Innovative Uses of Ethylene Vinyl Acetate in Solar Panels

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA in Solar Panels: Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a crucial component in solar panel manufacturing, revolutionizing the industry since its introduction in the 1980s. This versatile copolymer, composed of ethylene and vinyl acetate, has become the standard encapsulant material for photovoltaic modules due to its exceptional properties and performance characteristics.

The primary objective of utilizing EVA in solar panels is to enhance the overall efficiency, durability, and longevity of photovoltaic systems. EVA serves as a protective layer, encapsulating the solar cells and shielding them from environmental factors such as moisture, dust, and mechanical stress. This encapsulation is critical for maintaining the integrity and performance of the solar cells over extended periods.

The evolution of EVA in solar panel technology has been driven by the increasing demand for more efficient and cost-effective renewable energy solutions. As the solar industry has grown, so too has the need for advanced materials that can improve panel performance while reducing manufacturing costs. EVA has consistently met these challenges, adapting to new cell technologies and panel designs.

One of the key trends in EVA development for solar applications has been the focus on improving its optical properties. Manufacturers have worked to enhance the transparency of EVA films, allowing for greater light transmission to the solar cells. This optimization has directly contributed to increased panel efficiency, as more sunlight reaching the cells translates to higher energy output.

Another significant trend has been the enhancement of EVA's weathering resistance. As solar panels are exposed to harsh environmental conditions over decades, the ability of EVA to maintain its protective properties is crucial. Research and development efforts have led to formulations with improved UV stability and moisture resistance, extending the operational lifespan of solar panels.

The technical goals for EVA in solar panel applications continue to evolve. Current objectives include further improving the material's resistance to potential-induced degradation (PID), enhancing its thermal management properties, and developing formulations that can withstand even more extreme environmental conditions. Additionally, there is a growing focus on creating EVA formulations that are more environmentally friendly and easier to recycle at the end of a panel's life cycle.

As the solar industry moves towards higher efficiency cell technologies, such as heterojunction and perovskite cells, the role of EVA is being reevaluated and adapted. The encapsulant must be compatible with these new cell structures while maintaining or improving upon its current performance characteristics. This ongoing evolution underscores the critical role that EVA plays in the advancement of solar technology and highlights the need for continued innovation in this field.

The primary objective of utilizing EVA in solar panels is to enhance the overall efficiency, durability, and longevity of photovoltaic systems. EVA serves as a protective layer, encapsulating the solar cells and shielding them from environmental factors such as moisture, dust, and mechanical stress. This encapsulation is critical for maintaining the integrity and performance of the solar cells over extended periods.

The evolution of EVA in solar panel technology has been driven by the increasing demand for more efficient and cost-effective renewable energy solutions. As the solar industry has grown, so too has the need for advanced materials that can improve panel performance while reducing manufacturing costs. EVA has consistently met these challenges, adapting to new cell technologies and panel designs.

One of the key trends in EVA development for solar applications has been the focus on improving its optical properties. Manufacturers have worked to enhance the transparency of EVA films, allowing for greater light transmission to the solar cells. This optimization has directly contributed to increased panel efficiency, as more sunlight reaching the cells translates to higher energy output.

Another significant trend has been the enhancement of EVA's weathering resistance. As solar panels are exposed to harsh environmental conditions over decades, the ability of EVA to maintain its protective properties is crucial. Research and development efforts have led to formulations with improved UV stability and moisture resistance, extending the operational lifespan of solar panels.

The technical goals for EVA in solar panel applications continue to evolve. Current objectives include further improving the material's resistance to potential-induced degradation (PID), enhancing its thermal management properties, and developing formulations that can withstand even more extreme environmental conditions. Additionally, there is a growing focus on creating EVA formulations that are more environmentally friendly and easier to recycle at the end of a panel's life cycle.

As the solar industry moves towards higher efficiency cell technologies, such as heterojunction and perovskite cells, the role of EVA is being reevaluated and adapted. The encapsulant must be compatible with these new cell structures while maintaining or improving upon its current performance characteristics. This ongoing evolution underscores the critical role that EVA plays in the advancement of solar technology and highlights the need for continued innovation in this field.

Market Analysis for EVA-Enhanced Solar Panels

The market for EVA-enhanced solar panels has shown significant growth in recent years, driven by the increasing demand for renewable energy solutions and the continuous improvement in solar panel efficiency. Ethylene Vinyl Acetate (EVA) has emerged as a crucial component in solar panel manufacturing, primarily used as an encapsulant material to protect solar cells from environmental factors and enhance overall panel performance.

