How Vacuum Pumps Support High-Efficiency CO2 Capture Technologies

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Tech Evolution

Carbon dioxide capture technology has undergone significant evolution since its inception in the 1970s. Initially developed for enhanced oil recovery, CO2 capture has become a crucial tool in the fight against climate change. The technology has progressed through several key stages, each marked by advancements in efficiency, cost-effectiveness, and scalability.

In the early stages, CO2 capture primarily relied on chemical absorption processes using amine-based solvents. This method, while effective, was energy-intensive and costly. The 1990s saw the emergence of membrane separation technologies, offering a more energy-efficient alternative. However, these early membranes struggled with selectivity and durability issues.

The turn of the millennium brought about a shift towards more advanced absorption technologies. Improved solvents and process configurations led to significant reductions in energy requirements and capture costs. Concurrently, adsorption-based technologies, utilizing materials like activated carbon and zeolites, gained traction for their potential in both pre- and post-combustion capture scenarios.

The past decade has witnessed a surge in research and development of novel capture technologies. Calcium looping, chemical looping combustion, and cryogenic separation have emerged as promising alternatives, each offering unique advantages in specific applications. These technologies have demonstrated potential for higher capture rates and reduced energy penalties.

Most recently, the focus has shifted towards direct air capture (DAC) technologies, capable of extracting CO2 directly from the atmosphere. While still in its infancy, DAC represents a potential game-changer in the field of carbon capture, offering a solution for addressing historical emissions and hard-to-abate sectors.

Throughout this evolution, vacuum pumps have played an increasingly critical role in enhancing the efficiency of CO2 capture technologies. As capture processes have become more sophisticated, the demand for precise pressure control and gas handling has grown. Vacuum pumps have been instrumental in improving the performance of membrane separation systems, optimizing pressure swing adsorption cycles, and enabling the operation of advanced solvent regeneration processes.

The integration of high-performance vacuum pumps has allowed for better control over partial pressures, facilitating more efficient separation of CO2 from gas mixtures. This has led to improvements in capture rates, reductions in energy consumption, and enhanced overall system performance across various capture technologies.

As CO2 capture technologies continue to evolve, the role of vacuum pumps is expected to become even more crucial. Future developments are likely to focus on further improving energy efficiency, reducing equipment footprint, and enhancing the ability to handle diverse gas compositions. The synergy between advanced capture technologies and sophisticated vacuum systems will be key to achieving the high-efficiency, large-scale carbon capture solutions needed to address global climate challenges.

In the early stages, CO2 capture primarily relied on chemical absorption processes using amine-based solvents. This method, while effective, was energy-intensive and costly. The 1990s saw the emergence of membrane separation technologies, offering a more energy-efficient alternative. However, these early membranes struggled with selectivity and durability issues.

The turn of the millennium brought about a shift towards more advanced absorption technologies. Improved solvents and process configurations led to significant reductions in energy requirements and capture costs. Concurrently, adsorption-based technologies, utilizing materials like activated carbon and zeolites, gained traction for their potential in both pre- and post-combustion capture scenarios.

The past decade has witnessed a surge in research and development of novel capture technologies. Calcium looping, chemical looping combustion, and cryogenic separation have emerged as promising alternatives, each offering unique advantages in specific applications. These technologies have demonstrated potential for higher capture rates and reduced energy penalties.

Most recently, the focus has shifted towards direct air capture (DAC) technologies, capable of extracting CO2 directly from the atmosphere. While still in its infancy, DAC represents a potential game-changer in the field of carbon capture, offering a solution for addressing historical emissions and hard-to-abate sectors.

Throughout this evolution, vacuum pumps have played an increasingly critical role in enhancing the efficiency of CO2 capture technologies. As capture processes have become more sophisticated, the demand for precise pressure control and gas handling has grown. Vacuum pumps have been instrumental in improving the performance of membrane separation systems, optimizing pressure swing adsorption cycles, and enabling the operation of advanced solvent regeneration processes.

