How Vacuum Pumps Support High-Efficiency Enzyme Production

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Technology in Enzyme Production

Vacuum pump technology plays a crucial role in enhancing the efficiency of enzyme production processes. These pumps create and maintain low-pressure environments, which are essential for various stages of enzyme manufacturing. The primary function of vacuum pumps in this context is to remove air and other gases from reaction vessels, fermentation tanks, and processing equipment.

In enzyme production, vacuum pumps are utilized for several key purposes. Firstly, they aid in the concentration of enzyme solutions by facilitating the evaporation of water at lower temperatures. This gentle concentration method helps preserve the integrity and activity of enzymes, which are often sensitive to high temperatures. Secondly, vacuum pumps assist in the separation and purification of enzymes from reaction mixtures, enabling more efficient extraction and isolation of the desired products.

The technology also supports the drying of enzyme preparations, a critical step in producing stable, long-lasting enzyme powders. By reducing the pressure in drying chambers, vacuum pumps allow for the removal of moisture at lower temperatures, minimizing thermal degradation of the enzymes. This results in higher-quality final products with improved shelf life and activity.

Furthermore, vacuum pumps contribute to the creation of anaerobic conditions necessary for certain fermentation processes. By removing oxygen from fermentation tanks, these pumps help maintain optimal growth conditions for microorganisms producing specific enzymes. This controlled environment leads to higher yields and more consistent enzyme production.

In recent years, advancements in vacuum pump technology have led to the development of more efficient and specialized pumps for enzyme production. Oil-free and dry-running pumps have gained popularity due to their ability to maintain a clean processing environment, crucial for pharmaceutical-grade enzyme production. These pumps eliminate the risk of oil contamination, ensuring the purity of the final enzyme products.

Energy efficiency has also become a focus in vacuum pump design for enzyme production. Modern pumps incorporate variable speed drives and intelligent control systems, allowing for precise adjustment of vacuum levels and energy consumption based on process requirements. This optimization not only reduces operating costs but also contributes to more sustainable manufacturing practices in the enzyme industry.

As enzyme production continues to grow in importance across various sectors, including food processing, biofuels, and pharmaceuticals, the role of vacuum pump technology becomes increasingly significant. Ongoing research and development in this field aim to further enhance pump performance, reliability, and compatibility with specific enzyme production processes, driving innovation in both pump design and enzyme manufacturing techniques.

In enzyme production, vacuum pumps are utilized for several key purposes. Firstly, they aid in the concentration of enzyme solutions by facilitating the evaporation of water at lower temperatures. This gentle concentration method helps preserve the integrity and activity of enzymes, which are often sensitive to high temperatures. Secondly, vacuum pumps assist in the separation and purification of enzymes from reaction mixtures, enabling more efficient extraction and isolation of the desired products.

The technology also supports the drying of enzyme preparations, a critical step in producing stable, long-lasting enzyme powders. By reducing the pressure in drying chambers, vacuum pumps allow for the removal of moisture at lower temperatures, minimizing thermal degradation of the enzymes. This results in higher-quality final products with improved shelf life and activity.

Furthermore, vacuum pumps contribute to the creation of anaerobic conditions necessary for certain fermentation processes. By removing oxygen from fermentation tanks, these pumps help maintain optimal growth conditions for microorganisms producing specific enzymes. This controlled environment leads to higher yields and more consistent enzyme production.

In recent years, advancements in vacuum pump technology have led to the development of more efficient and specialized pumps for enzyme production. Oil-free and dry-running pumps have gained popularity due to their ability to maintain a clean processing environment, crucial for pharmaceutical-grade enzyme production. These pumps eliminate the risk of oil contamination, ensuring the purity of the final enzyme products.

Energy efficiency has also become a focus in vacuum pump design for enzyme production. Modern pumps incorporate variable speed drives and intelligent control systems, allowing for precise adjustment of vacuum levels and energy consumption based on process requirements. This optimization not only reduces operating costs but also contributes to more sustainable manufacturing practices in the enzyme industry.

As enzyme production continues to grow in importance across various sectors, including food processing, biofuels, and pharmaceuticals, the role of vacuum pump technology becomes increasingly significant. Ongoing research and development in this field aim to further enhance pump performance, reliability, and compatibility with specific enzyme production processes, driving innovation in both pump design and enzyme manufacturing techniques.