The global solar panel market is expected to continue its upward trajectory, with EVA playing a pivotal role in this growth. The market size for EVA in solar applications has been expanding steadily, as manufacturers recognize its benefits in terms of durability, transparency, and cost-effectiveness. This growth is further fueled by government initiatives and policies promoting clean energy adoption across various regions.

In terms of regional distribution, Asia-Pacific dominates the market for EVA-enhanced solar panels, with China leading in both production and consumption. Europe and North America follow, showing strong growth potential due to increasing environmental awareness and supportive regulatory frameworks. Emerging markets in Latin America and Africa are also presenting new opportunities for expansion.

The demand for EVA in solar panels is closely tied to the overall solar energy market trends. As solar energy becomes more competitive with traditional power sources, the demand for high-quality, efficient solar panels increases, subsequently driving the need for advanced EVA formulations. This trend is expected to continue as solar technology evolves and becomes more accessible to a broader range of consumers and industries.

One of the key factors influencing the market is the ongoing research and development in EVA formulations specifically tailored for solar applications. Manufacturers are focusing on developing EVA grades that offer improved UV resistance, better adhesion properties, and enhanced thermal management capabilities. These advancements are crucial in extending the lifespan of solar panels and improving their overall efficiency, thus driving market growth.

The competitive landscape of the EVA market for solar panels is characterized by a mix of large chemical companies and specialized manufacturers. Key players are investing in research and development to gain a competitive edge through product differentiation and improved performance characteristics. This competition is beneficial for the market as it leads to continuous innovation and cost reduction, making solar energy more accessible to a wider consumer base.

The global solar panel market is expected to continue its upward trajectory, with EVA playing a pivotal role in this growth. The market size for EVA in solar applications has been expanding steadily, as manufacturers recognize its benefits in terms of durability, transparency, and cost-effectiveness. This growth is further fueled by government initiatives and policies promoting clean energy adoption across various regions.

In terms of regional distribution, Asia-Pacific dominates the market for EVA-enhanced solar panels, with China leading in both production and consumption. Europe and North America follow, showing strong growth potential due to increasing environmental awareness and supportive regulatory frameworks. Emerging markets in Latin America and Africa are also presenting new opportunities for expansion.

The demand for EVA in solar panels is closely tied to the overall solar energy market trends. As solar energy becomes more competitive with traditional power sources, the demand for high-quality, efficient solar panels increases, subsequently driving the need for advanced EVA formulations. This trend is expected to continue as solar technology evolves and becomes more accessible to a broader range of consumers and industries.

One of the key factors influencing the market is the ongoing research and development in EVA formulations specifically tailored for solar applications. Manufacturers are focusing on developing EVA grades that offer improved UV resistance, better adhesion properties, and enhanced thermal management capabilities. These advancements are crucial in extending the lifespan of solar panels and improving their overall efficiency, thus driving market growth.

The competitive landscape of the EVA market for solar panels is characterized by a mix of large chemical companies and specialized manufacturers. Key players are investing in research and development to gain a competitive edge through product differentiation and improved performance characteristics. This competition is beneficial for the market as it leads to continuous innovation and cost reduction, making solar energy more accessible to a wider consumer base.

Current Challenges in EVA Solar Panel Applications

Ethylene Vinyl Acetate (EVA) has been a cornerstone material in solar panel encapsulation for decades. However, as the solar industry continues to evolve and demand higher efficiency and durability, several challenges have emerged in EVA applications for solar panels.

One of the primary challenges is the degradation of EVA under prolonged exposure to ultraviolet (UV) radiation. While EVA provides excellent initial transparency and adhesion, it tends to yellow and degrade over time when exposed to sunlight. This degradation not only affects the aesthetic appearance of solar panels but also reduces their overall efficiency by limiting light transmission to the photovoltaic cells.

Another significant challenge is the potential for moisture ingress in EVA-encapsulated solar panels. Despite its water-resistant properties, EVA can still allow some moisture penetration over extended periods. This can lead to corrosion of metal components within the panel, delamination of layers, and ultimately, reduced panel lifespan and performance.

