ICP-MS vs EDX: Which Detects Metals in Alloys Better?

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Detection Technology Background and Objectives

Metal detection technologies have evolved significantly over the past several decades, transitioning from simple magnetic methods to sophisticated analytical techniques capable of identifying specific elemental compositions with remarkable precision. The field has been driven by increasing demands across industries including manufacturing, aerospace, automotive, and materials science, where accurate alloy composition analysis is critical for quality control, research, and development.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) emerged in the 1980s as a revolutionary technique for elemental analysis, offering unprecedented sensitivity for detecting metals at parts-per-trillion levels. This technology ionizes samples using an argon plasma and separates ions based on their mass-to-charge ratio, enabling quantitative measurement of multiple elements simultaneously. The development of ICP-MS represented a significant leap forward from earlier atomic absorption spectroscopy methods.

X-ray Energy Dispersive Spectroscopy (EDX or EDS), conversely, has roots in the 1960s and gained prominence with the advancement of electron microscopy. This technique detects X-rays emitted from a sample when bombarded with an electron beam, with each element producing characteristic X-ray energy signatures. EDX has become increasingly sophisticated with improvements in detector technology and data processing capabilities.

The technological evolution in metal detection has been characterized by continuous improvements in sensitivity, accuracy, speed, and sample preparation requirements. Modern systems now incorporate advanced computing capabilities, automation, and sophisticated algorithms for data interpretation, significantly enhancing analytical capabilities.

The primary objective of this technical research is to comprehensively compare ICP-MS and EDX technologies for metal detection in alloys, evaluating their respective strengths, limitations, and optimal application scenarios. Specifically, we aim to determine which technology provides superior performance across various parameters including detection limits, accuracy, precision, sample requirements, speed of analysis, and cost-effectiveness.

Additionally, this research seeks to identify emerging trends and innovations in both technologies that may influence their future applications in alloy analysis. Understanding the complementary nature of these techniques is essential, as many advanced materials research facilities employ both methods for comprehensive characterization of metal alloys.

The findings from this investigation will inform strategic decisions regarding technology investment, application-specific methodology selection, and potential areas for technological improvement or hybridization to address current analytical challenges in metal detection and quantification in complex alloy systems.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) emerged in the 1980s as a revolutionary technique for elemental analysis, offering unprecedented sensitivity for detecting metals at parts-per-trillion levels. This technology ionizes samples using an argon plasma and separates ions based on their mass-to-charge ratio, enabling quantitative measurement of multiple elements simultaneously. The development of ICP-MS represented a significant leap forward from earlier atomic absorption spectroscopy methods.

X-ray Energy Dispersive Spectroscopy (EDX or EDS), conversely, has roots in the 1960s and gained prominence with the advancement of electron microscopy. This technique detects X-rays emitted from a sample when bombarded with an electron beam, with each element producing characteristic X-ray energy signatures. EDX has become increasingly sophisticated with improvements in detector technology and data processing capabilities.

The technological evolution in metal detection has been characterized by continuous improvements in sensitivity, accuracy, speed, and sample preparation requirements. Modern systems now incorporate advanced computing capabilities, automation, and sophisticated algorithms for data interpretation, significantly enhancing analytical capabilities.

The primary objective of this technical research is to comprehensively compare ICP-MS and EDX technologies for metal detection in alloys, evaluating their respective strengths, limitations, and optimal application scenarios. Specifically, we aim to determine which technology provides superior performance across various parameters including detection limits, accuracy, precision, sample requirements, speed of analysis, and cost-effectiveness.

Additionally, this research seeks to identify emerging trends and innovations in both technologies that may influence their future applications in alloy analysis. Understanding the complementary nature of these techniques is essential, as many advanced materials research facilities employ both methods for comprehensive characterization of metal alloys.

The findings from this investigation will inform strategic decisions regarding technology investment, application-specific methodology selection, and potential areas for technological improvement or hybridization to address current analytical challenges in metal detection and quantification in complex alloy systems.

Market Applications and Demand Analysis for Alloy Testing

The global market for metal alloy testing has experienced significant growth in recent years, driven by increasing quality control requirements across multiple industries. The demand for precise metal composition analysis has become critical as manufacturers seek to ensure product integrity, safety, and compliance with increasingly stringent regulatory standards.

