Effect of AGM Battery Charge Cycles on Memory Effect

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in lead-acid battery technology. Developed in the 1970s for military aircraft, AGM batteries have since found widespread application in various industries due to their superior performance characteristics.

Initially, AGM batteries were designed to address the limitations of traditional flooded lead-acid batteries, particularly in terms of electrolyte spillage and maintenance requirements. The key innovation was the use of a fiberglass mat separator to absorb and immobilize the electrolyte, allowing for a sealed, maintenance-free design.

Throughout the 1980s and 1990s, AGM technology continued to evolve, with improvements in manufacturing processes and materials leading to enhanced performance and longevity. The introduction of valve-regulated designs further improved safety and reduced gas emissions, making AGM batteries suitable for a broader range of applications.

A significant milestone in AGM battery evolution was the development of deep-cycle variants in the late 1990s. These batteries were specifically engineered to withstand repeated discharge and recharge cycles, making them ideal for use in renewable energy systems, marine applications, and electric vehicles.

The early 2000s saw advancements in plate design and alloy composition, resulting in AGM batteries with higher specific energy and power densities. This period also marked the beginning of research into the effects of charge cycles on battery performance, including the potential for memory effect.

In recent years, the focus has shifted towards optimizing AGM batteries for specific applications. For instance, start-stop automotive systems have driven the development of AGM batteries with enhanced charge acceptance and cycle life. Similarly, the growing demand for uninterruptible power supplies has led to AGM variants with improved high-rate discharge capabilities.

The ongoing evolution of AGM technology has also addressed environmental concerns. Modern AGM batteries boast higher recyclability rates and reduced lead content compared to their predecessors, aligning with global sustainability initiatives.

As we move into the future, AGM battery evolution continues to be driven by the need for higher energy density, longer cycle life, and faster charging capabilities. Research into advanced electrode materials and electrolyte additives promises to further enhance AGM performance, potentially mitigating issues such as sulfation and grid corrosion that can impact battery longevity.

Initially, AGM batteries were designed to address the limitations of traditional flooded lead-acid batteries, particularly in terms of electrolyte spillage and maintenance requirements. The key innovation was the use of a fiberglass mat separator to absorb and immobilize the electrolyte, allowing for a sealed, maintenance-free design.

Throughout the 1980s and 1990s, AGM technology continued to evolve, with improvements in manufacturing processes and materials leading to enhanced performance and longevity. The introduction of valve-regulated designs further improved safety and reduced gas emissions, making AGM batteries suitable for a broader range of applications.

A significant milestone in AGM battery evolution was the development of deep-cycle variants in the late 1990s. These batteries were specifically engineered to withstand repeated discharge and recharge cycles, making them ideal for use in renewable energy systems, marine applications, and electric vehicles.

The early 2000s saw advancements in plate design and alloy composition, resulting in AGM batteries with higher specific energy and power densities. This period also marked the beginning of research into the effects of charge cycles on battery performance, including the potential for memory effect.

In recent years, the focus has shifted towards optimizing AGM batteries for specific applications. For instance, start-stop automotive systems have driven the development of AGM batteries with enhanced charge acceptance and cycle life. Similarly, the growing demand for uninterruptible power supplies has led to AGM variants with improved high-rate discharge capabilities.

The ongoing evolution of AGM technology has also addressed environmental concerns. Modern AGM batteries boast higher recyclability rates and reduced lead content compared to their predecessors, aligning with global sustainability initiatives.

As we move into the future, AGM battery evolution continues to be driven by the need for higher energy density, longer cycle life, and faster charging capabilities. Research into advanced electrode materials and electrolyte additives promises to further enhance AGM performance, potentially mitigating issues such as sulfation and grid corrosion that can impact battery longevity.

Market Demand Analysis

The market demand for AGM (Absorbent Glass Mat) batteries has been steadily increasing due to their superior performance characteristics compared to traditional lead-acid batteries. AGM batteries are widely used in various applications, including automotive, marine, renewable energy storage, and uninterruptible power supplies (UPS). The growing concern over the memory effect in AGM batteries and its impact on charge cycles has created a significant market need for improved battery technologies and management systems.

In the automotive sector, the rise of start-stop technology in vehicles has driven the demand for AGM batteries. These batteries are better suited to handle frequent charge-discharge cycles associated with start-stop systems, which aim to improve fuel efficiency and reduce emissions. However, the potential memory effect in AGM batteries could impact their long-term performance, creating a market opportunity for solutions that address this issue.

The renewable energy sector has also contributed to the increased demand for AGM batteries. As solar and wind power installations grow, the need for reliable energy storage solutions becomes more critical. AGM batteries are often chosen for their deep-cycle capabilities and maintenance-free operation. The market seeks batteries that can maintain their capacity over numerous charge cycles, making the study of memory effect in AGM batteries particularly relevant.

