Hydrosulfuric Acid Interaction with Concrete: Structural Analysis

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

H2S-Concrete Interaction Background and Objectives

Hydrosulfuric acid, commonly known as hydrogen sulfide (H2S) in its gaseous form, represents a significant challenge for concrete structures in various industrial and environmental settings. The interaction between H2S and concrete has been documented since the early 20th century, with the first comprehensive studies emerging in the 1940s when wastewater infrastructure began experiencing accelerated deterioration in certain environments. This technical domain sits at the intersection of materials science, chemical engineering, and structural engineering, requiring multidisciplinary approaches to fully understand the degradation mechanisms.

The evolution of this technical field has seen several paradigm shifts, from initial empirical observations to sophisticated molecular-level analyses. Early research focused primarily on documenting failure cases, while modern approaches incorporate advanced analytical techniques such as X-ray diffraction, scanning electron microscopy, and computational modeling to predict degradation rates and patterns. The progression of understanding has moved from simple acid attack models to complex biogenic sulfuric acid generation processes that better explain field observations.

Recent technological advancements have enabled more precise monitoring and prediction of concrete deterioration under H2S exposure. The development of specialized sensors, non-destructive testing methods, and machine learning algorithms for degradation pattern recognition has significantly enhanced our ability to assess structural integrity in real-time. These innovations represent crucial milestones in the technical evolution of this field.

The primary objective of this technical investigation is to establish a comprehensive framework for analyzing and predicting the structural impacts of hydrosulfuric acid interaction with concrete across various exposure conditions. Specifically, we aim to quantify the relationship between H2S concentration, exposure duration, concrete composition, and resulting mechanical property degradation. This includes developing predictive models that can accurately estimate service life reductions based on exposure parameters.

Secondary objectives include identifying optimal concrete formulations that demonstrate enhanced resistance to H2S attack, evaluating the effectiveness of various protective coating systems, and establishing standardized testing protocols that can reliably accelerate and simulate long-term exposure effects. These objectives align with the industry's growing need for infrastructure resilience, particularly in wastewater systems, geothermal facilities, and oil and gas operations where H2S exposure is common.

The technical goals extend beyond mere material preservation to encompass structural integrity assessment methodologies that can be integrated into asset management systems. By establishing correlations between chemical degradation markers and structural performance metrics, we seek to develop early warning indicators that can trigger maintenance interventions before critical structural thresholds are compromised.

The evolution of this technical field has seen several paradigm shifts, from initial empirical observations to sophisticated molecular-level analyses. Early research focused primarily on documenting failure cases, while modern approaches incorporate advanced analytical techniques such as X-ray diffraction, scanning electron microscopy, and computational modeling to predict degradation rates and patterns. The progression of understanding has moved from simple acid attack models to complex biogenic sulfuric acid generation processes that better explain field observations.

Recent technological advancements have enabled more precise monitoring and prediction of concrete deterioration under H2S exposure. The development of specialized sensors, non-destructive testing methods, and machine learning algorithms for degradation pattern recognition has significantly enhanced our ability to assess structural integrity in real-time. These innovations represent crucial milestones in the technical evolution of this field.

The primary objective of this technical investigation is to establish a comprehensive framework for analyzing and predicting the structural impacts of hydrosulfuric acid interaction with concrete across various exposure conditions. Specifically, we aim to quantify the relationship between H2S concentration, exposure duration, concrete composition, and resulting mechanical property degradation. This includes developing predictive models that can accurately estimate service life reductions based on exposure parameters.

Secondary objectives include identifying optimal concrete formulations that demonstrate enhanced resistance to H2S attack, evaluating the effectiveness of various protective coating systems, and establishing standardized testing protocols that can reliably accelerate and simulate long-term exposure effects. These objectives align with the industry's growing need for infrastructure resilience, particularly in wastewater systems, geothermal facilities, and oil and gas operations where H2S exposure is common.

The technical goals extend beyond mere material preservation to encompass structural integrity assessment methodologies that can be integrated into asset management systems. By establishing correlations between chemical degradation markers and structural performance metrics, we seek to develop early warning indicators that can trigger maintenance interventions before critical structural thresholds are compromised.

Market Analysis of Acid-Resistant Concrete Solutions

The global market for acid-resistant concrete solutions has experienced significant growth in recent years, driven by increasing infrastructure development in corrosive environments and growing awareness of concrete durability issues. The market size for specialized acid-resistant concrete products reached approximately $7.2 billion in 2022, with projections indicating a compound annual growth rate of 5.8% through 2028.

