ICP-MS vs XRD: Comparative Review for Geological Specimen Study

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Analytical Techniques Background and Objectives

The analytical techniques of Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and X-Ray Diffraction (XRD) represent two cornerstone methodologies in modern geological specimen analysis. These techniques have evolved significantly since their inception, with ICP-MS first commercialized in the early 1980s and XRD dating back to the pioneering work of the Braggs in the early 20th century. Both technologies have undergone substantial refinements in sensitivity, accuracy, and application scope over the decades.

The evolution of ICP-MS has been characterized by improvements in detection limits, now reaching parts per trillion for many elements, alongside advancements in interference reduction technologies such as collision/reaction cells. Similarly, XRD has progressed from basic powder diffraction to sophisticated techniques including high-resolution synchrotron XRD and in-situ environmental chambers allowing real-time analysis of phase transformations.

Current technological trends indicate a movement toward more integrated analytical approaches, with multi-method platforms becoming increasingly common in geological research. The miniaturization of both technologies is also evident, with portable XRD units now available for field applications and efforts underway to develop more compact ICP-MS systems.

The primary objective of this comparative review is to establish a comprehensive understanding of the relative strengths, limitations, and complementary aspects of ICP-MS and XRD in geological specimen analysis. Specifically, we aim to evaluate their respective capabilities in elemental composition determination versus crystallographic structure identification, sensitivity thresholds, sample preparation requirements, and applicability across various geological materials.

Additionally, this review seeks to identify optimal scenarios for the application of each technique, as well as circumstances where their combined deployment offers synergistic benefits. The assessment will consider factors including but not limited to: analytical precision, detection limits, sample throughput, destructive versus non-destructive analysis, and cost-effectiveness.

Furthermore, we intend to explore emerging hybrid methodologies that integrate aspects of both techniques, such as micro-XRD coupled with laser ablation ICP-MS, which allow for spatially resolved analysis of both elemental composition and mineral phases. These technological convergences represent potentially transformative approaches for comprehensive geological specimen characterization.

The ultimate goal is to provide a strategic framework for researchers and industry professionals to make informed decisions regarding analytical technique selection based on specific research questions, sample characteristics, and available resources.

The evolution of ICP-MS has been characterized by improvements in detection limits, now reaching parts per trillion for many elements, alongside advancements in interference reduction technologies such as collision/reaction cells. Similarly, XRD has progressed from basic powder diffraction to sophisticated techniques including high-resolution synchrotron XRD and in-situ environmental chambers allowing real-time analysis of phase transformations.

Current technological trends indicate a movement toward more integrated analytical approaches, with multi-method platforms becoming increasingly common in geological research. The miniaturization of both technologies is also evident, with portable XRD units now available for field applications and efforts underway to develop more compact ICP-MS systems.

The primary objective of this comparative review is to establish a comprehensive understanding of the relative strengths, limitations, and complementary aspects of ICP-MS and XRD in geological specimen analysis. Specifically, we aim to evaluate their respective capabilities in elemental composition determination versus crystallographic structure identification, sensitivity thresholds, sample preparation requirements, and applicability across various geological materials.

Additionally, this review seeks to identify optimal scenarios for the application of each technique, as well as circumstances where their combined deployment offers synergistic benefits. The assessment will consider factors including but not limited to: analytical precision, detection limits, sample throughput, destructive versus non-destructive analysis, and cost-effectiveness.

Furthermore, we intend to explore emerging hybrid methodologies that integrate aspects of both techniques, such as micro-XRD coupled with laser ablation ICP-MS, which allow for spatially resolved analysis of both elemental composition and mineral phases. These technological convergences represent potentially transformative approaches for comprehensive geological specimen characterization.

The ultimate goal is to provide a strategic framework for researchers and industry professionals to make informed decisions regarding analytical technique selection based on specific research questions, sample characteristics, and available resources.

Market Demand Analysis for Geological Analysis Tools

The geological analysis tools market has witnessed significant growth in recent years, driven by increasing demand for accurate mineral identification and characterization across mining, environmental monitoring, and academic research sectors. The global market for geological analysis instruments was valued at approximately $5.2 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 6.9%.

Within this expanding market, both Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and X-Ray Diffraction (XRD) technologies have established themselves as essential analytical tools, albeit serving different analytical needs. The ICP-MS segment currently holds about 18% of the geological analysis tools market, with consistent growth due to its unparalleled sensitivity for trace element analysis. Meanwhile, XRD systems account for approximately 12% of the market, maintaining steady demand for their crystallographic structural analysis capabilities.

