Impacts of Regulatory Changes on Ethylene Vinyl Acetate Uses

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Regulatory Landscape and Objectives

Ethylene Vinyl Acetate (EVA) has been widely used across various industries due to its versatile properties. However, the regulatory landscape surrounding EVA has been evolving rapidly, driven by increasing environmental concerns and safety considerations. This changing regulatory environment has significant implications for the use and development of EVA-based products.

The primary objective of this technical research is to comprehensively examine the current regulatory framework governing EVA and its applications. We aim to identify key regulatory changes, assess their potential impacts on different sectors, and anticipate future regulatory trends that may shape the EVA market.

Recent years have witnessed a shift towards more stringent regulations, particularly in areas such as food contact materials, medical devices, and consumer products. The European Union, for instance, has implemented stricter guidelines for EVA use in food packaging, emphasizing the need for enhanced safety assessments and migration testing. Similarly, the U.S. Food and Drug Administration has revised its regulations on EVA in medical devices, focusing on biocompatibility and long-term safety.

These regulatory changes are driven by growing scientific evidence regarding potential health and environmental risks associated with certain additives and processing aids used in EVA production. As a result, manufacturers are now required to adapt their formulations and production processes to comply with new standards, which has led to increased research and development efforts in the field of EVA technology.

The global nature of supply chains and varying regulatory requirements across different regions present additional challenges for EVA producers and users. Harmonization of standards and regulations across major markets has become a key focus area, with international organizations working towards developing unified guidelines for EVA applications.

Looking ahead, we anticipate further regulatory developments in areas such as recycling and end-of-life management of EVA products. The push towards a circular economy is likely to result in new regulations promoting the recyclability and biodegradability of EVA materials. This trend is expected to drive innovation in EVA formulations and processing technologies, opening up new opportunities for sustainable product development.

As we delve deeper into this technical research, our goal is to provide a comprehensive understanding of the regulatory landscape surrounding EVA, analyze its impact on various industries, and identify potential strategies for navigating these regulatory challenges. This analysis will serve as a foundation for informed decision-making and strategic planning in the evolving EVA market.

The primary objective of this technical research is to comprehensively examine the current regulatory framework governing EVA and its applications. We aim to identify key regulatory changes, assess their potential impacts on different sectors, and anticipate future regulatory trends that may shape the EVA market.

Recent years have witnessed a shift towards more stringent regulations, particularly in areas such as food contact materials, medical devices, and consumer products. The European Union, for instance, has implemented stricter guidelines for EVA use in food packaging, emphasizing the need for enhanced safety assessments and migration testing. Similarly, the U.S. Food and Drug Administration has revised its regulations on EVA in medical devices, focusing on biocompatibility and long-term safety.

These regulatory changes are driven by growing scientific evidence regarding potential health and environmental risks associated with certain additives and processing aids used in EVA production. As a result, manufacturers are now required to adapt their formulations and production processes to comply with new standards, which has led to increased research and development efforts in the field of EVA technology.

The global nature of supply chains and varying regulatory requirements across different regions present additional challenges for EVA producers and users. Harmonization of standards and regulations across major markets has become a key focus area, with international organizations working towards developing unified guidelines for EVA applications.

Looking ahead, we anticipate further regulatory developments in areas such as recycling and end-of-life management of EVA products. The push towards a circular economy is likely to result in new regulations promoting the recyclability and biodegradability of EVA materials. This trend is expected to drive innovation in EVA formulations and processing technologies, opening up new opportunities for sustainable product development.

As we delve deeper into this technical research, our goal is to provide a comprehensive understanding of the regulatory landscape surrounding EVA, analyze its impact on various industries, and identify potential strategies for navigating these regulatory challenges. This analysis will serve as a foundation for informed decision-making and strategic planning in the evolving EVA market.

Market Demand Analysis for EVA Products

The global market for Ethylene Vinyl Acetate (EVA) products has shown significant growth in recent years, driven by increasing demand across various industries. The versatility of EVA, with its excellent flexibility, toughness, and adhesion properties, has led to its widespread adoption in sectors such as packaging, footwear, solar panels, and automotive.

In the packaging industry, EVA copolymers are extensively used for flexible packaging applications, including food packaging, due to their barrier properties and sealability. The growing e-commerce sector has further boosted demand for protective packaging materials, benefiting EVA product manufacturers.

