Hydrofluoric Acid vs Ammonia: Hazardous Reaction Study

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF-NH3 Reaction Background and Research Objectives

The interaction between hydrofluoric acid (HF) and ammonia (NH3) represents a significant area of study in chemical hazard management and industrial safety protocols. This reaction has been investigated since the early 20th century, with pioneering work by chemists such as Fritz Haber and Gilbert Lewis establishing fundamental principles of acid-base interactions that govern the HF-NH3 system. Over decades, research has evolved from basic characterization to sophisticated modeling of reaction kinetics and thermodynamics.

The reaction between HF and NH3 produces ammonium fluoride (NH4F) or, under certain conditions, ammonium bifluoride (NH4HF2). While seemingly straightforward, this reaction presents complex safety challenges due to the highly exothermic nature of the process and the hazardous properties of both reactants. Historical industrial incidents involving these chemicals have prompted increasingly stringent safety protocols and research initiatives focused on reaction control mechanisms.

Recent technological advancements have enabled more precise monitoring and control of this reaction, particularly in semiconductor manufacturing, where ultra-pure HF and NH3 are essential components. The development of in-situ spectroscopic techniques and real-time monitoring systems has significantly improved our understanding of reaction dynamics under various conditions, contributing to safer handling procedures.

The global regulatory landscape surrounding these chemicals has also evolved substantially, with organizations such as OSHA, EPA, and their international counterparts implementing progressively stricter guidelines for handling, storage, and emergency response. This regulatory evolution reflects growing awareness of both acute and chronic health risks associated with HF and NH3 exposure.

Our research objectives for this study encompass several critical dimensions. First, we aim to characterize the reaction kinetics between HF and NH3 across a broader range of concentrations and environmental conditions than previously documented, with particular attention to threshold conditions that may trigger rapid exothermic reactions. Second, we seek to develop improved predictive models for risk assessment that incorporate both thermodynamic parameters and practical handling scenarios.

Additionally, we intend to evaluate emerging neutralization and containment technologies specifically designed for HF-NH3 reactions, assessing their efficacy in laboratory and simulated industrial settings. The research will also explore potential applications of controlled HF-NH3 reactions in emerging fields such as advanced materials synthesis and green chemistry processes, where precisely managed acid-base reactions can yield valuable products.

Finally, this study aims to establish a comprehensive set of best practices for industries where these chemicals coexist, incorporating the latest sensor technologies, engineering controls, and emergency response protocols. The ultimate goal is to advance both fundamental understanding and practical safety measures related to this important but hazardous chemical interaction.

The reaction between HF and NH3 produces ammonium fluoride (NH4F) or, under certain conditions, ammonium bifluoride (NH4HF2). While seemingly straightforward, this reaction presents complex safety challenges due to the highly exothermic nature of the process and the hazardous properties of both reactants. Historical industrial incidents involving these chemicals have prompted increasingly stringent safety protocols and research initiatives focused on reaction control mechanisms.

Recent technological advancements have enabled more precise monitoring and control of this reaction, particularly in semiconductor manufacturing, where ultra-pure HF and NH3 are essential components. The development of in-situ spectroscopic techniques and real-time monitoring systems has significantly improved our understanding of reaction dynamics under various conditions, contributing to safer handling procedures.

The global regulatory landscape surrounding these chemicals has also evolved substantially, with organizations such as OSHA, EPA, and their international counterparts implementing progressively stricter guidelines for handling, storage, and emergency response. This regulatory evolution reflects growing awareness of both acute and chronic health risks associated with HF and NH3 exposure.

Our research objectives for this study encompass several critical dimensions. First, we aim to characterize the reaction kinetics between HF and NH3 across a broader range of concentrations and environmental conditions than previously documented, with particular attention to threshold conditions that may trigger rapid exothermic reactions. Second, we seek to develop improved predictive models for risk assessment that incorporate both thermodynamic parameters and practical handling scenarios.

Additionally, we intend to evaluate emerging neutralization and containment technologies specifically designed for HF-NH3 reactions, assessing their efficacy in laboratory and simulated industrial settings. The research will also explore potential applications of controlled HF-NH3 reactions in emerging fields such as advanced materials synthesis and green chemistry processes, where precisely managed acid-base reactions can yield valuable products.

