How Vacuum Pumps Support Integrated Optical Circuit Production

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech in IOC Production

Vacuum pumps play a crucial role in the production of integrated optical circuits (IOCs), serving as essential components in various stages of the manufacturing process. These pumps create and maintain the necessary vacuum environments that are vital for the precision and quality required in IOC fabrication.

The evolution of vacuum pump technology in IOC production has been closely tied to the advancements in semiconductor and photonics industries. Early vacuum systems were primarily mechanical, utilizing rotary vane or piston pumps. However, as the demands for cleaner and more stable vacuum environments increased, more sophisticated technologies emerged.

In modern IOC production, several types of vacuum pumps are employed, each serving specific purposes. Turbomolecular pumps, for instance, are widely used for achieving high and ultra-high vacuum levels. These pumps operate on the principle of momentum transfer, where rapidly spinning blades impart momentum to gas molecules, directing them towards the exhaust.

Cryogenic pumps, another critical technology in IOC manufacturing, work by condensing gases onto extremely cold surfaces. This method is particularly effective for removing water vapor and other condensable gases, which are detrimental to the IOC production process.

Dry pumps have gained significant traction in recent years due to their oil-free operation, which minimizes contamination risks. These pumps use a series of rotating screws or scrolls to compress and expel gases, making them ideal for processes that require high cleanliness standards.

The integration of smart technologies and Industry 4.0 principles has led to the development of vacuum pumps with advanced monitoring and control capabilities. These systems can now provide real-time data on pressure levels, pump performance, and maintenance needs, ensuring optimal operation and minimizing downtime in IOC production lines.

As IOC manufacturing techniques continue to evolve, demanding ever-higher precision and purity levels, vacuum pump technology is expected to advance further. Future developments may include more energy-efficient designs, improved materials for pump components, and enhanced integration with other process control systems in IOC fabrication facilities.

The evolution of vacuum pump technology in IOC production has been closely tied to the advancements in semiconductor and photonics industries. Early vacuum systems were primarily mechanical, utilizing rotary vane or piston pumps. However, as the demands for cleaner and more stable vacuum environments increased, more sophisticated technologies emerged.

In modern IOC production, several types of vacuum pumps are employed, each serving specific purposes. Turbomolecular pumps, for instance, are widely used for achieving high and ultra-high vacuum levels. These pumps operate on the principle of momentum transfer, where rapidly spinning blades impart momentum to gas molecules, directing them towards the exhaust.

Cryogenic pumps, another critical technology in IOC manufacturing, work by condensing gases onto extremely cold surfaces. This method is particularly effective for removing water vapor and other condensable gases, which are detrimental to the IOC production process.

Dry pumps have gained significant traction in recent years due to their oil-free operation, which minimizes contamination risks. These pumps use a series of rotating screws or scrolls to compress and expel gases, making them ideal for processes that require high cleanliness standards.

The integration of smart technologies and Industry 4.0 principles has led to the development of vacuum pumps with advanced monitoring and control capabilities. These systems can now provide real-time data on pressure levels, pump performance, and maintenance needs, ensuring optimal operation and minimizing downtime in IOC production lines.

As IOC manufacturing techniques continue to evolve, demanding ever-higher precision and purity levels, vacuum pump technology is expected to advance further. Future developments may include more energy-efficient designs, improved materials for pump components, and enhanced integration with other process control systems in IOC fabrication facilities.

Market Demand for IOC

The market demand for Integrated Optical Circuits (IOCs) has been experiencing significant growth in recent years, driven by the increasing need for high-speed data transmission and processing in various industries. The telecommunications sector, in particular, has been a major driver of IOC adoption, as optical networks continue to expand and upgrade to meet the growing bandwidth requirements of 5G and future 6G technologies.

The data center industry has also emerged as a key market for IOCs, with the rapid growth of cloud computing and big data applications necessitating faster and more efficient data processing and transmission solutions. IOCs offer advantages in terms of reduced power consumption, increased data transfer speeds, and improved signal integrity compared to traditional electronic circuits, making them increasingly attractive for data center operators seeking to optimize their infrastructure.