Industrial sectors represent the largest demand segment, accounting for nearly 42% of the total market share. Chemical processing facilities, wastewater treatment plants, and mining operations are particularly significant consumers due to their regular exposure to hydrosulfuric acid and other corrosive substances. The oil and gas sector follows closely, contributing about 28% of market demand, primarily for infrastructure in extraction and processing facilities where acid exposure is common.

Geographically, North America and Europe currently dominate the market with a combined share of 58%, attributed to stringent infrastructure maintenance regulations and higher adoption rates of advanced construction materials. However, the Asia-Pacific region is witnessing the fastest growth at 7.3% annually, driven by rapid industrialization in China, India, and Southeast Asian countries.

Customer needs analysis reveals three primary market drivers: cost-effectiveness over infrastructure lifetime, compliance with increasingly stringent environmental regulations, and performance reliability under extreme chemical exposure conditions. End-users consistently prioritize solutions that demonstrate long-term economic benefits despite higher initial investment costs compared to standard concrete.

Market research indicates a price premium of 30-45% for acid-resistant concrete solutions over conventional concrete, with customers increasingly willing to pay this premium based on total cost of ownership calculations that factor in reduced maintenance and extended service life. The return on investment typically becomes favorable within 3-5 years of installation in highly corrosive environments.

Emerging market trends include growing demand for prefabricated acid-resistant concrete elements, increasing interest in sustainable formulations with reduced environmental impact, and rising adoption of performance-based specifications rather than prescriptive standards. Additionally, there is expanding market potential in retrofit applications, where existing concrete structures require protection against hydrosulfuric acid damage.

Market segmentation analysis reveals distinct customer groups with varying needs: high-performance industrial applications requiring extreme chemical resistance, moderate-exposure municipal infrastructure projects balancing performance with cost, and specialized applications in food processing and pharmaceutical facilities where both acid resistance and hygiene standards must be met simultaneously.

Industrial sectors represent the largest demand segment, accounting for nearly 42% of the total market share. Chemical processing facilities, wastewater treatment plants, and mining operations are particularly significant consumers due to their regular exposure to hydrosulfuric acid and other corrosive substances. The oil and gas sector follows closely, contributing about 28% of market demand, primarily for infrastructure in extraction and processing facilities where acid exposure is common.

Geographically, North America and Europe currently dominate the market with a combined share of 58%, attributed to stringent infrastructure maintenance regulations and higher adoption rates of advanced construction materials. However, the Asia-Pacific region is witnessing the fastest growth at 7.3% annually, driven by rapid industrialization in China, India, and Southeast Asian countries.

Customer needs analysis reveals three primary market drivers: cost-effectiveness over infrastructure lifetime, compliance with increasingly stringent environmental regulations, and performance reliability under extreme chemical exposure conditions. End-users consistently prioritize solutions that demonstrate long-term economic benefits despite higher initial investment costs compared to standard concrete.

Market research indicates a price premium of 30-45% for acid-resistant concrete solutions over conventional concrete, with customers increasingly willing to pay this premium based on total cost of ownership calculations that factor in reduced maintenance and extended service life. The return on investment typically becomes favorable within 3-5 years of installation in highly corrosive environments.

Emerging market trends include growing demand for prefabricated acid-resistant concrete elements, increasing interest in sustainable formulations with reduced environmental impact, and rising adoption of performance-based specifications rather than prescriptive standards. Additionally, there is expanding market potential in retrofit applications, where existing concrete structures require protection against hydrosulfuric acid damage.

Market segmentation analysis reveals distinct customer groups with varying needs: high-performance industrial applications requiring extreme chemical resistance, moderate-exposure municipal infrastructure projects balancing performance with cost, and specialized applications in food processing and pharmaceutical facilities where both acid resistance and hygiene standards must be met simultaneously.

Current Challenges in H2S-Concrete Structural Integrity

The interaction between hydrogen sulfide (H2S) and concrete structures presents significant challenges for infrastructure in various industrial settings, particularly in wastewater treatment facilities, sewer systems, oil and gas operations, and geothermal plants. Current research indicates that H2S-induced concrete deterioration is accelerating due to increased industrial activities and aging infrastructure worldwide.

