ICP-MS vs FTIR: Comparative Study of Aviation Fuel Element Analysis

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aviation Fuel Analysis Background and Objectives

Aviation fuel quality control has evolved significantly over the past decades, driven by increasingly stringent safety requirements and environmental regulations in the aerospace industry. The analysis of elemental composition in aviation fuels represents a critical aspect of quality assurance, as even trace amounts of certain elements can lead to engine damage, reduced performance, or increased emissions. Historically, aviation fuel analysis relied on conventional wet chemistry methods, which were time-consuming and often lacked the sensitivity required for detecting ultra-low concentrations of contaminants.

The development of advanced analytical techniques has revolutionized the field of fuel analysis, with Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Fourier Transform Infrared Spectroscopy (FTIR) emerging as two prominent methodologies. ICP-MS, introduced in the 1980s, has gained significant traction due to its exceptional sensitivity for detecting metals and metalloids at parts-per-billion (ppb) or even parts-per-trillion (ppt) levels. FTIR, with its roots in the mid-20th century, has evolved into a powerful tool for molecular characterization of organic compounds in fuels.

The global aviation industry's continuous pursuit of improved fuel efficiency, reduced emissions, and enhanced safety has intensified the need for more precise and comprehensive fuel analysis techniques. As aircraft engines become more sophisticated and operate under more extreme conditions, the tolerance for impurities in aviation fuels has decreased substantially, necessitating more advanced analytical capabilities.

Current technological trends in aviation fuel analysis are moving toward faster, more sensitive, and field-deployable systems that can provide real-time data on fuel quality. Additionally, there is growing interest in techniques that can simultaneously analyze multiple parameters, reducing the need for separate testing methodologies and streamlining the quality control process.

The primary objective of this comparative study is to evaluate the relative strengths, limitations, and complementary aspects of ICP-MS and FTIR technologies specifically for aviation fuel element analysis. The study aims to determine which technique, or combination of techniques, offers the most comprehensive, accurate, and cost-effective solution for detecting and quantifying elemental contaminants in aviation fuels under various operational scenarios.

Furthermore, this research seeks to establish standardized protocols for the application of these technologies in aviation fuel testing, identify potential areas for technological improvement, and explore emerging hybrid approaches that might leverage the advantages of both methodologies. The findings will inform future research directions and industry best practices in aviation fuel quality assurance.

The development of advanced analytical techniques has revolutionized the field of fuel analysis, with Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Fourier Transform Infrared Spectroscopy (FTIR) emerging as two prominent methodologies. ICP-MS, introduced in the 1980s, has gained significant traction due to its exceptional sensitivity for detecting metals and metalloids at parts-per-billion (ppb) or even parts-per-trillion (ppt) levels. FTIR, with its roots in the mid-20th century, has evolved into a powerful tool for molecular characterization of organic compounds in fuels.

The global aviation industry's continuous pursuit of improved fuel efficiency, reduced emissions, and enhanced safety has intensified the need for more precise and comprehensive fuel analysis techniques. As aircraft engines become more sophisticated and operate under more extreme conditions, the tolerance for impurities in aviation fuels has decreased substantially, necessitating more advanced analytical capabilities.

Current technological trends in aviation fuel analysis are moving toward faster, more sensitive, and field-deployable systems that can provide real-time data on fuel quality. Additionally, there is growing interest in techniques that can simultaneously analyze multiple parameters, reducing the need for separate testing methodologies and streamlining the quality control process.

The primary objective of this comparative study is to evaluate the relative strengths, limitations, and complementary aspects of ICP-MS and FTIR technologies specifically for aviation fuel element analysis. The study aims to determine which technique, or combination of techniques, offers the most comprehensive, accurate, and cost-effective solution for detecting and quantifying elemental contaminants in aviation fuels under various operational scenarios.