Finally, this study aims to establish a comprehensive set of best practices for industries where these chemicals coexist, incorporating the latest sensor technologies, engineering controls, and emergency response protocols. The ultimate goal is to advance both fundamental understanding and practical safety measures related to this important but hazardous chemical interaction.

Industrial Applications and Safety Demand Analysis

The industrial applications of hydrofluoric acid (HF) and ammonia (NH3) span multiple sectors, creating significant market demand despite their hazardous nature. In semiconductor manufacturing, HF serves as a critical etching agent for silicon wafers, with the global semiconductor market projected to reach $1 trillion by 2030. This growth directly impacts HF demand in high-purity applications where substitutes remain limited due to HF's unique silicon dioxide dissolution properties.

Oil refining represents another major application area, where HF catalyzes alkylation processes to produce high-octane gasoline components. With global refining capacity exceeding 100 million barrels per day, the alkylation units using HF technology process approximately 1.5 million barrels daily, highlighting substantial industrial exposure to this hazardous substance.

Ammonia, conversely, dominates the fertilizer industry as the precursor to nitrogen fertilizers, with global production exceeding 175 million tonnes annually. The agricultural sector's dependence on ammonia-based fertilizers continues to grow with increasing global food demand, creating persistent exposure risks across the supply chain.

Both chemicals feature prominently in various manufacturing processes: HF in glass etching, metal surface treatment, and fluoropolymer production; ammonia in refrigeration systems, water treatment, and as a cleaning agent. This widespread industrial presence multiplies potential interaction scenarios between these reactive substances.

Safety concerns drive significant market demand for detection, containment, and neutralization technologies. The industrial safety equipment market specifically addressing chemical hazards exceeds $5 billion globally, with specialized HF and ammonia safety solutions representing a growing segment. Regulatory compliance requirements further amplify this demand, as facilities handling these chemicals must implement comprehensive safety protocols.

Recent industrial accidents involving these chemicals have intensified market interest in advanced safety technologies. Notable incidents include the 2019 Philadelphia refinery explosion involving HF and multiple ammonia refrigerant leaks in food processing facilities. Each major incident typically triggers regulatory reassessment and increased safety investment across affected industries.

The market increasingly demands integrated safety solutions that address the specific challenges of HF-ammonia interactions. These include specialized detection systems capable of monitoring both chemicals simultaneously, compatible personal protective equipment, and neutralization protocols effective against mixed chemical exposures. This represents an emerging market segment with significant growth potential as awareness of interaction hazards increases across industries where both chemicals may be present.

Oil refining represents another major application area, where HF catalyzes alkylation processes to produce high-octane gasoline components. With global refining capacity exceeding 100 million barrels per day, the alkylation units using HF technology process approximately 1.5 million barrels daily, highlighting substantial industrial exposure to this hazardous substance.

Ammonia, conversely, dominates the fertilizer industry as the precursor to nitrogen fertilizers, with global production exceeding 175 million tonnes annually. The agricultural sector's dependence on ammonia-based fertilizers continues to grow with increasing global food demand, creating persistent exposure risks across the supply chain.

Both chemicals feature prominently in various manufacturing processes: HF in glass etching, metal surface treatment, and fluoropolymer production; ammonia in refrigeration systems, water treatment, and as a cleaning agent. This widespread industrial presence multiplies potential interaction scenarios between these reactive substances.

Safety concerns drive significant market demand for detection, containment, and neutralization technologies. The industrial safety equipment market specifically addressing chemical hazards exceeds $5 billion globally, with specialized HF and ammonia safety solutions representing a growing segment. Regulatory compliance requirements further amplify this demand, as facilities handling these chemicals must implement comprehensive safety protocols.

Recent industrial accidents involving these chemicals have intensified market interest in advanced safety technologies. Notable incidents include the 2019 Philadelphia refinery explosion involving HF and multiple ammonia refrigerant leaks in food processing facilities. Each major incident typically triggers regulatory reassessment and increased safety investment across affected industries.

The market increasingly demands integrated safety solutions that address the specific challenges of HF-ammonia interactions. These include specialized detection systems capable of monitoring both chemicals simultaneously, compatible personal protective equipment, and neutralization protocols effective against mixed chemical exposures. This represents an emerging market segment with significant growth potential as awareness of interaction hazards increases across industries where both chemicals may be present.

