Interactive Effects of AGM Battery and Environmental Conditions

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in lead-acid battery technology. Originating in the 1980s, AGM batteries were initially developed for military aircraft, where their spill-proof design and high power density were crucial. The technology quickly found applications in other fields, particularly in the automotive and renewable energy sectors.

Early AGM batteries faced challenges such as limited cycle life and sensitivity to overcharging. However, continuous research and development led to substantial improvements. In the 1990s, enhanced manufacturing processes and materials resulted in increased durability and performance. The introduction of valve-regulated designs further improved safety and reduced maintenance requirements.

The 2000s saw a surge in AGM battery adoption, driven by the growing demand for start-stop systems in vehicles and the expansion of renewable energy storage solutions. This period marked significant advancements in electrode design and electrolyte formulations, leading to higher energy density and longer service life.

Recent years have witnessed the integration of smart battery management systems with AGM technology. These systems optimize charging processes and monitor battery health, extending the lifespan and reliability of AGM batteries. Additionally, improvements in plate design and separator materials have further enhanced the batteries' performance under various environmental conditions.

The interaction between AGM batteries and environmental conditions has been a key focus of recent developments. Research has shown that temperature fluctuations significantly impact AGM battery performance and longevity. In response, manufacturers have developed temperature-resistant formulations and adaptive charging algorithms to mitigate these effects.

Advancements in AGM technology have also addressed the challenges of extreme weather conditions. Enhanced cold-cranking performance for low-temperature environments and improved heat dissipation for high-temperature applications have expanded the operational range of AGM batteries.

The evolution of AGM batteries continues to be driven by the demands of emerging technologies and environmental concerns. Current research focuses on increasing energy density, improving fast-charging capabilities, and enhancing overall efficiency. These efforts aim to meet the growing needs of electric vehicles, renewable energy storage, and other high-demand applications while addressing the interactive effects between battery performance and environmental conditions.

Early AGM batteries faced challenges such as limited cycle life and sensitivity to overcharging. However, continuous research and development led to substantial improvements. In the 1990s, enhanced manufacturing processes and materials resulted in increased durability and performance. The introduction of valve-regulated designs further improved safety and reduced maintenance requirements.

The 2000s saw a surge in AGM battery adoption, driven by the growing demand for start-stop systems in vehicles and the expansion of renewable energy storage solutions. This period marked significant advancements in electrode design and electrolyte formulations, leading to higher energy density and longer service life.

Recent years have witnessed the integration of smart battery management systems with AGM technology. These systems optimize charging processes and monitor battery health, extending the lifespan and reliability of AGM batteries. Additionally, improvements in plate design and separator materials have further enhanced the batteries' performance under various environmental conditions.

The interaction between AGM batteries and environmental conditions has been a key focus of recent developments. Research has shown that temperature fluctuations significantly impact AGM battery performance and longevity. In response, manufacturers have developed temperature-resistant formulations and adaptive charging algorithms to mitigate these effects.

Advancements in AGM technology have also addressed the challenges of extreme weather conditions. Enhanced cold-cranking performance for low-temperature environments and improved heat dissipation for high-temperature applications have expanded the operational range of AGM batteries.

The evolution of AGM batteries continues to be driven by the demands of emerging technologies and environmental concerns. Current research focuses on increasing energy density, improving fast-charging capabilities, and enhancing overall efficiency. These efforts aim to meet the growing needs of electric vehicles, renewable energy storage, and other high-demand applications while addressing the interactive effects between battery performance and environmental conditions.

Market Demand Analysis

The market demand for AGM (Absorbent Glass Mat) batteries has been steadily increasing due to their superior performance characteristics and versatility across various applications. These batteries are particularly valued in automotive, marine, and renewable energy sectors for their deep-cycle capabilities, low maintenance requirements, and resistance to vibration.

In the automotive industry, AGM batteries are gaining traction as vehicles become more electrically sophisticated. The growing prevalence of start-stop systems and advanced driver assistance features has created a surge in demand for batteries that can handle frequent cycling and provide stable power output. This trend is expected to continue as electric and hybrid vehicles become more mainstream, further driving the need for high-performance battery solutions.

The renewable energy sector presents another significant market opportunity for AGM batteries. As solar and wind power installations increase globally, there is a corresponding demand for reliable energy storage solutions. AGM batteries are well-suited for off-grid and grid-tied renewable energy systems due to their ability to withstand deep discharges and maintain performance over time.