Furthermore, this research seeks to establish standardized protocols for the application of these technologies in aviation fuel testing, identify potential areas for technological improvement, and explore emerging hybrid approaches that might leverage the advantages of both methodologies. The findings will inform future research directions and industry best practices in aviation fuel quality assurance.

Market Demand for Advanced Fuel Analysis Techniques

The aviation fuel analysis market is experiencing significant growth driven by stringent safety regulations and increasing focus on fuel quality across the aerospace industry. Current market estimates value the global aviation fuel testing services market at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 5.8% through 2028. This growth is primarily fueled by the expanding commercial aviation sector, particularly in emerging economies across Asia-Pacific and Middle East regions.

Industry stakeholders, including fuel manufacturers, airlines, and regulatory bodies, are increasingly demanding more sophisticated analytical techniques that can provide comprehensive elemental analysis with greater precision and efficiency. Traditional methods are gradually being replaced by advanced technologies that offer enhanced detection capabilities for trace elements and contaminants that can significantly impact engine performance and safety.

The demand for ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and FTIR (Fourier Transform Infrared Spectroscopy) technologies specifically has seen notable growth, with approximately 65% of major aviation fuel testing laboratories investing in at least one of these technologies in the past five years. This trend reflects the industry's recognition of the critical importance of detailed elemental analysis in preventing engine damage, reducing maintenance costs, and ensuring compliance with increasingly stringent international standards.

Airlines and maintenance organizations are particularly interested in analytical methods that can detect metal contaminants at parts-per-billion levels, as these trace elements can catalyze fuel degradation and form deposits in fuel systems. Market research indicates that maintenance cost savings from improved fuel quality monitoring can exceed 300,000 USD annually for a mid-sized airline fleet.

Regulatory developments are also driving market demand, with organizations such as ASTM International, the International Air Transport Association (IATA), and various national aviation authorities continuously updating fuel quality specifications. These evolving standards create a persistent need for more sensitive and accurate analytical capabilities, particularly for detecting silicon, lead, copper, and other elements that can compromise fuel system integrity.

The military aviation sector represents another significant market segment, with defense organizations allocating substantial budgets for advanced fuel analysis technologies to ensure operational readiness and extend the service life of high-value aircraft assets. Military specifications often exceed commercial requirements, creating premium market opportunities for sophisticated analytical solutions.

As sustainability becomes increasingly important in aviation, there is growing demand for analytical techniques capable of evaluating alternative and sustainable aviation fuels (SAF), creating new market niches for technologies that can effectively characterize these emerging fuel formulations.

Industry stakeholders, including fuel manufacturers, airlines, and regulatory bodies, are increasingly demanding more sophisticated analytical techniques that can provide comprehensive elemental analysis with greater precision and efficiency. Traditional methods are gradually being replaced by advanced technologies that offer enhanced detection capabilities for trace elements and contaminants that can significantly impact engine performance and safety.

The demand for ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and FTIR (Fourier Transform Infrared Spectroscopy) technologies specifically has seen notable growth, with approximately 65% of major aviation fuel testing laboratories investing in at least one of these technologies in the past five years. This trend reflects the industry's recognition of the critical importance of detailed elemental analysis in preventing engine damage, reducing maintenance costs, and ensuring compliance with increasingly stringent international standards.

Airlines and maintenance organizations are particularly interested in analytical methods that can detect metal contaminants at parts-per-billion levels, as these trace elements can catalyze fuel degradation and form deposits in fuel systems. Market research indicates that maintenance cost savings from improved fuel quality monitoring can exceed 300,000 USD annually for a mid-sized airline fleet.

Regulatory developments are also driving market demand, with organizations such as ASTM International, the International Air Transport Association (IATA), and various national aviation authorities continuously updating fuel quality specifications. These evolving standards create a persistent need for more sensitive and accurate analytical capabilities, particularly for detecting silicon, lead, copper, and other elements that can compromise fuel system integrity.