The footwear industry remains a major consumer of EVA, particularly in the production of midsoles for athletic shoes. The global sports footwear market's expansion, fueled by increasing health awareness and sports participation, has directly contributed to the rising demand for EVA-based materials.

Renewable energy initiatives worldwide have significantly impacted the EVA market, especially in the solar panel industry. EVA is a crucial component in the encapsulation of photovoltaic cells, providing protection against environmental factors. As countries push for greater adoption of solar energy, the demand for EVA in this sector is expected to continue its upward trajectory.

The automotive industry's shift towards lightweight materials for improved fuel efficiency has also benefited EVA products. EVA is used in various automotive applications, including wire and cable insulation, gaskets, and interior components, contributing to the overall market growth.

Geographically, Asia-Pacific dominates the EVA market, with China and India being major consumers and producers. The region's rapid industrialization, growing population, and increasing disposable income have driven demand across multiple end-use industries.

However, regulatory changes have begun to impact the EVA market. Environmental concerns and stricter regulations on plastic use have led to increased scrutiny of EVA products, particularly in packaging applications. This has prompted manufacturers to invest in research and development of more sustainable alternatives or improved recycling methods for EVA-based materials.

The healthcare sector presents a growing opportunity for EVA products, particularly in medical devices and pharmaceutical packaging. The material's biocompatibility and flexibility make it suitable for various medical applications, a trend likely to accelerate in the wake of global health concerns.

In conclusion, while the EVA market faces challenges from regulatory changes, particularly in certain applications, overall demand remains strong across diverse industries. The market's future growth will likely be shaped by innovations in sustainable production methods, new application areas, and the ability of manufacturers to adapt to evolving regulatory landscapes.

In the packaging industry, EVA copolymers are extensively used for flexible packaging applications, including food packaging, due to their barrier properties and sealability. The growing e-commerce sector has further boosted demand for protective packaging materials, benefiting EVA product manufacturers.

The footwear industry remains a major consumer of EVA, particularly in the production of midsoles for athletic shoes. The global sports footwear market's expansion, fueled by increasing health awareness and sports participation, has directly contributed to the rising demand for EVA-based materials.

Renewable energy initiatives worldwide have significantly impacted the EVA market, especially in the solar panel industry. EVA is a crucial component in the encapsulation of photovoltaic cells, providing protection against environmental factors. As countries push for greater adoption of solar energy, the demand for EVA in this sector is expected to continue its upward trajectory.

The automotive industry's shift towards lightweight materials for improved fuel efficiency has also benefited EVA products. EVA is used in various automotive applications, including wire and cable insulation, gaskets, and interior components, contributing to the overall market growth.

Geographically, Asia-Pacific dominates the EVA market, with China and India being major consumers and producers. The region's rapid industrialization, growing population, and increasing disposable income have driven demand across multiple end-use industries.

However, regulatory changes have begun to impact the EVA market. Environmental concerns and stricter regulations on plastic use have led to increased scrutiny of EVA products, particularly in packaging applications. This has prompted manufacturers to invest in research and development of more sustainable alternatives or improved recycling methods for EVA-based materials.

The healthcare sector presents a growing opportunity for EVA products, particularly in medical devices and pharmaceutical packaging. The material's biocompatibility and flexibility make it suitable for various medical applications, a trend likely to accelerate in the wake of global health concerns.

In conclusion, while the EVA market faces challenges from regulatory changes, particularly in certain applications, overall demand remains strong across diverse industries. The market's future growth will likely be shaped by innovations in sustainable production methods, new application areas, and the ability of manufacturers to adapt to evolving regulatory landscapes.

Current EVA Regulations and Challenges

The current regulatory landscape for Ethylene Vinyl Acetate (EVA) is complex and dynamic, with various challenges facing manufacturers, distributors, and end-users. Regulations governing EVA usage span multiple jurisdictions and sectors, reflecting the material's diverse applications in industries such as packaging, solar panels, and footwear.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation significantly impacts EVA production and use. REACH requires manufacturers and importers to register chemicals, including EVA, and provide safety data. This has led to increased compliance costs and potential market access barriers for non-EU producers.

The United States Food and Drug Administration (FDA) regulates EVA in food contact applications, setting specific migration limits and requiring extensive testing for food packaging materials. These regulations ensure consumer safety but pose challenges for manufacturers in terms of product development and compliance demonstration.