The primary mechanism of concrete degradation involves the conversion of H2S gas to sulfuric acid (H2SO4) through bacterial action, particularly by Thiobacillus species. This biogenic sulfuric acid attack creates a highly corrosive environment with pH levels potentially dropping below 1, which conventional concrete materials are not designed to withstand. The resulting deterioration manifests as surface softening, progressive loss of cement paste, exposure of aggregates, and ultimately structural failure.

Recent field studies have documented alarming rates of concrete loss, with measurements showing up to 10mm per year in severely affected environments—significantly higher than historical averages of 1-3mm annually. This accelerated deterioration has created urgent challenges for infrastructure maintenance and rehabilitation strategies.

Material scientists face substantial difficulties in developing concrete formulations that maintain structural integrity under prolonged H2S exposure. Current Portland cement-based concretes exhibit vulnerability to sulfate attack, with calcium hydroxide and calcium silicate hydrate phases being particularly susceptible to chemical transformation into expansive products like ettringite and gypsum.

Monitoring and assessment methodologies present another significant challenge. Traditional inspection techniques often fail to detect early-stage deterioration occurring beneath the concrete surface, leading to underestimation of damage extent. The development of reliable non-destructive testing methods for H2S-affected structures remains an active research area with limited standardized protocols.

Rehabilitation of affected structures introduces additional complexities. Conventional repair materials frequently fail to bond adequately with deteriorated substrates, and the persistent presence of sulfur-oxidizing bacteria can rapidly compromise new protective layers. The industry lacks consensus on optimal rehabilitation strategies for severely damaged infrastructure.

Economic implications compound these technical challenges. The World Concrete Forum estimates global annual costs for H2S-related concrete damage at approximately $30 billion, with projections indicating this figure could double by 2030 if effective mitigation strategies are not implemented. This economic burden disproportionately affects municipalities with aging infrastructure and limited maintenance budgets.

Environmental considerations further complicate mitigation efforts, as many traditional concrete protection systems contain compounds with significant ecological impacts. Developing environmentally sustainable solutions that maintain effectiveness against H2S attack represents a critical research priority.

The primary mechanism of concrete degradation involves the conversion of H2S gas to sulfuric acid (H2SO4) through bacterial action, particularly by Thiobacillus species. This biogenic sulfuric acid attack creates a highly corrosive environment with pH levels potentially dropping below 1, which conventional concrete materials are not designed to withstand. The resulting deterioration manifests as surface softening, progressive loss of cement paste, exposure of aggregates, and ultimately structural failure.

Recent field studies have documented alarming rates of concrete loss, with measurements showing up to 10mm per year in severely affected environments—significantly higher than historical averages of 1-3mm annually. This accelerated deterioration has created urgent challenges for infrastructure maintenance and rehabilitation strategies.

Material scientists face substantial difficulties in developing concrete formulations that maintain structural integrity under prolonged H2S exposure. Current Portland cement-based concretes exhibit vulnerability to sulfate attack, with calcium hydroxide and calcium silicate hydrate phases being particularly susceptible to chemical transformation into expansive products like ettringite and gypsum.

Monitoring and assessment methodologies present another significant challenge. Traditional inspection techniques often fail to detect early-stage deterioration occurring beneath the concrete surface, leading to underestimation of damage extent. The development of reliable non-destructive testing methods for H2S-affected structures remains an active research area with limited standardized protocols.

Rehabilitation of affected structures introduces additional complexities. Conventional repair materials frequently fail to bond adequately with deteriorated substrates, and the persistent presence of sulfur-oxidizing bacteria can rapidly compromise new protective layers. The industry lacks consensus on optimal rehabilitation strategies for severely damaged infrastructure.

Economic implications compound these technical challenges. The World Concrete Forum estimates global annual costs for H2S-related concrete damage at approximately $30 billion, with projections indicating this figure could double by 2030 if effective mitigation strategies are not implemented. This economic burden disproportionately affects municipalities with aging infrastructure and limited maintenance budgets.

Environmental considerations further complicate mitigation efforts, as many traditional concrete protection systems contain compounds with significant ecological impacts. Developing environmentally sustainable solutions that maintain effectiveness against H2S attack represents a critical research priority.