Thermal management presents another hurdle for EVA in solar panel applications. As panels heat up during operation, EVA can soften and potentially flow, leading to issues such as cell displacement or bubbling. This thermal instability can compromise the structural integrity of the panel and impact its long-term reliability.

The crosslinking process of EVA during panel manufacturing also poses challenges. Achieving uniform and optimal crosslinking across the entire panel area is crucial for ensuring consistent performance and durability. However, variations in crosslinking can lead to inconsistencies in mechanical properties and adhesion strength, potentially resulting in premature panel failure.

Furthermore, as the solar industry pushes for higher efficiency panels, there is a growing need for encapsulant materials that can withstand higher operating temperatures. Traditional EVA formulations may not be suitable for next-generation high-temperature solar cells, necessitating the development of more thermally stable alternatives.

Recycling and end-of-life management of EVA-encapsulated solar panels also present significant environmental challenges. The strong adhesion of EVA to glass and other panel components makes it difficult to separate and recycle these materials efficiently at the end of the panel's life cycle.

Lastly, there is an ongoing challenge to improve the fire resistance of EVA encapsulants. While EVA provides good electrical insulation, its flammability can be a concern in certain applications, particularly in building-integrated photovoltaics where fire safety standards are stringent.

One of the primary challenges is the degradation of EVA under prolonged exposure to ultraviolet (UV) radiation. While EVA provides excellent initial transparency and adhesion, it tends to yellow and degrade over time when exposed to sunlight. This degradation not only affects the aesthetic appearance of solar panels but also reduces their overall efficiency by limiting light transmission to the photovoltaic cells.

Another significant challenge is the potential for moisture ingress in EVA-encapsulated solar panels. Despite its water-resistant properties, EVA can still allow some moisture penetration over extended periods. This can lead to corrosion of metal components within the panel, delamination of layers, and ultimately, reduced panel lifespan and performance.

Thermal management presents another hurdle for EVA in solar panel applications. As panels heat up during operation, EVA can soften and potentially flow, leading to issues such as cell displacement or bubbling. This thermal instability can compromise the structural integrity of the panel and impact its long-term reliability.

The crosslinking process of EVA during panel manufacturing also poses challenges. Achieving uniform and optimal crosslinking across the entire panel area is crucial for ensuring consistent performance and durability. However, variations in crosslinking can lead to inconsistencies in mechanical properties and adhesion strength, potentially resulting in premature panel failure.

Furthermore, as the solar industry pushes for higher efficiency panels, there is a growing need for encapsulant materials that can withstand higher operating temperatures. Traditional EVA formulations may not be suitable for next-generation high-temperature solar cells, necessitating the development of more thermally stable alternatives.

Recycling and end-of-life management of EVA-encapsulated solar panels also present significant environmental challenges. The strong adhesion of EVA to glass and other panel components makes it difficult to separate and recycle these materials efficiently at the end of the panel's life cycle.

Lastly, there is an ongoing challenge to improve the fire resistance of EVA encapsulants. While EVA provides good electrical insulation, its flammability can be a concern in certain applications, particularly in building-integrated photovoltaics where fire safety standards are stringent.

Existing EVA Solutions for Solar Panel Efficiency

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base for other adhesive systems. The material's low melting point and good flow characteristics make it ideal for these applications.

- EVA in foam and insulation products: EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as footwear, sports equipment, and building insulation. The material can be easily molded and shaped into various forms while maintaining its insulating properties.

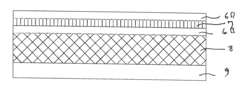

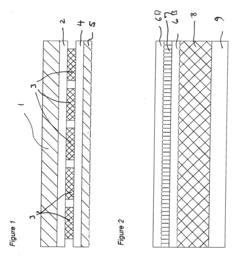

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules. Its transparency, weather resistance, and ability to protect solar cells from moisture and mechanical stress make it an ideal choice for this application. The material helps to extend the lifespan and efficiency of solar panels.