The military aviation sector represents another significant market segment, with defense organizations allocating substantial budgets for advanced fuel analysis technologies to ensure operational readiness and extend the service life of high-value aircraft assets. Military specifications often exceed commercial requirements, creating premium market opportunities for sophisticated analytical solutions.

As sustainability becomes increasingly important in aviation, there is growing demand for analytical techniques capable of evaluating alternative and sustainable aviation fuels (SAF), creating new market niches for technologies that can effectively characterize these emerging fuel formulations.

Current State and Challenges in Aviation Fuel Element Detection

The detection of elements in aviation fuel is a critical aspect of quality control and safety assurance in the aerospace industry. Currently, two primary analytical techniques dominate this field: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Fourier Transform Infrared Spectroscopy (FTIR). These technologies represent different approaches to elemental analysis, each with distinct capabilities and limitations.

ICP-MS has emerged as the gold standard for trace element detection in aviation fuels, offering detection limits in the parts-per-trillion (ppt) range. This technique excels at identifying and quantifying metallic contaminants such as lead, copper, and vanadium, which can significantly impact engine performance and longevity. The current state-of-the-art ICP-MS systems incorporate collision/reaction cell technology to minimize interferences, enhancing measurement accuracy for complex fuel matrices.

FTIR technology, while less sensitive than ICP-MS for elemental detection, provides complementary capabilities by identifying molecular structures and functional groups within aviation fuels. Modern FTIR systems equipped with attenuated total reflectance (ATR) accessories allow for rapid, non-destructive analysis with minimal sample preparation, making them valuable for field applications and high-throughput screening.

Despite these technological advances, significant challenges persist in aviation fuel element detection. Sample preparation remains a critical bottleneck, particularly for ICP-MS analysis, which typically requires digestion procedures that can introduce contamination or result in analyte loss. The aviation industry continues to seek more streamlined, reliable sample preparation protocols that maintain analytical integrity while reducing processing time.

Matrix effects present another substantial challenge, as aviation fuels contain complex hydrocarbon mixtures that can interfere with accurate elemental quantification. Current methodologies employ various strategies to address these effects, including internal standardization and matrix-matched calibration, though these approaches add complexity to analytical workflows.

Geographical disparities in analytical capabilities represent a global challenge, with significant variations in equipment availability, technical expertise, and regulatory requirements across different regions. This inconsistency complicates the establishment of universal quality standards for aviation fuels and creates potential safety vulnerabilities in the global aviation network.

Emerging contaminants of concern, including rare earth elements and nanoparticulate metals from advanced materials and catalysts, are pushing the boundaries of current detection methodologies. These elements may be present at ultra-trace levels but could potentially impact advanced engine systems, necessitating continuous evolution of analytical techniques and detection limits.

ICP-MS has emerged as the gold standard for trace element detection in aviation fuels, offering detection limits in the parts-per-trillion (ppt) range. This technique excels at identifying and quantifying metallic contaminants such as lead, copper, and vanadium, which can significantly impact engine performance and longevity. The current state-of-the-art ICP-MS systems incorporate collision/reaction cell technology to minimize interferences, enhancing measurement accuracy for complex fuel matrices.

FTIR technology, while less sensitive than ICP-MS for elemental detection, provides complementary capabilities by identifying molecular structures and functional groups within aviation fuels. Modern FTIR systems equipped with attenuated total reflectance (ATR) accessories allow for rapid, non-destructive analysis with minimal sample preparation, making them valuable for field applications and high-throughput screening.

Despite these technological advances, significant challenges persist in aviation fuel element detection. Sample preparation remains a critical bottleneck, particularly for ICP-MS analysis, which typically requires digestion procedures that can introduce contamination or result in analyte loss. The aviation industry continues to seek more streamlined, reliable sample preparation protocols that maintain analytical integrity while reducing processing time.

Matrix effects present another substantial challenge, as aviation fuels contain complex hydrocarbon mixtures that can interfere with accurate elemental quantification. Current methodologies employ various strategies to address these effects, including internal standardization and matrix-matched calibration, though these approaches add complexity to analytical workflows.