In the aerospace sector, alloy testing represents a crucial quality assurance step, with the market valued at approximately $1.2 billion in 2022. Aircraft components require extremely precise metal composition verification to prevent catastrophic failures, creating consistent demand for high-accuracy testing methods. Both ICP-MS and EDX technologies have found substantial applications in this sector, with ICP-MS preferred for final certification due to its superior detection limits.

The automotive industry constitutes another major market segment for alloy testing, particularly as lightweight alloys become more prevalent in vehicle manufacturing. This sector's testing market reached $890 million in 2022, with projected annual growth of 6.8% through 2028. EDX systems have gained significant traction in this space due to their non-destructive nature and ability to perform rapid on-site testing during production processes.

Medical device manufacturing represents a rapidly expanding application area, with alloy testing demand growing at 9.2% annually. The biocompatibility of implantable devices depends critically on precise metal composition, driving demand for ultra-sensitive testing methods like ICP-MS that can detect trace contaminants at parts-per-billion levels.

The electronics industry has emerged as another significant consumer of alloy testing services, particularly for analyzing solder compositions and connector materials. This market segment was valued at $750 million in 2022, with EDX systems holding approximately 65% market share due to their ability to analyze small components without sample destruction.

Geographically, North America and Europe currently dominate the alloy testing market, accounting for 58% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 11.3% annually, driven by expanding manufacturing capabilities in China, India, and Southeast Asian countries.

Market research indicates that laboratories and manufacturing facilities increasingly seek dual-technology solutions, implementing both ICP-MS and EDX systems to leverage their complementary strengths. This trend has created a growing market for integrated testing platforms and data management systems that can consolidate results from multiple analytical techniques.

In the aerospace sector, alloy testing represents a crucial quality assurance step, with the market valued at approximately $1.2 billion in 2022. Aircraft components require extremely precise metal composition verification to prevent catastrophic failures, creating consistent demand for high-accuracy testing methods. Both ICP-MS and EDX technologies have found substantial applications in this sector, with ICP-MS preferred for final certification due to its superior detection limits.

The automotive industry constitutes another major market segment for alloy testing, particularly as lightweight alloys become more prevalent in vehicle manufacturing. This sector's testing market reached $890 million in 2022, with projected annual growth of 6.8% through 2028. EDX systems have gained significant traction in this space due to their non-destructive nature and ability to perform rapid on-site testing during production processes.

Medical device manufacturing represents a rapidly expanding application area, with alloy testing demand growing at 9.2% annually. The biocompatibility of implantable devices depends critically on precise metal composition, driving demand for ultra-sensitive testing methods like ICP-MS that can detect trace contaminants at parts-per-billion levels.

The electronics industry has emerged as another significant consumer of alloy testing services, particularly for analyzing solder compositions and connector materials. This market segment was valued at $750 million in 2022, with EDX systems holding approximately 65% market share due to their ability to analyze small components without sample destruction.

Geographically, North America and Europe currently dominate the alloy testing market, accounting for 58% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 11.3% annually, driven by expanding manufacturing capabilities in China, India, and Southeast Asian countries.

Market research indicates that laboratories and manufacturing facilities increasingly seek dual-technology solutions, implementing both ICP-MS and EDX systems to leverage their complementary strengths. This trend has created a growing market for integrated testing platforms and data management systems that can consolidate results from multiple analytical techniques.

ICP-MS and EDX Current Capabilities and Limitations

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Energy Dispersive X-ray Spectroscopy (EDX) represent two distinct analytical approaches for metal detection in alloys, each with specific capabilities and limitations that determine their suitability for different applications.

ICP-MS offers exceptional sensitivity, capable of detecting elements at parts per trillion (ppt) levels, making it ideal for trace element analysis in alloys. This technique provides comprehensive elemental coverage across the periodic table, with particular strength in analyzing rare earth elements and heavy metals. The quantitative accuracy of ICP-MS typically reaches 1-3% relative standard deviation, enabling precise composition determination critical for high-performance alloys in aerospace and medical applications.

However, ICP-MS presents significant limitations for routine alloy analysis. The technique requires sample dissolution, making it destructive and time-consuming with preparation times often exceeding 24 hours. The equipment demands considerable laboratory infrastructure, including high-purity argon gas supply and specialized ventilation. With system costs ranging from $150,000 to $500,000 plus annual maintenance expenses of $15,000-30,000, ICP-MS represents a substantial investment that smaller facilities may find prohibitive.