- EVA in packaging and film applications: EVA is used in the production of flexible packaging materials and films. Its clarity, toughness, and barrier properties make it suitable for food packaging, shrink wrap, and agricultural films. The material can be easily processed using various film extrusion techniques and can be blended with other polymers to enhance specific properties.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is commonly employed in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and flexibility of EVA-based adhesives can be tailored by adjusting the vinyl acetate content and molecular weight.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and shock-absorbing capabilities. It is commonly used in footwear, sports equipment, and packaging applications. The foam can be crosslinked to improve its heat resistance and compression set properties.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a popular material for encapsulating solar cells in photovoltaic modules. It provides excellent transparency, weather resistance, and electrical insulation properties. The material helps protect the solar cells from environmental factors and ensures long-term performance of the solar panels.Expand Specific Solutions05 Modifications and blends of EVA

EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes the incorporation of flame retardants, UV stabilizers, and compatibilizers. EVA blends are used in various industries, including automotive, construction, and packaging, to achieve desired performance characteristics.Expand Specific Solutions

Key Players in EVA Solar Panel Industry

The innovative uses of Ethylene Vinyl Acetate (EVA) in solar panels represent a growing market within the renewable energy sector. The industry is in a mature growth phase, with increasing demand driven by global sustainability initiatives. Market size is substantial, with major players like DuPont, Bridgestone, and LG Chem investing heavily in R&D. Technological maturity is high, evidenced by advanced applications from companies such as Hanwha Total Energy and Sumitomo Chemical. However, there's still room for innovation, particularly in enhancing EVA's durability and efficiency in solar panel encapsulation, as demonstrated by emerging players like Abora Energy and S POLYTECH.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed innovative EVA-based encapsulant films for solar panels, such as their PV5400 Series. These films utilize a unique crosslinking technology that enhances moisture resistance and electrical insulation properties. The company's EVA formulations incorporate UV stabilizers and antioxidants to extend the service life of solar modules. DuPont's EVA films demonstrate excellent light transmission (>91%) and low shrinkage (<2%) after lamination [1][3]. They have also introduced EVA grades with improved adhesion to glass and backsheets, reducing the risk of delamination in harsh environmental conditions.

Strengths: Superior moisture resistance, excellent optical properties, and enhanced durability. Weaknesses: Potentially higher cost compared to standard EVA formulations, may require specialized processing equipment.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed a range of EVA encapsulant sheets for solar panels under their SOLAR EVA™ brand. Their innovative approach includes the use of reactive additives that improve crosslinking efficiency and reduce curing time. Mitsui's EVA formulations feature enhanced weatherability and low water vapor transmission rates (<1 g/m²/day) [2]. The company has also introduced EVA grades with improved low-temperature flexibility, addressing challenges in cold climate installations. Mitsui's research focuses on optimizing EVA's refractive index to maximize light transmission to solar cells, achieving up to 93% transmittance in the visible spectrum [4].

Strengths: Rapid curing, excellent weatherability, and optimized optical properties. Weaknesses: May have limited availability in some regions, potentially higher cost for specialized grades.

Innovative EVA Formulations for Solar Panels

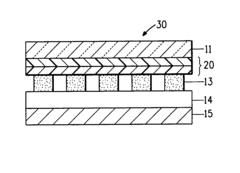

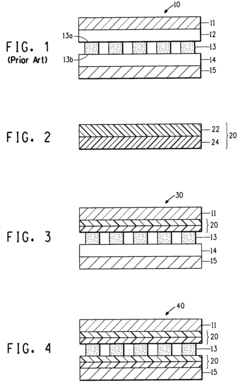

Low modulus solar cell encapsulant sheets with enhanced stability and adhesion

PatentActiveUS20080190481A1

Innovation

- A thermoplastic bi-layer film or sheet comprising a first surface layer of an acid copolymer or ionomer and a second surface layer of an ethylene acrylate ester copolymer, with specific compositions and additives to enhance adhesion, flexibility, and stability, eliminating the need for adhesion primers and improving physical properties.

Solar panels with opaque EVA film backseets

PatentInactiveUS20110272004A1

Innovation

- A solar panel design featuring a laminar backing sheet structure with two outer ethylene vinyl acetate copolymer layers and a core thermoplastic olefin polymer layer, each containing opacifying pigment, along with a polyester film and a weatherable exterior layer, which maintains high opacity and reduces surface particle agglomeration.

Environmental Impact of EVA in Solar Panels

The environmental impact of Ethylene Vinyl Acetate (EVA) in solar panels is a crucial consideration in the renewable energy sector. EVA plays a significant role as an encapsulant material in photovoltaic modules, providing essential protection and enhancing the overall performance of solar panels. However, its use also raises important environmental concerns that must be addressed.