In the automotive sector, the development of advanced driver assistance systems (ADAS) and autonomous vehicles has created a new demand for IOCs. These applications require high-speed, low-latency data processing capabilities, which IOCs can provide more effectively than conventional electronic circuits. As the automotive industry continues to evolve towards greater electrification and autonomy, the demand for IOCs in this sector is expected to grow substantially.

The aerospace and defense industries have also shown increasing interest in IOCs due to their potential for enhancing communication systems, radar technologies, and other mission-critical applications. The ability of IOCs to operate in harsh environments and their resistance to electromagnetic interference make them particularly suitable for these demanding applications.

In the medical field, IOCs are finding applications in advanced imaging systems, biosensors, and diagnostic tools. The miniaturization and integration capabilities of IOCs allow for the development of more compact and efficient medical devices, contributing to advancements in point-of-care diagnostics and personalized medicine.

The global market for IOCs is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, with Asia-Pacific expected to be the fastest-growing region. This growth is driven by the increasing adoption of IOCs in consumer electronics, particularly in smartphones and wearable devices, as well as the rapid expansion of 5G networks in countries like China and South Korea.

As the demand for IOCs continues to rise, manufacturers are investing in research and development to improve production processes and reduce costs. This includes advancements in vacuum pump technology, which plays a crucial role in the fabrication of IOCs by enabling the creation of the ultra-clean environments necessary for their production.

The data center industry has also emerged as a key market for IOCs, with the rapid growth of cloud computing and big data applications necessitating faster and more efficient data processing and transmission solutions. IOCs offer advantages in terms of reduced power consumption, increased data transfer speeds, and improved signal integrity compared to traditional electronic circuits, making them increasingly attractive for data center operators seeking to optimize their infrastructure.

In the automotive sector, the development of advanced driver assistance systems (ADAS) and autonomous vehicles has created a new demand for IOCs. These applications require high-speed, low-latency data processing capabilities, which IOCs can provide more effectively than conventional electronic circuits. As the automotive industry continues to evolve towards greater electrification and autonomy, the demand for IOCs in this sector is expected to grow substantially.

The aerospace and defense industries have also shown increasing interest in IOCs due to their potential for enhancing communication systems, radar technologies, and other mission-critical applications. The ability of IOCs to operate in harsh environments and their resistance to electromagnetic interference make them particularly suitable for these demanding applications.

In the medical field, IOCs are finding applications in advanced imaging systems, biosensors, and diagnostic tools. The miniaturization and integration capabilities of IOCs allow for the development of more compact and efficient medical devices, contributing to advancements in point-of-care diagnostics and personalized medicine.

The global market for IOCs is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, with Asia-Pacific expected to be the fastest-growing region. This growth is driven by the increasing adoption of IOCs in consumer electronics, particularly in smartphones and wearable devices, as well as the rapid expansion of 5G networks in countries like China and South Korea.

As the demand for IOCs continues to rise, manufacturers are investing in research and development to improve production processes and reduce costs. This includes advancements in vacuum pump technology, which plays a crucial role in the fabrication of IOCs by enabling the creation of the ultra-clean environments necessary for their production.

Vacuum Tech Challenges in IOC

The production of integrated optical circuits (IOCs) faces several critical challenges related to vacuum technology. One of the primary issues is maintaining ultra-high vacuum levels consistently across the entire fabrication process. This is essential for ensuring the purity of materials and preventing contamination that could compromise the performance of the optical circuits.

Achieving and sustaining the required vacuum levels presents significant technical hurdles. The vacuum systems must be capable of reaching pressures as low as 10^-9 to 10^-11 Torr, which demands highly sophisticated pumping technologies. Moreover, these systems need to handle a variety of gases and particles generated during different stages of IOC production, including deposition, etching, and lithography processes.

Another major challenge lies in the precise control of vacuum conditions during material deposition. The vacuum environment directly affects the quality and uniformity of thin films crucial for IOC functionality. Fluctuations in pressure or the presence of residual gases can lead to defects in the deposited layers, impacting the optical properties and overall performance of the circuits.

The integration of vacuum systems with other fabrication equipment poses additional complexities. Vacuum chambers must be designed to accommodate various tools and instruments while maintaining seal integrity. This often requires innovative engineering solutions to ensure compatibility between vacuum components and other process equipment without compromising cleanliness or vacuum performance.