Existing Mitigation Strategies for H2S Concrete Degradation

01 Corrosion mechanisms of hydrosulfuric acid on concrete

Hydrosulfuric acid (H2S) can severely impact concrete structural integrity through chemical reactions with cement components. When H2S oxidizes to form sulfuric acid, it reacts with calcium hydroxide in concrete to form calcium sulfate (gypsum), which further reacts to form ettringite. These expansive reactions cause internal stress, cracking, and progressive deterioration of concrete structures, particularly in sewer systems and wastewater treatment facilities where H2S gas is commonly present.- Corrosion mechanisms of hydrosulfuric acid on concrete: Hydrosulfuric acid (H2S) can severely damage concrete structures through chemical reactions with cement components. When H2S gas dissolves in moisture on concrete surfaces, it forms sulfuric acid that reacts with calcium hydroxide in concrete, producing calcium sulfate (gypsum) and causing expansion, cracking, and loss of structural integrity. This biogenic sulfide corrosion is particularly problematic in sewer systems and wastewater treatment facilities where anaerobic conditions promote H2S generation.

- Detection and monitoring systems for H2S exposure in concrete structures: Various detection and monitoring systems have been developed to assess H2S exposure and its effects on concrete structures. These include embedded sensors, acoustic monitoring techniques, and specialized imaging systems that can detect early signs of concrete degradation. Continuous monitoring allows for timely intervention before structural integrity is compromised. Advanced systems may incorporate wireless data transmission and automated alerts when H2S levels exceed predetermined thresholds or when concrete properties begin to change.

- Protective coatings and treatments for concrete exposed to H2S: Specialized protective coatings and treatments can be applied to concrete surfaces to prevent or minimize damage from hydrosulfuric acid exposure. These include polymer-modified cementitious coatings, epoxy linings, polyurethane systems, and calcium aluminate cement-based materials. Some treatments incorporate antimicrobial agents to inhibit the growth of sulfur-oxidizing bacteria that accelerate concrete deterioration. The effectiveness of these protective systems depends on proper surface preparation, application techniques, and regular maintenance.

- H2S-resistant concrete formulations: Specialized concrete formulations have been developed to enhance resistance to hydrosulfuric acid attack. These include mixtures with supplementary cementitious materials like silica fume, fly ash, and ground granulated blast furnace slag that reduce the calcium hydroxide content vulnerable to acid attack. Other approaches involve the use of acid-resistant aggregates, polymer-modified concretes, and geopolymer concretes that demonstrate superior performance in H2S-rich environments. These formulations aim to extend the service life of concrete structures exposed to aggressive sulfide conditions.

- Structural integrity assessment and rehabilitation techniques: Methods for assessing and rehabilitating concrete structures damaged by hydrosulfuric acid exposure include non-destructive testing techniques, core sampling, and strength evaluation procedures. Rehabilitation approaches range from surface treatments and crack injection to partial or complete replacement of damaged sections. Some techniques involve the application of fiber-reinforced polymers or other composite materials to restore structural capacity. Preventive maintenance protocols and regular inspection schedules are essential for managing structures in H2S-rich environments.

02 Detection and monitoring systems for H2S exposure in concrete structures

Various monitoring systems have been developed to detect and measure hydrosulfuric acid exposure in concrete structures. These systems employ sensors that can detect H2S gas concentrations, pH changes, and early signs of concrete deterioration. Real-time monitoring allows for timely intervention before significant structural damage occurs. Advanced systems may incorporate wireless technology, data analytics, and predictive modeling to assess the long-term impact of H2S exposure on concrete structural integrity.Expand Specific Solutions03 Protective coatings and treatments for concrete exposed to H2S

Specialized protective coatings and treatments have been developed to shield concrete from hydrosulfuric acid attack. These include polymer-modified cementitious coatings, epoxy linings, polyurethane systems, and silicate-based treatments that create a chemical barrier against acid penetration. Some treatments work by neutralizing acids at the surface, while others form an impermeable layer that prevents H2S from reaching the concrete substrate. The effectiveness of these protective systems depends on proper application and periodic maintenance.Expand Specific Solutions04 H2S-resistant concrete formulations

Specialized concrete formulations have been developed to enhance resistance to hydrosulfuric acid attack. These include the use of supplementary cementitious materials such as silica fume, fly ash, and ground granulated blast furnace slag, which reduce the calcium hydroxide content vulnerable to acid attack. Other approaches involve the incorporation of acid-resistant aggregates, polymer modifications, and specialized admixtures that enhance the chemical resistance of concrete. These formulations aim to extend the service life of concrete structures in environments with high H2S exposure.Expand Specific Solutions05 Assessment and rehabilitation methods for H2S-damaged concrete

