Lastly, the development of smart and connected vacuum systems presents both opportunities and challenges. Integrating sensors, data analytics, and remote monitoring capabilities can greatly enhance the efficiency and reliability of vacuum pumps. However, this integration also introduces complexities in terms of cybersecurity, data management, and the need for specialized skills in operation and maintenance.

Green Chemistry Solutions

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.

- Specialized vacuum pumps for specific applications: Vacuum pumps have been developed for specific industrial and scientific applications. These specialized pumps are designed to meet unique requirements such as high vacuum levels, corrosive gas handling, or clean room compatibility. Custom features and materials are incorporated to ensure optimal performance in specific operating conditions.

- Integration of vacuum pumps in semiconductor manufacturing: Vacuum pumps play a crucial role in semiconductor manufacturing processes. Innovations in this area focus on integrating pumps into complex fabrication systems, ensuring contamination-free environments, and maintaining precise vacuum levels. These advancements contribute to improved yield and quality in semiconductor production.

- Energy-efficient vacuum pump technologies: Efforts have been made to develop energy-efficient vacuum pump technologies. These innovations include improved motor designs, advanced control systems, and optimized pumping mechanisms. The focus is on reducing power consumption while maintaining or enhancing pump performance, contributing to overall energy savings in industrial processes.

- Vacuum pump maintenance and monitoring systems: Advancements in vacuum pump maintenance and monitoring systems have been developed to ensure optimal pump performance and longevity. These innovations include real-time monitoring of pump parameters, predictive maintenance algorithms, and automated diagnostic systems. Such technologies help prevent unexpected downtime and reduce maintenance costs.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed. These pumps are designed to handle specific gases and maintain ultra-high vacuum levels required in semiconductor fabrication. They often incorporate features to minimize contamination and ensure consistent performance in cleanroom environments.Expand Specific Solutions03 Energy-efficient vacuum pump systems

Innovations in vacuum pump technology have led to more energy-efficient systems. These developments include improved motor designs, advanced control systems, and optimized pumping mechanisms. Such enhancements result in reduced power consumption and lower operating costs while maintaining high performance levels.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping efficiency. These configurations often combine different types of pumps in series or parallel arrangements, allowing for better performance across a wide range of pressure conditions and applications.Expand Specific Solutions05 Vacuum pump monitoring and control systems

Advanced monitoring and control systems have been developed for vacuum pumps to optimize performance and maintenance. These systems incorporate sensors, data analysis, and automation to monitor pump conditions, predict failures, and adjust operating parameters in real-time. This leads to improved reliability, reduced downtime, and more efficient pump operation.Expand Specific Solutions

Key Vacuum Pump Makers

The vacuum pump industry supporting green chemistry processes is in a mature growth phase, with a global market size estimated to be in the billions of dollars. The technology has reached a high level of maturity, with established players like Edwards Ltd., Air Liquide SA, and Pfeiffer Vacuum GmbH dominating the market. These companies offer advanced vacuum solutions for various green chemistry applications, including energy-efficient processes and waste reduction. Emerging players such as Gokin Solar Co., Ltd. and Beijing Tongjia Hongrui Technology Co., Ltd. are focusing on specialized applications in renewable energy sectors, indicating a trend towards diversification and sustainability in the industry. The competitive landscape is characterized by ongoing innovation in pump efficiency, reliability, and environmental performance to meet the evolving demands of green chemistry processes.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for green chemistry processes. Their GXS dry screw vacuum pumps utilize innovative screw technology to provide high performance in harsh chemical environments[1]. These pumps are designed with corrosion-resistant materials and offer improved energy efficiency, reducing power consumption by up to 50% compared to traditional pumps[2]. Edwards' pumps also incorporate intelligent control systems that optimize performance based on process demands, further enhancing energy efficiency and reducing waste[3]. The company has focused on developing pumps with lower environmental impact, including designs that minimize oil usage and emissions, supporting cleaner manufacturing processes in the chemical industry[4].