One of the primary environmental benefits of EVA in solar panels is its contribution to the longevity and efficiency of photovoltaic systems. By effectively sealing and protecting solar cells from moisture, dust, and other environmental factors, EVA helps extend the lifespan of solar panels. This increased durability reduces the frequency of panel replacements, thereby minimizing waste generation and the need for raw materials in the long term.

Despite these advantages, the production and disposal of EVA-containing solar panels present environmental challenges. The manufacturing process of EVA involves the use of petrochemicals, which can contribute to greenhouse gas emissions and energy consumption. Additionally, the cross-linking of EVA during the lamination process makes it difficult to separate from other components at the end of a solar panel's life cycle, complicating recycling efforts.

The end-of-life management of solar panels containing EVA is a growing concern. As the first generation of large-scale solar installations reaches retirement age, the industry faces the challenge of responsibly disposing of or recycling these panels. The presence of EVA complicates the recycling process, as it must be separated from other valuable materials such as glass and silicon. Current recycling technologies for EVA-containing panels are limited and often energy-intensive, potentially offsetting some of the environmental benefits gained during the panel's operational life.

Researchers and manufacturers are exploring innovative solutions to mitigate the environmental impact of EVA in solar panels. These efforts include developing more environmentally friendly encapsulant materials, improving EVA formulations for easier recycling, and advancing recycling technologies specifically designed for solar panel components. Some promising approaches involve the use of thermoplastic materials that can be more easily separated and recycled compared to traditional EVA.

Furthermore, the solar industry is increasingly adopting lifecycle assessment methodologies to evaluate and reduce the environmental footprint of solar panels, including the impact of EVA. This holistic approach considers factors such as raw material extraction, manufacturing processes, transportation, use phase, and end-of-life management. By identifying areas of significant environmental impact, manufacturers can focus on developing more sustainable practices and materials throughout the solar panel lifecycle.

In conclusion, while EVA plays a crucial role in enhancing the performance and durability of solar panels, its environmental impact remains a complex issue. Balancing the benefits of increased panel efficiency and longevity against the challenges of production and end-of-life management is essential for the sustainable growth of the solar energy sector. Ongoing research and innovation in materials science and recycling technologies will be key to minimizing the environmental footprint of EVA in solar panels and ensuring the long-term sustainability of photovoltaic technology.

One of the primary environmental benefits of EVA in solar panels is its contribution to the longevity and efficiency of photovoltaic systems. By effectively sealing and protecting solar cells from moisture, dust, and other environmental factors, EVA helps extend the lifespan of solar panels. This increased durability reduces the frequency of panel replacements, thereby minimizing waste generation and the need for raw materials in the long term.

Despite these advantages, the production and disposal of EVA-containing solar panels present environmental challenges. The manufacturing process of EVA involves the use of petrochemicals, which can contribute to greenhouse gas emissions and energy consumption. Additionally, the cross-linking of EVA during the lamination process makes it difficult to separate from other components at the end of a solar panel's life cycle, complicating recycling efforts.

The end-of-life management of solar panels containing EVA is a growing concern. As the first generation of large-scale solar installations reaches retirement age, the industry faces the challenge of responsibly disposing of or recycling these panels. The presence of EVA complicates the recycling process, as it must be separated from other valuable materials such as glass and silicon. Current recycling technologies for EVA-containing panels are limited and often energy-intensive, potentially offsetting some of the environmental benefits gained during the panel's operational life.

Researchers and manufacturers are exploring innovative solutions to mitigate the environmental impact of EVA in solar panels. These efforts include developing more environmentally friendly encapsulant materials, improving EVA formulations for easier recycling, and advancing recycling technologies specifically designed for solar panel components. Some promising approaches involve the use of thermoplastic materials that can be more easily separated and recycled compared to traditional EVA.

Furthermore, the solar industry is increasingly adopting lifecycle assessment methodologies to evaluate and reduce the environmental footprint of solar panels, including the impact of EVA. This holistic approach considers factors such as raw material extraction, manufacturing processes, transportation, use phase, and end-of-life management. By identifying areas of significant environmental impact, manufacturers can focus on developing more sustainable practices and materials throughout the solar panel lifecycle.

In conclusion, while EVA plays a crucial role in enhancing the performance and durability of solar panels, its environmental impact remains a complex issue. Balancing the benefits of increased panel efficiency and longevity against the challenges of production and end-of-life management is essential for the sustainable growth of the solar energy sector. Ongoing research and innovation in materials science and recycling technologies will be key to minimizing the environmental footprint of EVA in solar panels and ensuring the long-term sustainability of photovoltaic technology.

