Influence of Humidity on Lithium Iron Phosphate Battery Longevity

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Humidity Challenges and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a promising energy storage solution, particularly in electric vehicles and renewable energy systems. The technology has evolved significantly since its inception, with researchers and manufacturers continuously striving to enhance its performance and longevity. However, one of the critical challenges facing LFP batteries is the influence of humidity on their lifespan and overall performance.

The primary objective of this technical research is to comprehensively examine the impact of humidity on LFP battery longevity and identify potential solutions to mitigate its adverse effects. This investigation aims to provide insights that can guide future developments in LFP battery technology, ultimately leading to more robust and durable energy storage systems.

Historically, LFP batteries have been praised for their thermal stability and safety compared to other lithium-ion chemistries. However, as the demand for longer-lasting and more reliable batteries grows, addressing environmental factors such as humidity has become increasingly important. The interaction between moisture and battery components can lead to various degradation mechanisms, including corrosion of current collectors, decomposition of electrolytes, and structural changes in the cathode material.

Recent trends in LFP battery research have focused on developing moisture-resistant materials and improving cell design to minimize humidity ingress. These efforts align with the broader goal of extending battery life and enhancing performance under diverse environmental conditions. As the adoption of LFP batteries expands into new applications and geographical regions with varying climates, understanding and mitigating humidity-related challenges becomes crucial for ensuring consistent performance and longevity.

The technical goals of this research include quantifying the effects of different humidity levels on LFP battery degradation rates, identifying the most vulnerable components to moisture exposure, and exploring innovative materials and designs that can enhance humidity resistance. Additionally, this study aims to establish guidelines for optimal operating conditions and storage practices that can maximize LFP battery lifespan in humid environments.

By addressing these objectives, this research seeks to contribute to the advancement of LFP battery technology, potentially leading to the development of next-generation batteries with improved resilience to environmental factors. The findings from this investigation will not only benefit battery manufacturers but also inform end-users and system integrators about best practices for maintaining and deploying LFP batteries in diverse climatic conditions.

The primary objective of this technical research is to comprehensively examine the impact of humidity on LFP battery longevity and identify potential solutions to mitigate its adverse effects. This investigation aims to provide insights that can guide future developments in LFP battery technology, ultimately leading to more robust and durable energy storage systems.

Historically, LFP batteries have been praised for their thermal stability and safety compared to other lithium-ion chemistries. However, as the demand for longer-lasting and more reliable batteries grows, addressing environmental factors such as humidity has become increasingly important. The interaction between moisture and battery components can lead to various degradation mechanisms, including corrosion of current collectors, decomposition of electrolytes, and structural changes in the cathode material.

Recent trends in LFP battery research have focused on developing moisture-resistant materials and improving cell design to minimize humidity ingress. These efforts align with the broader goal of extending battery life and enhancing performance under diverse environmental conditions. As the adoption of LFP batteries expands into new applications and geographical regions with varying climates, understanding and mitigating humidity-related challenges becomes crucial for ensuring consistent performance and longevity.

The technical goals of this research include quantifying the effects of different humidity levels on LFP battery degradation rates, identifying the most vulnerable components to moisture exposure, and exploring innovative materials and designs that can enhance humidity resistance. Additionally, this study aims to establish guidelines for optimal operating conditions and storage practices that can maximize LFP battery lifespan in humid environments.

By addressing these objectives, this research seeks to contribute to the advancement of LFP battery technology, potentially leading to the development of next-generation batteries with improved resilience to environmental factors. The findings from this investigation will not only benefit battery manufacturers but also inform end-users and system integrators about best practices for maintaining and deploying LFP batteries in diverse climatic conditions.

Market Analysis for Humidity-Resistant LFP Batteries

The market for humidity-resistant Lithium Iron Phosphate (LFP) batteries is experiencing significant growth, driven by the increasing demand for reliable energy storage solutions in diverse environmental conditions. As the global energy transition accelerates, LFP batteries are gaining traction in various applications, including electric vehicles, renewable energy storage, and grid stabilization systems. The need for humidity-resistant LFP batteries is particularly pronounced in regions with high humidity levels, such as tropical and coastal areas.