Strengths: High energy efficiency, corrosion resistance, and intelligent control systems. Weaknesses: May have higher initial costs compared to traditional pumps, and potential complexity in maintenance due to advanced features.

LEYBOLD AG

Technical Solution: LEYBOLD AG has developed a range of vacuum solutions specifically designed to support green chemistry processes. Their DRYVAC series of dry compressing screw vacuum pumps are engineered for harsh chemical applications, offering high reliability and minimal maintenance requirements[1]. These pumps feature advanced rotor designs that improve pumping speeds while reducing energy consumption. LEYBOLD's pumps incorporate smart monitoring systems that allow for predictive maintenance, optimizing uptime and reducing waste[2]. The company has also focused on developing pumps with reduced environmental impact, including designs that eliminate the need for operating fluids, supporting cleaner and more sustainable chemical processes[3]. LEYBOLD's vacuum systems are designed to be modular, allowing for easy integration into existing green chemistry setups and facilitating process optimization[4].

Strengths: High reliability, low maintenance, and modular design for easy integration. Weaknesses: Potentially higher upfront costs and may require specialized training for operation and maintenance.

Vacuum Pump Innovations

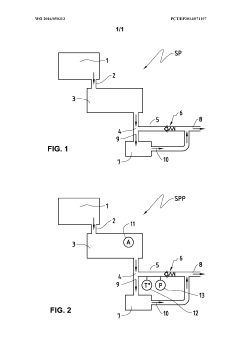

Pumping system for generating a vacuum and method for pumping by means of this pumping system

PatentWO2016050313A1

Innovation

- A pumping system comprising a main pin vacuum pump and an auxiliary vacuum pump connected in parallel, with a non-return valve, allowing the auxiliary pump to operate continuously to maintain pressure and reduce energy consumption, eliminating the need for additional sensors and control systems.

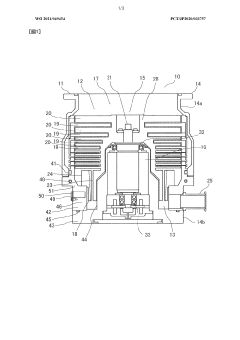

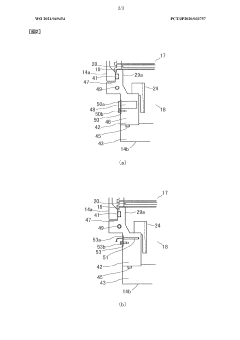

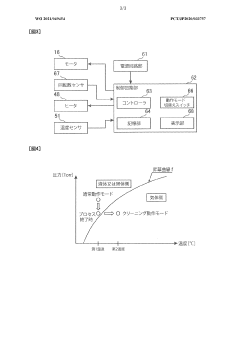

Vacuum pump and vacuum pump system

PatentWO2021049454A1

Innovation

- A vacuum pump system with a temperature control mechanism that switches between normal and cleaning operation modes, using a higher temperature and lower rotation speed to gasify and remove side reaction products without overhauling, utilizing a cartridge heater and auxiliary pump for efficient exhaust.

Environmental Impact

Vacuum pumps play a crucial role in supporting green chemistry processes, and their environmental impact is a key consideration in their application. These devices contribute significantly to reducing the environmental footprint of chemical processes by enabling more efficient and sustainable operations.

One of the primary environmental benefits of vacuum pumps in green chemistry is their ability to lower energy consumption. By operating at reduced pressures, chemical reactions can occur at lower temperatures, resulting in substantial energy savings. This reduction in energy requirements not only decreases the carbon footprint of chemical processes but also leads to cost savings for industries.

Furthermore, vacuum pumps facilitate the recovery and recycling of solvents and other valuable materials. In many chemical processes, solvents are used in large quantities and can be a significant source of waste and environmental pollution. Vacuum distillation and separation techniques enabled by these pumps allow for the efficient recovery of solvents, reducing the need for fresh materials and minimizing waste generation.