Mining and mineral exploration industries remain the largest consumers of these technologies, accounting for 42% of the total market share. These sectors particularly value the complementary nature of ICP-MS and XRD for comprehensive ore characterization and grade control. Environmental monitoring applications represent the fastest-growing segment, expanding at 8.3% annually as regulatory requirements for soil and water analysis become more stringent worldwide.

Geographically, North America dominates the market with 34% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the most rapid growth, particularly in China and India, where expanding mining activities and environmental concerns are driving increased adoption of advanced analytical technologies.

Customer surveys indicate evolving market demands, with 76% of end-users expressing interest in instruments offering improved automation and sample throughput. Additionally, 68% of respondents prioritize systems that can integrate multiple analytical techniques, suggesting a growing market for hybrid or complementary ICP-MS/XRD solutions. Cost remains a significant consideration, with 82% of potential buyers citing initial investment and operational expenses as key decision factors.

The academic and research sector represents a stable 23% of the market, with universities and geological surveys consistently investing in both technologies for fundamental research. This segment particularly values instruments with high precision and versatility across diverse sample types, from meteorites to deep-sea sediments.

Within this expanding market, both Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and X-Ray Diffraction (XRD) technologies have established themselves as essential analytical tools, albeit serving different analytical needs. The ICP-MS segment currently holds about 18% of the geological analysis tools market, with consistent growth due to its unparalleled sensitivity for trace element analysis. Meanwhile, XRD systems account for approximately 12% of the market, maintaining steady demand for their crystallographic structural analysis capabilities.

Mining and mineral exploration industries remain the largest consumers of these technologies, accounting for 42% of the total market share. These sectors particularly value the complementary nature of ICP-MS and XRD for comprehensive ore characterization and grade control. Environmental monitoring applications represent the fastest-growing segment, expanding at 8.3% annually as regulatory requirements for soil and water analysis become more stringent worldwide.

Geographically, North America dominates the market with 34% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the most rapid growth, particularly in China and India, where expanding mining activities and environmental concerns are driving increased adoption of advanced analytical technologies.

Customer surveys indicate evolving market demands, with 76% of end-users expressing interest in instruments offering improved automation and sample throughput. Additionally, 68% of respondents prioritize systems that can integrate multiple analytical techniques, suggesting a growing market for hybrid or complementary ICP-MS/XRD solutions. Cost remains a significant consideration, with 82% of potential buyers citing initial investment and operational expenses as key decision factors.

The academic and research sector represents a stable 23% of the market, with universities and geological surveys consistently investing in both technologies for fundamental research. This segment particularly values instruments with high precision and versatility across diverse sample types, from meteorites to deep-sea sediments.

Current Status and Challenges in Geological Specimen Analysis

The field of geological specimen analysis has witnessed significant advancements in recent decades, with Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and X-Ray Diffraction (XRD) emerging as two dominant analytical techniques. These methodologies serve distinct yet complementary roles in modern geoscience research, each with its own set of capabilities and limitations.

Currently, ICP-MS technology has reached a high level of sophistication, offering detection limits in the parts per trillion range for many elements. This exceptional sensitivity has made it the gold standard for trace element analysis in geological specimens. Modern instruments feature improved plasma stability, enhanced ion transmission efficiency, and advanced collision/reaction cell technologies that effectively minimize polyatomic interferences. However, ICP-MS systems still face challenges with sample preparation requirements, as geological materials must undergo complete dissolution, which can be problematic for refractory minerals.

XRD technology has similarly evolved, with current systems featuring high-resolution detectors, advanced optics, and sophisticated data processing algorithms. Modern XRD instruments can identify crystalline phases present at concentrations as low as 0.5% in mixed samples. The non-destructive nature of XRD analysis represents a significant advantage for valuable or rare geological specimens. Nevertheless, XRD analysis struggles with amorphous materials and complex mineral mixtures where peak overlapping occurs.

A major challenge in the geological analysis field is the integration of complementary techniques to provide comprehensive characterization of specimens. While ICP-MS excels at elemental composition determination, it provides no information about mineral structures. Conversely, XRD reveals crystallographic information but offers limited quantitative elemental data. This complementarity necessitates multi-technique approaches, which increase analysis complexity and cost.