In contrast, EDX offers rapid, non-destructive analysis with minimal sample preparation, typically delivering results within minutes. Modern EDX systems provide spatial resolution down to 1 μm, enabling microstructural analysis and identification of inclusions or precipitates within alloys. The technique excels at analyzing major and minor elements in bulk materials, particularly for elements with atomic numbers above 11 (sodium).

EDX limitations include relatively poor detection limits (typically 0.1-0.5 weight percent) that prevent reliable trace element analysis. Quantitative accuracy ranges from 5-15% relative error, significantly less precise than ICP-MS. Light elements (Z<11) present particular challenges due to low-energy X-ray absorption, making carbon, boron, and beryllium difficult to quantify accurately in alloy systems.

The operational environments for these techniques differ substantially. EDX systems function effectively in manufacturing environments with minimal sample preparation, while ICP-MS requires controlled laboratory conditions with stringent contamination protocols. This distinction significantly impacts their practical utility in production settings where rapid quality control decisions are essential.

Recent technological developments have somewhat narrowed these capability gaps. Modern EDX systems with silicon drift detectors have improved light element detection, while automated sample preparation systems have reduced ICP-MS analysis times. However, the fundamental strengths and limitations of each technique remain largely unchanged, necessitating careful selection based on specific analytical requirements.

ICP-MS offers exceptional sensitivity, capable of detecting elements at parts per trillion (ppt) levels, making it ideal for trace element analysis in alloys. This technique provides comprehensive elemental coverage across the periodic table, with particular strength in analyzing rare earth elements and heavy metals. The quantitative accuracy of ICP-MS typically reaches 1-3% relative standard deviation, enabling precise composition determination critical for high-performance alloys in aerospace and medical applications.

However, ICP-MS presents significant limitations for routine alloy analysis. The technique requires sample dissolution, making it destructive and time-consuming with preparation times often exceeding 24 hours. The equipment demands considerable laboratory infrastructure, including high-purity argon gas supply and specialized ventilation. With system costs ranging from $150,000 to $500,000 plus annual maintenance expenses of $15,000-30,000, ICP-MS represents a substantial investment that smaller facilities may find prohibitive.

In contrast, EDX offers rapid, non-destructive analysis with minimal sample preparation, typically delivering results within minutes. Modern EDX systems provide spatial resolution down to 1 μm, enabling microstructural analysis and identification of inclusions or precipitates within alloys. The technique excels at analyzing major and minor elements in bulk materials, particularly for elements with atomic numbers above 11 (sodium).

EDX limitations include relatively poor detection limits (typically 0.1-0.5 weight percent) that prevent reliable trace element analysis. Quantitative accuracy ranges from 5-15% relative error, significantly less precise than ICP-MS. Light elements (Z<11) present particular challenges due to low-energy X-ray absorption, making carbon, boron, and beryllium difficult to quantify accurately in alloy systems.

The operational environments for these techniques differ substantially. EDX systems function effectively in manufacturing environments with minimal sample preparation, while ICP-MS requires controlled laboratory conditions with stringent contamination protocols. This distinction significantly impacts their practical utility in production settings where rapid quality control decisions are essential.

Recent technological developments have somewhat narrowed these capability gaps. Modern EDX systems with silicon drift detectors have improved light element detection, while automated sample preparation systems have reduced ICP-MS analysis times. However, the fundamental strengths and limitations of each technique remain largely unchanged, necessitating careful selection based on specific analytical requirements.

Comparative Analysis of ICP-MS and EDX Methodologies

01 ICP-MS technology for trace metal detection

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is a highly sensitive analytical technique used for detecting metals at trace levels. It can identify and quantify multiple elements simultaneously with detection limits in the parts per trillion range. The technique involves ionizing the sample with inductively coupled plasma and then using mass spectrometry to separate and quantify the ions. ICP-MS is particularly valuable for environmental monitoring, pharmaceutical analysis, and materials characterization where ultra-low detection limits are required.- ICP-MS technology for trace metal detection: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is a highly sensitive analytical technique used for detecting metals at trace levels. It can identify and quantify multiple elements simultaneously with detection limits in the parts per trillion range. The technique involves ionizing the sample with inductively coupled plasma and then using mass spectrometry to separate and quantify the ions. ICP-MS is particularly valuable for environmental monitoring, pharmaceutical analysis, and geological studies where ultra-low detection limits are required.