Current Understanding and Technical Challenges

The current understanding of the reaction between hydrofluoric acid (HF) and ammonia (NH₃) reveals a complex chemical interaction with significant safety implications. When these two substances come into contact, they undergo a neutralization reaction forming ammonium fluoride (NH₄F), which can further react to produce ammonium bifluoride (NH₄HF₂) under certain conditions. This reaction is highly exothermic, releasing substantial heat that can accelerate reaction rates and potentially lead to dangerous situations in industrial settings.

Research indicates that the reaction kinetics are influenced by multiple factors including concentration ratios, temperature, pressure, and the presence of catalysts or inhibitors. At industrial scale, these variables become critical control points for safety management. Recent studies have demonstrated that even small variations in these parameters can significantly alter reaction pathways and byproduct formation.

One of the primary technical challenges in studying this reaction is the inherent hazardous nature of both reactants. Hydrofluoric acid is exceptionally corrosive and toxic, capable of penetrating skin and causing deep tissue damage and systemic toxicity. Ammonia, while less immediately dangerous than HF, is a respiratory irritant that can cause severe lung damage at high concentrations. These properties make laboratory investigations difficult and necessitate specialized containment systems and safety protocols.

Measurement and monitoring technologies present another significant challenge. Real-time analysis of reaction progression requires sensors that can withstand both highly acidic and basic conditions while providing accurate data. Current sensor technologies often suffer from rapid degradation in these harsh chemical environments, limiting continuous monitoring capabilities during the reaction process.

Computational modeling of the reaction faces limitations due to the complex behavior of hydrogen bonding networks in the HF-NH₃ system. Existing models struggle to accurately predict reaction behavior across varying concentration ranges and environmental conditions, creating gaps in predictive capabilities for industrial risk assessment.

Containment and material compatibility issues further complicate research efforts. Few materials can withstand both hydrofluoric acid and the heat generated during neutralization with ammonia. This creates engineering challenges for reaction vessels and safety systems in both research and industrial applications.

Regulatory frameworks worldwide have established varying standards for handling these chemicals, creating compliance challenges for multinational research and manufacturing operations. The absence of harmonized global standards necessitates customized safety protocols across different jurisdictions, complicating technology transfer and consistent implementation of safety measures.

Research indicates that the reaction kinetics are influenced by multiple factors including concentration ratios, temperature, pressure, and the presence of catalysts or inhibitors. At industrial scale, these variables become critical control points for safety management. Recent studies have demonstrated that even small variations in these parameters can significantly alter reaction pathways and byproduct formation.

One of the primary technical challenges in studying this reaction is the inherent hazardous nature of both reactants. Hydrofluoric acid is exceptionally corrosive and toxic, capable of penetrating skin and causing deep tissue damage and systemic toxicity. Ammonia, while less immediately dangerous than HF, is a respiratory irritant that can cause severe lung damage at high concentrations. These properties make laboratory investigations difficult and necessitate specialized containment systems and safety protocols.

Measurement and monitoring technologies present another significant challenge. Real-time analysis of reaction progression requires sensors that can withstand both highly acidic and basic conditions while providing accurate data. Current sensor technologies often suffer from rapid degradation in these harsh chemical environments, limiting continuous monitoring capabilities during the reaction process.

Computational modeling of the reaction faces limitations due to the complex behavior of hydrogen bonding networks in the HF-NH₃ system. Existing models struggle to accurately predict reaction behavior across varying concentration ranges and environmental conditions, creating gaps in predictive capabilities for industrial risk assessment.

Containment and material compatibility issues further complicate research efforts. Few materials can withstand both hydrofluoric acid and the heat generated during neutralization with ammonia. This creates engineering challenges for reaction vessels and safety systems in both research and industrial applications.

Regulatory frameworks worldwide have established varying standards for handling these chemicals, creating compliance challenges for multinational research and manufacturing operations. The absence of harmonized global standards necessitates customized safety protocols across different jurisdictions, complicating technology transfer and consistent implementation of safety measures.

