Hydrofluoric Acid Methods for High-Precision Glass Cutting

HF Glass Cutting Technology Background and Objectives

Glass cutting technology has evolved significantly over the centuries, from manual scoring and breaking to advanced precision methods. Hydrofluoric acid (HF) based glass cutting represents a specialized chemical approach that emerged in the mid-20th century as an alternative to mechanical methods. This technique leverages the unique property of HF to selectively dissolve silicon dioxide, the primary component of glass, creating precise cuts with minimal mechanical stress on the material.

The evolution of HF glass cutting technology has been driven by increasing demands from industries requiring high-precision glass components, particularly electronics, optics, and semiconductor manufacturing. Traditional mechanical cutting methods often introduce microcracks and edge defects that compromise structural integrity and optical performance. As device miniaturization continues across multiple industries, the need for glass components with pristine edges and complex geometries has intensified.

Current technological trends in HF glass cutting focus on enhancing precision while addressing environmental and safety concerns. The development of controlled etching processes, improved masking techniques, and integration with complementary technologies like laser pre-scoring represent significant advancements. Additionally, research into HF alternatives and concentration optimization aims to maintain cutting quality while reducing hazardous exposure risks.

The primary technical objectives for HF glass cutting development include achieving sub-micron precision for increasingly complex geometries, reducing processing time without compromising quality, and developing environmentally sustainable processes with minimal waste generation. Particular emphasis is placed on creating methods compatible with ultra-thin glass substrates (below 100μm thickness) that are becoming essential in flexible electronics and advanced display technologies.

Another critical objective is the development of automated systems that can maintain consistent quality while reducing human exposure to hazardous chemicals. This includes closed-loop process control systems that can adjust parameters in real-time based on optical inspection feedback, ensuring dimensional accuracy and edge quality across large production volumes.

Looking forward, the integration of HF glass cutting with digital manufacturing paradigms represents a significant technological goal. This includes developing predictive models for etch behavior based on glass composition, temperature, and concentration variables, enabling precise digital process design before physical implementation. Such capabilities would dramatically reduce development cycles for new glass components and enable more complex geometries previously considered unfeasible.

Market Analysis for Precision Glass Processing

The precision glass processing market has experienced significant growth in recent years, driven primarily by increasing demand from electronics, automotive, and architectural industries. The global market for precision glass processing was valued at approximately 12.3 billion USD in 2022 and is projected to reach 18.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 7.2%. This growth trajectory is particularly evident in regions with strong electronics manufacturing bases such as East Asia, North America, and Western Europe.

The electronics sector constitutes the largest market segment, accounting for roughly 42% of the total market share. This dominance is attributed to the escalating demand for smartphones, tablets, and other consumer electronics that require high-precision glass components. The automotive industry follows as the second-largest consumer, representing 27% of the market, with increasing integration of glass displays and sensors in modern vehicles.

Hydrofluoric acid (HF) methods for glass cutting maintain a substantial market presence despite emerging alternative technologies. Approximately 35% of precision glass processing still relies on HF-based techniques due to their cost-effectiveness and established infrastructure. However, this segment is experiencing slower growth (3.5% CAGR) compared to newer laser-based methods (11.2% CAGR).

Market analysis reveals several key trends influencing the precision glass processing landscape. First, there is a growing preference for environmentally friendly processing methods due to stringent regulations regarding HF handling and disposal. Second, manufacturers are increasingly demanding higher precision tolerances to accommodate advanced electronic components and displays. Third, the market is witnessing a shift toward integrated processing solutions that combine multiple techniques to optimize efficiency and quality.

Consumer electronics manufacturers represent the most significant customer segment, with companies like Apple, Samsung, and Huawei collectively accounting for 31% of end-user demand. These companies typically require glass components with tolerances in the micrometer range and exceptional surface quality. The automotive sector's requirements are evolving rapidly, with premium vehicle manufacturers now specifying glass components with similar precision to those used in consumer electronics.

Market forecasts indicate that while HF-based methods will continue to serve specific applications, their overall market share is expected to decline to approximately 22% by 2030. This transition presents both challenges and opportunities for industry participants, particularly those with established expertise in traditional processing methods who must now adapt to changing market demands and environmental considerations.