- EDX spectroscopy for elemental analysis: Energy Dispersive X-ray (EDX) spectroscopy is a technique used for the elemental analysis of materials. It works by detecting X-rays emitted from a sample during bombardment by an electron beam, allowing for the identification of elements present in the sample. EDX provides rapid, non-destructive analysis and is often integrated with scanning electron microscopes. While less sensitive than ICP-MS for trace elements, EDX offers advantages in spatial resolution, allowing for mapping of elemental distribution across a sample surface.

- Comparative capabilities of ICP-MS and EDX for metal detection: ICP-MS and EDX offer complementary capabilities for metal detection. ICP-MS provides superior sensitivity (parts per trillion) and is ideal for trace element analysis but requires sample dissolution. EDX offers moderate sensitivity (typically parts per thousand) but allows for non-destructive analysis and spatial mapping of elements. The selection between these techniques depends on factors such as required detection limits, sample type, and whether spatial distribution information is needed. For comprehensive metal analysis, these techniques are sometimes used in combination to leverage their respective strengths.

- Sample preparation methods for metal analysis: Effective sample preparation is crucial for accurate metal detection using ICP-MS and EDX techniques. For ICP-MS, samples typically require digestion using acids or other reagents to bring metals into solution. EDX may require surface cleaning, polishing, or coating depending on the sample type. Proper preparation methods help minimize interference, reduce contamination, and ensure representative sampling. The choice of preparation technique depends on the sample matrix, target metals, and required detection limits. Advances in sample preparation automation have improved throughput and reproducibility for both analytical methods.

- Innovations in metal detection instrumentation: Recent innovations have enhanced the capabilities of both ICP-MS and EDX for metal detection. These include the development of collision/reaction cells in ICP-MS to reduce interferences, improved detector technologies for better sensitivity, and software advancements for data processing. For EDX, developments include silicon drift detectors with improved energy resolution and sensitivity. Portable and field-deployable versions of both technologies have emerged, enabling on-site analysis. Integration with other analytical techniques, such as chromatography for ICP-MS or electron microscopy for EDX, has further expanded their applications in metal detection and characterization.

02 EDX spectroscopy for elemental analysis

Energy Dispersive X-ray (EDX) spectroscopy is a technique used for the elemental analysis of materials. It works by detecting X-rays emitted from a sample during bombardment by an electron beam, allowing for identification of the elemental composition of the analyzed volume. EDX provides rapid, non-destructive analysis and is often integrated with scanning electron microscopes (SEM). While not as sensitive as ICP-MS for trace elements, EDX offers spatial resolution and is particularly useful for analyzing the distribution of elements in solid samples and identifying contaminants.Expand Specific Solutions03 Comparative capabilities of ICP-MS and EDX for metal detection

ICP-MS and EDX have complementary capabilities for metal detection. ICP-MS offers superior sensitivity (parts per trillion) and is ideal for trace element analysis in solutions, but requires sample dissolution. EDX provides immediate results with minimal sample preparation and offers spatial mapping of elements, but has higher detection limits (typically parts per thousand to parts per million). The selection between these techniques depends on the specific application requirements, including detection limits needed, sample type, and whether spatial distribution information is required.Expand Specific Solutions04 Sample preparation methods for metal analysis

Effective sample preparation is crucial for accurate metal detection using ICP-MS and EDX techniques. For ICP-MS, samples typically require digestion using acids or other reagents to convert solid samples into solution form. For EDX, samples may need polishing, coating, or sectioning to expose the area of interest. Proper preparation methods can significantly improve detection limits, reduce interference, and enhance analytical accuracy. Techniques such as microwave digestion, acid dissolution, and fusion methods are commonly employed depending on the sample matrix and target elements.Expand Specific Solutions05 Advanced applications and combined analytical approaches