Telecommunications and data centers represent another significant market segment for AGM batteries. These industries require reliable backup power systems to ensure uninterrupted operations. The potential impact of memory effect on AGM battery performance in these critical applications has led to increased interest in research and development of solutions to mitigate this issue.

Market analysis indicates that the global AGM battery market is expected to grow substantially in the coming years. This growth is driven by the increasing adoption of AGM batteries in various industries and the ongoing shift towards cleaner energy solutions. However, the market also faces challenges related to battery performance and longevity, with the memory effect being a key concern.

The industrial sector, including material handling equipment and electric forklifts, represents another area of growing demand for AGM batteries. These applications require batteries that can withstand frequent charge cycles while maintaining consistent performance. The potential impact of memory effect on AGM batteries in these high-use scenarios has created a market need for advanced battery management systems and improved charging protocols.

As environmental regulations become more stringent, there is an increasing focus on battery recycling and sustainability. This trend has led to a market demand for AGM batteries with longer lifespans and improved charge cycle performance. Addressing the memory effect issue could contribute significantly to extending battery life and reducing the environmental impact of battery production and disposal.

In the automotive sector, the rise of start-stop technology in vehicles has driven the demand for AGM batteries. These batteries are better suited to handle frequent charge-discharge cycles associated with start-stop systems, which aim to improve fuel efficiency and reduce emissions. However, the potential memory effect in AGM batteries could impact their long-term performance, creating a market opportunity for solutions that address this issue.

The renewable energy sector has also contributed to the increased demand for AGM batteries. As solar and wind power installations grow, the need for reliable energy storage solutions becomes more critical. AGM batteries are often chosen for their deep-cycle capabilities and maintenance-free operation. The market seeks batteries that can maintain their capacity over numerous charge cycles, making the study of memory effect in AGM batteries particularly relevant.

Telecommunications and data centers represent another significant market segment for AGM batteries. These industries require reliable backup power systems to ensure uninterrupted operations. The potential impact of memory effect on AGM battery performance in these critical applications has led to increased interest in research and development of solutions to mitigate this issue.

Market analysis indicates that the global AGM battery market is expected to grow substantially in the coming years. This growth is driven by the increasing adoption of AGM batteries in various industries and the ongoing shift towards cleaner energy solutions. However, the market also faces challenges related to battery performance and longevity, with the memory effect being a key concern.

The industrial sector, including material handling equipment and electric forklifts, represents another area of growing demand for AGM batteries. These applications require batteries that can withstand frequent charge cycles while maintaining consistent performance. The potential impact of memory effect on AGM batteries in these high-use scenarios has created a market need for advanced battery management systems and improved charging protocols.

As environmental regulations become more stringent, there is an increasing focus on battery recycling and sustainability. This trend has led to a market demand for AGM batteries with longer lifespans and improved charge cycle performance. Addressing the memory effect issue could contribute significantly to extending battery life and reducing the environmental impact of battery production and disposal.

Technical Challenges

The development of Absorbent Glass Mat (AGM) battery technology has brought significant advancements in energy storage solutions. However, several technical challenges persist in relation to the effect of charge cycles on the memory effect in AGM batteries. These challenges are crucial to address for improving battery performance and longevity.

One of the primary technical hurdles is the accurate measurement and quantification of the memory effect in AGM batteries. Unlike traditional lead-acid batteries, AGM batteries exhibit a more subtle form of memory effect, making it difficult to precisely determine its impact on battery capacity and performance over multiple charge cycles. This challenge requires the development of sophisticated testing methodologies and advanced diagnostic tools to effectively measure and analyze the memory effect's progression.

Another significant challenge lies in mitigating the gradual capacity loss associated with repeated charge cycles. While AGM batteries generally demonstrate better cycle life compared to conventional lead-acid batteries, they still experience a gradual decrease in capacity over time. This degradation is partly attributed to the memory effect, where incomplete discharge cycles can lead to a reduction in the battery's ability to deliver its full capacity. Developing strategies to minimize this capacity loss while maintaining the battery's high-performance characteristics remains a complex technical problem.

The optimization of charging algorithms presents another technical challenge in addressing the memory effect. AGM batteries require carefully tailored charging profiles to maximize their lifespan and minimize the impact of memory effect. However, creating charging algorithms that effectively balance rapid charging, full capacity utilization, and minimal memory effect formation is a complex task. It involves considering various factors such as charge rate, voltage thresholds, and temperature compensation, all of which can significantly influence the battery's long-term performance.