In the renewable energy sector, regulations promoting sustainability have driven increased demand for EVA in solar panel encapsulation. However, end-of-life regulations for solar panels, such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive, present new challenges for EVA recycling and disposal.

The automotive industry faces stringent emissions regulations, indirectly affecting EVA use in vehicle components. As automakers seek lightweight materials to improve fuel efficiency, EVA's role in noise, vibration, and harshness (NVH) reduction becomes more critical, but must be balanced with recyclability requirements.

One of the primary challenges in EVA regulation is the lack of global harmonization. Different countries and regions have varying standards and testing requirements, creating a complex regulatory environment for global manufacturers and distributors. This disparity can lead to increased costs, longer time-to-market, and potential trade barriers.

Another significant challenge is the evolving nature of regulations, particularly concerning environmental and health impacts. As new scientific data emerges, regulatory bodies may revise their stance on certain chemicals used in EVA production or processing, requiring manufacturers to adapt quickly to maintain compliance.

The increasing focus on circular economy principles presents both opportunities and challenges for the EVA industry. While EVA's recyclability is generally favorable, regulations promoting closed-loop systems and extended producer responsibility are pushing manufacturers to innovate in product design and end-of-life management.

Lastly, the growing concern over microplastics and their environmental impact has led to increased scrutiny of EVA foam products, particularly in marine applications. This emerging regulatory focus may require manufacturers to develop new formulations or alternative materials to meet evolving environmental standards.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation significantly impacts EVA production and use. REACH requires manufacturers and importers to register chemicals, including EVA, and provide safety data. This has led to increased compliance costs and potential market access barriers for non-EU producers.

The United States Food and Drug Administration (FDA) regulates EVA in food contact applications, setting specific migration limits and requiring extensive testing for food packaging materials. These regulations ensure consumer safety but pose challenges for manufacturers in terms of product development and compliance demonstration.

In the renewable energy sector, regulations promoting sustainability have driven increased demand for EVA in solar panel encapsulation. However, end-of-life regulations for solar panels, such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive, present new challenges for EVA recycling and disposal.

The automotive industry faces stringent emissions regulations, indirectly affecting EVA use in vehicle components. As automakers seek lightweight materials to improve fuel efficiency, EVA's role in noise, vibration, and harshness (NVH) reduction becomes more critical, but must be balanced with recyclability requirements.

One of the primary challenges in EVA regulation is the lack of global harmonization. Different countries and regions have varying standards and testing requirements, creating a complex regulatory environment for global manufacturers and distributors. This disparity can lead to increased costs, longer time-to-market, and potential trade barriers.

Another significant challenge is the evolving nature of regulations, particularly concerning environmental and health impacts. As new scientific data emerges, regulatory bodies may revise their stance on certain chemicals used in EVA production or processing, requiring manufacturers to adapt quickly to maintain compliance.

The increasing focus on circular economy principles presents both opportunities and challenges for the EVA industry. While EVA's recyclability is generally favorable, regulations promoting closed-loop systems and extended producer responsibility are pushing manufacturers to innovate in product design and end-of-life management.

Lastly, the growing concern over microplastics and their environmental impact has led to increased scrutiny of EVA foam products, particularly in marine applications. This emerging regulatory focus may require manufacturers to develop new formulations or alternative materials to meet evolving environmental standards.

Existing Compliance Strategies for EVA

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The vinyl acetate content can be varied to modify the properties of the material, making it suitable for a wide range of applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and thermal properties can be tailored by adjusting the vinyl acetate content and molecular weight of the EVA copolymer.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It is commonly used in footwear, sports equipment, and building insulation. The foam structure can be controlled by adjusting the blowing agent and processing conditions.

- EVA in solar panel encapsulation: EVA is a preferred material for solar panel encapsulation due to its transparency, weather resistance, and electrical insulation properties. It protects the solar cells from environmental factors and ensures long-term performance. The EVA formulation can be optimized to enhance UV stability and prevent yellowing over time.