Advanced applications of ICP-MS and EDX include their integration with other analytical techniques to enhance metal detection capabilities. Hyphenated techniques such as laser ablation ICP-MS (LA-ICP-MS) allow for direct solid sampling with high sensitivity and spatial resolution. Similarly, EDX combined with scanning electron microscopy (SEM-EDX) provides both imaging and elemental analysis capabilities. These combined approaches are particularly valuable in fields such as forensics, archaeology, semiconductor manufacturing, and materials science where both spatial distribution and ultra-trace detection of metals are important.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The metal detection technology landscape for alloys is currently in a mature growth phase, with ICP-MS and EDX technologies competing in a market valued at approximately $3-4 billion annually. ICP-MS offers superior sensitivity and accuracy for trace element detection, as demonstrated by industry leaders like Bioyong Technology and Revvity Health Sciences who have developed advanced mass spectrometry solutions. Meanwhile, EDX technology provides faster, non-destructive analysis with lower operational costs, with companies like Jiangsu Skyray Instrument and NCS Testing Technology dominating this segment. The competitive landscape is further shaped by research institutions like Tianjin University and Changzhou University, which are advancing both technologies through innovative applications in metallurgical analysis, while industrial players such as Shanxi Taigang Stainless Steel and China Petroleum & Chemical Corp represent significant end-users driving market demand.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed sophisticated analytical methodologies utilizing both ICP-MS and EDX for metal detection in their advanced alloy development programs. Their ICP-MS approach employs sector-field technology (HR-ICP-MS) with magnetic sector analyzers achieving mass resolution exceeding 10,000, allowing separation of isotopes with minimal mass differences. This is particularly valuable for analyzing complex alloys containing rare earth elements where isobaric interferences are problematic. Their sample preparation protocols include specialized microwave digestion techniques optimized for difficult-to-dissolve alloys. For EDX analysis, DuPont utilizes wavelength dispersive systems (WD-XRF) alongside energy dispersive technology, providing enhanced resolution for closely spaced elemental peaks. Their research has established that while ICP-MS delivers detection limits approximately 1000 times lower than EDX (ppt vs ppm range), their optimized EDX methodologies offer significant advantages for production environments where rapid, non-destructive analysis is required. DuPont has integrated these complementary techniques into their quality control systems for specialty alloy manufacturing.

Strengths: High-resolution ICP-MS capabilities provide exceptional isotopic discrimination; integrated analytical approach combining multiple techniques; extensive experience with challenging alloy matrices including refractory metals. Weaknesses: Their analytical systems require significant expertise to operate effectively; higher capital investment compared to single-technique approaches.

Revvity Health Sciences, Inc.

Technical Solution: Revvity Health Sciences has developed advanced analytical platforms for metal detection in alloys, focusing on high-precision applications in medical devices and implantable materials. Their ICP-MS technology incorporates time-of-flight mass analyzers with simultaneous multi-element detection capabilities, achieving sub-ppt detection limits for critical elements. Their proprietary sample introduction system features a desolvating nebulizer that significantly reduces oxide formation and enhances sensitivity for refractory elements common in biomedical alloys. For EDX analysis, Revvity employs micro-XRF systems with polycapillary X-ray optics enabling spatial resolution down to 20 μm, critical for analyzing compositional gradients in advanced alloys. Their comparative studies demonstrate that while ICP-MS provides approximately 100-1000x better detection limits than EDX for most elements, their EDX systems offer superior capabilities for non-destructive mapping of elemental distributions across alloy interfaces and microstructures. Revvity has pioneered specialized protocols for detecting trace contaminants in implant-grade alloys, where even ppm-level impurities can impact biocompatibility.

Strengths: Exceptional sensitivity for trace contaminants in biomedical alloys; advanced spatial mapping capabilities with micro-XRF; comprehensive validation protocols meeting regulatory requirements for medical materials. Weaknesses: Their analytical systems are optimized for specialized applications rather than general industrial use; higher operational costs due to ultra-high purity requirements.

Technical Principles and Innovations in Metal Detection

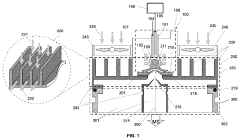

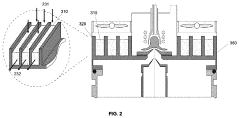

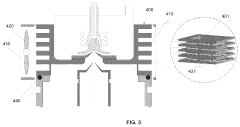

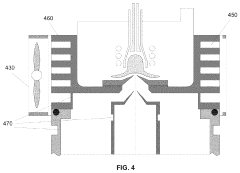

Air-cooled interface for inductively coupled plasma mass spectrometer (ICP-MS)

PatentActiveUS11864303B2

Innovation

- An air-cooled interface for ICP-MS systems using fins, open-cell metal foams, compact heat exchangers, or heat pipes to manage heat dissipation, with adjustable thermal resistors to direct heat away from sensitive components and prevent recombination, utilizing natural or forced convection to enhance cooling efficiency.