Marine applications represent a niche but growing market for AGM batteries. Their spill-proof design and ability to withstand harsh marine environments make them ideal for use in boats and other watercraft. The recreational boating industry, in particular, has shown increased adoption of AGM technology.

The telecommunications industry is another key driver of AGM battery demand. As network infrastructure expands and becomes more critical, the need for reliable backup power solutions has intensified. AGM batteries are favored for their long service life and low self-discharge rates, making them suitable for uninterruptible power supply (UPS) systems in data centers and cell towers.

However, the market demand for AGM batteries is not without challenges. The interactive effects of AGM batteries and environmental conditions play a crucial role in their performance and longevity. Temperature fluctuations, humidity levels, and exposure to extreme conditions can significantly impact battery life and efficiency. This has led to increased focus on research and development to enhance AGM battery resilience across diverse environmental scenarios.

The global AGM battery market is projected to experience substantial growth in the coming years. Factors such as increasing vehicle electrification, expansion of renewable energy projects, and the growing need for reliable backup power systems are expected to drive this growth. Additionally, advancements in AGM technology to address environmental challenges and improve overall performance are likely to further stimulate market demand.

In the automotive industry, AGM batteries are gaining traction as vehicles become more electrically sophisticated. The growing prevalence of start-stop systems and advanced driver assistance features has created a surge in demand for batteries that can handle frequent cycling and provide stable power output. This trend is expected to continue as electric and hybrid vehicles become more mainstream, further driving the need for high-performance battery solutions.

The renewable energy sector presents another significant market opportunity for AGM batteries. As solar and wind power installations increase globally, there is a corresponding demand for reliable energy storage solutions. AGM batteries are well-suited for off-grid and grid-tied renewable energy systems due to their ability to withstand deep discharges and maintain performance over time.

Marine applications represent a niche but growing market for AGM batteries. Their spill-proof design and ability to withstand harsh marine environments make them ideal for use in boats and other watercraft. The recreational boating industry, in particular, has shown increased adoption of AGM technology.

The telecommunications industry is another key driver of AGM battery demand. As network infrastructure expands and becomes more critical, the need for reliable backup power solutions has intensified. AGM batteries are favored for their long service life and low self-discharge rates, making them suitable for uninterruptible power supply (UPS) systems in data centers and cell towers.

However, the market demand for AGM batteries is not without challenges. The interactive effects of AGM batteries and environmental conditions play a crucial role in their performance and longevity. Temperature fluctuations, humidity levels, and exposure to extreme conditions can significantly impact battery life and efficiency. This has led to increased focus on research and development to enhance AGM battery resilience across diverse environmental scenarios.

The global AGM battery market is projected to experience substantial growth in the coming years. Factors such as increasing vehicle electrification, expansion of renewable energy projects, and the growing need for reliable backup power systems are expected to drive this growth. Additionally, advancements in AGM technology to address environmental challenges and improve overall performance are likely to further stimulate market demand.

Technical Challenges

The development of AGM (Absorbent Glass Mat) batteries has been a significant advancement in energy storage technology. However, their performance and longevity are heavily influenced by environmental conditions, presenting several technical challenges that require careful consideration and innovative solutions.

One of the primary challenges is temperature sensitivity. AGM batteries are known to be particularly susceptible to extreme temperatures, both hot and cold. In high-temperature environments, the battery's internal chemical reactions accelerate, potentially leading to increased self-discharge rates and reduced overall lifespan. Conversely, in cold temperatures, the battery's capacity and ability to deliver power can be significantly diminished, affecting its reliability in critical applications.

Humidity and moisture pose another set of challenges for AGM batteries. While these batteries are designed to be sealed and maintenance-free, prolonged exposure to high humidity environments can lead to condensation on the battery's exterior. This moisture can potentially find its way into the battery, causing corrosion of internal components and degradation of the electrolyte, ultimately compromising the battery's performance and longevity.

Vibration and shock resistance present additional technical hurdles. Although AGM batteries are generally more resistant to vibration compared to flooded lead-acid batteries, continuous exposure to severe vibrations or sudden impacts can still cause internal damage. This can lead to the separation of the glass mat from the lead plates or the formation of cracks in the battery casing, both of which can significantly impair the battery's functionality.