- EVA in packaging and film applications: EVA is extensively used in packaging films and flexible packaging materials due to its excellent clarity, flexibility, and barrier properties. It is often blended with other polymers to enhance specific characteristics such as heat-sealability, puncture resistance, and gas permeability. EVA films find applications in food packaging, agricultural films, and shrink wrap.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The material's low melting point and good flow characteristics make it ideal for these applications.Expand Specific Solutions03 EVA in foam and insulation products

EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as shoe soles, sports equipment, and building insulation. The material can be easily foamed and molded into various shapes and densities.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a popular material for encapsulating solar cells in photovoltaic modules. Its transparency, weather resistance, and ability to protect the cells from moisture and mechanical stress make it an ideal choice for this application. The material also helps in improving the overall efficiency and lifespan of solar panels.Expand Specific Solutions05 Modifications and blends of EVA

EVA can be modified or blended with other materials to enhance its properties or create new functionalities. This includes crosslinking, adding fillers or reinforcing agents, and blending with other polymers. These modifications can improve properties such as heat resistance, mechanical strength, and flame retardancy, expanding the range of applications for EVA-based materials.Expand Specific Solutions

Key Stakeholders in EVA Industry

The regulatory changes impacting Ethylene Vinyl Acetate (EVA) uses are shaping a competitive landscape in a mature industry with established players. The global EVA market, valued at several billion dollars, is experiencing moderate growth driven by diverse applications in sectors like packaging, solar panels, and footwear. Technologically, the industry is well-developed, with key players such as DuPont, Celanese, and BASF leading innovation. Chinese companies like Sinopec are also gaining prominence. The market is characterized by ongoing R&D efforts to improve product performance and comply with evolving regulations, particularly in areas of sustainability and environmental impact.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA production technologies to adapt to regulatory changes. They have implemented a new catalytic process that reduces VOC emissions by up to 30% compared to traditional methods[1]. Sinopec has also invested in developing bio-based EVA alternatives, using renewable feedstocks to produce EVA with similar properties but a lower carbon footprint[3]. Their research focuses on improving EVA's thermal stability and weatherability to meet stricter environmental regulations in construction and automotive industries[5]. Sinopec has also introduced a novel crosslinking technology that enhances EVA's performance in photovoltaic encapsulants, meeting new energy efficiency standards[7].

Strengths: Large-scale production capabilities, strong R&D infrastructure, and integrated supply chain. Weaknesses: Potential higher costs associated with new technologies and regulatory compliance.

Celanese International Corp.

Technical Solution: Celanese has developed a proprietary EVA production process that significantly reduces energy consumption and greenhouse gas emissions. Their VitalDose® EVA technology platform focuses on creating high-purity grades for medical and pharmaceutical applications, meeting stringent regulatory requirements[2]. Celanese has also introduced a range of EVA grades with enhanced biodegradability to address environmental concerns[4]. Their research efforts have resulted in EVA formulations with improved flame retardancy without the use of halogenated compounds, aligning with new fire safety regulations[6]. Additionally, Celanese has developed EVA-based composites with enhanced barrier properties for food packaging, meeting evolving FDA guidelines[8].

Strengths: Strong focus on specialty EVA grades, extensive experience in regulatory compliance for sensitive applications. Weaknesses: Potentially higher production costs for specialty grades, limited presence in some geographic markets.

Critical Regulatory Changes Affecting EVA

Graft ethylene-vinyl acetate copolymer and resin composition containing the same

PatentWO1997002302A1

Innovation

- A graft-modified ethylene-vinyl acetate copolymer is developed by incorporating a glycidyl group-containing compound and unsaturated glycidyl ester, along with a radical initiator, to enhance thermal stability and adhesion, and is blended with polyamide or polyester resins to improve mechanical and thermal properties.

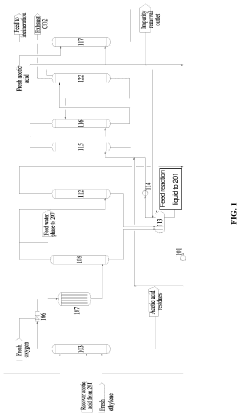

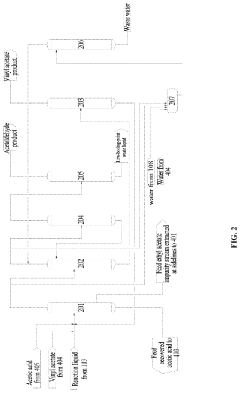

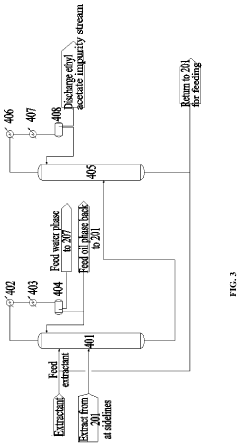

Method for producing vinyl acetate

PatentActiveUS20230312452A1

Innovation

- A method involving a gas phase oxidation process with a system integration that includes specific towers and reactors for ethylene recovery, acetic acid evaporation, oxygen mixing, and separation processes, utilizing acetic acid as an extractant in the rectifying and separating towers to enhance the separation of vinyl acetate from ethyl acetate.