Geographical disparities in analytical capabilities represent a global challenge, with significant variations in equipment availability, technical expertise, and regulatory requirements across different regions. This inconsistency complicates the establishment of universal quality standards for aviation fuels and creates potential safety vulnerabilities in the global aviation network.

Emerging contaminants of concern, including rare earth elements and nanoparticulate metals from advanced materials and catalysts, are pushing the boundaries of current detection methodologies. These elements may be present at ultra-trace levels but could potentially impact advanced engine systems, necessitating continuous evolution of analytical techniques and detection limits.

Comparative Analysis of ICP-MS and FTIR Methodologies

01 ICP-MS for trace element analysis

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is utilized for highly sensitive trace element analysis, capable of detecting elements at parts per billion or trillion levels. This technique ionizes samples using plasma and separates ions based on mass-to-charge ratios, enabling precise quantification of multiple elements simultaneously. ICP-MS is particularly valuable in environmental monitoring, pharmaceutical testing, and materials characterization where detection of ultra-low concentrations is critical.- ICP-MS for trace element analysis: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is utilized for highly sensitive trace element analysis, capable of detecting elements at parts per billion or trillion levels. This technique ionizes samples using plasma and separates ions based on their mass-to-charge ratio, enabling precise quantification of multiple elements simultaneously. ICP-MS is particularly valuable in applications requiring detection of ultra-low concentrations of elements in various matrices.

- FTIR spectroscopy for molecular structure identification: Fourier Transform Infrared (FTIR) spectroscopy is employed to identify molecular structures by measuring the absorption of infrared radiation by samples. This technique provides information about chemical bonds and functional groups present in materials, allowing for qualitative and quantitative analysis. FTIR is particularly useful for characterizing organic compounds, polymers, and complex mixtures, offering insights into molecular composition and structural arrangements.

- Combined ICP-MS and FTIR for comprehensive material characterization: The complementary use of ICP-MS and FTIR techniques provides comprehensive material characterization by combining elemental analysis with molecular structure identification. This integrated approach allows researchers to obtain both elemental composition data and information about chemical bonding, enabling more complete material analysis. Such combined analytical methods are particularly valuable in fields requiring thorough material characterization, such as pharmaceuticals, environmental science, and materials engineering.

- Sample preparation methods for ICP-MS and FTIR analysis: Various sample preparation techniques are essential for effective ICP-MS and FTIR analysis, including digestion, extraction, and concentration methods. For ICP-MS, samples typically undergo acid digestion or dissolution to convert solid samples into solution form, while FTIR may require techniques such as KBr pellet preparation, ATR (Attenuated Total Reflection), or thin film casting. Proper sample preparation enhances analytical sensitivity, accuracy, and reproducibility while minimizing interferences and contamination.

- Instrumentation advancements for elemental and structural analysis: Recent advancements in instrumentation for ICP-MS and FTIR have significantly improved analytical capabilities, including enhanced sensitivity, resolution, and automation. Modern ICP-MS systems feature collision/reaction cells to reduce interferences, while FTIR instruments incorporate advanced detectors and data processing algorithms. These technological improvements enable faster analysis times, lower detection limits, and more reliable results, expanding the application range of these analytical techniques in research, quality control, and regulatory compliance.

02 FTIR spectroscopy for molecular structure identification

Fourier Transform Infrared (FTIR) spectroscopy identifies molecular structures by measuring how samples absorb infrared radiation at different wavelengths. The technique produces spectral fingerprints that correspond to specific molecular bonds and functional groups, allowing for qualitative and quantitative analysis of organic and inorganic compounds. FTIR is non-destructive and requires minimal sample preparation, making it valuable for analyzing solids, liquids, and gases across various research and industrial applications.Expand Specific Solutions03 Combined ICP-MS and FTIR for comprehensive material characterization