The use of vacuum pumps also supports the principles of atom economy and waste reduction in green chemistry. By enabling reactions to occur under milder conditions, these pumps help minimize unwanted side reactions and improve product selectivity. This leads to higher yields and fewer byproducts, ultimately reducing the amount of waste generated in chemical processes.

In addition, vacuum pumps contribute to the development of safer chemical processes. By allowing reactions to take place at lower temperatures and pressures, they reduce the risk of accidents and the potential for the release of hazardous materials into the environment. This aspect is particularly important in the pharmaceutical and fine chemicals industries, where safety and environmental concerns are paramount.

Vacuum technology also plays a vital role in the development of alternative energy sources and environmental remediation techniques. For instance, vacuum pumps are essential in the production of solar panels and in the purification of biofuels. They are also used in soil vapor extraction processes for the remediation of contaminated sites, helping to remove volatile organic compounds from soil and groundwater.

However, it is important to note that the environmental impact of vacuum pumps themselves should be considered. Efforts are being made to develop more energy-efficient pump designs and to use environmentally friendly lubricants and sealing materials. Additionally, proper maintenance and operation of vacuum pumps are crucial to ensure their optimal performance and longevity, further minimizing their environmental impact over their lifecycle.

One of the primary environmental benefits of vacuum pumps in green chemistry is their ability to lower energy consumption. By operating at reduced pressures, chemical reactions can occur at lower temperatures, resulting in substantial energy savings. This reduction in energy requirements not only decreases the carbon footprint of chemical processes but also leads to cost savings for industries.

Furthermore, vacuum pumps facilitate the recovery and recycling of solvents and other valuable materials. In many chemical processes, solvents are used in large quantities and can be a significant source of waste and environmental pollution. Vacuum distillation and separation techniques enabled by these pumps allow for the efficient recovery of solvents, reducing the need for fresh materials and minimizing waste generation.

The use of vacuum pumps also supports the principles of atom economy and waste reduction in green chemistry. By enabling reactions to occur under milder conditions, these pumps help minimize unwanted side reactions and improve product selectivity. This leads to higher yields and fewer byproducts, ultimately reducing the amount of waste generated in chemical processes.

In addition, vacuum pumps contribute to the development of safer chemical processes. By allowing reactions to take place at lower temperatures and pressures, they reduce the risk of accidents and the potential for the release of hazardous materials into the environment. This aspect is particularly important in the pharmaceutical and fine chemicals industries, where safety and environmental concerns are paramount.

Vacuum technology also plays a vital role in the development of alternative energy sources and environmental remediation techniques. For instance, vacuum pumps are essential in the production of solar panels and in the purification of biofuels. They are also used in soil vapor extraction processes for the remediation of contaminated sites, helping to remove volatile organic compounds from soil and groundwater.

However, it is important to note that the environmental impact of vacuum pumps themselves should be considered. Efforts are being made to develop more energy-efficient pump designs and to use environmentally friendly lubricants and sealing materials. Additionally, proper maintenance and operation of vacuum pumps are crucial to ensure their optimal performance and longevity, further minimizing their environmental impact over their lifecycle.

Energy Efficiency

Energy efficiency is a critical aspect of vacuum pump technology in supporting green chemistry processes. The integration of energy-efficient vacuum pumps has significantly contributed to reducing the environmental impact of chemical manufacturing while simultaneously improving process efficiency and cost-effectiveness. Modern vacuum pumps are designed to optimize energy consumption through various innovative features and operational strategies.

One of the key advancements in energy-efficient vacuum pump design is the implementation of variable speed drives (VSDs). These systems allow pumps to adjust their operating speed based on the actual process requirements, rather than running at a constant speed. By matching the pump's output to the specific needs of the chemical process, VSDs can reduce energy consumption by up to 50% compared to traditional fixed-speed pumps. This not only lowers operational costs but also minimizes the carbon footprint of the entire manufacturing process.