Market Demand for Efficient Enzyme Manufacturing

The enzyme manufacturing industry has witnessed significant growth in recent years, driven by increasing demand across various sectors such as food and beverages, pharmaceuticals, biofuels, and industrial applications. The global enzyme market is experiencing robust expansion, with a particular emphasis on efficient production methods to meet the rising demand while maintaining cost-effectiveness and sustainability.

In the food and beverage sector, enzymes play a crucial role in improving product quality, enhancing flavors, and extending shelf life. The growing consumer preference for natural and clean-label products has further boosted the demand for enzymes as alternatives to synthetic additives. This trend is expected to continue, creating a substantial market for efficient enzyme manufacturing processes.

The pharmaceutical industry represents another major driver for enzyme demand, particularly in the production of biopharmaceuticals and diagnostic tools. As personalized medicine and targeted therapies gain traction, the need for specialized enzymes in drug development and production is increasing. This sector requires high-purity enzymes produced through efficient and controlled processes, emphasizing the importance of advanced manufacturing techniques.

Biofuel production has emerged as a significant market for enzymes, with cellulases and amylases being key components in the conversion of biomass to ethanol and other biofuels. As governments worldwide push for renewable energy sources, the demand for these enzymes is projected to grow, necessitating more efficient production methods to meet large-scale requirements.

Industrial applications, including textile processing, paper and pulp production, and waste management, also contribute to the increasing demand for enzymes. These sectors are continuously seeking ways to reduce energy consumption, minimize environmental impact, and improve process efficiency, all of which can be achieved through the use of enzymes.

The market demand for efficient enzyme manufacturing is further intensified by the need for cost reduction in enzyme production. As enzymes find applications in more diverse fields, manufacturers are under pressure to develop scalable and economical production processes. This has led to a growing interest in technologies that can enhance enzyme yield, improve purity, and reduce production time and costs.

Sustainability considerations are also shaping the market demand for efficient enzyme manufacturing. Industries are increasingly looking for eco-friendly alternatives to chemical processes, and enzymes offer a promising solution. However, to make enzyme use more widespread and economically viable, production methods need to be optimized for energy efficiency and reduced environmental impact.

In the food and beverage sector, enzymes play a crucial role in improving product quality, enhancing flavors, and extending shelf life. The growing consumer preference for natural and clean-label products has further boosted the demand for enzymes as alternatives to synthetic additives. This trend is expected to continue, creating a substantial market for efficient enzyme manufacturing processes.

The pharmaceutical industry represents another major driver for enzyme demand, particularly in the production of biopharmaceuticals and diagnostic tools. As personalized medicine and targeted therapies gain traction, the need for specialized enzymes in drug development and production is increasing. This sector requires high-purity enzymes produced through efficient and controlled processes, emphasizing the importance of advanced manufacturing techniques.

Biofuel production has emerged as a significant market for enzymes, with cellulases and amylases being key components in the conversion of biomass to ethanol and other biofuels. As governments worldwide push for renewable energy sources, the demand for these enzymes is projected to grow, necessitating more efficient production methods to meet large-scale requirements.

Industrial applications, including textile processing, paper and pulp production, and waste management, also contribute to the increasing demand for enzymes. These sectors are continuously seeking ways to reduce energy consumption, minimize environmental impact, and improve process efficiency, all of which can be achieved through the use of enzymes.

The market demand for efficient enzyme manufacturing is further intensified by the need for cost reduction in enzyme production. As enzymes find applications in more diverse fields, manufacturers are under pressure to develop scalable and economical production processes. This has led to a growing interest in technologies that can enhance enzyme yield, improve purity, and reduce production time and costs.

Sustainability considerations are also shaping the market demand for efficient enzyme manufacturing. Industries are increasingly looking for eco-friendly alternatives to chemical processes, and enzymes offer a promising solution. However, to make enzyme use more widespread and economically viable, production methods need to be optimized for energy efficiency and reduced environmental impact.

Current Challenges in Vacuum-Assisted Enzyme Production

Vacuum-assisted enzyme production has revolutionized the biotechnology industry, offering significant improvements in yield and efficiency. However, several challenges persist in this field, hindering the full realization of its potential. One of the primary issues is maintaining optimal vacuum conditions throughout the production process. Fluctuations in vacuum levels can lead to inconsistent enzyme activity and reduced product quality.