The automotive sector represents a substantial market opportunity for humidity-resistant LFP batteries. Electric vehicle manufacturers are seeking battery technologies that can withstand diverse climatic conditions while maintaining long-term performance and safety. This demand is further amplified by the growing electric vehicle market in Southeast Asian countries, where high humidity is a persistent challenge.

In the stationary energy storage sector, there is a rising need for robust battery systems that can operate reliably in humid environments. This is particularly relevant for off-grid and microgrid applications in developing countries, where energy storage systems are often exposed to harsh environmental conditions. The ability of humidity-resistant LFP batteries to maintain their performance and longevity in these settings makes them an attractive option for such applications.

The renewable energy sector also presents a significant market for humidity-resistant LFP batteries. As solar and wind energy installations continue to expand globally, the demand for efficient and durable energy storage solutions is increasing. Humidity-resistant LFP batteries can play a crucial role in enhancing the reliability and efficiency of renewable energy systems, especially in regions prone to high humidity levels.

Market analysis indicates that the Asia-Pacific region is expected to be a key growth driver for humidity-resistant LFP batteries. Countries like China, Japan, and South Korea are investing heavily in advanced battery technologies, while emerging markets in Southeast Asia are showing increased adoption of energy storage solutions. This regional focus is likely to shape the competitive landscape and drive innovation in humidity-resistant LFP battery technology.

The market for humidity-resistant LFP batteries is also influenced by regulatory factors and sustainability goals. As governments worldwide implement stricter environmental regulations and push for cleaner energy solutions, the demand for efficient and durable battery technologies is expected to rise. This regulatory environment creates favorable conditions for the adoption of advanced LFP battery technologies, including those with enhanced humidity resistance.

The automotive sector represents a substantial market opportunity for humidity-resistant LFP batteries. Electric vehicle manufacturers are seeking battery technologies that can withstand diverse climatic conditions while maintaining long-term performance and safety. This demand is further amplified by the growing electric vehicle market in Southeast Asian countries, where high humidity is a persistent challenge.

In the stationary energy storage sector, there is a rising need for robust battery systems that can operate reliably in humid environments. This is particularly relevant for off-grid and microgrid applications in developing countries, where energy storage systems are often exposed to harsh environmental conditions. The ability of humidity-resistant LFP batteries to maintain their performance and longevity in these settings makes them an attractive option for such applications.

The renewable energy sector also presents a significant market for humidity-resistant LFP batteries. As solar and wind energy installations continue to expand globally, the demand for efficient and durable energy storage solutions is increasing. Humidity-resistant LFP batteries can play a crucial role in enhancing the reliability and efficiency of renewable energy systems, especially in regions prone to high humidity levels.

Market analysis indicates that the Asia-Pacific region is expected to be a key growth driver for humidity-resistant LFP batteries. Countries like China, Japan, and South Korea are investing heavily in advanced battery technologies, while emerging markets in Southeast Asia are showing increased adoption of energy storage solutions. This regional focus is likely to shape the competitive landscape and drive innovation in humidity-resistant LFP battery technology.

The market for humidity-resistant LFP batteries is also influenced by regulatory factors and sustainability goals. As governments worldwide implement stricter environmental regulations and push for cleaner energy solutions, the demand for efficient and durable battery technologies is expected to rise. This regulatory environment creates favorable conditions for the adoption of advanced LFP battery technologies, including those with enhanced humidity resistance.

Current State of Humidity Impact on LFP Batteries

The current state of humidity impact on Lithium Iron Phosphate (LFP) batteries is a critical area of research in the energy storage industry. Humidity has been identified as a significant environmental factor affecting the longevity and performance of LFP batteries. Recent studies have shown that exposure to high humidity levels can lead to accelerated degradation of battery components, particularly the cathode material.