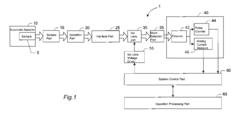

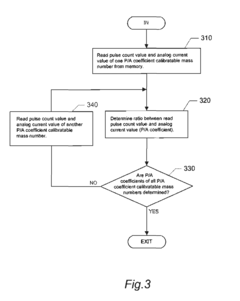

Inductively coupled plasma mass spectroscopy apparatus and measured data processing method in the inductively coupled plasma mass spectroscopy apparatus

PatentActiveUS8530829B2

Innovation

- An ICP-MS apparatus and method that uses standard density samples to generate a working curve and adjusts ion lens voltage to ensure signal intensities fall within a calibration range, combined with a P/A coefficient estimation method that correlates P/A coefficients from different measurements to accurately determine coefficients for mass numbers outside the initial calibration range.

Cost-Benefit Analysis of Implementation

When evaluating the implementation of ICP-MS versus EDX for metal detection in alloys, cost-benefit analysis reveals significant differences in initial investment, operational expenses, and long-term value proposition.

The initial capital expenditure for ICP-MS systems typically ranges from $150,000 to $300,000, substantially higher than EDX analyzers which generally cost between $50,000 and $150,000. This price differential represents a significant barrier to entry for smaller laboratories or manufacturing facilities with limited capital budgets.

Operational costs further differentiate these technologies. ICP-MS requires specialized gases (argon), higher-grade reagents, and more extensive sample preparation protocols. Annual maintenance contracts for ICP-MS systems average $15,000-25,000, compared to $8,000-15,000 for EDX systems. Additionally, ICP-MS demands more specialized operator training, increasing personnel costs by approximately 20-30% compared to EDX operation.

Sample throughput considerations impact cost efficiency significantly. While ICP-MS requires more extensive sample preparation (acid digestion, dilution), it can analyze multiple samples simultaneously. EDX offers non-destructive, rapid analysis with minimal sample preparation, enabling higher throughput in production environments where speed is critical.

Return on investment calculations must account for analytical capabilities relative to specific industry needs. For applications requiring ultra-trace element detection (ppb-ppt levels) or isotopic analysis, ICP-MS delivers superior value despite higher costs. Conversely, for routine quality control or field applications where moderate sensitivity (ppm levels) is sufficient, EDX provides better cost efficiency.

Facility requirements represent another cost consideration. ICP-MS demands controlled laboratory environments with specialized ventilation, gas supply infrastructure, and waste disposal systems. EDX systems, particularly portable models, have minimal facility requirements, offering flexibility for in-field or production-floor deployment without significant infrastructure investment.

Long-term value assessment must incorporate technological obsolescence factors. ICP-MS systems typically maintain analytical relevance for 8-10 years before major upgrades become necessary, while EDX systems may require updates after 5-7 years due to detector and X-ray tube limitations. This extended operational lifespan partially offsets the higher initial investment in ICP-MS technology.

The initial capital expenditure for ICP-MS systems typically ranges from $150,000 to $300,000, substantially higher than EDX analyzers which generally cost between $50,000 and $150,000. This price differential represents a significant barrier to entry for smaller laboratories or manufacturing facilities with limited capital budgets.

Operational costs further differentiate these technologies. ICP-MS requires specialized gases (argon), higher-grade reagents, and more extensive sample preparation protocols. Annual maintenance contracts for ICP-MS systems average $15,000-25,000, compared to $8,000-15,000 for EDX systems. Additionally, ICP-MS demands more specialized operator training, increasing personnel costs by approximately 20-30% compared to EDX operation.

Sample throughput considerations impact cost efficiency significantly. While ICP-MS requires more extensive sample preparation (acid digestion, dilution), it can analyze multiple samples simultaneously. EDX offers non-destructive, rapid analysis with minimal sample preparation, enabling higher throughput in production environments where speed is critical.

Return on investment calculations must account for analytical capabilities relative to specific industry needs. For applications requiring ultra-trace element detection (ppb-ppt levels) or isotopic analysis, ICP-MS delivers superior value despite higher costs. Conversely, for routine quality control or field applications where moderate sensitivity (ppm levels) is sufficient, EDX provides better cost efficiency.