Cost-Benefit Analysis of EVA in Solar Energy

The cost-benefit analysis of Ethylene Vinyl Acetate (EVA) in solar energy reveals a compelling case for its continued use and potential for innovation in solar panel manufacturing. EVA's primary function as an encapsulant material provides significant benefits that outweigh its costs, making it a crucial component in the solar energy industry.

From a cost perspective, EVA is relatively inexpensive compared to alternative encapsulant materials. Its widespread availability and established manufacturing processes contribute to its cost-effectiveness. The material's low melting point allows for easier processing during solar panel production, reducing energy consumption and associated costs. Additionally, EVA's compatibility with automated manufacturing techniques further enhances production efficiency and reduces labor costs.

The benefits of EVA in solar panels are substantial. Its excellent optical properties, including high light transmittance, ensure that a maximum amount of sunlight reaches the solar cells, thereby improving overall panel efficiency. EVA's flexibility and ability to absorb thermal stresses protect the fragile silicon cells from mechanical damage, extending the lifespan of solar panels. This durability translates to reduced maintenance and replacement costs over the long term.

EVA's weather resistance properties provide protection against moisture ingress and UV radiation, which are critical factors in maintaining solar panel performance over time. This resistance to environmental degradation contributes to the longevity of solar installations, offering a better return on investment for both manufacturers and end-users.

However, there are some drawbacks to consider. EVA can experience degradation over time, particularly in high-temperature environments, which may lead to yellowing and reduced light transmission. This degradation can potentially impact the long-term efficiency of solar panels. Research and development efforts are ongoing to address these issues, focusing on improving EVA formulations to enhance its thermal stability and UV resistance.

Innovative uses of EVA in solar panels are being explored to further improve its cost-benefit ratio. These include the development of EVA formulations with enhanced thermal management properties, which could lead to increased panel efficiency and longevity. Additionally, research into EVA composites with nanomaterials shows promise in improving the material's overall performance and durability.

In conclusion, the cost-benefit analysis of EVA in solar energy demonstrates its significant value proposition. While there are areas for improvement, the material's low cost, excellent optical properties, and protective capabilities make it an indispensable component in current solar panel technology. Ongoing innovations in EVA formulations and applications are likely to further enhance its cost-effectiveness and performance in the solar energy sector.

From a cost perspective, EVA is relatively inexpensive compared to alternative encapsulant materials. Its widespread availability and established manufacturing processes contribute to its cost-effectiveness. The material's low melting point allows for easier processing during solar panel production, reducing energy consumption and associated costs. Additionally, EVA's compatibility with automated manufacturing techniques further enhances production efficiency and reduces labor costs.

The benefits of EVA in solar panels are substantial. Its excellent optical properties, including high light transmittance, ensure that a maximum amount of sunlight reaches the solar cells, thereby improving overall panel efficiency. EVA's flexibility and ability to absorb thermal stresses protect the fragile silicon cells from mechanical damage, extending the lifespan of solar panels. This durability translates to reduced maintenance and replacement costs over the long term.

EVA's weather resistance properties provide protection against moisture ingress and UV radiation, which are critical factors in maintaining solar panel performance over time. This resistance to environmental degradation contributes to the longevity of solar installations, offering a better return on investment for both manufacturers and end-users.

However, there are some drawbacks to consider. EVA can experience degradation over time, particularly in high-temperature environments, which may lead to yellowing and reduced light transmission. This degradation can potentially impact the long-term efficiency of solar panels. Research and development efforts are ongoing to address these issues, focusing on improving EVA formulations to enhance its thermal stability and UV resistance.

Innovative uses of EVA in solar panels are being explored to further improve its cost-benefit ratio. These include the development of EVA formulations with enhanced thermal management properties, which could lead to increased panel efficiency and longevity. Additionally, research into EVA composites with nanomaterials shows promise in improving the material's overall performance and durability.

In conclusion, the cost-benefit analysis of EVA in solar energy demonstrates its significant value proposition. While there are areas for improvement, the material's low cost, excellent optical properties, and protective capabilities make it an indispensable component in current solar panel technology. Ongoing innovations in EVA formulations and applications are likely to further enhance its cost-effectiveness and performance in the solar energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!