The integration of high-performance vacuum pumps has allowed for better control over partial pressures, facilitating more efficient separation of CO2 from gas mixtures. This has led to improvements in capture rates, reductions in energy consumption, and enhanced overall system performance across various capture technologies.

As CO2 capture technologies continue to evolve, the role of vacuum pumps is expected to become even more crucial. Future developments are likely to focus on further improving energy efficiency, reducing equipment footprint, and enhancing the ability to handle diverse gas compositions. The synergy between advanced capture technologies and sophisticated vacuum systems will be key to achieving the high-efficiency, large-scale carbon capture solutions needed to address global climate challenges.

Market Demand for CO2 Capture

The market demand for CO2 capture technologies has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations aimed at reducing greenhouse gas emissions. As global efforts to combat climate change intensify, industries across various sectors are seeking efficient and cost-effective solutions to capture and store carbon dioxide emissions.

The power generation sector, particularly coal and natural gas-fired power plants, represents a significant market for CO2 capture technologies. These facilities are under increasing pressure to reduce their carbon footprint while maintaining operational efficiency. The industrial sector, including cement production, steel manufacturing, and chemical processing, also contributes substantially to the demand for CO2 capture solutions.

Market analysis indicates that the global carbon capture and storage (CCS) market is poised for substantial growth. This expansion is fueled by government initiatives, such as carbon pricing mechanisms and emissions reduction targets, which incentivize the adoption of CO2 capture technologies. Additionally, the potential for enhanced oil recovery (EOR) using captured CO2 has created a secondary market, further driving demand in regions with suitable geological formations.

The transportation sector, particularly aviation and shipping, is emerging as a new frontier for CO2 capture technologies. As these industries face challenges in transitioning to low-carbon alternatives, carbon capture presents a viable option for mitigating emissions while maintaining operational capabilities.

Developing economies, especially those heavily reliant on fossil fuels, are showing increased interest in CO2 capture technologies as they seek to balance economic growth with environmental sustainability. This trend is expected to create new market opportunities and drive innovation in more cost-effective and scalable capture solutions.

The market demand is not limited to large-scale industrial applications. There is a growing interest in smaller, modular CO2 capture systems for distributed applications, such as in commercial buildings and small-scale industrial processes. This diversification of the market is likely to spur further technological advancements and cost reductions in capture technologies.

As the urgency to address climate change intensifies, the market for CO2 capture technologies is expected to expand beyond traditional industrial applications. Negative emissions technologies, such as direct air capture, are gaining traction as a means to actively remove CO2 from the atmosphere. This emerging sector represents a potentially significant market opportunity for advanced capture technologies in the coming decades.

The power generation sector, particularly coal and natural gas-fired power plants, represents a significant market for CO2 capture technologies. These facilities are under increasing pressure to reduce their carbon footprint while maintaining operational efficiency. The industrial sector, including cement production, steel manufacturing, and chemical processing, also contributes substantially to the demand for CO2 capture solutions.

Market analysis indicates that the global carbon capture and storage (CCS) market is poised for substantial growth. This expansion is fueled by government initiatives, such as carbon pricing mechanisms and emissions reduction targets, which incentivize the adoption of CO2 capture technologies. Additionally, the potential for enhanced oil recovery (EOR) using captured CO2 has created a secondary market, further driving demand in regions with suitable geological formations.

The transportation sector, particularly aviation and shipping, is emerging as a new frontier for CO2 capture technologies. As these industries face challenges in transitioning to low-carbon alternatives, carbon capture presents a viable option for mitigating emissions while maintaining operational capabilities.

Developing economies, especially those heavily reliant on fossil fuels, are showing increased interest in CO2 capture technologies as they seek to balance economic growth with environmental sustainability. This trend is expected to create new market opportunities and drive innovation in more cost-effective and scalable capture solutions.

The market demand is not limited to large-scale industrial applications. There is a growing interest in smaller, modular CO2 capture systems for distributed applications, such as in commercial buildings and small-scale industrial processes. This diversification of the market is likely to spur further technological advancements and cost reductions in capture technologies.