Another important development is the use of advanced materials and coatings in pump construction. These materials, such as ceramic composites and specialized polymers, reduce friction and wear within the pump mechanism, leading to improved efficiency and longer operational lifespans. The reduced friction translates directly into lower energy consumption, as less power is required to overcome internal resistance within the pump.

Heat recovery systems have also been integrated into modern vacuum pump designs, further enhancing their energy efficiency. These systems capture waste heat generated during pump operation and repurpose it for other processes within the chemical plant, such as preheating reactants or maintaining optimal temperatures in storage tanks. By utilizing this otherwise wasted energy, facilities can significantly reduce their overall energy consumption and associated costs.

Intelligent control systems and predictive maintenance algorithms have revolutionized the operation of vacuum pumps in green chemistry applications. These systems continuously monitor pump performance, adjusting operational parameters in real-time to maintain optimal efficiency. Additionally, they can predict potential failures or maintenance needs, allowing for proactive interventions that prevent energy-wasting malfunctions and extend the pump's operational life.

The development of multi-stage vacuum pump systems has also contributed to improved energy efficiency. By combining different pump technologies in series, these systems can achieve high vacuum levels more efficiently than single-stage pumps. Each stage is optimized for a specific pressure range, ensuring that energy is used most effectively throughout the entire vacuum generation process.

In conclusion, the focus on energy efficiency in vacuum pump technology has led to significant advancements that directly support green chemistry processes. These innovations not only reduce the environmental impact of chemical manufacturing but also offer substantial economic benefits through reduced energy costs and improved process efficiency. As the demand for sustainable chemical processes continues to grow, further developments in energy-efficient vacuum pump technology are expected to play a crucial role in shaping the future of green chemistry.

One of the key advancements in energy-efficient vacuum pump design is the implementation of variable speed drives (VSDs). These systems allow pumps to adjust their operating speed based on the actual process requirements, rather than running at a constant speed. By matching the pump's output to the specific needs of the chemical process, VSDs can reduce energy consumption by up to 50% compared to traditional fixed-speed pumps. This not only lowers operational costs but also minimizes the carbon footprint of the entire manufacturing process.

Another important development is the use of advanced materials and coatings in pump construction. These materials, such as ceramic composites and specialized polymers, reduce friction and wear within the pump mechanism, leading to improved efficiency and longer operational lifespans. The reduced friction translates directly into lower energy consumption, as less power is required to overcome internal resistance within the pump.

Heat recovery systems have also been integrated into modern vacuum pump designs, further enhancing their energy efficiency. These systems capture waste heat generated during pump operation and repurpose it for other processes within the chemical plant, such as preheating reactants or maintaining optimal temperatures in storage tanks. By utilizing this otherwise wasted energy, facilities can significantly reduce their overall energy consumption and associated costs.

Intelligent control systems and predictive maintenance algorithms have revolutionized the operation of vacuum pumps in green chemistry applications. These systems continuously monitor pump performance, adjusting operational parameters in real-time to maintain optimal efficiency. Additionally, they can predict potential failures or maintenance needs, allowing for proactive interventions that prevent energy-wasting malfunctions and extend the pump's operational life.

The development of multi-stage vacuum pump systems has also contributed to improved energy efficiency. By combining different pump technologies in series, these systems can achieve high vacuum levels more efficiently than single-stage pumps. Each stage is optimized for a specific pressure range, ensuring that energy is used most effectively throughout the entire vacuum generation process.

In conclusion, the focus on energy efficiency in vacuum pump technology has led to significant advancements that directly support green chemistry processes. These innovations not only reduce the environmental impact of chemical manufacturing but also offer substantial economic benefits through reduced energy costs and improved process efficiency. As the demand for sustainable chemical processes continues to grow, further developments in energy-efficient vacuum pump technology are expected to play a crucial role in shaping the future of green chemistry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!