Contamination control remains a persistent challenge in IOC production. Even minute particles or molecular contaminants can cause significant issues in the fabrication of nanoscale optical structures. Vacuum systems must incorporate advanced filtration and purification mechanisms to eliminate potential sources of contamination, including outgassing from chamber materials and backstreaming from pump oils.

Scalability and cost-effectiveness of vacuum technologies present ongoing challenges as the demand for larger and more complex IOCs increases. Developing vacuum systems capable of handling larger wafer sizes and higher throughput while maintaining the required vacuum levels is crucial for the industry's growth. This necessitates continuous innovation in pump designs, chamber configurations, and vacuum control systems.

Lastly, the energy efficiency of vacuum systems in IOC production is an emerging concern. The power consumption of high-performance vacuum pumps can be substantial, contributing significantly to the overall energy footprint of fabrication facilities. Improving the energy efficiency of vacuum technologies without compromising their performance is a key area of focus for sustainable IOC manufacturing.

Achieving and sustaining the required vacuum levels presents significant technical hurdles. The vacuum systems must be capable of reaching pressures as low as 10^-9 to 10^-11 Torr, which demands highly sophisticated pumping technologies. Moreover, these systems need to handle a variety of gases and particles generated during different stages of IOC production, including deposition, etching, and lithography processes.

Another major challenge lies in the precise control of vacuum conditions during material deposition. The vacuum environment directly affects the quality and uniformity of thin films crucial for IOC functionality. Fluctuations in pressure or the presence of residual gases can lead to defects in the deposited layers, impacting the optical properties and overall performance of the circuits.

The integration of vacuum systems with other fabrication equipment poses additional complexities. Vacuum chambers must be designed to accommodate various tools and instruments while maintaining seal integrity. This often requires innovative engineering solutions to ensure compatibility between vacuum components and other process equipment without compromising cleanliness or vacuum performance.

Contamination control remains a persistent challenge in IOC production. Even minute particles or molecular contaminants can cause significant issues in the fabrication of nanoscale optical structures. Vacuum systems must incorporate advanced filtration and purification mechanisms to eliminate potential sources of contamination, including outgassing from chamber materials and backstreaming from pump oils.

Scalability and cost-effectiveness of vacuum technologies present ongoing challenges as the demand for larger and more complex IOCs increases. Developing vacuum systems capable of handling larger wafer sizes and higher throughput while maintaining the required vacuum levels is crucial for the industry's growth. This necessitates continuous innovation in pump designs, chamber configurations, and vacuum control systems.

Lastly, the energy efficiency of vacuum systems in IOC production is an emerging concern. The power consumption of high-performance vacuum pumps can be substantial, contributing significantly to the overall energy footprint of fabrication facilities. Improving the energy efficiency of vacuum technologies without compromising their performance is a key area of focus for sustainable IOC manufacturing.

Current Vacuum Solutions for IOC

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, innovative sealing mechanisms, and optimized fluid flow paths. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed. These pumps are designed to handle specific gases and maintain ultra-high vacuum levels required in semiconductor fabrication. Features may include corrosion-resistant materials, contamination control mechanisms, and integration with process control systems.

- Energy-efficient vacuum pump systems: Innovations in vacuum pump technology have focused on improving energy efficiency. This includes the development of variable speed drives, intelligent control systems, and heat recovery mechanisms. Such advancements help reduce power consumption and operating costs while maintaining optimal performance.

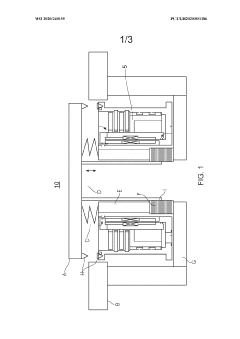

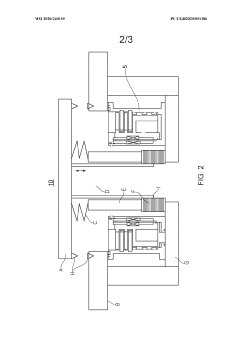

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping efficiency. These configurations typically combine different pump types or multiple pumping stages in series. This approach allows for better gas handling capabilities and the ability to reach lower ultimate pressures.