LFP batteries, known for their stability and safety compared to other lithium-ion chemistries, are not immune to the effects of moisture. The interaction between humidity and LFP batteries primarily occurs through two mechanisms: direct water ingress into the battery cell and moisture absorption by the electrode materials. These processes can trigger a series of detrimental reactions that compromise battery performance and lifespan.

One of the main concerns is the hydrolysis of the electrolyte when exposed to moisture. This reaction can produce hydrofluoric acid (HF), which is highly corrosive and can attack the protective layers on electrode surfaces. Consequently, this leads to increased internal resistance and capacity fade over time. Additionally, moisture can cause the dissolution of metal ions from the cathode, altering its structure and reducing its ability to intercalate lithium ions effectively.

Research has also revealed that humidity can affect the solid electrolyte interphase (SEI) layer formation on the anode. The SEI layer is crucial for battery stability and performance, and its compromised integrity due to moisture exposure can result in increased side reactions and accelerated capacity loss. Furthermore, high humidity environments can promote the growth of lithium dendrites, potentially leading to internal short circuits and safety hazards.

Current industry practices involve rigorous moisture control during battery manufacturing and the implementation of advanced sealing technologies to prevent water ingress during operation. However, the long-term effects of ambient humidity on LFP batteries in real-world applications remain a challenge, particularly in regions with high humidity levels or in applications where batteries are exposed to varying environmental conditions.

Recent advancements in coating technologies and electrolyte additives have shown promise in mitigating humidity-related degradation. Some researchers have developed moisture-resistant cathode coatings that can significantly reduce water absorption and subsequent degradation. Additionally, novel electrolyte formulations with water-scavenging additives are being explored to minimize the impact of any moisture that does penetrate the cell.

Despite these developments, there is still a need for comprehensive long-term studies to fully understand the complex interactions between humidity and LFP battery components. The industry is actively working on developing more robust testing protocols that can accurately simulate and accelerate humidity-induced aging, allowing for better prediction of battery life in diverse environmental conditions.

LFP batteries, known for their stability and safety compared to other lithium-ion chemistries, are not immune to the effects of moisture. The interaction between humidity and LFP batteries primarily occurs through two mechanisms: direct water ingress into the battery cell and moisture absorption by the electrode materials. These processes can trigger a series of detrimental reactions that compromise battery performance and lifespan.

One of the main concerns is the hydrolysis of the electrolyte when exposed to moisture. This reaction can produce hydrofluoric acid (HF), which is highly corrosive and can attack the protective layers on electrode surfaces. Consequently, this leads to increased internal resistance and capacity fade over time. Additionally, moisture can cause the dissolution of metal ions from the cathode, altering its structure and reducing its ability to intercalate lithium ions effectively.

Research has also revealed that humidity can affect the solid electrolyte interphase (SEI) layer formation on the anode. The SEI layer is crucial for battery stability and performance, and its compromised integrity due to moisture exposure can result in increased side reactions and accelerated capacity loss. Furthermore, high humidity environments can promote the growth of lithium dendrites, potentially leading to internal short circuits and safety hazards.

Current industry practices involve rigorous moisture control during battery manufacturing and the implementation of advanced sealing technologies to prevent water ingress during operation. However, the long-term effects of ambient humidity on LFP batteries in real-world applications remain a challenge, particularly in regions with high humidity levels or in applications where batteries are exposed to varying environmental conditions.

Recent advancements in coating technologies and electrolyte additives have shown promise in mitigating humidity-related degradation. Some researchers have developed moisture-resistant cathode coatings that can significantly reduce water absorption and subsequent degradation. Additionally, novel electrolyte formulations with water-scavenging additives are being explored to minimize the impact of any moisture that does penetrate the cell.

Despite these developments, there is still a need for comprehensive long-term studies to fully understand the complex interactions between humidity and LFP battery components. The industry is actively working on developing more robust testing protocols that can accurately simulate and accelerate humidity-induced aging, allowing for better prediction of battery life in diverse environmental conditions.