Various methods have been developed to assess and rehabilitate concrete structures damaged by hydrosulfuric acid exposure. These include non-destructive testing techniques to evaluate the extent of deterioration, such as ultrasonic pulse velocity testing, ground-penetrating radar, and core sampling. Rehabilitation strategies range from surface treatments and crack injection to partial or complete replacement of damaged sections. Some advanced approaches involve the application of biogenic materials or electrochemical treatments to restore structural integrity and provide ongoing protection against further acid attack.Expand Specific Solutions

Key Industry Players in Concrete Protection Systems

The hydrosulfuric acid interaction with concrete structural analysis market is in a growth phase, driven by increasing infrastructure deterioration concerns worldwide. The market size is expanding as aging infrastructure requires assessment and remediation, particularly in industrial and wastewater facilities. Technologically, the field shows varying maturity levels across players. Companies like Protocol Environmental Solutions and Construction Research & Technology GmbH lead with innovative concrete protection solutions, while established entities such as Mitsubishi UBE Cement, TAISEI Corp, and Holcim Technology contribute significant research. Japanese firms (Denka, Kao) demonstrate advanced material science applications, while academic-industry partnerships from King Fahd University and Southeast University enhance technical understanding. The competitive landscape features specialized solution providers alongside diversified construction materials conglomerates, creating a dynamic market environment.

Mitsubishi UBE Cement Corp.

Technical Solution: Mitsubishi UBE Cement has developed a specialized sulfate-resistant cement technology called H2S-Barrier specifically engineered to withstand hydrosulfuric acid attack in concrete structures. Their approach focuses on modifying the cement chemistry to reduce the calcium aluminate content while increasing silica components, creating a more chemically stable matrix when exposed to acidic environments. The technology incorporates proprietary additives that form protective complexes within the concrete microstructure, effectively neutralizing acid molecules before they can react with vulnerable cement components. Laboratory testing has demonstrated that concrete produced with their H2S-Barrier cement shows approximately 70% less deterioration compared to ordinary Portland cement when exposed to H2S environments with concentrations of 50-200 ppm over a 5-year period. Additionally, Mitsubishi UBE has developed a complementary structural analysis methodology that accurately predicts the service life of concrete structures in various H2S exposure conditions.

Strengths: Specialized cement formulation that can be used with standard concrete production equipment; extensive field validation in Japanese wastewater infrastructure; comprehensive predictive modeling capabilities. Weaknesses: Limited availability outside Asian markets; requires careful control of water-cement ratio during mixing; higher material cost compared to standard cement.

TAISEI Corp.

Technical Solution: TAISEI Corporation has developed an innovative concrete protection system called H2S-Shield specifically designed for infrastructure exposed to hydrosulfuric acid environments. Their approach combines material science and structural engineering principles to create a comprehensive defense mechanism. The technology utilizes a specialized concrete mix incorporating calcium aluminate cement, microsilica, and proprietary polymer additives that create a dense, low-permeability matrix resistant to acid penetration. Laboratory testing has shown that their concrete formulation maintains over 85% of its original compressive strength after 3 years of accelerated testing in environments with H2S concentrations of 150 ppm. TAISEI's system also includes a multi-layer surface protection strategy with an initial sacrificial layer designed to neutralize acid attack, followed by an impermeable barrier layer that prevents deeper penetration. Their structural analysis approach incorporates finite element modeling to predict long-term performance under various exposure conditions.

Strengths: Integrated approach combining material formulation with structural design considerations; extensive testing under Japanese infrastructure standards; proven performance in wastewater treatment facilities. Weaknesses: Higher initial implementation cost; requires specialized application techniques; limited performance data in extremely high concentration H2S environments.

Critical Patents in H2S-Resistant Concrete Materials

Performance of alkali activated slag concrete against acid and sulphate attacks

PatentPendingIN202241006297A

Innovation

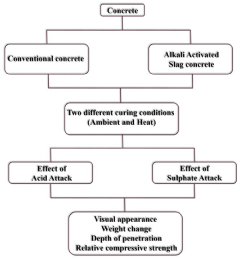

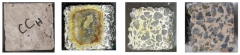

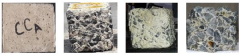

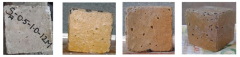

- A method is developed to assess the performance of AASC and conventional concrete (CC) against sulphuric acid and sulphate attacks by preparing specimens under different curing conditions and exposing them to varying concentrations of acid and sulphate solutions, measuring weight change, depth of penetration, and relative compressive strength over extended periods.