Established Protocols for HF-NH3 Handling

01 Chemical reaction mechanisms and products

The reaction between hydrofluoric acid and ammonia produces ammonium fluoride or ammonium bifluoride. This neutralization reaction is exothermic and can generate significant heat. The reaction kinetics depend on concentration, temperature, and pressure conditions. Understanding these mechanisms is crucial for controlling the hazardous nature of this reaction in industrial processes.- Chemical reaction mechanisms and safety concerns: The reaction between hydrofluoric acid and ammonia is highly exothermic and potentially hazardous. When these chemicals combine, they form ammonium fluoride compounds while releasing significant heat. This reaction poses serious safety risks including potential for thermal burns, toxic gas release, and container pressurization. The reaction kinetics are influenced by concentration levels, temperature, and reaction conditions, requiring careful control measures to prevent dangerous situations.

- Neutralization and treatment systems: Specialized systems have been developed for the safe neutralization of hydrofluoric acid using ammonia or ammonia-based compounds. These systems typically include controlled dosing mechanisms, monitoring equipment, and containment vessels designed to handle the exothermic reaction safely. Some systems incorporate cooling mechanisms to dissipate heat generated during neutralization, while others use staged reaction processes to minimize hazards and ensure complete conversion to safer byproducts.

- Protective equipment and containment solutions: Handling the hydrofluoric acid and ammonia reaction requires specialized protective equipment and containment solutions. These include chemical-resistant materials specifically designed to withstand both hydrofluoric acid and ammonia, emergency ventilation systems to remove toxic vapors, and specialized storage containers that prevent accidental mixing. Safety systems often incorporate multiple redundant barriers, leak detection technology, and emergency neutralization capabilities to mitigate risks associated with this hazardous reaction.

- Industrial applications and process safety: Despite its hazardous nature, the controlled reaction between hydrofluoric acid and ammonia has important industrial applications, including semiconductor manufacturing, metal surface treatment, and chemical synthesis. Industrial processes utilizing this reaction incorporate extensive safety protocols, including automated monitoring systems, emergency shutdown capabilities, and precise chemical delivery systems. Process safety management includes detailed risk assessments, operator training programs, and engineering controls designed specifically for the unique hazards of this chemical interaction.

- Waste management and environmental considerations: The byproducts of hydrofluoric acid and ammonia reactions require specialized waste management protocols to prevent environmental contamination. Treatment systems have been developed to neutralize and safely dispose of reaction products, often incorporating multiple treatment stages to ensure complete conversion to non-hazardous materials. Environmental monitoring systems detect potential releases, while containment technologies prevent soil and groundwater contamination. Regulatory compliance requires detailed documentation of handling procedures, emergency response plans, and waste disposal methods specific to these hazardous materials.

02 Safety measures and hazard prevention

When handling hydrofluoric acid and ammonia reactions, specific safety protocols must be implemented due to the corrosive nature of both reactants and the exothermic reaction. These include proper ventilation systems, specialized containment vessels, neutralization procedures, and emergency response equipment. Personal protective equipment designed specifically for these chemicals is essential to prevent exposure to toxic fumes and potential burns.Expand Specific Solutions03 Industrial applications and process control

Despite the hazardous nature, controlled reactions between hydrofluoric acid and ammonia are utilized in various industrial applications including semiconductor manufacturing, glass etching, and chemical synthesis. Specialized equipment and precise process control systems are employed to manage reaction parameters such as temperature, pressure, and concentration ratios to ensure safety while achieving desired chemical outcomes.Expand Specific Solutions04 Waste treatment and environmental considerations

The byproducts and waste streams from hydrofluoric acid and ammonia reactions require specialized treatment methods to prevent environmental contamination. Neutralization techniques, precipitation processes, and filtration systems are employed to handle these hazardous wastes. Environmental monitoring and compliance with regulations are essential aspects of managing facilities where these reactions occur to prevent air and water pollution.Expand Specific Solutions05 Detection and monitoring systems

Advanced detection and monitoring systems are critical for early identification of potential hazards in facilities where hydrofluoric acid and ammonia may interact. These include specialized gas sensors, automated alarm systems, continuous monitoring equipment, and emergency shutdown mechanisms. Real-time data collection and analysis help prevent accidental reactions and mitigate risks associated with equipment failure or human error.Expand Specific Solutions