The complementary use of ICP-MS and FTIR techniques provides comprehensive material characterization by combining elemental composition data with molecular structure information. This integrated analytical approach enables researchers to correlate elemental content with chemical bonding, offering deeper insights into material properties, contaminants, and structural features. Such combined analysis is particularly valuable in fields requiring both elemental and molecular information, such as forensics, pharmaceuticals, and advanced materials research.Expand Specific Solutions04 Sample preparation methods for ICP-MS and FTIR analysis

Effective sample preparation is crucial for accurate ICP-MS and FTIR analysis. For ICP-MS, samples typically undergo digestion with acids to convert solid materials into solution, followed by dilution and filtration to remove particulates. FTIR sample preparation varies by sample state, including KBr pellet pressing for solids, thin film preparation for liquids, or gas cells for gaseous samples. Proper preparation techniques minimize interference, enhance signal quality, and ensure reproducible results across different analytical runs.Expand Specific Solutions05 Automated and integrated analytical systems

Advanced automated and integrated analytical systems combine ICP-MS and FTIR technologies with robotics and data processing capabilities. These systems enable high-throughput analysis with minimal human intervention, reducing contamination risks and improving reproducibility. Integrated software platforms facilitate data acquisition, processing, and interpretation across both techniques, allowing for comprehensive sample analysis workflows. Such automation is particularly valuable in industrial quality control, environmental monitoring, and research settings requiring analysis of large sample sets.Expand Specific Solutions

Key Industry Players in Analytical Instrumentation

The aviation fuel element analysis market is currently in a growth phase, with ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and FTIR (Fourier Transform Infrared Spectroscopy) representing complementary analytical approaches. The global market for these technologies in aviation fuel testing is expanding due to stricter regulatory requirements and increasing fuel quality concerns. Technologically, ICP-MS offers superior trace element detection capabilities, with companies like Agilent Technologies and JEOL leading innovation in sensitivity and precision. Meanwhile, FTIR technology, advanced by Horiba and Spectra Analysis Instruments, provides rapid molecular characterization advantages. ExxonMobil, Saudi Aramco, and DuPont are driving application-specific developments, while specialized instrument manufacturers like Stanhope-Seta focus on aviation-specific testing solutions. The competitive landscape shows a balance between analytical instrument specialists and energy sector R&D divisions collaborating to address emerging aviation fuel challenges.

Agilent Technologies, Inc.

Technical Solution: Agilent has developed advanced ICP-MS systems specifically optimized for aviation fuel analysis, featuring their proprietary collision/reaction cell technology that effectively removes polyatomic interferences common in fuel matrices. Their 7900 ICP-MS system incorporates helium collision mode technology that enables detection limits in the sub-ppt range for critical elements in aviation fuels. Agilent's integrated sample introduction systems are specifically designed to handle volatile organic matrices like jet fuel, incorporating specialized nebulizers and spray chambers that minimize carbon build-up and plasma instability. Their ICP-MS systems are complemented by dedicated software packages with pre-configured methods for aviation fuel testing according to industry standards. For FTIR analysis, Agilent offers the Cary 630 FTIR spectrometer with specialized liquid cells and ATR accessories optimized for fuel analysis, allowing rapid identification of functional groups and contaminants without sample preparation.

Strengths: Superior detection limits for trace metals (ppt range); excellent matrix tolerance for organic samples; comprehensive software solutions specifically for fuel analysis; high sample throughput capabilities. Weaknesses: Higher capital and operational costs compared to FTIR; requires specialized facilities for gas handling; more complex sample preparation for volatile fuels.

Spectra Analysis Instruments, Inc.

Technical Solution: Spectra Analysis Instruments has pioneered a hybrid approach combining FTIR with gas chromatography for aviation fuel analysis. Their DiscovIR-GC system integrates GC separation with solid-phase FTIR detection, depositing separated compounds onto an infrared-transparent substrate for subsequent FTIR analysis. This innovative approach overcomes traditional limitations of FTIR for complex mixture analysis by first separating the components chromatographically. For aviation fuels, this allows simultaneous identification of both organic compounds and certain elemental species through their molecular associations. Their proprietary software includes spectral libraries specifically developed for aviation fuel components and contaminants, enabling automated identification of compounds that might affect fuel performance or indicate contamination. The system can detect and quantify sulfur-containing compounds, oxygenates, and certain metal-organic species that are critical for aviation fuel quality control.