As the urgency to address climate change intensifies, the market for CO2 capture technologies is expected to expand beyond traditional industrial applications. Negative emissions technologies, such as direct air capture, are gaining traction as a means to actively remove CO2 from the atmosphere. This emerging sector represents a potentially significant market opportunity for advanced capture technologies in the coming decades.

Vacuum Pump Challenges in CO2 Capture

Vacuum pumps play a crucial role in CO2 capture technologies, yet they face several significant challenges in this application. One of the primary issues is the corrosive nature of the gas mixtures involved in CO2 capture processes. These mixtures often contain moisture, sulfur compounds, and other corrosive elements that can rapidly degrade pump components, leading to reduced efficiency and increased maintenance requirements.

The high flow rates required for industrial-scale CO2 capture present another major challenge. Vacuum pumps must handle large volumes of gas while maintaining consistent performance, which puts considerable strain on pump mechanisms. This demand for high capacity often conflicts with the need for energy efficiency, as larger pumps typically consume more power.

Contamination is a persistent problem in CO2 capture applications. Particulate matter, liquid droplets, and other impurities in the gas stream can accumulate within the pump, causing wear, reducing efficiency, and potentially leading to pump failure. This necessitates robust filtration systems and regular maintenance, adding complexity and cost to the overall system.

The variability in gas composition and flow rates in CO2 capture processes poses additional challenges for vacuum pump design and operation. Pumps must be able to adapt to fluctuations in input conditions while maintaining optimal performance, which requires sophisticated control systems and flexible pump designs.

Heat management is another critical issue, particularly in high-capacity systems. The compression of large gas volumes generates significant heat, which must be effectively dissipated to prevent overheating and maintain pump efficiency. This often necessitates advanced cooling systems, adding to the complexity and energy consumption of the overall setup.

Vacuum pumps in CO2 capture applications must also contend with the issue of seal integrity. The high pressure differentials and potentially hazardous nature of the gases being handled demand extremely reliable sealing solutions to prevent leaks and ensure safe operation. This challenge is compounded by the need for seals that can withstand corrosive environments and maintain their effectiveness over long periods.

Lastly, the economic viability of CO2 capture technologies heavily depends on the energy efficiency of the vacuum pumps employed. Striking a balance between performance, reliability, and energy consumption remains a significant challenge, as the power requirements of vacuum pumps can substantially impact the overall efficiency and cost-effectiveness of CO2 capture systems.

The high flow rates required for industrial-scale CO2 capture present another major challenge. Vacuum pumps must handle large volumes of gas while maintaining consistent performance, which puts considerable strain on pump mechanisms. This demand for high capacity often conflicts with the need for energy efficiency, as larger pumps typically consume more power.

Contamination is a persistent problem in CO2 capture applications. Particulate matter, liquid droplets, and other impurities in the gas stream can accumulate within the pump, causing wear, reducing efficiency, and potentially leading to pump failure. This necessitates robust filtration systems and regular maintenance, adding complexity and cost to the overall system.

The variability in gas composition and flow rates in CO2 capture processes poses additional challenges for vacuum pump design and operation. Pumps must be able to adapt to fluctuations in input conditions while maintaining optimal performance, which requires sophisticated control systems and flexible pump designs.

Heat management is another critical issue, particularly in high-capacity systems. The compression of large gas volumes generates significant heat, which must be effectively dissipated to prevent overheating and maintain pump efficiency. This often necessitates advanced cooling systems, adding to the complexity and energy consumption of the overall setup.

Vacuum pumps in CO2 capture applications must also contend with the issue of seal integrity. The high pressure differentials and potentially hazardous nature of the gases being handled demand extremely reliable sealing solutions to prevent leaks and ensure safe operation. This challenge is compounded by the need for seals that can withstand corrosive environments and maintain their effectiveness over long periods.