Another challenge lies in the scalability of vacuum systems for large-scale enzyme production. As production volumes increase, maintaining uniform vacuum distribution across larger reactors becomes increasingly difficult. This can result in uneven enzyme production rates and compromised product consistency, particularly in continuous flow systems.

The energy consumption of vacuum pumps presents a significant hurdle in achieving sustainable enzyme production. High-efficiency vacuum pumps often require substantial power input, which can offset the energy savings gained from improved enzyme yields. Balancing energy efficiency with vacuum performance remains a critical challenge for manufacturers.

Contamination control is another crucial concern in vacuum-assisted enzyme production. The vacuum environment can potentially introduce contaminants or facilitate the growth of unwanted microorganisms, compromising the purity of the final enzyme product. Developing effective filtration and sterilization methods compatible with vacuum systems is an ongoing challenge.

The sensitivity of certain enzymes to vacuum conditions poses additional complications. Some enzymes may denature or lose activity when exposed to extreme low pressures, limiting the applicability of vacuum-assisted production for these sensitive biomolecules. Identifying optimal vacuum ranges for different enzyme classes and developing protective strategies are areas requiring further research.

Maintenance and downtime of vacuum systems also present operational challenges. Vacuum pumps require regular servicing to maintain peak performance, and any equipment failure can lead to significant production disruptions. Minimizing maintenance requirements and improving the reliability of vacuum systems are crucial for ensuring continuous, high-efficiency enzyme production.

Lastly, the integration of vacuum technology with other process intensification methods, such as immobilized enzyme reactors or membrane separation systems, presents both opportunities and challenges. While these combinations can potentially enhance overall process efficiency, they also introduce additional complexity in system design and control, requiring sophisticated engineering solutions to optimize their synergistic effects.

Another challenge lies in the scalability of vacuum systems for large-scale enzyme production. As production volumes increase, maintaining uniform vacuum distribution across larger reactors becomes increasingly difficult. This can result in uneven enzyme production rates and compromised product consistency, particularly in continuous flow systems.

The energy consumption of vacuum pumps presents a significant hurdle in achieving sustainable enzyme production. High-efficiency vacuum pumps often require substantial power input, which can offset the energy savings gained from improved enzyme yields. Balancing energy efficiency with vacuum performance remains a critical challenge for manufacturers.

Contamination control is another crucial concern in vacuum-assisted enzyme production. The vacuum environment can potentially introduce contaminants or facilitate the growth of unwanted microorganisms, compromising the purity of the final enzyme product. Developing effective filtration and sterilization methods compatible with vacuum systems is an ongoing challenge.

The sensitivity of certain enzymes to vacuum conditions poses additional complications. Some enzymes may denature or lose activity when exposed to extreme low pressures, limiting the applicability of vacuum-assisted production for these sensitive biomolecules. Identifying optimal vacuum ranges for different enzyme classes and developing protective strategies are areas requiring further research.

Maintenance and downtime of vacuum systems also present operational challenges. Vacuum pumps require regular servicing to maintain peak performance, and any equipment failure can lead to significant production disruptions. Minimizing maintenance requirements and improving the reliability of vacuum systems are crucial for ensuring continuous, high-efficiency enzyme production.

Lastly, the integration of vacuum technology with other process intensification methods, such as immobilized enzyme reactors or membrane separation systems, presents both opportunities and challenges. While these combinations can potentially enhance overall process efficiency, they also introduce additional complexity in system design and control, requiring sophisticated engineering solutions to optimize their synergistic effects.

Existing Vacuum Solutions for Enzyme Production

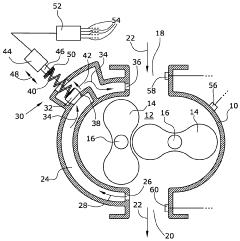

01 Improved rotor design for vacuum pumps

Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can lead to better performance and higher vacuum levels.- Improved rotor design for vacuum pumps: Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can lead to better performance and higher vacuum levels.

- Innovative sealing mechanisms: Developing new sealing mechanisms or improving existing ones can greatly enhance vacuum pump efficiency. Effective seals prevent leakage, maintain vacuum integrity, and reduce power consumption. This may involve using advanced materials, precision engineering, or novel sealing techniques to minimize friction and wear while maximizing sealing effectiveness.

- Energy-efficient motor and drive systems: Incorporating energy-efficient motors and drive systems can significantly improve the overall efficiency of vacuum pumps. This includes using variable speed drives, high-efficiency electric motors, and intelligent control systems that optimize power consumption based on the required vacuum level and operating conditions.