Current Challenges in HF-Based Glass Cutting

Despite the widespread use of hydrofluoric acid (HF) in glass cutting applications, several significant challenges continue to impede its optimal implementation in high-precision manufacturing environments. The primary concern remains the extreme toxicity of HF, which poses severe health risks to operators. Even at low concentrations, HF can cause deep tissue damage and systemic toxicity through skin absorption, while inhalation of vapors can lead to respiratory damage. These safety concerns necessitate extensive protective measures that increase operational complexity and costs.

Environmental considerations also present substantial challenges. The disposal of HF waste requires specialized neutralization processes to prevent contamination of water systems. Regulatory frameworks governing HF usage have become increasingly stringent worldwide, with some regions implementing restrictions that complicate manufacturing operations and supply chain logistics.

From a technical perspective, the etching process itself exhibits inherent limitations affecting precision. The isotropic nature of HF etching makes it difficult to achieve highly directional cuts with perfectly vertical sidewalls, which is particularly problematic for applications requiring nanometer-scale precision. Additionally, the etching rate can be inconsistent across different glass compositions, leading to unpredictable results when processing specialized or composite glass materials.

Quality control presents another significant hurdle. The chemical etching process can introduce surface roughness and micro-cracks that compromise the structural integrity and optical properties of the final product. These defects are often difficult to detect during production but can lead to product failures in the field.

The time-intensive nature of HF etching processes also conflicts with modern manufacturing demands for high throughput. Complete etching cycles can require hours or even days depending on glass thickness and desired cut quality, creating production bottlenecks that are increasingly unacceptable in competitive manufacturing environments.

Temperature sensitivity further complicates process control, as etching rates vary significantly with even minor temperature fluctuations. This necessitates sophisticated temperature regulation systems that add complexity and cost to manufacturing setups.

Recent industry trends toward thinner, stronger, and more specialized glass formulations have exacerbated these challenges. Many newer glass compositions, particularly those incorporating rare earth elements or specialized coatings, respond unpredictably to traditional HF etching methods, requiring extensive process recalibration and testing.

Current HF Glass Cutting Methodologies

01 Chemical etching with hydrofluoric acid

Hydrofluoric acid is used as a primary chemical agent for high-precision glass cutting through controlled etching processes. The acid selectively dissolves silica in glass, allowing for precise cutting patterns. The concentration of the acid, exposure time, and temperature are critical parameters that affect the precision and quality of the cut. This method is particularly effective for creating complex shapes and patterns in glass substrates that would be difficult to achieve with mechanical methods.- Chemical etching with hydrofluoric acid: Hydrofluoric acid is used as a primary chemical agent for high-precision glass cutting through controlled etching processes. The acid selectively dissolves the silica in glass, allowing for precise cutting patterns. The concentration of the acid, exposure time, and temperature are critical parameters that affect the precision and quality of the cut. This method is particularly useful for creating complex shapes and patterns in glass substrates that would be difficult to achieve with mechanical cutting methods.

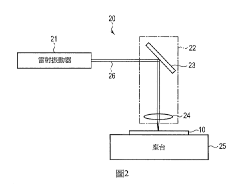

- Laser-assisted hydrofluoric acid cutting: This technique combines laser technology with hydrofluoric acid etching to achieve high-precision glass cutting. The laser creates microscopic cracks or modifies the glass surface structure in specific patterns, which are then selectively etched by hydrofluoric acid. This hybrid approach allows for more controlled and precise cutting than using acid alone, especially for thick glass or when creating intricate designs. The method reduces the amount of acid needed and improves the overall precision of the cutting process.

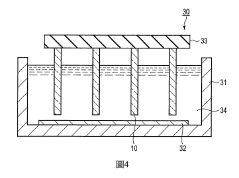

- Masking techniques for selective etching: Masking techniques are employed to protect specific areas of glass from hydrofluoric acid exposure, enabling selective etching for high-precision cutting. Various masking materials such as photoresists, waxes, or polymer films are applied to the glass surface before acid treatment. The mask patterns can be created using photolithography or other patterning methods to achieve precise geometries. After etching, the masks are removed, revealing the precisely cut glass structures. This approach is particularly valuable for manufacturing microfluidic devices, optical components, and semiconductor substrates.

- Temperature-controlled etching processes: Temperature control during hydrofluoric acid etching significantly impacts the precision of glass cutting. By carefully regulating the temperature of the acid solution and the glass substrate, the etching rate and uniformity can be optimized. Lower temperatures generally provide slower but more controlled etching, while higher temperatures increase the reaction rate but may reduce precision. Advanced temperature-controlled systems use thermostatic baths, cooling systems, or heated chambers to maintain optimal conditions throughout the etching process, resulting in higher precision cuts with smoother edges.