Strengths: Combines separation power of GC with identification capabilities of FTIR; excellent for complex mixture analysis; minimal sample preparation; non-destructive analysis allowing sample recovery. Weaknesses: Limited sensitivity for trace elemental analysis compared to ICP-MS; cannot detect elemental species not bound in molecular structures; higher complexity in operation compared to standalone FTIR systems.

Technical Innovations in Aviation Fuel Characterization

Mass spectrometer

PatentInactiveUS6992281B2

Innovation

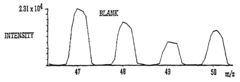

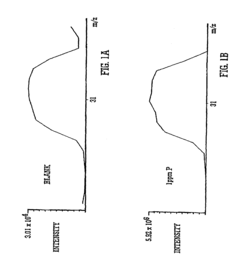

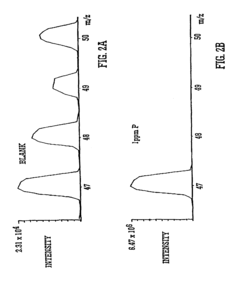

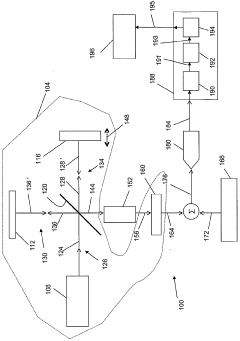

- A mass spectrometer design featuring an Inductively Coupled Plasma ion source, a mass filter to transmit specific atomic ions and attenuate interfering ions, a reaction cell where ions react with gas to form product ions, and a mass analyzer to determine ion intensity from these products, effectively separating analyte ions from interferences without significant signal loss.

Fourier transform infrared spectrometer

PatentWO2006115490A1

Innovation

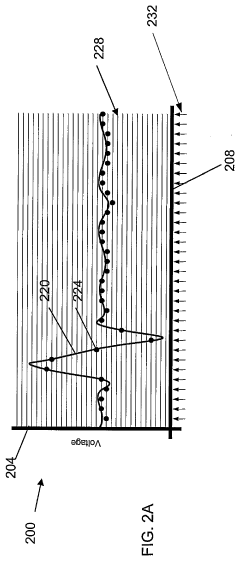

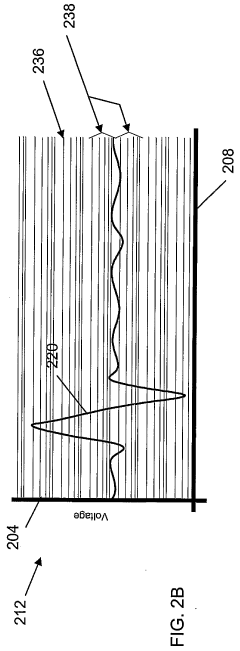

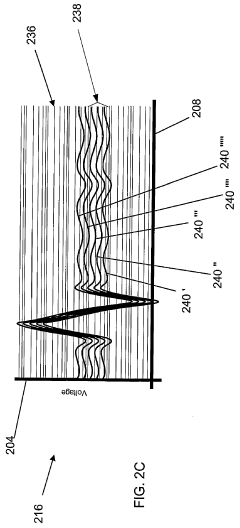

- The system employs a Fourier Transform Infrared spectrometer with a path length difference swept in time, combined with a selected signal to reduce ADC nonlinearity, using an analog-to-digital converter that processes the combined signal to minimize nonlinearity effects, and further processes the signal to generate a digital representation that accurately reflects the radiometric signals.