Leading Research Institutions and Chemical Companies

The hydrofluoric acid vs ammonia hazardous reaction study landscape is currently in a growth phase, with an estimated market size of $3.5-4 billion and expanding at 5-7% annually. The competitive environment features established chemical manufacturers like DAIKIN INDUSTRIES and Arkema France SA focusing on industrial applications, while Honeywell International Technologies and The Chemours Co. lead in safety protocol development. Research institutions including Shanghai University and the German Cancer Research Center contribute significant academic insights. The technology maturity varies across sectors, with companies like Halliburton Energy Services and Baker Hughes advancing specialized applications for energy industries, while pharmaceutical players such as Abbott Laboratories and Glaxo Group Ltd. focus on controlled reaction management for drug development applications.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced containment and neutralization systems for hydrofluoric acid (HF) and ammonia reactions. Their technology employs a multi-stage reaction control process that monitors temperature, pressure, and gas evolution in real-time to prevent hazardous outcomes. The system incorporates proprietary catalysts that facilitate controlled neutralization of HF with ammonia to form stable ammonium fluoride compounds while minimizing exothermic reaction risks. Honeywell's approach includes specialized corrosion-resistant materials for handling equipment and reaction vessels, specifically designed to withstand both the highly corrosive nature of HF and the potential formation of ammonium bifluoride. Their safety protocols integrate automated emergency shutdown mechanisms triggered by multiple parameter deviations, reducing human exposure risks during critical situations.

Strengths: Industry-leading safety systems with real-time monitoring capabilities; proprietary materials technology resistant to both HF and ammonia corrosion; extensive experience in industrial chemical handling. Weaknesses: Higher implementation costs compared to basic safety systems; requires specialized training for operation; system complexity may present maintenance challenges.

Arkema France SA

Technical Solution: Arkema has pioneered a comprehensive approach to HF-ammonia reaction management through their SAFE-REACT™ technology platform. This system employs specialized reaction vessels with gradient cooling zones that precisely control the highly exothermic neutralization process. Their technology incorporates proprietary fluoropolymer linings resistant to both HF's aggressive corrosion and ammonia's alkaline properties. Arkema's process utilizes controlled stoichiometric addition of reagents through automated dispensing systems, maintaining optimal NH3:HF ratios to prevent dangerous concentration spikes. The company has developed specialized scrubber systems that capture and neutralize any fugitive emissions, with particular attention to the volatile ammonium fluoride compounds that can form. Their approach includes comprehensive waste treatment protocols for the resulting fluoride-containing byproducts, ensuring environmental compliance.

Strengths: Extensive experience with fluorine chemistry and handling; proprietary materials specifically designed for HF-ammonia compatibility; integrated environmental management systems for byproducts. Weaknesses: Technology requires significant capital investment; system optimization needs regular expert oversight; limited flexibility for small-scale applications.

Critical Reaction Mechanisms and Safety Parameters

Tetrafluoroborate compounds, compositions and related methods of use

PatentInactiveUS20130178405A1

Innovation

- Development of non-corrosive cleaning compositions using tetrafluoroboric acid in combination with an organic nitrogenous base, such as urea, which forms a tetrafluoroborate salt, offering safer and more effective cleaning without the hazards associated with hydrofluoric acid.

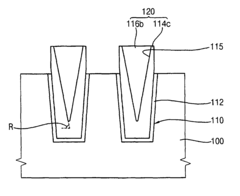

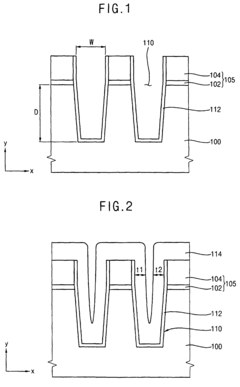

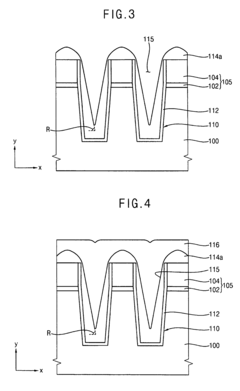

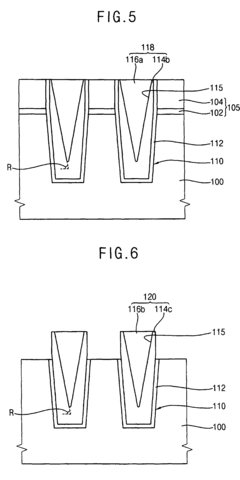

Method of removing an oxide and method of filling a trench using the same

PatentActiveUS7745305B2

Innovation

- A method using a reaction gas with fluorine and nitrogen, specifically hydrofluoric acid (HF) vapor and ammonia (NH3), to etch the oxide layer, forming byproducts that are then removed, minimizing damage and voids, and allowing for conformal filling of trenches with a second oxide layer.