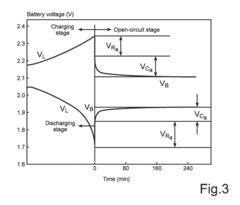

The challenge of maintaining optimal charge levels in varying environmental conditions is also noteworthy. AGM batteries require precise charging algorithms that must adapt to temperature fluctuations to prevent overcharging or undercharging, both of which can severely impact battery life and performance. Developing robust charge control systems that can accurately sense and respond to environmental changes remains a significant technical challenge.

Furthermore, the interaction between AGM batteries and renewable energy systems, particularly in off-grid applications, presents unique challenges. The intermittent nature of renewable sources like solar and wind power requires AGM batteries to handle frequent charge and discharge cycles, which can be further complicated by varying environmental conditions. Balancing the energy input from these sources with the battery's optimal operating parameters across different environmental scenarios is a complex technical problem.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, electrochemistry, and intelligent control systems. Researchers and engineers are continually working on developing more resilient battery chemistries, improved thermal management systems, and sophisticated battery management algorithms to mitigate the impact of environmental factors on AGM battery performance.

One of the primary challenges is temperature sensitivity. AGM batteries are known to be particularly susceptible to extreme temperatures, both hot and cold. In high-temperature environments, the battery's internal chemical reactions accelerate, potentially leading to increased self-discharge rates and reduced overall lifespan. Conversely, in cold temperatures, the battery's capacity and ability to deliver power can be significantly diminished, affecting its reliability in critical applications.

Humidity and moisture pose another set of challenges for AGM batteries. While these batteries are designed to be sealed and maintenance-free, prolonged exposure to high humidity environments can lead to condensation on the battery's exterior. This moisture can potentially find its way into the battery, causing corrosion of internal components and degradation of the electrolyte, ultimately compromising the battery's performance and longevity.

Vibration and shock resistance present additional technical hurdles. Although AGM batteries are generally more resistant to vibration compared to flooded lead-acid batteries, continuous exposure to severe vibrations or sudden impacts can still cause internal damage. This can lead to the separation of the glass mat from the lead plates or the formation of cracks in the battery casing, both of which can significantly impair the battery's functionality.

The challenge of maintaining optimal charge levels in varying environmental conditions is also noteworthy. AGM batteries require precise charging algorithms that must adapt to temperature fluctuations to prevent overcharging or undercharging, both of which can severely impact battery life and performance. Developing robust charge control systems that can accurately sense and respond to environmental changes remains a significant technical challenge.

Furthermore, the interaction between AGM batteries and renewable energy systems, particularly in off-grid applications, presents unique challenges. The intermittent nature of renewable sources like solar and wind power requires AGM batteries to handle frequent charge and discharge cycles, which can be further complicated by varying environmental conditions. Balancing the energy input from these sources with the battery's optimal operating parameters across different environmental scenarios is a complex technical problem.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, electrochemistry, and intelligent control systems. Researchers and engineers are continually working on developing more resilient battery chemistries, improved thermal management systems, and sophisticated battery management algorithms to mitigate the impact of environmental factors on AGM battery performance.

Current AGM Solutions

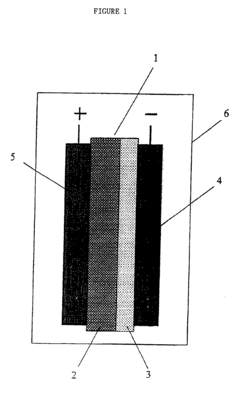

01 AGM battery structure and design

Advancements in AGM battery structure and design focus on improving performance and efficiency. This includes innovations in electrode arrangements, separator materials, and overall battery construction to enhance capacity, lifespan, and charge-discharge characteristics.- AGM battery structure and design: Innovations in AGM battery structure and design focus on improving performance and efficiency. This includes advancements in electrode configurations, separator materials, and overall battery construction to enhance capacity, lifespan, and charge-discharge characteristics.

- Electrolyte management in AGM batteries: Developments in electrolyte management systems for AGM batteries aim to optimize electrolyte distribution and retention. These innovations help maintain battery performance, reduce maintenance requirements, and extend battery life by ensuring proper electrolyte levels and distribution throughout the battery cells.

- Thermal management of AGM batteries: Advancements in thermal management systems for AGM batteries focus on regulating battery temperature during operation and charging. These innovations help prevent overheating, improve safety, and maintain optimal performance across various environmental conditions.