- Automated systems for precision hydrofluoric acid cutting: Automated systems have been developed to enhance the precision and safety of hydrofluoric acid glass cutting processes. These systems incorporate robotic handling, computerized control of acid application, and precise timing mechanisms to ensure consistent results. Some advanced systems include real-time monitoring of the etching process using optical sensors or electrical measurements to determine when the desired cut depth has been achieved. Automation also improves safety by minimizing human exposure to the hazardous acid while enabling mass production of precisely cut glass components for various industries including electronics, optics, and medical devices.

02 Laser-assisted hydrofluoric acid cutting

This advanced technique combines laser technology with hydrofluoric acid etching to achieve high-precision glass cutting. The laser creates microscopic cracks or modifies the surface structure of the glass, which then serves as pathways for the hydrofluoric acid to penetrate more effectively. This hybrid approach allows for more controlled and precise cutting, especially for thick glass or specialized glass compositions, while reducing the overall amount of acid needed in the process.Expand Specific Solutions03 Masking techniques for selective etching

Masking techniques are employed to protect specific areas of glass from hydrofluoric acid exposure, enabling selective etching for high-precision cutting. Various masking materials resistant to hydrofluoric acid, such as certain polymers, waxes, or photoresists, are applied to the glass surface in precise patterns. After the acid etching process, the mask is removed, revealing the precisely cut glass structure. This method is particularly valuable for manufacturing microfluidic devices, optical components, and semiconductor substrates.Expand Specific Solutions04 Temperature-controlled etching processes

Temperature control during hydrofluoric acid etching significantly impacts the precision of glass cutting. By carefully regulating the temperature of both the acid solution and the glass substrate, the etching rate can be precisely controlled. Lower temperatures generally result in slower but more controlled etching, while elevated temperatures increase the reaction rate but may reduce precision. Advanced systems incorporate temperature monitoring and regulation equipment to maintain optimal conditions throughout the etching process, ensuring consistent high-precision results.Expand Specific Solutions05 Safety and environmental considerations in HF cutting

High-precision glass cutting with hydrofluoric acid requires stringent safety protocols and environmental considerations. Advanced systems incorporate closed-loop processing to minimize acid exposure, neutralization systems to treat waste acid, and automated handling to reduce human contact with the dangerous chemical. Personal protective equipment and specialized training are essential for operators. Modern methods also focus on reducing the concentration and quantity of hydrofluoric acid used through process optimization, alternative formulations, and recycling techniques to minimize environmental impact while maintaining cutting precision.Expand Specific Solutions

Leading Companies in Precision Glass Processing

The hydrofluoric acid glass cutting technology market is currently in a growth phase, with increasing demand for high-precision applications in electronics, optics, and semiconductor industries. The global market size is estimated to exceed $2 billion, driven by the proliferation of advanced display technologies and miniaturized electronic components. Leading players like SCHOTT AG, Corning, and AGC Inc. have established strong technological capabilities through decades of R&D investment, while companies such as Nippon Electric Glass, HOYA Corp, and Stella Chemifa Corp. are advancing specialized applications. Regional competitors including Jianghua Micro-electronics and Runma Electronic Material are rapidly expanding their market presence through cost-effective solutions. The technology continues to evolve with innovations in environmentally safer processes and higher precision capabilities for next-generation display and semiconductor applications.

SCHOTT AG

AGC, Inc. (Japan)

Key Patents and Innovations in HF Glass Processing

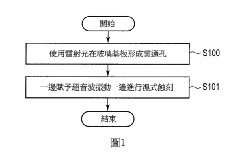

- Combining laser processing with wet-etching using a specific etching solution containing hydrofluoric acid at low concentration (4% by weight or less) and a higher concentration of a larger molecular size acid.

- Using an acid with larger molecular size than hydrofluoric acid at a higher concentration than the hydrofluoric acid in the etching solution, which likely controls the etching rate and improves precision.

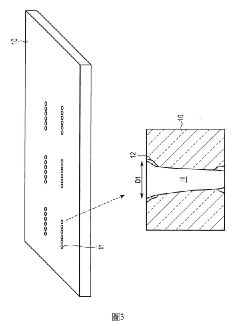

- Creating through holes in glass substrates with a two-step process (laser forming followed by chemical etching), which likely produces cleaner, more precise holes than either method alone.