Environmental Impact of EVA Usage

The environmental impact of Ethylene Vinyl Acetate (EVA) usage is a critical consideration in the context of regulatory changes affecting its applications. EVA, a copolymer of ethylene and vinyl acetate, has widespread use in various industries due to its versatile properties. However, its production, use, and disposal have significant environmental implications that need to be carefully evaluated.

One of the primary environmental concerns associated with EVA usage is its contribution to plastic pollution. As a thermoplastic material, EVA can persist in the environment for extended periods, potentially contributing to the accumulation of microplastics in ecosystems. This is particularly problematic in marine environments, where EVA particles can be ingested by marine life, leading to potential bioaccumulation in the food chain.

The production process of EVA also raises environmental issues. The manufacturing of EVA involves the use of petrochemical feedstocks, which are derived from non-renewable resources. This reliance on fossil fuels contributes to greenhouse gas emissions and climate change. Additionally, the production process may release volatile organic compounds (VOCs) and other pollutants, potentially impacting air quality in surrounding areas.

End-of-life management of EVA products presents another environmental challenge. While EVA can be recycled, the recycling process is not always straightforward due to the presence of additives and the varying compositions of EVA products. Improper disposal or incineration of EVA waste can release harmful chemicals into the environment, including dioxins and furans.

The use of EVA in certain applications, such as in the production of solar panels, presents a double-edged sword from an environmental perspective. While solar energy contributes to reducing carbon emissions, the EVA used in panel encapsulation may leach chemicals over time, potentially contaminating soil and water resources.

Regulatory changes aimed at addressing these environmental concerns are likely to have significant impacts on EVA usage. Stricter regulations on plastic waste management and recycling may drive innovations in EVA formulations to improve recyclability. Similarly, regulations targeting VOC emissions may lead to the development of cleaner production processes for EVA.

Furthermore, the push towards a circular economy model may encourage the development of bio-based alternatives to traditional EVA, reducing reliance on petrochemical feedstocks. This shift could potentially mitigate some of the environmental impacts associated with EVA production and disposal.

In conclusion, the environmental impact of EVA usage is multifaceted, encompassing issues related to plastic pollution, resource depletion, emissions, and waste management. As regulatory frameworks evolve to address these concerns, the EVA industry will need to adapt through technological innovations and sustainable practices to mitigate its environmental footprint.

One of the primary environmental concerns associated with EVA usage is its contribution to plastic pollution. As a thermoplastic material, EVA can persist in the environment for extended periods, potentially contributing to the accumulation of microplastics in ecosystems. This is particularly problematic in marine environments, where EVA particles can be ingested by marine life, leading to potential bioaccumulation in the food chain.

The production process of EVA also raises environmental issues. The manufacturing of EVA involves the use of petrochemical feedstocks, which are derived from non-renewable resources. This reliance on fossil fuels contributes to greenhouse gas emissions and climate change. Additionally, the production process may release volatile organic compounds (VOCs) and other pollutants, potentially impacting air quality in surrounding areas.

End-of-life management of EVA products presents another environmental challenge. While EVA can be recycled, the recycling process is not always straightforward due to the presence of additives and the varying compositions of EVA products. Improper disposal or incineration of EVA waste can release harmful chemicals into the environment, including dioxins and furans.

The use of EVA in certain applications, such as in the production of solar panels, presents a double-edged sword from an environmental perspective. While solar energy contributes to reducing carbon emissions, the EVA used in panel encapsulation may leach chemicals over time, potentially contaminating soil and water resources.

Regulatory changes aimed at addressing these environmental concerns are likely to have significant impacts on EVA usage. Stricter regulations on plastic waste management and recycling may drive innovations in EVA formulations to improve recyclability. Similarly, regulations targeting VOC emissions may lead to the development of cleaner production processes for EVA.