Regulatory Framework for Hazardous Chemical Reactions

The regulatory landscape governing hazardous chemical reactions, particularly those involving hydrofluoric acid (HF) and ammonia, is complex and multi-layered. At the international level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides standardized criteria for classifying chemical hazards and communicating these hazards through labeling and safety data sheets. This framework specifically addresses the high toxicity of HF and the potential for dangerous exothermic reactions when it interacts with ammonia.

In the United States, the Occupational Safety and Health Administration (OSHA) has established the Process Safety Management (PSM) standard (29 CFR 1910.119), which applies directly to facilities handling hydrofluoric acid above threshold quantities. The Environmental Protection Agency's Risk Management Program (RMP) complements OSHA's regulations by focusing on preventing accidental releases of hazardous substances, including both HF and ammonia, into the environment.

The European Union's regulatory approach is governed by the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and CLP (Classification, Labelling and Packaging) regulations. These frameworks mandate comprehensive risk assessments for chemical reactions involving highly hazardous substances like HF and ammonia, with particular emphasis on reaction chemistry safety and containment measures.

Industry-specific standards further enhance the regulatory framework. The American Chemistry Council's Responsible Care program and the Chemical Facility Anti-Terrorism Standards (CFATS) provide additional guidelines for handling these hazardous chemicals. For laboratories and research facilities, NFPA 45 (Standard on Fire Protection for Laboratories Using Chemicals) offers specific protocols for managing the HF-ammonia reaction risks.

Regulatory compliance for HF-ammonia reactions necessitates rigorous documentation requirements, including detailed process safety information, hazard analyses, and emergency response plans. Facilities must maintain comprehensive records of risk assessments, safety measures, and incident reports related to these chemicals.

Recent regulatory trends show an increasing focus on inherently safer design principles, encouraging the substitution of highly hazardous chemicals like HF with less dangerous alternatives where technically feasible. There is also growing emphasis on community right-to-know provisions, requiring facilities to disclose information about stored chemicals to local emergency planning committees and first responders.

Enforcement mechanisms for these regulations include regular inspections, substantial financial penalties for violations, and potential criminal liability for willful non-compliance resulting in serious incidents. The regulatory framework continues to evolve, with ongoing efforts to harmonize international standards and incorporate lessons learned from incidents involving these highly reactive chemicals.

In the United States, the Occupational Safety and Health Administration (OSHA) has established the Process Safety Management (PSM) standard (29 CFR 1910.119), which applies directly to facilities handling hydrofluoric acid above threshold quantities. The Environmental Protection Agency's Risk Management Program (RMP) complements OSHA's regulations by focusing on preventing accidental releases of hazardous substances, including both HF and ammonia, into the environment.

The European Union's regulatory approach is governed by the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and CLP (Classification, Labelling and Packaging) regulations. These frameworks mandate comprehensive risk assessments for chemical reactions involving highly hazardous substances like HF and ammonia, with particular emphasis on reaction chemistry safety and containment measures.

Industry-specific standards further enhance the regulatory framework. The American Chemistry Council's Responsible Care program and the Chemical Facility Anti-Terrorism Standards (CFATS) provide additional guidelines for handling these hazardous chemicals. For laboratories and research facilities, NFPA 45 (Standard on Fire Protection for Laboratories Using Chemicals) offers specific protocols for managing the HF-ammonia reaction risks.

Regulatory compliance for HF-ammonia reactions necessitates rigorous documentation requirements, including detailed process safety information, hazard analyses, and emergency response plans. Facilities must maintain comprehensive records of risk assessments, safety measures, and incident reports related to these chemicals.

Recent regulatory trends show an increasing focus on inherently safer design principles, encouraging the substitution of highly hazardous chemicals like HF with less dangerous alternatives where technically feasible. There is also growing emphasis on community right-to-know provisions, requiring facilities to disclose information about stored chemicals to local emergency planning committees and first responders.

Enforcement mechanisms for these regulations include regular inspections, substantial financial penalties for violations, and potential criminal liability for willful non-compliance resulting in serious incidents. The regulatory framework continues to evolve, with ongoing efforts to harmonize international standards and incorporate lessons learned from incidents involving these highly reactive chemicals.