Lastly, the economic viability of CO2 capture technologies heavily depends on the energy efficiency of the vacuum pumps employed. Striking a balance between performance, reliability, and energy consumption remains a significant challenge, as the power requirements of vacuum pumps can substantially impact the overall efficiency and cost-effectiveness of CO2 capture systems.

Current Vacuum Pump Solutions

01 Improved rotor design for vacuum pumps

Enhancing the rotor design in vacuum pumps can significantly increase efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, improve sealing, and maximize pumping capacity. Advanced rotor designs can lead to better performance and energy efficiency in vacuum systems.- Improved rotor design for vacuum pumps: Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping speed. Advanced rotor designs can also help in maintaining consistent performance across different pressure ranges.

- Multi-stage vacuum pump systems: Implementing multi-stage vacuum pump systems can enhance overall efficiency. By combining different types of pumps in series or parallel configurations, these systems can achieve higher vacuum levels and improved pumping speeds. Each stage is optimized for a specific pressure range, allowing for better performance across a wide range of operating conditions.

- Advanced sealing technologies: Incorporating advanced sealing technologies in vacuum pumps can significantly reduce leakage and improve efficiency. This includes the use of innovative materials and designs for gaskets, O-rings, and other sealing components. Improved sealing can help maintain higher vacuum levels and reduce the energy required to operate the pump.

- Energy-efficient motor and drive systems: Utilizing energy-efficient motors and drive systems can greatly enhance the overall efficiency of vacuum pumps. This includes the use of variable speed drives, high-efficiency electric motors, and advanced control systems that optimize power consumption based on the required vacuum level and pumping speed.

- Innovative cooling and lubrication methods: Implementing innovative cooling and lubrication methods can improve the efficiency and longevity of vacuum pumps. This includes advanced heat dissipation techniques, optimized lubricant formulations, and intelligent lubrication systems that reduce friction and wear while maintaining optimal operating temperatures.

02 Multi-stage vacuum pump systems

Implementing multi-stage vacuum pump systems can improve overall efficiency. By combining different types of pumps or multiple pumping stages, these systems can achieve higher vacuum levels and better performance across a wider range of operating conditions. This approach allows for optimized energy consumption and improved pumping speed.Expand Specific Solutions03 Advanced sealing technologies

Incorporating advanced sealing technologies in vacuum pumps can enhance their efficiency. This includes the use of improved materials and designs for seals, gaskets, and O-rings to minimize leakage and maintain higher vacuum levels. Better sealing can lead to reduced power consumption and improved pump longevity.Expand Specific Solutions04 Intelligent control systems for vacuum pumps

Implementing intelligent control systems can optimize vacuum pump operation. These systems can adjust pump speed, monitor performance parameters, and manage multiple pumps in a network to maximize efficiency. Advanced control algorithms and sensors enable real-time optimization of pump operation based on demand and operating conditions.Expand Specific Solutions05 Energy recovery and heat management in vacuum systems

Improving energy recovery and heat management in vacuum systems can enhance overall efficiency. This includes techniques for capturing and reusing waste heat, implementing cooling systems to maintain optimal operating temperatures, and designing pumps with better thermal management properties. These approaches can reduce energy consumption and improve pump performance.Expand Specific Solutions

Key Players in CO2 Capture Industry

The vacuum pump technology for high-efficiency CO2 capture is in a growth phase, with increasing market size driven by global decarbonization efforts. The technology's maturity is advancing rapidly, as evidenced by the involvement of diverse players across industries. Companies like Air Liquide, Edwards Ltd., and Sumitomo Heavy Industries are leveraging their expertise in industrial gases and machinery to develop advanced vacuum pump solutions. Research institutions such as Arizona State University and the Spanish National Research Council are contributing to fundamental advancements. Energy giants like Shell and ExxonMobil are also investing in this technology, recognizing its potential in carbon capture and storage applications. Specialized firms like Carboncapture, Inc. and Global Thermostat Operations LLC are focusing on direct air capture technologies, further driving innovation in the field.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed specialized vacuum pump solutions tailored for CO2 capture applications. Their dry screw vacuum pumps, such as the GXS series, are designed to handle the corrosive and condensable nature of CO2-rich gas streams. These pumps employ advanced sealing technologies and corrosion-resistant materials to ensure long-term reliability in carbon capture environments. Edwards' vacuum systems are capable of maintaining precise low-pressure conditions required for efficient CO2 desorption in various capture technologies, including amine-based and membrane systems. The company's pumps have demonstrated energy savings of up to 50% compared to traditional liquid ring pumps in CO2 capture applications [4][6]. Additionally, Edwards offers intelligent pump control systems that optimize performance based on process conditions, further enhancing overall capture efficiency.