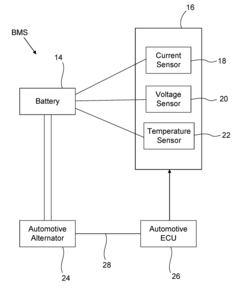

- AGM battery monitoring and control systems: Innovations in monitoring and control systems for AGM batteries involve the development of advanced sensors, data analysis techniques, and management algorithms. These systems aim to optimize battery performance, predict maintenance needs, and enhance overall battery life and reliability.

- AGM battery manufacturing processes: Advancements in AGM battery manufacturing processes focus on improving production efficiency, quality control, and cost-effectiveness. These innovations include automated assembly techniques, advanced material handling systems, and novel production methods to enhance battery performance and consistency.

02 Electrolyte management in AGM batteries

Techniques for optimizing electrolyte distribution and retention within AGM batteries are crucial for their performance. This involves methods for improving absorption and distribution of the electrolyte within the glass mat separator, as well as strategies to prevent electrolyte loss during operation.Expand Specific Solutions03 Thermal management of AGM batteries

Effective thermal management is essential for AGM battery performance and longevity. This includes innovations in heat dissipation, temperature control systems, and thermal insulation to maintain optimal operating conditions and prevent degradation due to temperature fluctuations.Expand Specific Solutions04 AGM battery monitoring and management systems

Advanced monitoring and management systems for AGM batteries are being developed to optimize performance and extend battery life. These systems include sensors, data analysis tools, and control mechanisms to monitor battery health, predict failures, and adjust charging parameters in real-time.Expand Specific Solutions05 AGM battery manufacturing processes

Innovations in AGM battery manufacturing processes aim to improve production efficiency, reduce costs, and enhance product quality. This includes advancements in automated assembly, quality control measures, and the use of novel materials and techniques in battery production.Expand Specific Solutions

Key Industry Players

The interactive effects of AGM battery and environmental conditions represent a dynamic field in the automotive and energy storage sectors. The market is in a growth phase, driven by increasing demand for advanced battery technologies in electric vehicles and renewable energy systems. Major players like LG Energy Solution, Daimler Truck AG, and Nissan Motor Co. are investing heavily in research and development to improve AGM battery performance under various environmental conditions. The technology is maturing rapidly, with companies such as Fengfan Co., Ltd. and Stryten Energy LLC focusing on enhancing battery durability and efficiency across diverse climates. As the market expands, collaborations between automotive manufacturers and battery specialists are becoming more prevalent, accelerating innovation in this field.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive approach to address the interactive effects of AGM batteries and environmental conditions in their vehicle fleet. Their solution incorporates an adaptive battery management system (BMS) that dynamically adjusts charging parameters based on ambient temperature and battery state[2]. GM's AGM batteries feature a temperature-resistant casing and internal structure designed to withstand extreme thermal cycling[4]. The company has also implemented a predictive algorithm that anticipates environmental impacts on battery performance, allowing for proactive adjustments to vehicle systems[6]. Furthermore, GM has integrated their AGM battery technology with start-stop systems, optimizing fuel efficiency while managing battery stress under varying environmental conditions[8].

Strengths: Comprehensive vehicle integration, advanced BMS, and predictive environmental adaptation. Weaknesses: System complexity may increase maintenance requirements and potential points of failure.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a hybrid AGM-Lithium battery system that addresses the interactive effects of environmental conditions. This innovative approach combines the robustness of AGM technology with the high energy density of lithium-ion cells[1]. The system utilizes advanced thermal management techniques, including phase-change materials and intelligent cooling circuits, to maintain optimal operating temperatures across diverse environments[3]. LG's solution also incorporates AI-driven predictive modeling to anticipate and mitigate the impact of environmental factors on battery performance[5]. The company has implemented a modular design that allows for easy replacement and upgrading of battery components, enhancing long-term adaptability to changing environmental conditions[7].

Strengths: Innovative hybrid technology, advanced thermal management, and AI-driven predictive capabilities. Weaknesses: Higher initial cost and potential complexity in system integration.

Core AGM Innovations

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Reinforced multilayer separator for lead-acid batteries

PatentInactiveUS6869726B2

Innovation

- A battery separator comprising at least one fibrous layer and one support layer with macroscopic openings, where the support layer is made of acid-resistant material and has openings penetrating its thickness, providing direct ionic transfer and mechanical strengthening through lamination with the fibrous layer.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) batteries is closely tied to their interaction with various environmental conditions. These batteries, known for their sealed design and high performance, exhibit different behaviors and efficiencies depending on the surrounding environment.