Environmental Impact Assessment Methodologies

Environmental impact assessment methodologies for hydrofluoric acid (HF) and ammonia reactions require comprehensive frameworks that account for both immediate and long-term ecological consequences. Traditional assessment approaches often fail to capture the unique hazards presented by these highly reactive chemicals, necessitating specialized evaluation protocols.

The Tiered Risk Assessment Model has emerged as a preferred methodology, beginning with screening-level assessments that identify potential exposure pathways, followed by detailed quantitative analysis of environmental fate and transport. For HF-ammonia reactions specifically, this model incorporates reaction kinetics data to predict formation of ammonium fluoride compounds and their subsequent environmental behavior.

Lifecycle Assessment (LCA) methodologies have been adapted to evaluate the cradle-to-grave environmental impacts of processes involving these chemicals. These assessments track resource consumption, emissions, and waste generation across all stages from raw material extraction through disposal. Recent innovations in LCA frameworks include specialized characterization factors for fluoride compounds in aquatic ecosystems.

Fugitive emission modeling represents another critical assessment component, utilizing computational fluid dynamics to predict gas dispersion patterns following accidental releases. These models incorporate meteorological data, topographical features, and chemical reaction rates to generate exposure scenarios for ecological risk assessment.

Biomonitoring protocols complement these approaches by measuring fluoride accumulation in sentinel species. Studies have demonstrated that certain lichens and mosses serve as effective bioindicators for atmospheric fluoride deposition, while aquatic invertebrates provide insights into waterborne exposure pathways.

Ecosystem vulnerability mapping has gained prominence as a methodology that integrates geographical information systems with ecological sensitivity data. This approach identifies habitats particularly susceptible to fluoride or ammonia contamination, enabling targeted mitigation strategies and prioritized protection efforts.

Emerging methodologies include real-time monitoring systems that employ sensor networks to detect chemical releases and trigger automated impact assessment protocols. These systems utilize machine learning algorithms to predict environmental fate based on detected concentrations, reaction conditions, and environmental parameters.

Standardization efforts by organizations such as ISO and EPA have resulted in harmonized protocols for assessing environmental impacts of hazardous chemical reactions, though specific guidance for HF-ammonia interactions remains under development. The integration of these diverse methodologies provides a comprehensive framework for evaluating and mitigating the environmental risks associated with these hazardous reactions.

The Tiered Risk Assessment Model has emerged as a preferred methodology, beginning with screening-level assessments that identify potential exposure pathways, followed by detailed quantitative analysis of environmental fate and transport. For HF-ammonia reactions specifically, this model incorporates reaction kinetics data to predict formation of ammonium fluoride compounds and their subsequent environmental behavior.

Lifecycle Assessment (LCA) methodologies have been adapted to evaluate the cradle-to-grave environmental impacts of processes involving these chemicals. These assessments track resource consumption, emissions, and waste generation across all stages from raw material extraction through disposal. Recent innovations in LCA frameworks include specialized characterization factors for fluoride compounds in aquatic ecosystems.

Fugitive emission modeling represents another critical assessment component, utilizing computational fluid dynamics to predict gas dispersion patterns following accidental releases. These models incorporate meteorological data, topographical features, and chemical reaction rates to generate exposure scenarios for ecological risk assessment.

Biomonitoring protocols complement these approaches by measuring fluoride accumulation in sentinel species. Studies have demonstrated that certain lichens and mosses serve as effective bioindicators for atmospheric fluoride deposition, while aquatic invertebrates provide insights into waterborne exposure pathways.

Ecosystem vulnerability mapping has gained prominence as a methodology that integrates geographical information systems with ecological sensitivity data. This approach identifies habitats particularly susceptible to fluoride or ammonia contamination, enabling targeted mitigation strategies and prioritized protection efforts.

Emerging methodologies include real-time monitoring systems that employ sensor networks to detect chemical releases and trigger automated impact assessment protocols. These systems utilize machine learning algorithms to predict environmental fate based on detected concentrations, reaction conditions, and environmental parameters.

Standardization efforts by organizations such as ISO and EPA have resulted in harmonized protocols for assessing environmental impacts of hazardous chemical reactions, though specific guidance for HF-ammonia interactions remains under development. The integration of these diverse methodologies provides a comprehensive framework for evaluating and mitigating the environmental risks associated with these hazardous reactions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!