Strengths: Specialized design for CO2 capture applications, high reliability, and energy efficiency. Weaknesses: Potentially higher initial cost compared to general-purpose vacuum pumps.

Global Thermostat Operations LLC

Technical Solution: Global Thermostat has pioneered a direct air capture (DAC) technology that utilizes vacuum pumps in conjunction with a novel amine-based sorbent to extract CO2 directly from ambient air. Their system employs a honeycomb-structured ceramic monolith coated with the proprietary sorbent material. Vacuum pumps are used to create a pressure gradient that enhances CO2 adsorption onto the sorbent and facilitates efficient desorption during the regeneration phase. The technology has demonstrated the ability to capture CO2 at concentrations as low as 400 ppm, with capture costs projected to be significantly lower than other DAC methods [7][9]. Global Thermostat's modular design allows for scalable implementation, from small-scale applications to large industrial facilities. The company has also developed innovative heat integration strategies, utilizing low-grade waste heat from industrial processes to power the CO2 capture system, further improving overall efficiency.

Strengths: Ability to capture CO2 directly from ambient air, modular and scalable design, and potential for low-cost carbon removal. Weaknesses: Relatively new technology with limited large-scale deployment experience.

Innovative Vacuum Pump Designs

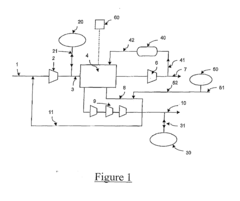

Re-pressurisation of a VSA treating a gaseous mix containing a fuel

PatentActiveEP2179776A1

Innovation

- Implementing a VSA process with a vacuum pump repressurization system using an external inert gas, such as nitrogen or purified CO2, to quickly restore atmospheric pressure and prevent the formation of flammable mixtures, while also optimizing the adsorption cycle and adsorbent arrangement for efficient CO2 capture.

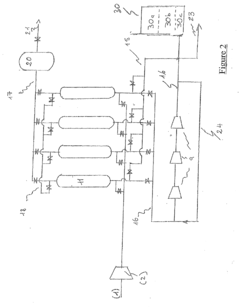

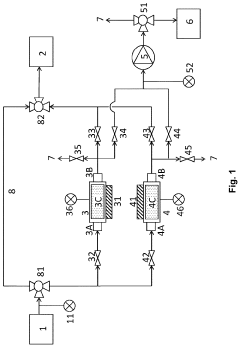

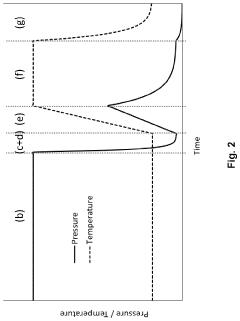

Improvements relating to carbon dioxide capture

PatentInactiveUS20220176309A1

Innovation

- A method and system for capturing carbon dioxide from compressed dry air using a carbon dioxide-adsorbent material in a chamber, where compressed dry air is adsorbed at a first temperature, the adsorbent is heated to release CO2 at a second temperature, and the CO2 is removed, integrating with existing compressed dry air systems to minimize energy and capital expenditures.

Environmental Impact Assessment

The implementation of vacuum pumps in high-efficiency CO2 capture technologies has significant environmental implications. These systems contribute to reducing greenhouse gas emissions by effectively capturing and storing carbon dioxide from industrial processes and power generation. The environmental impact of this technology is multifaceted, affecting air quality, energy consumption, and overall carbon footprint.