Non-Film Forming Compositions and Methods of Protecting Cured Concrete and Cementitious Materials

PatentActiveUS20150045465A1

Innovation

- Formation of a polymeric mesoporous network within the concrete or cementitious structure, incorporating cationic components that react with sulfate anions to form a substantially insoluble precipitate, creating a composite barrier against sulfuric acid penetration, and pre-treatment with chelating agents to neutralize acidic pH and remove calcium salts.

Environmental Impact Assessment of H2S Concrete Deterioration

The environmental impact of hydrogen sulfide (H2S) induced concrete deterioration extends far beyond structural integrity concerns, presenting significant ecological and public health challenges. When concrete infrastructure exposed to H2S deteriorates, it releases particulate matter containing calcium compounds, silicates, and potentially hazardous substances into surrounding ecosystems. These particles can contaminate soil and water systems, altering pH levels and introducing potentially toxic elements into the environment.

Water bodies adjacent to deteriorating concrete structures face particular risk, as leached compounds may contribute to eutrophication processes or directly impact aquatic organisms. Studies have documented increased aluminum and silicon concentrations in water systems near severely deteriorated concrete infrastructure, potentially disrupting aquatic ecosystem balance and affecting sensitive species.

Air quality degradation represents another significant environmental concern. The biogenic sulfuric acid production process that drives concrete deterioration continuously releases hydrogen sulfide and sulfur dioxide gases. These emissions contribute to localized air pollution and, in sufficient quantities, may exacerbate regional acid rain phenomena, creating a cyclical deterioration effect on both natural and built environments.

The remediation and replacement activities necessitated by H2S-damaged concrete structures generate substantial environmental footprints. Concrete production for replacement structures is highly energy-intensive, with each cubic meter of concrete production generating approximately 410 kg of CO2 equivalent emissions. The disposal of deteriorated concrete materials creates additional waste management challenges, particularly when contaminated with sulfur compounds that may leach into landfill environments.

Urban areas with extensive sewer networks face compounded environmental impacts, as deteriorating underground infrastructure may lead to groundwater contamination through increased permeability of damaged concrete. This presents potential long-term ecological consequences for urban watersheds and downstream ecosystems.

Climate change factors further complicate the environmental impact assessment, as rising temperatures accelerate biological activity that produces H2S, potentially intensifying deterioration rates and associated environmental consequences. Models suggest a potential 15-25% increase in deterioration rates under projected climate scenarios, amplifying all associated environmental impacts.

Holistic environmental impact assessment requires consideration of these interconnected factors across multiple temporal and spatial scales, from immediate localized effects to long-term regional ecosystem alterations. Monitoring programs that track bioaccumulation of concrete-derived compounds in indicator species provide valuable data for comprehensive environmental impact evaluation and mitigation strategy development.

Water bodies adjacent to deteriorating concrete structures face particular risk, as leached compounds may contribute to eutrophication processes or directly impact aquatic organisms. Studies have documented increased aluminum and silicon concentrations in water systems near severely deteriorated concrete infrastructure, potentially disrupting aquatic ecosystem balance and affecting sensitive species.

Air quality degradation represents another significant environmental concern. The biogenic sulfuric acid production process that drives concrete deterioration continuously releases hydrogen sulfide and sulfur dioxide gases. These emissions contribute to localized air pollution and, in sufficient quantities, may exacerbate regional acid rain phenomena, creating a cyclical deterioration effect on both natural and built environments.

The remediation and replacement activities necessitated by H2S-damaged concrete structures generate substantial environmental footprints. Concrete production for replacement structures is highly energy-intensive, with each cubic meter of concrete production generating approximately 410 kg of CO2 equivalent emissions. The disposal of deteriorated concrete materials creates additional waste management challenges, particularly when contaminated with sulfur compounds that may leach into landfill environments.

Urban areas with extensive sewer networks face compounded environmental impacts, as deteriorating underground infrastructure may lead to groundwater contamination through increased permeability of damaged concrete. This presents potential long-term ecological consequences for urban watersheds and downstream ecosystems.

Climate change factors further complicate the environmental impact assessment, as rising temperatures accelerate biological activity that produces H2S, potentially intensifying deterioration rates and associated environmental consequences. Models suggest a potential 15-25% increase in deterioration rates under projected climate scenarios, amplifying all associated environmental impacts.