Existing Humidity Mitigation Solutions for LFP Batteries

01 Electrolyte composition optimization

Improving the longevity of lithium iron phosphate batteries by optimizing the electrolyte composition. This includes using additives or modifying the electrolyte formulation to enhance the stability of the electrode-electrolyte interface, reduce side reactions, and improve the overall cycling performance of the battery.- Electrode material optimization: Improving the longevity of Lithium Iron Phosphate (LFP) batteries through optimization of electrode materials. This includes enhancing the structure and composition of cathode materials, developing novel anode materials, and improving the interface between electrodes and electrolytes. These advancements aim to increase the battery's capacity, cycling stability, and overall lifespan.

- Electrolyte formulation: Developing advanced electrolyte formulations to enhance the performance and longevity of LFP batteries. This involves creating new electrolyte compositions, additives, and solvents that improve ionic conductivity, reduce side reactions, and enhance the stability of the solid electrolyte interphase (SEI) layer. These innovations contribute to better cycling efficiency and extended battery life.

- Battery management systems: Implementing sophisticated battery management systems (BMS) to optimize the performance and lifespan of LFP batteries. These systems monitor and control various parameters such as temperature, voltage, and state of charge to prevent overcharging, over-discharging, and thermal runaway. Advanced BMS algorithms can also predict battery health and adapt charging strategies to maximize longevity.

- Thermal management techniques: Developing effective thermal management techniques to maintain optimal operating temperatures for LFP batteries. This includes innovative cooling systems, heat dissipation methods, and thermal insulation strategies. Proper thermal management helps prevent degradation caused by extreme temperatures, thereby extending the battery's lifespan and maintaining its performance over time.

- Manufacturing process improvements: Enhancing manufacturing processes to improve the quality and consistency of LFP batteries. This involves optimizing production techniques, implementing stringent quality control measures, and developing new methods for electrode coating and cell assembly. These improvements result in batteries with fewer defects, more uniform performance, and increased longevity.

02 Cathode material modification

Enhancing the longevity of lithium iron phosphate batteries through modifications to the cathode material. This involves doping the LiFePO4 structure with other elements, optimizing particle size and morphology, or applying surface coatings to improve the material's stability, conductivity, and resistance to degradation during cycling.Expand Specific Solutions03 Advanced charging protocols

Implementing sophisticated charging protocols to extend the lifespan of lithium iron phosphate batteries. This includes developing smart charging algorithms, pulse charging techniques, or temperature-controlled charging methods that minimize stress on the battery components and reduce capacity fade over time.Expand Specific Solutions04 Thermal management systems

Designing and integrating effective thermal management systems to maintain optimal operating temperatures for lithium iron phosphate batteries. This involves using advanced cooling techniques, heat dissipation materials, or active temperature control mechanisms to prevent thermal degradation and extend battery life.Expand Specific Solutions05 Battery management system optimization

Improving battery management systems (BMS) to enhance the longevity of lithium iron phosphate batteries. This includes developing advanced algorithms for state-of-charge and state-of-health estimation, implementing more precise voltage and current control, and optimizing cell balancing techniques to ensure uniform degradation across all cells in a battery pack.Expand Specific Solutions

Key Players in LFP Battery Manufacturing

The competitive landscape for the influence of humidity on lithium iron phosphate battery longevity is in a mature development stage, with significant market size and established players. The global lithium-ion battery market, including LFP batteries, is projected to reach $129.3 billion by 2027. Technologically, the field is advanced, with companies like LG Energy Solution, Arkema, and Hefei Guoxuan High-Tech Power Energy leading research efforts. These firms, along with others like Vehicle Energy Japan and Soteria Battery Innovation Group, are focusing on improving battery performance and longevity under various environmental conditions, including humidity. The industry is characterized by ongoing innovation and collaboration between battery manufacturers, material suppliers, and research institutions to address challenges related to battery degradation in humid environments.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced lithium iron phosphate (LFP) batteries with improved humidity resistance. Their technology incorporates a specialized coating on the cathode particles, which acts as a barrier against moisture ingress. This coating is composed of hydrophobic materials that repel water molecules, significantly reducing the battery's susceptibility to humidity-induced degradation[1]. Additionally, they have implemented a novel electrolyte formulation that includes hygroscopic additives, which can absorb any residual moisture within the cell, further protecting the active materials from humidity-related damage[3]. The company has also introduced a multi-layer pouch design for their LFP cells, incorporating moisture-resistant materials to enhance the overall protection against environmental factors[5].