Vacuum pumps play a crucial role in enhancing the efficiency of CO2 capture processes, leading to improved environmental outcomes. By creating low-pressure environments, these pumps facilitate the separation and concentration of CO2 from flue gases, enabling higher capture rates and purity levels. This increased efficiency translates to a more substantial reduction in CO2 emissions released into the atmosphere, directly mitigating climate change impacts.

However, the operation of vacuum pumps in CO2 capture systems also has environmental considerations. The energy required to power these pumps contributes to the overall energy consumption of the capture process. This energy demand may partially offset the environmental benefits if not sourced from renewable or low-carbon energy sources. Consequently, the net environmental impact depends on the balance between CO2 captured and the emissions associated with the energy used to operate the system.

The use of vacuum pumps in CO2 capture technologies also influences water consumption and waste generation. Some capture processes involve water-based solvents, and the vacuum systems may affect water usage and potential contamination. Proper management of waste streams, including spent solvents and other byproducts, is essential to minimize negative environmental impacts and ensure responsible disposal or recycling practices.

Noise pollution is another environmental factor to consider. Vacuum pumps can generate significant noise levels, potentially affecting local ecosystems and human communities near industrial facilities. Implementing noise reduction measures and strategic placement of equipment can help mitigate these impacts.

Long-term environmental benefits of vacuum pump-supported CO2 capture technologies extend beyond immediate emission reductions. By enabling more efficient and cost-effective carbon capture, these systems contribute to the broader adoption of carbon capture and storage (CCS) technologies across industries. This widespread implementation has the potential to significantly reduce global CO2 emissions, playing a crucial role in meeting climate change mitigation targets and supporting the transition to a low-carbon economy.

In conclusion, while vacuum pumps in CO2 capture technologies offer substantial environmental benefits through improved capture efficiency, a comprehensive assessment must consider the full lifecycle impact, including energy consumption, resource use, and potential local environmental effects. Balancing these factors is crucial for maximizing the positive environmental outcomes of this technology.

Vacuum pumps play a crucial role in enhancing the efficiency of CO2 capture processes, leading to improved environmental outcomes. By creating low-pressure environments, these pumps facilitate the separation and concentration of CO2 from flue gases, enabling higher capture rates and purity levels. This increased efficiency translates to a more substantial reduction in CO2 emissions released into the atmosphere, directly mitigating climate change impacts.

However, the operation of vacuum pumps in CO2 capture systems also has environmental considerations. The energy required to power these pumps contributes to the overall energy consumption of the capture process. This energy demand may partially offset the environmental benefits if not sourced from renewable or low-carbon energy sources. Consequently, the net environmental impact depends on the balance between CO2 captured and the emissions associated with the energy used to operate the system.

The use of vacuum pumps in CO2 capture technologies also influences water consumption and waste generation. Some capture processes involve water-based solvents, and the vacuum systems may affect water usage and potential contamination. Proper management of waste streams, including spent solvents and other byproducts, is essential to minimize negative environmental impacts and ensure responsible disposal or recycling practices.

Noise pollution is another environmental factor to consider. Vacuum pumps can generate significant noise levels, potentially affecting local ecosystems and human communities near industrial facilities. Implementing noise reduction measures and strategic placement of equipment can help mitigate these impacts.

Long-term environmental benefits of vacuum pump-supported CO2 capture technologies extend beyond immediate emission reductions. By enabling more efficient and cost-effective carbon capture, these systems contribute to the broader adoption of carbon capture and storage (CCS) technologies across industries. This widespread implementation has the potential to significantly reduce global CO2 emissions, playing a crucial role in meeting climate change mitigation targets and supporting the transition to a low-carbon economy.