Standardization remains another significant challenge, particularly for complex geological matrices. Reference materials that accurately represent the diverse range of geological specimens are limited, affecting calibration quality and inter-laboratory reproducibility. This issue is especially pronounced for rare earth elements and platinum group elements analysis via ICP-MS.

Accessibility presents a further challenge, as both technologies require substantial capital investment and specialized expertise. This creates disparities in analytical capabilities between well-funded research institutions and those with limited resources, particularly in developing regions with significant geological resources but limited analytical infrastructure.

Environmental considerations are increasingly important, with ICP-MS facing scrutiny due to its consumption of high-purity acids and generation of waste solutions containing heavy metals. XRD, while generally more environmentally friendly, still requires careful handling of X-ray radiation sources.

Currently, ICP-MS technology has reached a high level of sophistication, offering detection limits in the parts per trillion range for many elements. This exceptional sensitivity has made it the gold standard for trace element analysis in geological specimens. Modern instruments feature improved plasma stability, enhanced ion transmission efficiency, and advanced collision/reaction cell technologies that effectively minimize polyatomic interferences. However, ICP-MS systems still face challenges with sample preparation requirements, as geological materials must undergo complete dissolution, which can be problematic for refractory minerals.

XRD technology has similarly evolved, with current systems featuring high-resolution detectors, advanced optics, and sophisticated data processing algorithms. Modern XRD instruments can identify crystalline phases present at concentrations as low as 0.5% in mixed samples. The non-destructive nature of XRD analysis represents a significant advantage for valuable or rare geological specimens. Nevertheless, XRD analysis struggles with amorphous materials and complex mineral mixtures where peak overlapping occurs.

A major challenge in the geological analysis field is the integration of complementary techniques to provide comprehensive characterization of specimens. While ICP-MS excels at elemental composition determination, it provides no information about mineral structures. Conversely, XRD reveals crystallographic information but offers limited quantitative elemental data. This complementarity necessitates multi-technique approaches, which increase analysis complexity and cost.

Standardization remains another significant challenge, particularly for complex geological matrices. Reference materials that accurately represent the diverse range of geological specimens are limited, affecting calibration quality and inter-laboratory reproducibility. This issue is especially pronounced for rare earth elements and platinum group elements analysis via ICP-MS.

Accessibility presents a further challenge, as both technologies require substantial capital investment and specialized expertise. This creates disparities in analytical capabilities between well-funded research institutions and those with limited resources, particularly in developing regions with significant geological resources but limited analytical infrastructure.

Environmental considerations are increasingly important, with ICP-MS facing scrutiny due to its consumption of high-purity acids and generation of waste solutions containing heavy metals. XRD, while generally more environmentally friendly, still requires careful handling of X-ray radiation sources.

Comparative Analysis of ICP-MS and XRD Methodologies

01 Material characterization using ICP-MS and XRD

The combination of Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and X-Ray Diffraction (XRD) technologies provides comprehensive material characterization capabilities. ICP-MS offers precise elemental composition analysis at trace levels, while XRD determines crystalline structure and phase identification. Together, these complementary techniques enable researchers to analyze both the elemental makeup and structural properties of materials, which is crucial for quality control, materials science research, and product development.- Material characterization using ICP-MS and XRD: The combination of Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and X-Ray Diffraction (XRD) technologies provides comprehensive material characterization capabilities. ICP-MS offers precise elemental composition analysis at trace levels, while XRD determines crystalline structure and phase identification. Together, these complementary techniques enable researchers to analyze both chemical composition and structural properties of various materials, making them valuable tools in materials science, metallurgy, and quality control applications.

- Advanced sample preparation methods for ICP-MS and XRD analysis: Effective sample preparation techniques are crucial for obtaining accurate results in ICP-MS and XRD analyses. These methods include specialized digestion procedures for ICP-MS to ensure complete dissolution of samples, and grinding or milling processes for XRD to achieve appropriate particle size distribution. Advanced preparation systems may incorporate automation, precise temperature control, and contamination prevention measures to enhance reproducibility and reliability of analytical results across various sample types.

- Integrated analytical systems combining ICP-MS and XRD technologies: Integrated analytical systems that combine ICP-MS and XRD technologies in a single platform or workflow enable more efficient and comprehensive material analysis. These systems feature automated sample handling, synchronized data acquisition, and integrated software for correlative analysis. By streamlining the analytical process, these integrated solutions reduce analysis time, minimize sample consumption, and provide more complete characterization of complex materials with applications in pharmaceuticals, semiconductors, and advanced materials research.