- Advanced cooling and lubrication techniques: Implementing improved cooling and lubrication systems can enhance vacuum pump efficiency by reducing friction, preventing overheating, and extending component life. This may involve using innovative cooling designs, advanced lubricants, or oil-free technologies to minimize energy loss and maintenance requirements.

- Optimized pump chamber geometry: Refining the geometry of the pump chamber can lead to increased efficiency in vacuum pumps. This includes optimizing the shape and dimensions of the chamber to improve gas flow, reduce turbulence, and enhance compression ratios. Advanced computational fluid dynamics simulations can be used to design more efficient pump chamber configurations.

02 Innovative sealing mechanisms

Developing new sealing mechanisms or improving existing ones can boost vacuum pump efficiency. Effective seals prevent leakage, maintain vacuum integrity, and reduce power consumption. This may involve using advanced materials, precision engineering, or novel sealing techniques to minimize friction and wear while maximizing pump performance.Expand Specific Solutions03 Energy-efficient motor and drive systems

Incorporating energy-efficient motors and drive systems can greatly enhance vacuum pump efficiency. This includes using variable speed drives, high-efficiency electric motors, and intelligent control systems that optimize power consumption based on demand. Such improvements can lead to significant energy savings and improved overall pump performance.Expand Specific Solutions04 Advanced cooling and lubrication techniques

Implementing advanced cooling and lubrication systems can improve vacuum pump efficiency by reducing heat generation and minimizing friction. This may involve using innovative cooling methods, high-performance lubricants, or self-lubricating materials to extend pump life, reduce maintenance, and enhance overall efficiency.Expand Specific Solutions05 Optimized pump chamber geometry

Refining the pump chamber geometry can lead to improved vacuum pump efficiency. This includes optimizing the shape and dimensions of the chamber to reduce dead space, improve gas flow dynamics, and enhance compression ratios. Advanced computational fluid dynamics simulations can be used to design more efficient pump chambers.Expand Specific Solutions

Key Players in Vacuum Pump and Enzyme Industries

The vacuum pump industry supporting high-efficiency enzyme production is in a mature stage, with a well-established global market. The technology has reached a high level of sophistication, as evidenced by the presence of major players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Leybold AG. These companies offer advanced vacuum solutions for various applications, including enzyme production. The market size is substantial, driven by increasing demand in biotechnology and pharmaceutical sectors. Companies such as Oerlikon Leybold Vacuum and Ateliers Busch SA are continuously innovating to improve pump efficiency and reliability, indicating ongoing technological advancements in this field.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for high-efficiency enzyme production. Their GXS dry screw vacuum pumps offer oil-free operation, crucial for maintaining product purity in enzyme manufacturing[1]. These pumps provide consistent vacuum levels, essential for optimal enzyme activity and yield. Edwards has also introduced intelligent pump control systems that automatically adjust vacuum levels based on real-time process requirements, enhancing energy efficiency and process control[2]. Their latest innovation includes the integration of IoT capabilities, allowing for predictive maintenance and remote monitoring, which significantly reduces downtime in enzyme production facilities[3].

Strengths: Oil-free operation ensures product purity; Intelligent control systems optimize energy efficiency; IoT integration enables predictive maintenance. Weaknesses: Higher initial investment compared to traditional pumps; May require specialized training for operators.

Oerlikon Leybold Vacuum

Technical Solution: Oerlikon Leybold Vacuum has developed the DRYVAC series, specifically designed for demanding processes like enzyme production. These pumps utilize a unique screw technology that provides high pumping speeds and deep ultimate pressures, crucial for maintaining optimal conditions in enzyme reactors[4]. The DRYVAC pumps feature a corrosion-resistant design, allowing them to handle aggressive vapors often present in biochemical processes. Leybold has also implemented an advanced heat management system in these pumps, ensuring stable operation even under high-load conditions typical in industrial enzyme production[5]. Additionally, their pumps incorporate a smart monitoring system that provides real-time data on pump performance and process conditions, enabling proactive maintenance and process optimization[6].

Strengths: Corrosion-resistant design suitable for aggressive environments; Advanced heat management for stable operation; Smart monitoring system for process optimization. Weaknesses: May have higher power consumption compared to some competitors; Specialized maintenance required.