Strengths: Enhanced longevity in humid environments, improved safety due to reduced moisture-related degradation, and potential for use in a wider range of applications. Weaknesses: Possible increased production costs due to additional protective measures, and potential reduction in energy density due to protective coatings.

Arkema France SA

Technical Solution: Arkema has developed a proprietary polymer-based coating technology for LFP battery components to mitigate the effects of humidity. Their approach involves encapsulating the cathode materials with a thin, uniform layer of fluoropolymer, which provides excellent moisture resistance while maintaining good ionic conductivity[2]. This coating is applied through a specialized vapor deposition process, ensuring complete coverage of the active materials. Furthermore, Arkema has introduced a new binder system for the electrode manufacturing process that incorporates hydrophobic elements, creating an additional barrier against moisture penetration throughout the electrode structure[4]. The company has also developed advanced separator materials with enhanced moisture resistance properties, contributing to the overall humidity tolerance of the battery system[6].

Strengths: High-performance moisture barrier, minimal impact on battery performance, and potential for long-term stability in humid conditions. Weaknesses: Complex manufacturing process may increase production costs, and potential challenges in scaling up the technology for mass production.

Core Innovations in LFP Battery Moisture Resistance

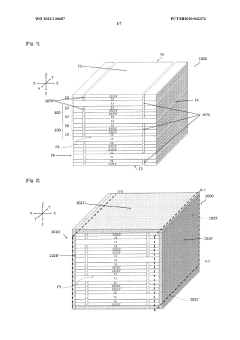

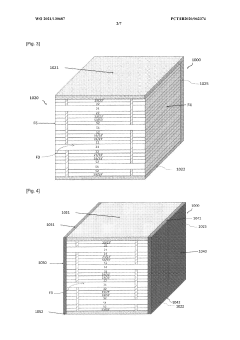

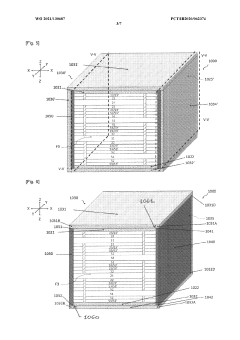

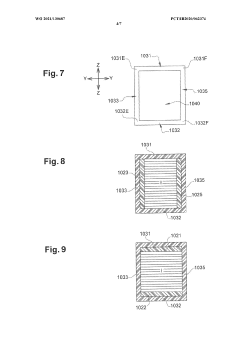

Electrochemical battery device with improved lifetime, comprising improved sealing and electrical conduction means, and manufacturing method thereof

PatentWO2021130687A1

Innovation

- A battery architecture featuring a dual encapsulation system, comprising a primary and additional encapsulation system, where the primary system provides initial protection with materials like parylene and polyimide, and the additional system, made from glasses and ceramics, ensures a tight seal with a water vapor transmission rate of less than 10^-5 g/m².d, covering all faces of the battery stack and accommodating electrode connections to prevent creeping short-circuits.

Complex carbon oxides, method for preparing same

PatentActiveEP2387090A1

Innovation

- A process is developed to control the atmosphere during the preparation, pyrolysis, and storage of carbon complex oxides to maintain a humidity level below 1000 ppm, resulting in a stable material (C-AMXO4) with a carbon film, which prevents oxidation and degradation.

Environmental Factors Affecting LFP Battery Performance

Environmental factors play a crucial role in the performance and longevity of Lithium Iron Phosphate (LFP) batteries. Among these factors, temperature, humidity, and atmospheric pressure are particularly significant. These elements can impact the battery's chemical reactions, physical structure, and overall efficiency.