- Environmental and geological applications of ICP-MS and XRD: ICP-MS and XRD technologies are extensively used in environmental monitoring and geological studies. These techniques enable the analysis of soil, sediment, and rock samples to determine elemental composition, mineral content, and crystalline structures. Applications include pollution assessment, mineral exploration, geochemical mapping, and studying environmental transformations of materials. The combination of these technologies provides valuable insights into environmental processes, geological formations, and the impact of human activities on natural systems.

- Quality control and process monitoring using ICP-MS and XRD: ICP-MS and XRD technologies play crucial roles in industrial quality control and process monitoring applications. These analytical methods enable manufacturers to verify raw material purity, monitor production processes, and ensure final product quality. The techniques are particularly valuable in industries requiring precise composition control and structural verification, such as pharmaceuticals, semiconductors, ceramics, and advanced materials manufacturing. Implementation of these technologies in production environments often involves specialized sampling systems, rapid analysis protocols, and integration with manufacturing control systems.

02 Sample preparation methods for ICP-MS and XRD analysis

Effective sample preparation is critical for accurate results in both ICP-MS and XRD analyses. For ICP-MS, this typically involves digestion procedures to convert solid samples into solution form, often using acids or other reagents. For XRD, samples must be properly ground, mounted, and sometimes pre-treated to ensure optimal diffraction patterns. Specialized equipment and methodologies have been developed to streamline these preparation processes, improving efficiency and reducing contamination risks.Expand Specific Solutions03 Integrated systems combining ICP-MS and XRD technologies

Integrated analytical systems that combine ICP-MS and XRD technologies in a single workflow or instrument platform enhance research efficiency. These systems allow for sequential or simultaneous analysis of samples using both techniques, reducing handling time and potential for contamination. Advanced software solutions enable correlation of data from both methods, providing more comprehensive material insights. Such integrated approaches are particularly valuable in industries requiring thorough material characterization, such as pharmaceuticals, semiconductors, and advanced materials research.Expand Specific Solutions04 Applications in environmental and geological analysis

ICP-MS and XRD technologies are extensively used in environmental monitoring and geological studies. ICP-MS provides sensitive detection of heavy metals and other pollutants in environmental samples, while XRD helps identify mineral compositions in soil, sediment, and rock samples. Together, these techniques enable researchers to track pollution sources, study geological formations, analyze soil quality, and investigate environmental remediation processes. The combination offers insights into both elemental contamination levels and the structural forms in which these elements exist.Expand Specific Solutions05 Advancements in detection sensitivity and data processing

Recent technological advancements have significantly improved the detection sensitivity and data processing capabilities of both ICP-MS and XRD systems. Modern ICP-MS instruments can detect elements at parts-per-trillion levels, while XRD systems feature enhanced resolution for complex crystal structure analysis. Machine learning algorithms and advanced software solutions have revolutionized data interpretation, enabling automated pattern recognition, background correction, and multivariate analysis. These improvements allow for faster analysis times, reduced sample requirements, and more accurate results even with complex or mixed samples.Expand Specific Solutions

Key Manufacturers and Research Institutions

The ICP-MS vs XRD technology landscape is currently in a mature growth phase, with the global analytical instrumentation market valued at approximately $5.2 billion. Leading players include Thermo Fisher Scientific, Shimadzu Corp, and CNOOC, who have established strong market positions through advanced technological capabilities. The competitive landscape features a mix of specialized instrument manufacturers and research institutions, with companies like Jiangsu Skyray Instrument emerging as regional competitors. Academic institutions such as China University of Geosciences Beijing and University of Oslo contribute significantly to technological advancement through research collaborations. The technology demonstrates high maturity in geological applications, with ongoing innovation focused on improving sensitivity, resolution, and sample preparation techniques for complex geological specimens.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has developed advanced ICP-MS systems specifically designed for geological applications, including their iCAP RQ and iCAP TQ ICP-MS platforms. These systems incorporate Triple Quadrupole technology that effectively eliminates polyatomic interferences common in geological samples through Collision/Reaction Cell (CRC) technology. Their instruments feature high-sensitivity detectors capable of measuring trace elements down to parts-per-trillion levels, essential for rare earth element analysis in geological specimens. Thermo Fisher's latest systems integrate helium collision cell technology that significantly reduces matrix effects in complex geological samples. Their software solutions include specialized geological analysis packages with pre-configured methods for various rock types and mineral classifications, streamlining the analytical workflow for geoscientists.