- A method involving a chamfering tool with a diamond-tipped cutting edge and a controlled cutting angle is used to create a smooth, angled edge on glass substrates, ensuring minimal chipping and cracking.

Environmental and Safety Considerations for HF Processing

Hydrofluoric acid (HF) processing in glass cutting presents significant environmental and safety challenges that require comprehensive management strategies. The volatile nature of HF makes it one of the most hazardous chemicals used in industrial applications, capable of causing severe tissue damage and systemic toxicity through skin contact, inhalation, or ingestion.

Worker safety protocols for HF processing must include specialized training programs, proper personal protective equipment (PPE), and emergency response procedures. Standard PPE requirements include chemical-resistant full-body suits, face shields, specialized gloves, and respiratory protection. Facilities must implement engineering controls such as closed systems, ventilation hoods, and automated handling equipment to minimize direct worker exposure.

Environmental considerations for HF processing are equally critical. HF waste cannot be disposed of through conventional waste streams due to its high reactivity and environmental persistence. Neutralization processes using calcium compounds are typically required before disposal, converting the acid to less harmful calcium fluoride. Wastewater from HF processes must undergo specialized treatment to remove fluoride ions before release into municipal systems.

Regulatory compliance frameworks for HF handling vary globally but generally include strict reporting requirements, storage regulations, and disposal protocols. In the United States, HF processing falls under multiple regulatory bodies including OSHA, EPA, and Department of Transportation guidelines. The European Union's REACH regulations impose additional documentation and risk management requirements for HF use.

Recent technological innovations have focused on reducing HF-related risks through process containment improvements and development of less hazardous alternatives. Closed-loop recycling systems can significantly reduce waste generation, while newer calcium fluoride precipitation methods improve the efficiency of neutralization processes. Some manufacturers have implemented real-time monitoring systems for HF vapor detection, providing immediate alerts when concentrations approach dangerous levels.

Industry best practices now emphasize substitution where technically feasible. Alternative glass cutting technologies such as laser cutting, water jet cutting, and mechanical scoring are increasingly being evaluated as potential replacements for HF-based processes, particularly for applications where ultra-high precision is not the primary requirement. These alternative methods generally offer improved safety profiles and reduced environmental impact, though often with trade-offs in terms of edge quality, processing speed, or capital investment requirements.

Quality Control Standards for HF-Cut Glass Products

Quality control standards for HF-cut glass products must be rigorously defined and implemented to ensure consistent product quality and safety. The hydrofluoric acid cutting method, while offering superior precision for specialized glass applications, requires comprehensive quality assurance protocols due to the critical nature of the process and potential defects.

Primary dimensional tolerances for HF-cut glass typically range from ±0.05mm to ±0.1mm, significantly tighter than conventional mechanical cutting methods. Edge quality standards must specify maximum allowable chip size (typically <0.2mm), edge straightness deviation (<0.1mm per 100mm length), and corner radius consistency (±0.1mm). These parameters require measurement using calibrated optical systems with resolution capabilities of at least 5μm.

Surface quality inspection standards for HF-cut glass should address potential acid etching artifacts, including surface roughness measurements (Ra value <0.05μm for optical applications), absence of frosting effects, and uniform edge profiles. Specialized lighting techniques, including dark field illumination and polarized light inspection, are essential for detecting subtle surface anomalies that may compromise product integrity.

Stress distribution analysis using photoelastic methods should be standardized to quantify residual stress patterns near cut edges. Maximum allowable stress concentration values typically range from 2-5 MPa for consumer electronics applications and below 1 MPa for precision optical components. Automated birefringence measurement systems can provide quantitative data for statistical process control.

Chemical residue testing protocols must verify complete neutralization and removal of fluoride compounds, with maximum allowable residual fluoride levels typically set at <0.5 ppm for consumer products and <0.1 ppm for medical applications. Ion chromatography and fluoride-selective electrode methods represent the gold standards for verification testing.

Standardized environmental testing regimens should include humidity resistance (85% RH/85°C for 1000 hours), thermal cycling (-40°C to +85°C, 500 cycles), and mechanical shock resistance (50G, 11ms half-sine pulse). These accelerated aging tests help predict long-term reliability of HF-cut glass components under various operating conditions.

Documentation requirements for quality control should include complete process traceability, statistical process control charts for critical parameters, and verification of operator certification for handling hazardous materials. Regular calibration of measurement equipment and validation of test methods complete the quality assurance framework necessary for consistent production of high-precision HF-cut glass products.