In conclusion, while vacuum pumps in CO2 capture technologies offer substantial environmental benefits through improved capture efficiency, a comprehensive assessment must consider the full lifecycle impact, including energy consumption, resource use, and potential local environmental effects. Balancing these factors is crucial for maximizing the positive environmental outcomes of this technology.

Economic Viability Analysis

The economic viability of vacuum pump-supported CO2 capture technologies is a critical factor in their widespread adoption and implementation. Initial capital investments for these systems can be substantial, encompassing the costs of vacuum pumps, capture units, and associated infrastructure. However, the long-term operational benefits often outweigh these upfront expenses.

Energy consumption is a significant consideration in the economic analysis. Vacuum pumps, while requiring electricity to operate, can significantly enhance the efficiency of CO2 capture processes. This improved efficiency translates to reduced energy requirements for the overall capture system, potentially leading to substantial cost savings over time. The exact energy balance and associated costs depend on factors such as the specific capture technology employed, the scale of operations, and local energy prices.

Maintenance and operational costs also play a crucial role in the economic assessment. Vacuum pumps generally have lower maintenance requirements compared to other components in CO2 capture systems, contributing to reduced ongoing expenses. However, regular servicing and occasional part replacements must be factored into the long-term cost projections.

The economic viability is further influenced by the potential revenue streams or cost avoidances associated with captured CO2. In some regions, carbon pricing mechanisms or tax incentives can provide financial benefits for CO2 capture. Additionally, the captured CO2 can be sold for use in various industries, such as enhanced oil recovery or food and beverage production, creating additional revenue opportunities.

Scalability is another important economic consideration. Vacuum pump-supported CO2 capture technologies can often be scaled up or down relatively easily, allowing for flexibility in implementation across different industrial settings. This scalability can lead to economies of scale, potentially reducing per-unit costs as the capture capacity increases.

The economic viability also depends on regulatory environments and policy support. Government incentives, carbon pricing schemes, and emissions reduction mandates can significantly impact the financial attractiveness of these technologies. As global efforts to combat climate change intensify, the economic case for CO2 capture technologies is likely to strengthen.

In conclusion, while the initial investment in vacuum pump-supported CO2 capture technologies can be significant, the long-term economic benefits, including improved efficiency, reduced operational costs, and potential revenue streams, make them an increasingly viable option for industries seeking to reduce their carbon footprint.

Energy consumption is a significant consideration in the economic analysis. Vacuum pumps, while requiring electricity to operate, can significantly enhance the efficiency of CO2 capture processes. This improved efficiency translates to reduced energy requirements for the overall capture system, potentially leading to substantial cost savings over time. The exact energy balance and associated costs depend on factors such as the specific capture technology employed, the scale of operations, and local energy prices.

Maintenance and operational costs also play a crucial role in the economic assessment. Vacuum pumps generally have lower maintenance requirements compared to other components in CO2 capture systems, contributing to reduced ongoing expenses. However, regular servicing and occasional part replacements must be factored into the long-term cost projections.

The economic viability is further influenced by the potential revenue streams or cost avoidances associated with captured CO2. In some regions, carbon pricing mechanisms or tax incentives can provide financial benefits for CO2 capture. Additionally, the captured CO2 can be sold for use in various industries, such as enhanced oil recovery or food and beverage production, creating additional revenue opportunities.

Scalability is another important economic consideration. Vacuum pump-supported CO2 capture technologies can often be scaled up or down relatively easily, allowing for flexibility in implementation across different industrial settings. This scalability can lead to economies of scale, potentially reducing per-unit costs as the capture capacity increases.

The economic viability also depends on regulatory environments and policy support. Government incentives, carbon pricing schemes, and emissions reduction mandates can significantly impact the financial attractiveness of these technologies. As global efforts to combat climate change intensify, the economic case for CO2 capture technologies is likely to strengthen.

In conclusion, while the initial investment in vacuum pump-supported CO2 capture technologies can be significant, the long-term economic benefits, including improved efficiency, reduced operational costs, and potential revenue streams, make them an increasingly viable option for industries seeking to reduce their carbon footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!