Innovations in Vacuum Technology for Bioprocessing

Use of spectroscopic techniques to monitor and control reactant gas input into a pre-pump reactive gas injection system

PatentActiveEP1960648A2

Innovation

- A system with a reactant gas injector and sensors to measure gas concentrations upstream and downstream of devices in the vacuum exhaust path, controlling the reactant gas flow based on concentration differences to prevent deposit formation, using techniques like infrared spectroscopy to optimize the use of fluorine or other reactive gases.

Vacuum pump, and method for operating a vacuum pump

PatentWO2009074408A2

Innovation

- A controllable valve device in the flow channel, connected to a control device that adjusts based on pump parameters like time, temperature, and pressure, allowing for increased differential pressures without overheating, utilizing an electric servomotor to vary the spring force and control the valve position.

Environmental Impact of Vacuum-Based Enzyme Production

The environmental impact of vacuum-based enzyme production is a critical consideration in the biotechnology industry. This process, while highly efficient, has both positive and negative implications for the environment. One of the primary benefits is the reduced energy consumption compared to traditional enzyme production methods. Vacuum pumps enable lower operating temperatures and pressures, which translates to significant energy savings and a smaller carbon footprint.

Furthermore, vacuum-based enzyme production often results in higher product yields and purity. This efficiency means less waste generation and fewer resources consumed per unit of enzyme produced. The reduced waste output not only minimizes the environmental burden but also decreases the need for extensive waste treatment processes, which can be energy-intensive and potentially polluting.

However, the use of vacuum pumps is not without environmental concerns. The operation of these pumps requires electricity, which, depending on the energy source, may contribute to greenhouse gas emissions. Additionally, the production and disposal of vacuum pump equipment and components can have environmental implications, particularly if not managed responsibly.

Water usage is another important factor to consider. While vacuum-based processes generally require less water than conventional methods, the water that is used may need specialized treatment before release, especially if it contains trace amounts of enzymes or other biological materials. Proper water management and recycling systems can help mitigate this impact.

The chemicals used in vacuum-based enzyme production, including solvents and cleaning agents, also warrant attention. These substances must be carefully handled and disposed of to prevent environmental contamination. Many facilities are adopting green chemistry principles to reduce the use of harmful chemicals and implement more environmentally friendly alternatives.

Noise pollution is an often-overlooked environmental aspect of vacuum pump operation. Industrial-scale vacuum systems can generate significant noise, which may affect local ecosystems and communities if not properly managed through sound insulation and strategic facility design.

On a broader scale, the adoption of vacuum-based enzyme production can lead to more sustainable practices in various industries that utilize enzymes. For instance, in the textile, food, and biofuel sectors, enzymes produced through this efficient method can replace more environmentally harmful chemical processes, contributing to overall industrial sustainability.

In conclusion, while vacuum-based enzyme production offers substantial environmental benefits through energy efficiency and waste reduction, it is crucial to address and mitigate its potential negative impacts. Continuous improvement in technology, responsible resource management, and adherence to environmental best practices are essential to maximize the sustainability of this production method.

Furthermore, vacuum-based enzyme production often results in higher product yields and purity. This efficiency means less waste generation and fewer resources consumed per unit of enzyme produced. The reduced waste output not only minimizes the environmental burden but also decreases the need for extensive waste treatment processes, which can be energy-intensive and potentially polluting.

However, the use of vacuum pumps is not without environmental concerns. The operation of these pumps requires electricity, which, depending on the energy source, may contribute to greenhouse gas emissions. Additionally, the production and disposal of vacuum pump equipment and components can have environmental implications, particularly if not managed responsibly.

Water usage is another important factor to consider. While vacuum-based processes generally require less water than conventional methods, the water that is used may need specialized treatment before release, especially if it contains trace amounts of enzymes or other biological materials. Proper water management and recycling systems can help mitigate this impact.

The chemicals used in vacuum-based enzyme production, including solvents and cleaning agents, also warrant attention. These substances must be carefully handled and disposed of to prevent environmental contamination. Many facilities are adopting green chemistry principles to reduce the use of harmful chemicals and implement more environmentally friendly alternatives.

Noise pollution is an often-overlooked environmental aspect of vacuum pump operation. Industrial-scale vacuum systems can generate significant noise, which may affect local ecosystems and communities if not properly managed through sound insulation and strategic facility design.