Temperature is one of the most critical environmental factors affecting LFP battery performance. Extreme temperatures, both high and low, can significantly reduce battery capacity and lifespan. High temperatures accelerate chemical reactions within the battery, leading to faster degradation of active materials and electrolytes. Conversely, low temperatures slow down chemical processes, reducing the battery's ability to deliver power efficiently.

Humidity is another key factor influencing LFP battery performance. Excessive moisture can lead to corrosion of battery components, particularly metal parts such as terminals and connectors. This corrosion can increase internal resistance, reducing the battery's overall efficiency and power output. Additionally, high humidity levels can cause swelling of battery cells, potentially leading to mechanical stress and damage to the battery structure.

Atmospheric pressure, while less commonly discussed, also impacts LFP battery performance. Changes in pressure can affect the gas exchange processes within the battery, potentially altering the internal chemical balance. This is particularly relevant for batteries used in applications involving significant altitude changes or in pressurized environments.

The interaction between these environmental factors can compound their effects on LFP batteries. For instance, high temperature combined with high humidity can accelerate corrosion processes and increase the rate of capacity loss. Similarly, low temperature and high humidity can lead to condensation issues, potentially causing short circuits or other electrical problems.

To mitigate the impact of these environmental factors, various strategies are employed in battery design and application. Thermal management systems are often integrated to maintain optimal operating temperatures. Protective coatings and sealants are used to shield batteries from moisture and corrosive elements. Additionally, advanced battery management systems (BMS) are implemented to monitor and control battery conditions, adjusting performance parameters based on environmental inputs.

Understanding and managing these environmental factors is crucial for optimizing LFP battery performance across diverse applications. From electric vehicles operating in varying climates to stationary energy storage systems exposed to different atmospheric conditions, considering these factors is essential for ensuring long-term reliability and efficiency of LFP batteries.

Temperature is one of the most critical environmental factors affecting LFP battery performance. Extreme temperatures, both high and low, can significantly reduce battery capacity and lifespan. High temperatures accelerate chemical reactions within the battery, leading to faster degradation of active materials and electrolytes. Conversely, low temperatures slow down chemical processes, reducing the battery's ability to deliver power efficiently.

Humidity is another key factor influencing LFP battery performance. Excessive moisture can lead to corrosion of battery components, particularly metal parts such as terminals and connectors. This corrosion can increase internal resistance, reducing the battery's overall efficiency and power output. Additionally, high humidity levels can cause swelling of battery cells, potentially leading to mechanical stress and damage to the battery structure.

Atmospheric pressure, while less commonly discussed, also impacts LFP battery performance. Changes in pressure can affect the gas exchange processes within the battery, potentially altering the internal chemical balance. This is particularly relevant for batteries used in applications involving significant altitude changes or in pressurized environments.

The interaction between these environmental factors can compound their effects on LFP batteries. For instance, high temperature combined with high humidity can accelerate corrosion processes and increase the rate of capacity loss. Similarly, low temperature and high humidity can lead to condensation issues, potentially causing short circuits or other electrical problems.

To mitigate the impact of these environmental factors, various strategies are employed in battery design and application. Thermal management systems are often integrated to maintain optimal operating temperatures. Protective coatings and sealants are used to shield batteries from moisture and corrosive elements. Additionally, advanced battery management systems (BMS) are implemented to monitor and control battery conditions, adjusting performance parameters based on environmental inputs.

Understanding and managing these environmental factors is crucial for optimizing LFP battery performance across diverse applications. From electric vehicles operating in varying climates to stationary energy storage systems exposed to different atmospheric conditions, considering these factors is essential for ensuring long-term reliability and efficiency of LFP batteries.

Regulatory Standards for LFP Battery Safety and Longevity

Regulatory standards for LFP battery safety and longevity play a crucial role in ensuring the reliability and performance of lithium iron phosphate (LFP) batteries across various applications. These standards are developed and enforced by regulatory bodies to address potential risks associated with battery usage, including those related to humidity exposure.