Temperature plays a crucial role in AGM battery performance and longevity. In extreme cold conditions, the chemical reactions within the battery slow down, reducing its capacity and power output. Conversely, high temperatures accelerate these reactions, potentially leading to increased self-discharge rates and shortened battery life. This temperature sensitivity not only affects the battery's immediate performance but also influences its long-term environmental footprint through reduced lifespan and increased replacement frequency.

Humidity levels also significantly impact AGM batteries. While their sealed nature provides better protection against moisture compared to traditional lead-acid batteries, prolonged exposure to high humidity can still lead to accelerated corrosion of internal components. This corrosion can result in decreased efficiency and premature failure, contributing to increased waste generation and resource consumption for replacements.

The environmental conditions in which AGM batteries operate also affect their charging and discharging characteristics. In environments with frequent temperature fluctuations, the battery's internal resistance may vary, leading to inconsistent charging patterns. This inconsistency can result in suboptimal energy utilization, potentially increasing the overall energy demand and associated environmental impacts from power generation.

Furthermore, the interaction between AGM batteries and their environment extends to their end-of-life management. The disposal and recycling processes for these batteries are influenced by the environmental conditions they have been exposed to throughout their lifecycle. Batteries subjected to harsh environments may degrade faster, leading to more frequent disposal and recycling needs, which in turn increases the environmental burden associated with these processes.

The environmental impact of AGM batteries is also reflected in their role in renewable energy systems. In off-grid or backup power applications, the performance of these batteries under varying environmental conditions directly affects the efficiency and reliability of the entire system. Suboptimal battery performance due to environmental factors can lead to increased reliance on non-renewable energy sources, potentially offsetting the environmental benefits of such systems.

In conclusion, the interactive effects between AGM batteries and environmental conditions have far-reaching implications for their overall environmental impact. Understanding and mitigating these effects is crucial for optimizing battery performance, extending lifespan, and minimizing the ecological footprint associated with their production, use, and disposal.

Temperature plays a crucial role in AGM battery performance and longevity. In extreme cold conditions, the chemical reactions within the battery slow down, reducing its capacity and power output. Conversely, high temperatures accelerate these reactions, potentially leading to increased self-discharge rates and shortened battery life. This temperature sensitivity not only affects the battery's immediate performance but also influences its long-term environmental footprint through reduced lifespan and increased replacement frequency.

Humidity levels also significantly impact AGM batteries. While their sealed nature provides better protection against moisture compared to traditional lead-acid batteries, prolonged exposure to high humidity can still lead to accelerated corrosion of internal components. This corrosion can result in decreased efficiency and premature failure, contributing to increased waste generation and resource consumption for replacements.

The environmental conditions in which AGM batteries operate also affect their charging and discharging characteristics. In environments with frequent temperature fluctuations, the battery's internal resistance may vary, leading to inconsistent charging patterns. This inconsistency can result in suboptimal energy utilization, potentially increasing the overall energy demand and associated environmental impacts from power generation.

Furthermore, the interaction between AGM batteries and their environment extends to their end-of-life management. The disposal and recycling processes for these batteries are influenced by the environmental conditions they have been exposed to throughout their lifecycle. Batteries subjected to harsh environments may degrade faster, leading to more frequent disposal and recycling needs, which in turn increases the environmental burden associated with these processes.

The environmental impact of AGM batteries is also reflected in their role in renewable energy systems. In off-grid or backup power applications, the performance of these batteries under varying environmental conditions directly affects the efficiency and reliability of the entire system. Suboptimal battery performance due to environmental factors can lead to increased reliance on non-renewable energy sources, potentially offsetting the environmental benefits of such systems.

In conclusion, the interactive effects between AGM batteries and environmental conditions have far-reaching implications for their overall environmental impact. Understanding and mitigating these effects is crucial for optimizing battery performance, extending lifespan, and minimizing the ecological footprint associated with their production, use, and disposal.

Safety Regulations

Safety regulations play a crucial role in the development, manufacturing, and use of AGM (Absorbent Glass Mat) batteries, especially considering their interactive effects with environmental conditions. These regulations are designed to ensure the safe operation of AGM batteries across various applications and environments.

One of the primary safety concerns addressed by regulations is the potential for thermal runaway in AGM batteries. Environmental conditions, particularly high temperatures, can significantly impact battery performance and safety. Regulatory bodies have established temperature limits for AGM battery operation and storage, typically ranging from -20°C to 60°C. Manufacturers are required to implement thermal management systems and provide clear guidelines for users to prevent overheating and potential fire hazards.