On a broader scale, the adoption of vacuum-based enzyme production can lead to more sustainable practices in various industries that utilize enzymes. For instance, in the textile, food, and biofuel sectors, enzymes produced through this efficient method can replace more environmentally harmful chemical processes, contributing to overall industrial sustainability.

In conclusion, while vacuum-based enzyme production offers substantial environmental benefits through energy efficiency and waste reduction, it is crucial to address and mitigate its potential negative impacts. Continuous improvement in technology, responsible resource management, and adherence to environmental best practices are essential to maximize the sustainability of this production method.

Cost-Benefit Analysis of Vacuum Technology in Bioprocessing

The implementation of vacuum technology in bioprocessing, particularly in enzyme production, presents a complex cost-benefit scenario that requires careful analysis. Initial investment in vacuum pump systems can be substantial, encompassing equipment costs, installation, and integration into existing production lines. However, these upfront expenses are often offset by long-term operational benefits and increased productivity.

Vacuum pumps contribute significantly to process efficiency by facilitating faster drying times, lower processing temperatures, and reduced oxygen exposure. These factors collectively lead to higher enzyme yields and improved product quality. The accelerated production cycles enabled by vacuum technology translate to increased throughput, potentially boosting overall revenue and market competitiveness.

Energy consumption is a critical consideration in the cost-benefit equation. While vacuum pumps require electricity to operate, they often lead to net energy savings in the broader production process. By allowing for lower temperature operations, vacuum systems can substantially reduce heating and cooling costs, which typically constitute a significant portion of bioprocessing energy expenditure.

Maintenance costs for vacuum systems should be factored into the analysis. Regular servicing and occasional part replacements are necessary to ensure optimal performance and longevity of the equipment. However, these costs are generally outweighed by the reduction in product loss and improved consistency in enzyme quality, which vacuum technology facilitates.

The implementation of vacuum technology can also lead to savings in raw material costs. By enabling more efficient extraction and purification processes, vacuum pumps can reduce the amount of solvents and other chemicals required in enzyme production. This not only decreases direct material costs but also minimizes waste treatment expenses.

From a regulatory perspective, the use of vacuum technology can aid in compliance with stringent quality standards. The controlled environment provided by vacuum systems helps in maintaining product integrity and reduces the risk of contamination. This can lead to fewer batch rejections and recalls, thereby avoiding potential financial losses and reputational damage.

In conclusion, while the initial investment in vacuum technology for enzyme production may be significant, the long-term benefits in terms of increased efficiency, reduced operational costs, and improved product quality often justify the expenditure. Companies must conduct thorough analyses of their specific production processes, scale, and market demands to accurately assess the return on investment and determine the optimal implementation strategy for vacuum technology in their bioprocessing operations.

Vacuum pumps contribute significantly to process efficiency by facilitating faster drying times, lower processing temperatures, and reduced oxygen exposure. These factors collectively lead to higher enzyme yields and improved product quality. The accelerated production cycles enabled by vacuum technology translate to increased throughput, potentially boosting overall revenue and market competitiveness.

Energy consumption is a critical consideration in the cost-benefit equation. While vacuum pumps require electricity to operate, they often lead to net energy savings in the broader production process. By allowing for lower temperature operations, vacuum systems can substantially reduce heating and cooling costs, which typically constitute a significant portion of bioprocessing energy expenditure.

Maintenance costs for vacuum systems should be factored into the analysis. Regular servicing and occasional part replacements are necessary to ensure optimal performance and longevity of the equipment. However, these costs are generally outweighed by the reduction in product loss and improved consistency in enzyme quality, which vacuum technology facilitates.

The implementation of vacuum technology can also lead to savings in raw material costs. By enabling more efficient extraction and purification processes, vacuum pumps can reduce the amount of solvents and other chemicals required in enzyme production. This not only decreases direct material costs but also minimizes waste treatment expenses.

From a regulatory perspective, the use of vacuum technology can aid in compliance with stringent quality standards. The controlled environment provided by vacuum systems helps in maintaining product integrity and reduces the risk of contamination. This can lead to fewer batch rejections and recalls, thereby avoiding potential financial losses and reputational damage.

In conclusion, while the initial investment in vacuum technology for enzyme production may be significant, the long-term benefits in terms of increased efficiency, reduced operational costs, and improved product quality often justify the expenditure. Companies must conduct thorough analyses of their specific production processes, scale, and market demands to accurately assess the return on investment and determine the optimal implementation strategy for vacuum technology in their bioprocessing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!