The International Electrotechnical Commission (IEC) has established several standards specifically for LFP batteries. IEC 62619 outlines safety requirements for large format lithium-ion cells and batteries, including LFP chemistry. This standard addresses various aspects of battery design, manufacturing, and testing, with specific provisions for environmental conditions such as humidity.

In the United States, the Underwriters Laboratories (UL) has developed UL 1642, which covers safety standards for lithium batteries. While not exclusive to LFP batteries, this standard includes requirements for testing battery performance under various environmental conditions, including humidity exposure.

The Society of Automotive Engineers (SAE) has also contributed to the regulatory landscape with SAE J2929, which provides safety standards for electric and hybrid vehicle battery systems. This standard includes requirements for evaluating battery performance under different environmental conditions, including humidity levels.

In Europe, the European Committee for Electrotechnical Standardization (CENELEC) has adopted EN 62619, which is harmonized with the IEC standard. This ensures consistency in safety requirements across European Union member states for LFP batteries used in industrial applications.

These regulatory standards typically require manufacturers to conduct rigorous testing to evaluate battery performance and safety under various humidity conditions. Such tests may include storage at high humidity levels, cycling under humid conditions, and assessing the impact of moisture ingress on battery components.

Specific to the influence of humidity on LFP battery longevity, regulatory standards often mandate accelerated life testing under controlled humidity conditions. These tests aim to simulate long-term exposure to different humidity levels and assess their impact on battery capacity, internal resistance, and overall lifespan.

Manufacturers are required to demonstrate compliance with these standards through extensive documentation and third-party certification. This process ensures that LFP batteries meet minimum safety and performance criteria, including resilience to humidity-related degradation, before they can be marketed and sold in various jurisdictions.

As the understanding of humidity's impact on LFP battery longevity continues to evolve, regulatory bodies regularly update their standards to incorporate new findings and technological advancements. This ongoing process helps to maintain the balance between promoting innovation in battery technology and ensuring the safety and reliability of LFP batteries in diverse applications and environmental conditions.

The International Electrotechnical Commission (IEC) has established several standards specifically for LFP batteries. IEC 62619 outlines safety requirements for large format lithium-ion cells and batteries, including LFP chemistry. This standard addresses various aspects of battery design, manufacturing, and testing, with specific provisions for environmental conditions such as humidity.

In the United States, the Underwriters Laboratories (UL) has developed UL 1642, which covers safety standards for lithium batteries. While not exclusive to LFP batteries, this standard includes requirements for testing battery performance under various environmental conditions, including humidity exposure.

The Society of Automotive Engineers (SAE) has also contributed to the regulatory landscape with SAE J2929, which provides safety standards for electric and hybrid vehicle battery systems. This standard includes requirements for evaluating battery performance under different environmental conditions, including humidity levels.

In Europe, the European Committee for Electrotechnical Standardization (CENELEC) has adopted EN 62619, which is harmonized with the IEC standard. This ensures consistency in safety requirements across European Union member states for LFP batteries used in industrial applications.

These regulatory standards typically require manufacturers to conduct rigorous testing to evaluate battery performance and safety under various humidity conditions. Such tests may include storage at high humidity levels, cycling under humid conditions, and assessing the impact of moisture ingress on battery components.

Specific to the influence of humidity on LFP battery longevity, regulatory standards often mandate accelerated life testing under controlled humidity conditions. These tests aim to simulate long-term exposure to different humidity levels and assess their impact on battery capacity, internal resistance, and overall lifespan.

Manufacturers are required to demonstrate compliance with these standards through extensive documentation and third-party certification. This process ensures that LFP batteries meet minimum safety and performance criteria, including resilience to humidity-related degradation, before they can be marketed and sold in various jurisdictions.

As the understanding of humidity's impact on LFP battery longevity continues to evolve, regulatory bodies regularly update their standards to incorporate new findings and technological advancements. This ongoing process helps to maintain the balance between promoting innovation in battery technology and ensuring the safety and reliability of LFP batteries in diverse applications and environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!