Strengths: Industry-leading sensitivity and interference removal capabilities; comprehensive software solutions specifically for geological applications; extensive global support network. Weaknesses: Higher acquisition and operational costs compared to competitors; complex systems require specialized training; consumables can be expensive for routine analyses.

Nanjing Geological Survey Center of China Geological Survey

Technical Solution: The Nanjing Geological Survey Center has developed a comprehensive analytical framework integrating both ICP-MS and XRD technologies specifically tailored for regional geological mapping projects. Their approach combines high-throughput ICP-MS screening with targeted XRD analysis, creating an efficient workflow for processing large sample sets from geological surveys. The Center has pioneered specialized sample preparation protocols that optimize specimens for sequential analysis by both techniques, minimizing sample consumption and contamination risks. Their data integration platform incorporates machine learning algorithms to correlate elemental composition data from ICP-MS with crystallographic information from XRD, enabling automated mineral identification with higher accuracy than either technique alone. The Center has also established extensive reference databases of Chinese geological formations, enhancing the contextual interpretation of analytical results for regional geological studies.

Strengths: Unparalleled expertise in regional geological mapping applications; extensive reference databases specific to Chinese geological formations; optimized workflows for high-throughput analysis. Weaknesses: Technologies primarily optimized for regional survey applications rather than specialized research; limited commercial availability of their integrated systems outside China; some proprietary methods not fully disclosed in scientific literature.

Technical Principles and Innovations in Spectroscopy

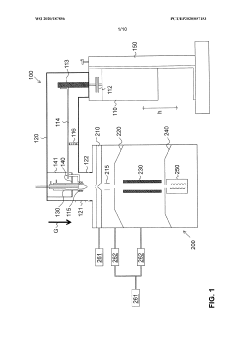

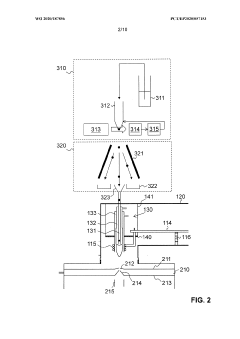

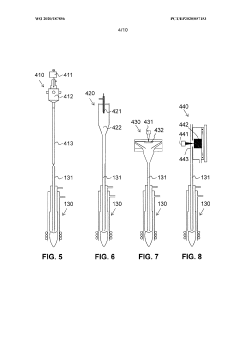

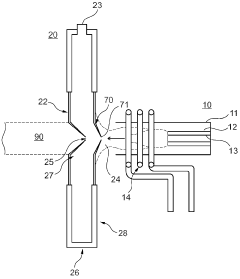

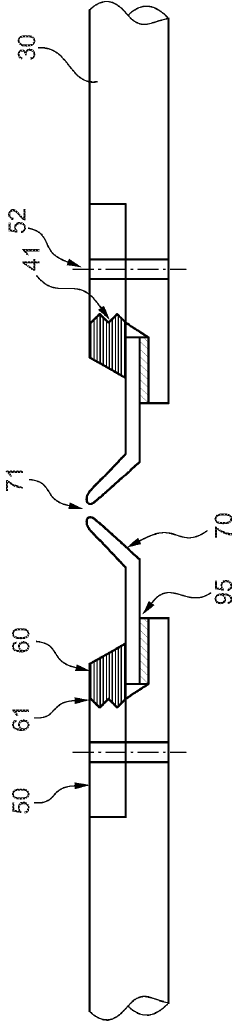

Ion source for inductively coupled plasma mass spectrometry

PatentWO2020187856A1

Innovation

- An ICP source with a vertically oriented plasma torch and injector tube allows sample introduction along a downwards-pointing vertical direction, reducing dependence on carrier gas flow and enabling 100% transport efficiency by utilizing gravity, and includes a metallic cooling plate and electromagnetic coupling element for efficient plasma generation.

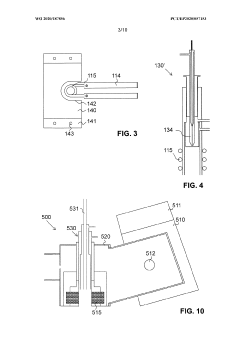

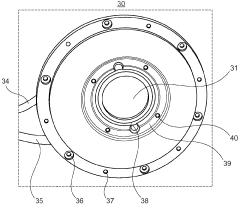

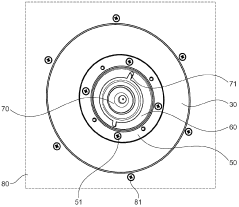

Cooling plate for icp-ms

PatentActiveGB2585327A

Innovation

- A cooling plate made from bronze is used, which provides sufficient thermal conductivity and enhanced chemical resistance, reducing the risk of corrosion and degradation, and eliminating the need for a corrosion-resistant coating.