- Vacuum pump noise reduction techniques: Various methods have been developed to reduce noise levels in vacuum pumps. These techniques include acoustic enclosures, vibration isolation systems, and optimized impeller designs. Such innovations help create quieter working environments and comply with noise regulations in industrial settings.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.Expand Specific Solutions03 Energy-efficient vacuum pump systems

Innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of variable speed drives, optimized motor designs, and intelligent control systems. Such advancements result in reduced power consumption, lower operating costs, and improved environmental sustainability of vacuum pump operations.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping efficiency. These configurations typically combine different pump types or multiple pumping stages in series. This approach allows for better gas handling capabilities, wider operating pressure ranges, and enhanced overall system performance.Expand Specific Solutions05 Vacuum pump monitoring and control systems

Advanced monitoring and control systems have been developed for vacuum pumps to optimize performance and maintenance. These systems incorporate sensors, data analytics, and remote monitoring capabilities. Features may include predictive maintenance algorithms, real-time performance monitoring, and automated adjustment of pump parameters for optimal operation.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump market for integrated optical circuit production is in a growth phase, driven by increasing demand for advanced semiconductor devices. The market size is expanding, with major players like Edwards Ltd., ASML Netherlands BV, and Tokyo Electron Ltd. leading the way. These companies are investing heavily in R&D to improve vacuum pump technology, enhancing efficiency and precision in chip manufacturing processes. The technology is relatively mature but continues to evolve, with companies like Pfeiffer Vacuum GmbH and LEYBOLD AG focusing on innovations to meet the stringent requirements of next-generation optical circuits. As the industry progresses, we can expect further advancements in vacuum pump technology to support the production of more complex and miniaturized integrated optical circuits.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for integrated optical circuit production. Their innovative dry pumps, such as the iXH series, provide high pumping speeds and low power consumption, crucial for maintaining clean and stable vacuum environments in photonics manufacturing processes[1]. These pumps incorporate intelligent control systems that optimize performance and reduce maintenance needs, ensuring consistent vacuum levels during critical deposition and etching steps[2]. Edwards' pumps also feature advanced abatement systems to handle potentially harmful process gases, contributing to both safety and environmental compliance in optical circuit fabrication[3].

Strengths: High pumping efficiency, intelligent control systems, and advanced abatement capabilities. Weaknesses: Potentially higher initial cost compared to traditional pumps, and may require specialized training for operation and maintenance.

ASML Netherlands BV

Technical Solution: ASML, a leader in photolithography systems, integrates advanced vacuum technologies into their EUV (Extreme Ultraviolet) lithography machines for integrated optical circuit production. Their systems utilize specialized vacuum chambers and pumps to maintain the ultra-clean, high-vacuum environment necessary for EUV light generation and precise pattern transfer onto silicon wafers[4]. ASML's vacuum solutions include multi-stage pump systems that achieve and maintain extreme vacuum levels (10^-9 mbar or lower) required for EUV optics[5]. They have also developed innovative vacuum-compatible wafer handling systems that minimize contamination risks during the lithography process, crucial for producing high-performance optical circuits[6].

Strengths: Cutting-edge EUV lithography integration, ultra-high vacuum capabilities, and contamination control. Weaknesses: Extremely high system costs and complexity, limiting accessibility to only the most advanced semiconductor manufacturers.

Innovative Vacuum Tech for IOC

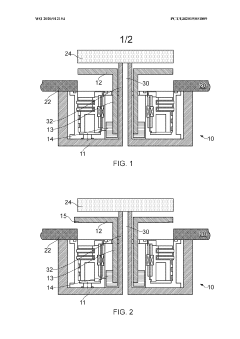

Vacuum pump with through channel and vacuum chamber

PatentWO2020012154A1

Innovation

- A vacuum pump design featuring a rotor, stator, and a controllable valve plate with an axial passage for central substrate mounting and power connections, allowing for uniform gas flow and fast pressure control, along with the option of magnetic levitation for rotor positioning and actuator-controlled axial movement of the valve plate to optimize inlet conductance.