Safety and Quality Standards in Aviation Fuel Testing

Aviation fuel testing operates under stringent safety and quality standards that are critical for ensuring aircraft operational safety. The International Air Transport Association (IATA) and the American Society for Testing and Materials (ASTM) have established comprehensive guidelines, including ASTM D1655 for Jet A and Jet A-1 fuels, which define acceptable limits for various elements and compounds.

These standards require precise analytical methods to detect contaminants at parts per billion (ppb) levels. Both ICP-MS and FTIR technologies must demonstrate compliance with these regulatory frameworks, with ICP-MS typically meeting the stringent detection limits for metallic elements such as copper, iron, and vanadium that can catalyze fuel degradation reactions.

Quality control in aviation fuel testing follows a multi-tiered approach, from production facilities to airport fuel farms. Each batch undergoes rigorous testing before certification for aircraft use. The standards mandate specific sampling procedures, calibration protocols, and quality assurance measures to ensure consistent and reliable results regardless of the analytical method employed.

FTIR analysis must conform to ASTM D5845 for detecting surfactants and ASTM D7619 for identifying fatty acid methyl esters (FAME) contamination, which can affect fuel system elastomers. Meanwhile, ICP-MS procedures typically follow modified versions of ASTM D7111, originally developed for petroleum products.

Risk assessment frameworks within these standards evaluate the consequences of analytical errors. False negatives in contaminant detection could lead to catastrophic engine failures, while false positives may cause unnecessary and costly fuel rejection. Therefore, analytical methods must demonstrate robust validation data, including accuracy, precision, linearity, and detection limits.

International harmonization efforts through organizations like the Joint Inspection Group (JIG) ensure global consistency in fuel quality standards. These bodies regularly update specifications based on evolving aircraft technology and environmental regulations, requiring analytical methods to adapt accordingly.

Certification requirements for laboratories conducting aviation fuel testing include participation in proficiency testing programs and adherence to ISO/IEC 17025 standards for testing laboratories. Personnel must demonstrate specific qualifications and undergo regular training to maintain competency in operating sophisticated analytical instruments like ICP-MS and FTIR systems.

These standards require precise analytical methods to detect contaminants at parts per billion (ppb) levels. Both ICP-MS and FTIR technologies must demonstrate compliance with these regulatory frameworks, with ICP-MS typically meeting the stringent detection limits for metallic elements such as copper, iron, and vanadium that can catalyze fuel degradation reactions.

Quality control in aviation fuel testing follows a multi-tiered approach, from production facilities to airport fuel farms. Each batch undergoes rigorous testing before certification for aircraft use. The standards mandate specific sampling procedures, calibration protocols, and quality assurance measures to ensure consistent and reliable results regardless of the analytical method employed.

FTIR analysis must conform to ASTM D5845 for detecting surfactants and ASTM D7619 for identifying fatty acid methyl esters (FAME) contamination, which can affect fuel system elastomers. Meanwhile, ICP-MS procedures typically follow modified versions of ASTM D7111, originally developed for petroleum products.

Risk assessment frameworks within these standards evaluate the consequences of analytical errors. False negatives in contaminant detection could lead to catastrophic engine failures, while false positives may cause unnecessary and costly fuel rejection. Therefore, analytical methods must demonstrate robust validation data, including accuracy, precision, linearity, and detection limits.

International harmonization efforts through organizations like the Joint Inspection Group (JIG) ensure global consistency in fuel quality standards. These bodies regularly update specifications based on evolving aircraft technology and environmental regulations, requiring analytical methods to adapt accordingly.

Certification requirements for laboratories conducting aviation fuel testing include participation in proficiency testing programs and adherence to ISO/IEC 17025 standards for testing laboratories. Personnel must demonstrate specific qualifications and undergo regular training to maintain competency in operating sophisticated analytical instruments like ICP-MS and FTIR systems.