Cost-Benefit Analysis of Analytical Instrumentation

When evaluating ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and XRD (X-Ray Diffraction) technologies for geological specimen analysis, cost-benefit considerations are paramount for research institutions and commercial laboratories. The initial investment for ICP-MS systems typically ranges from $150,000 to $300,000, while XRD instruments generally cost between $100,000 and $250,000, making XRD slightly more accessible from a capital expenditure perspective.

Operational costs present significant differences between these technologies. ICP-MS requires ongoing expenses for argon gas, high-purity acids for sample preparation, and regular replacement of consumables such as nebulizers, cones, and torch assemblies. These operational costs can amount to $15,000-$30,000 annually. XRD systems, conversely, have lower operational costs, typically $5,000-$15,000 per year, primarily for X-ray tube replacement every few years and minimal sample preparation materials.

Sample throughput capabilities directly impact cost-effectiveness. ICP-MS excels in this regard, processing 60-100 samples daily with multi-element analysis capabilities, whereas XRD typically handles 20-40 samples per day. This higher throughput can significantly offset the higher operational costs of ICP-MS in high-volume laboratory settings.

Maintenance requirements represent another crucial cost factor. ICP-MS systems demand more frequent professional maintenance, typically requiring 2-3 service visits annually at $3,000-$5,000 per visit. XRD systems generally need only annual maintenance at similar per-visit costs but with lower frequency, resulting in reduced downtime and maintenance expenses.

Staff expertise requirements differ substantially between technologies. ICP-MS operation requires specialized training and often dedicated technicians with analytical chemistry backgrounds, commanding higher salaries ($60,000-$80,000 annually). XRD can often be operated by researchers with less specialized training after initial orientation, potentially reducing personnel costs.

Return on investment calculations must consider the analytical value derived from each technique. ICP-MS provides comprehensive elemental composition data at trace levels, enabling multiple research applications from a single analysis. XRD delivers specific crystallographic information that, while more limited in scope, is irreplaceable for mineralogical studies. The optimal cost-benefit ratio ultimately depends on the specific research focus and sample volume of the institution.

Operational costs present significant differences between these technologies. ICP-MS requires ongoing expenses for argon gas, high-purity acids for sample preparation, and regular replacement of consumables such as nebulizers, cones, and torch assemblies. These operational costs can amount to $15,000-$30,000 annually. XRD systems, conversely, have lower operational costs, typically $5,000-$15,000 per year, primarily for X-ray tube replacement every few years and minimal sample preparation materials.

Sample throughput capabilities directly impact cost-effectiveness. ICP-MS excels in this regard, processing 60-100 samples daily with multi-element analysis capabilities, whereas XRD typically handles 20-40 samples per day. This higher throughput can significantly offset the higher operational costs of ICP-MS in high-volume laboratory settings.

Maintenance requirements represent another crucial cost factor. ICP-MS systems demand more frequent professional maintenance, typically requiring 2-3 service visits annually at $3,000-$5,000 per visit. XRD systems generally need only annual maintenance at similar per-visit costs but with lower frequency, resulting in reduced downtime and maintenance expenses.

Staff expertise requirements differ substantially between technologies. ICP-MS operation requires specialized training and often dedicated technicians with analytical chemistry backgrounds, commanding higher salaries ($60,000-$80,000 annually). XRD can often be operated by researchers with less specialized training after initial orientation, potentially reducing personnel costs.

Return on investment calculations must consider the analytical value derived from each technique. ICP-MS provides comprehensive elemental composition data at trace levels, enabling multiple research applications from a single analysis. XRD delivers specific crystallographic information that, while more limited in scope, is irreplaceable for mineralogical studies. The optimal cost-benefit ratio ultimately depends on the specific research focus and sample volume of the institution.

Environmental and Sample Preparation Considerations

Environmental sample preparation represents a critical determinant in the accuracy and reliability of both ICP-MS and XRD analyses for geological specimens. The two techniques impose distinctly different requirements on sample preparation protocols, which must be carefully considered when selecting the appropriate analytical method for specific geological investigations.