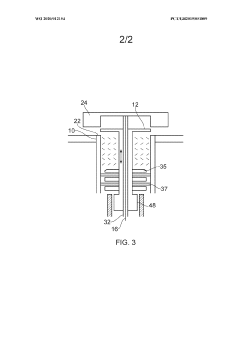

Vacuum assembly and vacuum pump with an axial through passage

PatentWO2020240155A1

Innovation

- A vacuum pump with a hollow shaft defining an axial passage that extends through the pump, allowing the cathode plate to be powered and sealed without disrupting gas flow, eliminating the need for a poppet valve and reducing hardware requirements by using a movable cathode plate for sealing and power supply access.

Environmental Impact of Vacuum

The use of vacuum pumps in integrated optical circuit production has significant environmental implications that warrant careful consideration. The primary environmental impact stems from the energy consumption associated with operating vacuum systems. These pumps require substantial electrical power to maintain the low-pressure environments necessary for various manufacturing processes. As the demand for integrated optical circuits continues to grow, the cumulative energy usage and associated carbon footprint of vacuum pump operations become increasingly significant.

Moreover, the production of vacuum pumps themselves involves resource-intensive processes and materials, contributing to environmental concerns. The manufacturing of precision components, such as rotors, stators, and seals, often requires specialized materials and energy-intensive fabrication techniques. Additionally, the lubricants and working fluids used in some vacuum pump designs may pose environmental risks if not properly managed or disposed of.

Noise pollution is another environmental factor to consider. High-performance vacuum pumps can generate considerable noise levels, potentially affecting the working environment and surrounding areas. This necessitates the implementation of sound insulation measures, which may have their own environmental implications in terms of material usage and energy consumption.

The disposal and recycling of vacuum pump components at the end of their lifecycle present further environmental challenges. Many of these components contain valuable materials that could be reclaimed, but the specialized nature of the equipment often complicates recycling efforts. Improper disposal can lead to soil and water contamination, particularly if pumps contain hazardous materials or lubricants.

On a positive note, the precision enabled by vacuum technology in integrated optical circuit production can lead to more efficient and compact devices. This efficiency can translate to reduced energy consumption and material usage in the final products, potentially offsetting some of the environmental impacts of the manufacturing process. Furthermore, advancements in vacuum pump technology are continually improving energy efficiency and reducing environmental impact.

To mitigate these environmental concerns, manufacturers are increasingly focusing on developing more sustainable vacuum solutions. This includes the design of energy-efficient pumps, the use of environmentally friendly materials and lubricants, and the implementation of comprehensive recycling programs for end-of-life equipment. Additionally, the integration of smart control systems and predictive maintenance techniques can optimize pump operation, further reducing energy consumption and extending equipment lifespan.

Moreover, the production of vacuum pumps themselves involves resource-intensive processes and materials, contributing to environmental concerns. The manufacturing of precision components, such as rotors, stators, and seals, often requires specialized materials and energy-intensive fabrication techniques. Additionally, the lubricants and working fluids used in some vacuum pump designs may pose environmental risks if not properly managed or disposed of.

Noise pollution is another environmental factor to consider. High-performance vacuum pumps can generate considerable noise levels, potentially affecting the working environment and surrounding areas. This necessitates the implementation of sound insulation measures, which may have their own environmental implications in terms of material usage and energy consumption.

The disposal and recycling of vacuum pump components at the end of their lifecycle present further environmental challenges. Many of these components contain valuable materials that could be reclaimed, but the specialized nature of the equipment often complicates recycling efforts. Improper disposal can lead to soil and water contamination, particularly if pumps contain hazardous materials or lubricants.

On a positive note, the precision enabled by vacuum technology in integrated optical circuit production can lead to more efficient and compact devices. This efficiency can translate to reduced energy consumption and material usage in the final products, potentially offsetting some of the environmental impacts of the manufacturing process. Furthermore, advancements in vacuum pump technology are continually improving energy efficiency and reducing environmental impact.

To mitigate these environmental concerns, manufacturers are increasingly focusing on developing more sustainable vacuum solutions. This includes the design of energy-efficient pumps, the use of environmentally friendly materials and lubricants, and the implementation of comprehensive recycling programs for end-of-life equipment. Additionally, the integration of smart control systems and predictive maintenance techniques can optimize pump operation, further reducing energy consumption and extending equipment lifespan.

Cleanroom Requirements for IOC

The production of integrated optical circuits (IOCs) demands an exceptionally clean environment to ensure the highest quality and reliability of the final product. Cleanroom requirements for IOC manufacturing are stringent and multifaceted, encompassing various aspects of environmental control and contamination prevention.