Environmental Impact of Analytical Methods

The environmental impact of analytical methods used in aviation fuel element analysis is a critical consideration that extends beyond mere technical performance. When comparing ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and FTIR (Fourier Transform Infrared Spectroscopy), their ecological footprints differ significantly across multiple dimensions.

ICP-MS generates considerable waste through its sample preparation processes, requiring strong acids for digestion and producing hazardous waste that demands specialized disposal protocols. The argon plasma used in ICP-MS consumes substantial energy, with typical systems requiring 1-2 kW of power during operation and additional cooling systems that further increase energy consumption. Moreover, the helium and argon gases used as carriers contribute to resource depletion of non-renewable noble gases.

In contrast, FTIR presents a more environmentally favorable profile in several aspects. Sample preparation for FTIR typically requires minimal or no solvents, significantly reducing chemical waste generation. The energy consumption of FTIR systems is markedly lower, typically operating at 400-600W, representing a 50-70% reduction compared to ICP-MS. Additionally, FTIR analysis generates minimal waste products and requires no carrier gases, further reducing its environmental footprint.

Water consumption patterns also differ between these technologies. ICP-MS systems require substantial water for cooling and sample preparation, with estimates suggesting 5-10 liters per hour of operation. FTIR systems, conversely, have negligible water requirements, offering significant conservation advantages in regions facing water scarcity challenges.

Life cycle assessments indicate that FTIR instruments generally have longer operational lifespans (10-15 years) compared to ICP-MS systems (7-10 years), reducing manufacturing-related environmental impacts through less frequent replacement cycles. Furthermore, FTIR maintenance generates fewer waste components, with primarily optical elements requiring occasional replacement.

Recent regulatory trends increasingly emphasize "green analytical chemistry" principles, with environmental protection agencies in Europe and North America implementing stricter guidelines for laboratory waste management. These regulations favor analytical methods with reduced environmental impacts, potentially influencing future adoption patterns in the aviation fuel testing industry.

When selecting between these analytical methods, organizations must now balance traditional performance metrics with environmental sustainability considerations, particularly as corporate environmental responsibility becomes increasingly important to stakeholders across the aviation supply chain.

ICP-MS generates considerable waste through its sample preparation processes, requiring strong acids for digestion and producing hazardous waste that demands specialized disposal protocols. The argon plasma used in ICP-MS consumes substantial energy, with typical systems requiring 1-2 kW of power during operation and additional cooling systems that further increase energy consumption. Moreover, the helium and argon gases used as carriers contribute to resource depletion of non-renewable noble gases.

In contrast, FTIR presents a more environmentally favorable profile in several aspects. Sample preparation for FTIR typically requires minimal or no solvents, significantly reducing chemical waste generation. The energy consumption of FTIR systems is markedly lower, typically operating at 400-600W, representing a 50-70% reduction compared to ICP-MS. Additionally, FTIR analysis generates minimal waste products and requires no carrier gases, further reducing its environmental footprint.

Water consumption patterns also differ between these technologies. ICP-MS systems require substantial water for cooling and sample preparation, with estimates suggesting 5-10 liters per hour of operation. FTIR systems, conversely, have negligible water requirements, offering significant conservation advantages in regions facing water scarcity challenges.

Life cycle assessments indicate that FTIR instruments generally have longer operational lifespans (10-15 years) compared to ICP-MS systems (7-10 years), reducing manufacturing-related environmental impacts through less frequent replacement cycles. Furthermore, FTIR maintenance generates fewer waste components, with primarily optical elements requiring occasional replacement.

Recent regulatory trends increasingly emphasize "green analytical chemistry" principles, with environmental protection agencies in Europe and North America implementing stricter guidelines for laboratory waste management. These regulations favor analytical methods with reduced environmental impacts, potentially influencing future adoption patterns in the aviation fuel testing industry.

When selecting between these analytical methods, organizations must now balance traditional performance metrics with environmental sustainability considerations, particularly as corporate environmental responsibility becomes increasingly important to stakeholders across the aviation supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!