For ICP-MS analysis, samples typically require complete dissolution, necessitating aggressive acid digestion procedures often involving hydrofluoric acid (HF), nitric acid, and perchloric acid combinations. This dissolution step presents significant safety considerations and requires specialized laboratory facilities with proper ventilation systems and acid-resistant materials. Environmental conditions during sample preparation must be meticulously controlled to prevent cross-contamination, as ICP-MS can detect elements at parts-per-trillion levels.

In contrast, XRD sample preparation generally involves mechanical processing rather than chemical dissolution. Specimens must be ground to fine powder (typically <10 μm particle size) to ensure random orientation of crystallites and minimize preferred orientation effects that can skew diffraction patterns. This preparation is less hazardous than ICP-MS protocols but requires careful attention to prevent phase transformations induced by excessive grinding, which can generate heat and pressure that alter the crystal structure.

Humidity represents a significant environmental factor affecting both techniques differently. For XRD, hygroscopic minerals may absorb atmospheric moisture, potentially causing phase transitions or altered diffraction patterns. Conversely, ICP-MS sample solutions must be protected from evaporation to maintain accurate concentration measurements, particularly during extended analytical runs.

Temperature stability is crucial for both methods but particularly critical for XRD, where thermal expansion of crystal lattices can shift peak positions. Laboratories conducting high-precision XRD analyses typically maintain strict temperature control (±1°C) to ensure reproducible results.

Sample heterogeneity presents challenges for both techniques, though in different ways. For ICP-MS, obtaining a representative subsample is essential since only milligram quantities are typically analyzed. XRD similarly requires representative sampling, with the additional consideration that minority phases below 1-5% abundance may remain undetected unless concentration techniques are employed.

Cross-contamination prevention requires different approaches for each technique. For ICP-MS, ultra-clean laboratory protocols with acid-washed containers and high-purity reagents are essential. XRD sample preparation must avoid contamination with materials that might introduce spurious diffraction peaks, particularly when analyzing for trace mineral phases.

The selection between these techniques must therefore consider not only the analytical capabilities but also the practical constraints of sample preparation facilities, environmental controls, and safety protocols available in the laboratory setting.

For ICP-MS analysis, samples typically require complete dissolution, necessitating aggressive acid digestion procedures often involving hydrofluoric acid (HF), nitric acid, and perchloric acid combinations. This dissolution step presents significant safety considerations and requires specialized laboratory facilities with proper ventilation systems and acid-resistant materials. Environmental conditions during sample preparation must be meticulously controlled to prevent cross-contamination, as ICP-MS can detect elements at parts-per-trillion levels.

In contrast, XRD sample preparation generally involves mechanical processing rather than chemical dissolution. Specimens must be ground to fine powder (typically <10 μm particle size) to ensure random orientation of crystallites and minimize preferred orientation effects that can skew diffraction patterns. This preparation is less hazardous than ICP-MS protocols but requires careful attention to prevent phase transformations induced by excessive grinding, which can generate heat and pressure that alter the crystal structure.

Humidity represents a significant environmental factor affecting both techniques differently. For XRD, hygroscopic minerals may absorb atmospheric moisture, potentially causing phase transitions or altered diffraction patterns. Conversely, ICP-MS sample solutions must be protected from evaporation to maintain accurate concentration measurements, particularly during extended analytical runs.

Temperature stability is crucial for both methods but particularly critical for XRD, where thermal expansion of crystal lattices can shift peak positions. Laboratories conducting high-precision XRD analyses typically maintain strict temperature control (±1°C) to ensure reproducible results.

Sample heterogeneity presents challenges for both techniques, though in different ways. For ICP-MS, obtaining a representative subsample is essential since only milligram quantities are typically analyzed. XRD similarly requires representative sampling, with the additional consideration that minority phases below 1-5% abundance may remain undetected unless concentration techniques are employed.

Cross-contamination prevention requires different approaches for each technique. For ICP-MS, ultra-clean laboratory protocols with acid-washed containers and high-purity reagents are essential. XRD sample preparation must avoid contamination with materials that might introduce spurious diffraction peaks, particularly when analyzing for trace mineral phases.

The selection between these techniques must therefore consider not only the analytical capabilities but also the practical constraints of sample preparation facilities, environmental controls, and safety protocols available in the laboratory setting.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!