Particle control is paramount in IOC cleanrooms. These facilities typically require Class 100 (ISO 5) or better cleanliness levels, allowing no more than 100 particles of 0.5 microns or larger per cubic foot of air. This level of cleanliness is achieved through a combination of HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filtration systems, which remove 99.99% of airborne particles.

Temperature and humidity control are critical factors in maintaining a stable environment for IOC production. Cleanrooms are typically maintained at a temperature of 20°C ± 0.5°C and relative humidity of 45% ± 5%. These tight tolerances are necessary to prevent thermal expansion or contraction of materials and to avoid moisture-related issues that could affect the delicate optical components.

Airflow management is another crucial aspect of IOC cleanrooms. Unidirectional (laminar) airflow is employed to sweep particles away from the work area and maintain a consistent clean environment. The air change rate in these facilities is typically high, with 60 to 100 air changes per hour to ensure rapid removal of any generated particles.

Electrostatic discharge (ESD) control is essential in IOC cleanrooms to protect sensitive electronic components. This involves the use of ESD-safe flooring, workstations, and tools, as well as requiring personnel to wear ESD-safe garments and follow proper grounding procedures.

Cleanroom garments play a vital role in maintaining cleanliness. Full-body coveralls, hoods, boots, gloves, and face masks are standard requirements for personnel entering the cleanroom. These garments are made from low-particle-shedding materials and are designed to minimize contamination from human sources.

Chemical contamination control is also crucial in IOC production. This involves the use of specialized materials that do not outgas or generate particles, as well as careful control of any chemicals used in the manufacturing process. Fume hoods and specialized exhaust systems are employed to remove any potentially harmful vapors.

Vacuum systems play a significant role in maintaining cleanroom integrity. They are used not only in the production processes but also in contamination control, helping to remove particles and maintain the required pressure differentials between different cleanroom zones.

Regular monitoring and validation of cleanroom conditions are essential to ensure compliance with the strict requirements. This includes particle counting, microbial testing, and continuous monitoring of environmental parameters such as temperature, humidity, and pressure differentials.

Particle control is paramount in IOC cleanrooms. These facilities typically require Class 100 (ISO 5) or better cleanliness levels, allowing no more than 100 particles of 0.5 microns or larger per cubic foot of air. This level of cleanliness is achieved through a combination of HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filtration systems, which remove 99.99% of airborne particles.

Temperature and humidity control are critical factors in maintaining a stable environment for IOC production. Cleanrooms are typically maintained at a temperature of 20°C ± 0.5°C and relative humidity of 45% ± 5%. These tight tolerances are necessary to prevent thermal expansion or contraction of materials and to avoid moisture-related issues that could affect the delicate optical components.

Airflow management is another crucial aspect of IOC cleanrooms. Unidirectional (laminar) airflow is employed to sweep particles away from the work area and maintain a consistent clean environment. The air change rate in these facilities is typically high, with 60 to 100 air changes per hour to ensure rapid removal of any generated particles.

Electrostatic discharge (ESD) control is essential in IOC cleanrooms to protect sensitive electronic components. This involves the use of ESD-safe flooring, workstations, and tools, as well as requiring personnel to wear ESD-safe garments and follow proper grounding procedures.

Cleanroom garments play a vital role in maintaining cleanliness. Full-body coveralls, hoods, boots, gloves, and face masks are standard requirements for personnel entering the cleanroom. These garments are made from low-particle-shedding materials and are designed to minimize contamination from human sources.

Chemical contamination control is also crucial in IOC production. This involves the use of specialized materials that do not outgas or generate particles, as well as careful control of any chemicals used in the manufacturing process. Fume hoods and specialized exhaust systems are employed to remove any potentially harmful vapors.

Vacuum systems play a significant role in maintaining cleanroom integrity. They are used not only in the production processes but also in contamination control, helping to remove particles and maintain the required pressure differentials between different cleanroom zones.

Regular monitoring and validation of cleanroom conditions are essential to ensure compliance with the strict requirements. This includes particle counting, microbial testing, and continuous monitoring of environmental parameters such as temperature, humidity, and pressure differentials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!