Furthermore, the push towards a circular economy model may encourage the development of bio-based alternatives to traditional EVA, reducing reliance on petrochemical feedstocks. This shift could potentially mitigate some of the environmental impacts associated with EVA production and disposal.

In conclusion, the environmental impact of EVA usage is multifaceted, encompassing issues related to plastic pollution, resource depletion, emissions, and waste management. As regulatory frameworks evolve to address these concerns, the EVA industry will need to adapt through technological innovations and sustainable practices to mitigate its environmental footprint.

Global Trade Implications for EVA

The global trade landscape for Ethylene Vinyl Acetate (EVA) is undergoing significant shifts due to regulatory changes impacting its uses. These changes are reshaping trade patterns, market dynamics, and supply chain strategies across various industries that rely on EVA.

One of the primary implications is the potential for trade barriers and restrictions. As countries implement stricter regulations on EVA usage, particularly in sectors like packaging and consumer goods, exporters may face challenges in meeting diverse regulatory requirements across different markets. This could lead to increased compliance costs and the need for product reformulations to adhere to varying standards.

The regulatory changes are also influencing global production and distribution networks. Manufacturers may need to relocate or diversify their production facilities to align with regional regulatory frameworks, potentially altering established trade routes and logistics patterns. This shift could create new opportunities for countries with more favorable regulatory environments to become key players in the EVA supply chain.

Furthermore, the evolving regulatory landscape is driving innovation in EVA alternatives and substitutes. As certain applications of EVA face restrictions, industries are exploring alternative materials that comply with new regulations. This trend is likely to impact trade flows, with potential growth in the trade of EVA substitutes and a corresponding shift in demand for traditional EVA products.

The changes are also affecting pricing dynamics in the global EVA market. Regulatory compliance costs, coupled with potential supply chain disruptions, may lead to price fluctuations and impact the competitiveness of EVA-based products in international markets. This could result in shifts in trade balances and market shares among key producing and consuming countries.

Additionally, the regulatory changes are influencing trade agreements and negotiations. Countries and trade blocs may need to reassess and potentially renegotiate trade terms related to EVA and its applications, considering the new regulatory landscape. This could lead to the emergence of new trade partnerships and alliances focused on harmonizing EVA-related standards and facilitating compliant trade.

Lastly, the global trade implications extend to technology transfer and intellectual property considerations. As companies adapt to new regulations, there may be an increase in cross-border collaborations and technology sharing to develop compliant EVA formulations and applications. This could lead to new patterns in patent filings, licensing agreements, and international research partnerships related to EVA technologies.

One of the primary implications is the potential for trade barriers and restrictions. As countries implement stricter regulations on EVA usage, particularly in sectors like packaging and consumer goods, exporters may face challenges in meeting diverse regulatory requirements across different markets. This could lead to increased compliance costs and the need for product reformulations to adhere to varying standards.

The regulatory changes are also influencing global production and distribution networks. Manufacturers may need to relocate or diversify their production facilities to align with regional regulatory frameworks, potentially altering established trade routes and logistics patterns. This shift could create new opportunities for countries with more favorable regulatory environments to become key players in the EVA supply chain.

Furthermore, the evolving regulatory landscape is driving innovation in EVA alternatives and substitutes. As certain applications of EVA face restrictions, industries are exploring alternative materials that comply with new regulations. This trend is likely to impact trade flows, with potential growth in the trade of EVA substitutes and a corresponding shift in demand for traditional EVA products.

The changes are also affecting pricing dynamics in the global EVA market. Regulatory compliance costs, coupled with potential supply chain disruptions, may lead to price fluctuations and impact the competitiveness of EVA-based products in international markets. This could result in shifts in trade balances and market shares among key producing and consuming countries.

Additionally, the regulatory changes are influencing trade agreements and negotiations. Countries and trade blocs may need to reassess and potentially renegotiate trade terms related to EVA and its applications, considering the new regulatory landscape. This could lead to the emergence of new trade partnerships and alliances focused on harmonizing EVA-related standards and facilitating compliant trade.

Lastly, the global trade implications extend to technology transfer and intellectual property considerations. As companies adapt to new regulations, there may be an increase in cross-border collaborations and technology sharing to develop compliant EVA formulations and applications. This could lead to new patterns in patent filings, licensing agreements, and international research partnerships related to EVA technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!