Facility requirements represent another cost consideration. ICP-MS demands controlled laboratory environments with specialized ventilation, gas supply infrastructure, and waste disposal systems. EDX systems, particularly portable models, have minimal facility requirements, offering flexibility for in-field or production-floor deployment without significant infrastructure investment.

Long-term value assessment must incorporate technological obsolescence factors. ICP-MS systems typically maintain analytical relevance for 8-10 years before major upgrades become necessary, while EDX systems may require updates after 5-7 years due to detector and X-ray tube limitations. This extended operational lifespan partially offsets the higher initial investment in ICP-MS technology.

Industry Standards and Calibration Protocols

The standardization of analytical methods for metal detection in alloys is critical for ensuring reliable and comparable results across different laboratories and industries. For ICP-MS (Inductively Coupled Plasma Mass Spectrometry), the primary international standards are established by organizations such as ASTM International, ISO, and NIST. ASTM E2618 specifically addresses the determination of elements in metallic matrices using ICP-MS, providing detailed protocols for sample preparation, instrument calibration, and data interpretation.

ISO 17294-2 offers comprehensive guidelines for ICP-MS applications, including specific procedures for metal analysis in various matrices. These standards typically require multi-point calibration curves using certified reference materials (CRMs) that closely match the composition of the alloy being analyzed, ensuring matrix effects are properly accounted for.

For EDX (Energy Dispersive X-ray Spectroscopy), calibration standards are governed by ISO 22309 and ASTM E1508, which outline procedures for quantitative analysis of bulk specimens. Unlike ICP-MS, EDX calibration often employs standardless analysis methods, where fundamental parameter approaches calculate compositions based on theoretical principles rather than direct calibration curves.

Both techniques require regular verification using certified reference materials. For ICP-MS, these typically include solution-based standards from organizations like NIST, while EDX relies on solid reference materials with certified compositions similar to the alloys being analyzed. The frequency of calibration differs significantly: ICP-MS requires daily calibration and regular quality control checks, whereas EDX systems may maintain calibration for weeks or months with periodic verification.

Detection limit verification protocols also differ substantially between the techniques. ICP-MS standards require determination of method detection limits (MDLs) through analysis of low-concentration samples, typically achieving parts-per-billion sensitivity. EDX standards acknowledge higher detection limits (typically 0.1-0.5% by weight) and focus more on accuracy within the detectable range rather than pushing detection limits lower.

Industry-specific standards have also emerged, with aerospace (AS9100), automotive (IATF 16949), and medical device (ISO 13485) sectors developing specialized protocols for metal analysis that incorporate either ICP-MS or EDX depending on the specific requirements for precision, sample throughput, and detection limits.

ISO 17294-2 offers comprehensive guidelines for ICP-MS applications, including specific procedures for metal analysis in various matrices. These standards typically require multi-point calibration curves using certified reference materials (CRMs) that closely match the composition of the alloy being analyzed, ensuring matrix effects are properly accounted for.

For EDX (Energy Dispersive X-ray Spectroscopy), calibration standards are governed by ISO 22309 and ASTM E1508, which outline procedures for quantitative analysis of bulk specimens. Unlike ICP-MS, EDX calibration often employs standardless analysis methods, where fundamental parameter approaches calculate compositions based on theoretical principles rather than direct calibration curves.

Both techniques require regular verification using certified reference materials. For ICP-MS, these typically include solution-based standards from organizations like NIST, while EDX relies on solid reference materials with certified compositions similar to the alloys being analyzed. The frequency of calibration differs significantly: ICP-MS requires daily calibration and regular quality control checks, whereas EDX systems may maintain calibration for weeks or months with periodic verification.

Detection limit verification protocols also differ substantially between the techniques. ICP-MS standards require determination of method detection limits (MDLs) through analysis of low-concentration samples, typically achieving parts-per-billion sensitivity. EDX standards acknowledge higher detection limits (typically 0.1-0.5% by weight) and focus more on accuracy within the detectable range rather than pushing detection limits lower.

Industry-specific standards have also emerged, with aerospace (AS9100), automotive (IATF 16949), and medical device (ISO 13485) sectors developing specialized protocols for metal analysis that incorporate either ICP-MS or EDX depending on the specific requirements for precision, sample throughput, and detection limits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!