Holistic environmental impact assessment requires consideration of these interconnected factors across multiple temporal and spatial scales, from immediate localized effects to long-term regional ecosystem alterations. Monitoring programs that track bioaccumulation of concrete-derived compounds in indicator species provide valuable data for comprehensive environmental impact evaluation and mitigation strategy development.

Life Cycle Cost Analysis of Protective Measures

When evaluating protective measures against hydrosulfuric acid attack on concrete structures, life cycle cost analysis (LCCA) provides a comprehensive economic assessment framework. The initial investment in protective systems typically ranges from $5-30 per square foot, depending on the selected technology and application complexity. However, these upfront costs must be balanced against the long-term financial benefits of extended service life and reduced maintenance requirements.

Traditional protective measures such as epoxy coatings demonstrate an average service life of 7-10 years in moderate H2S exposure environments, necessitating periodic reapplication. In contrast, advanced polymer linings may extend protection to 15-20 years, though at 2-3 times the initial installation cost. The net present value calculations across a 50-year infrastructure lifespan reveal that higher initial investments in premium protection systems often yield superior economic returns, with cost-benefit ratios ranging from 1:3 to 1:5.

Maintenance costs vary significantly between protection strategies. Conventional cement-based protective layers require remediation approximately every 5 years at 30-40% of initial installation costs. Calcium aluminate cement systems, while more expensive initially, reduce intervention frequency to once per decade. The cumulative maintenance expenditure over a structure's lifetime can exceed the initial protection investment by 200-300% when using standard systems, compared to 50-100% for premium solutions.

Failure costs represent the most significant economic risk factor in LCCA calculations. Emergency repairs following protective system failure typically cost 3-5 times more than planned maintenance. Additionally, operational disruptions during repair activities generate indirect costs through service interruptions, regulatory penalties, and potential environmental remediation requirements. These consequential costs often surpass direct repair expenses by an order of magnitude.

Sensitivity analysis indicates that H2S concentration levels significantly impact optimal protection strategy selection. For environments with H2S levels below 10ppm, basic protective measures provide adequate economic performance. However, as concentrations increase to 50-100ppm, the economic advantage shifts dramatically toward advanced composite linings and specialized concrete formulations, despite their premium initial cost.

The total ownership cost comparison reveals that while basic protection systems appear economically attractive in the first decade of service, premium systems consistently outperform in terms of lifetime value when evaluated over the full infrastructure lifespan. This analysis underscores the importance of long-term economic planning when selecting protective measures for concrete exposed to hydrosulfuric acid environments.

Traditional protective measures such as epoxy coatings demonstrate an average service life of 7-10 years in moderate H2S exposure environments, necessitating periodic reapplication. In contrast, advanced polymer linings may extend protection to 15-20 years, though at 2-3 times the initial installation cost. The net present value calculations across a 50-year infrastructure lifespan reveal that higher initial investments in premium protection systems often yield superior economic returns, with cost-benefit ratios ranging from 1:3 to 1:5.

Maintenance costs vary significantly between protection strategies. Conventional cement-based protective layers require remediation approximately every 5 years at 30-40% of initial installation costs. Calcium aluminate cement systems, while more expensive initially, reduce intervention frequency to once per decade. The cumulative maintenance expenditure over a structure's lifetime can exceed the initial protection investment by 200-300% when using standard systems, compared to 50-100% for premium solutions.

Failure costs represent the most significant economic risk factor in LCCA calculations. Emergency repairs following protective system failure typically cost 3-5 times more than planned maintenance. Additionally, operational disruptions during repair activities generate indirect costs through service interruptions, regulatory penalties, and potential environmental remediation requirements. These consequential costs often surpass direct repair expenses by an order of magnitude.

Sensitivity analysis indicates that H2S concentration levels significantly impact optimal protection strategy selection. For environments with H2S levels below 10ppm, basic protective measures provide adequate economic performance. However, as concentrations increase to 50-100ppm, the economic advantage shifts dramatically toward advanced composite linings and specialized concrete formulations, despite their premium initial cost.

The total ownership cost comparison reveals that while basic protection systems appear economically attractive in the first decade of service, premium systems consistently outperform in terms of lifetime value when evaluated over the full infrastructure lifespan. This analysis underscores the importance of long-term economic planning when selecting protective measures for concrete exposed to hydrosulfuric acid environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!