Regulations also focus on the structural integrity of AGM batteries under different environmental conditions. Vibration and shock resistance standards are in place to ensure that batteries can withstand the rigors of transportation and use in mobile applications. These standards are particularly important for AGM batteries used in automotive and marine environments, where exposure to constant vibration and potential impacts is common.

The interaction between AGM batteries and moisture is another key area addressed by safety regulations. While AGM batteries are sealed and generally resistant to moisture, prolonged exposure to high humidity or submersion can still pose risks. Regulations mandate specific ingress protection (IP) ratings for AGM batteries used in outdoor or potentially wet environments, ensuring that the battery's internal components remain protected from water and dust.

Electromagnetic compatibility (EMC) regulations are also relevant, as AGM batteries can both emit and be affected by electromagnetic interference. These regulations ensure that AGM batteries do not interfere with other electronic systems and remain functional in the presence of external electromagnetic fields, which is crucial in automotive and industrial applications.

Safety regulations extend to the charging process of AGM batteries, recognizing that environmental conditions can affect charging efficiency and safety. Manufacturers are required to provide charging algorithms that adapt to temperature variations, preventing overcharging in high-temperature environments or undercharging in cold conditions. Additionally, regulations mandate the inclusion of safety features such as overcharge protection, short circuit protection, and pressure relief valves to mitigate risks associated with gas generation and pressure buildup under adverse environmental conditions.

The transportation of AGM batteries is subject to strict regulations due to their classification as dangerous goods. These regulations specify packaging requirements, labeling standards, and handling procedures to ensure safe transport across different environmental conditions. Special attention is given to air transport, where changes in pressure and temperature can significantly impact battery safety.

Compliance with these safety regulations is typically verified through rigorous testing procedures. Standardized tests simulate various environmental conditions to assess battery performance and safety. These tests include temperature cycling, humidity exposure, altitude simulation, and vibration testing, among others. Certification bodies conduct these tests and issue approvals based on the results, ensuring that AGM batteries meet the required safety standards before entering the market.

One of the primary safety concerns addressed by regulations is the potential for thermal runaway in AGM batteries. Environmental conditions, particularly high temperatures, can significantly impact battery performance and safety. Regulatory bodies have established temperature limits for AGM battery operation and storage, typically ranging from -20°C to 60°C. Manufacturers are required to implement thermal management systems and provide clear guidelines for users to prevent overheating and potential fire hazards.

Regulations also focus on the structural integrity of AGM batteries under different environmental conditions. Vibration and shock resistance standards are in place to ensure that batteries can withstand the rigors of transportation and use in mobile applications. These standards are particularly important for AGM batteries used in automotive and marine environments, where exposure to constant vibration and potential impacts is common.

The interaction between AGM batteries and moisture is another key area addressed by safety regulations. While AGM batteries are sealed and generally resistant to moisture, prolonged exposure to high humidity or submersion can still pose risks. Regulations mandate specific ingress protection (IP) ratings for AGM batteries used in outdoor or potentially wet environments, ensuring that the battery's internal components remain protected from water and dust.

Electromagnetic compatibility (EMC) regulations are also relevant, as AGM batteries can both emit and be affected by electromagnetic interference. These regulations ensure that AGM batteries do not interfere with other electronic systems and remain functional in the presence of external electromagnetic fields, which is crucial in automotive and industrial applications.

Safety regulations extend to the charging process of AGM batteries, recognizing that environmental conditions can affect charging efficiency and safety. Manufacturers are required to provide charging algorithms that adapt to temperature variations, preventing overcharging in high-temperature environments or undercharging in cold conditions. Additionally, regulations mandate the inclusion of safety features such as overcharge protection, short circuit protection, and pressure relief valves to mitigate risks associated with gas generation and pressure buildup under adverse environmental conditions.

The transportation of AGM batteries is subject to strict regulations due to their classification as dangerous goods. These regulations specify packaging requirements, labeling standards, and handling procedures to ensure safe transport across different environmental conditions. Special attention is given to air transport, where changes in pressure and temperature can significantly impact battery safety.

Compliance with these safety regulations is typically verified through rigorous testing procedures. Standardized tests simulate various environmental conditions to assess battery performance and safety. These tests include temperature cycling, humidity exposure, altitude simulation, and vibration testing, among others. Certification bodies conduct these tests and issue approvals based on the results, ensuring that AGM batteries meet the required safety standards before entering the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!