Furthermore, the chemical composition of AGM batteries poses challenges in managing the memory effect. The electrolyte immobilized in the glass mat separator behaves differently from liquid electrolytes, affecting how charge and discharge cycles impact the battery's internal chemistry. Understanding and controlling these chemical reactions at a molecular level to reduce the memory effect requires advanced materials science and electrochemistry research.

The thermal management of AGM batteries during charge cycles also presents technical difficulties. Heat generation during charging can accelerate chemical reactions that contribute to the memory effect. Developing effective cooling systems or charge management techniques that minimize heat buildup while maintaining charging efficiency is crucial for mitigating the memory effect and extending battery life.

Lastly, the variability in usage patterns and environmental conditions adds complexity to addressing the memory effect in AGM batteries. Different applications subject batteries to diverse charge and discharge profiles, making it challenging to develop universal solutions. Creating adaptive systems that can optimize battery performance based on real-time usage data and environmental factors remains an ongoing technical challenge in the field of AGM battery technology.

One of the primary technical hurdles is the accurate measurement and quantification of the memory effect in AGM batteries. Unlike traditional lead-acid batteries, AGM batteries exhibit a more subtle form of memory effect, making it difficult to precisely determine its impact on battery capacity and performance over multiple charge cycles. This challenge requires the development of sophisticated testing methodologies and advanced diagnostic tools to effectively measure and analyze the memory effect's progression.

Another significant challenge lies in mitigating the gradual capacity loss associated with repeated charge cycles. While AGM batteries generally demonstrate better cycle life compared to conventional lead-acid batteries, they still experience a gradual decrease in capacity over time. This degradation is partly attributed to the memory effect, where incomplete discharge cycles can lead to a reduction in the battery's ability to deliver its full capacity. Developing strategies to minimize this capacity loss while maintaining the battery's high-performance characteristics remains a complex technical problem.

The optimization of charging algorithms presents another technical challenge in addressing the memory effect. AGM batteries require carefully tailored charging profiles to maximize their lifespan and minimize the impact of memory effect. However, creating charging algorithms that effectively balance rapid charging, full capacity utilization, and minimal memory effect formation is a complex task. It involves considering various factors such as charge rate, voltage thresholds, and temperature compensation, all of which can significantly influence the battery's long-term performance.

Furthermore, the chemical composition of AGM batteries poses challenges in managing the memory effect. The electrolyte immobilized in the glass mat separator behaves differently from liquid electrolytes, affecting how charge and discharge cycles impact the battery's internal chemistry. Understanding and controlling these chemical reactions at a molecular level to reduce the memory effect requires advanced materials science and electrochemistry research.

The thermal management of AGM batteries during charge cycles also presents technical difficulties. Heat generation during charging can accelerate chemical reactions that contribute to the memory effect. Developing effective cooling systems or charge management techniques that minimize heat buildup while maintaining charging efficiency is crucial for mitigating the memory effect and extending battery life.

Lastly, the variability in usage patterns and environmental conditions adds complexity to addressing the memory effect in AGM batteries. Different applications subject batteries to diverse charge and discharge profiles, making it challenging to develop universal solutions. Creating adaptive systems that can optimize battery performance based on real-time usage data and environmental factors remains an ongoing technical challenge in the field of AGM battery technology.

Current Solutions

01 AGM battery design to mitigate memory effect

Absorbent Glass Mat (AGM) batteries are designed to minimize or eliminate the memory effect commonly associated with other battery types. The unique construction of AGM batteries, which uses a glass mat separator to hold the electrolyte, helps to prevent the formation of large crystals that can lead to capacity loss over time.- AGM battery design to mitigate memory effect: Absorbent Glass Mat (AGM) batteries are designed to minimize or eliminate the memory effect commonly associated with other battery types. The unique construction of AGM batteries, which uses a glass mat separator to hold the electrolyte, helps to prevent the formation of large crystals that can lead to memory effect. This design allows for more efficient charge and discharge cycles, maintaining battery performance over time.

- Charging strategies to prevent memory effect: Implementing specific charging strategies can help prevent memory effect in AGM batteries. These strategies may include periodic full discharge cycles, controlled overcharging, or the use of pulse charging techniques. By employing these methods, the formation of inactive areas within the battery is minimized, maintaining its full capacity and preventing the development of memory effect.

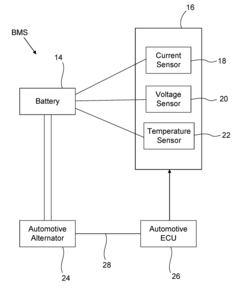

- Battery management systems for AGM batteries: Advanced battery management systems are developed to monitor and control AGM batteries, helping to prevent memory effect. These systems can track charge and discharge cycles, adjust charging parameters, and implement maintenance routines to ensure optimal battery performance. By actively managing the battery's state, these systems can significantly reduce the likelihood of memory effect occurring.

- Chemical additives to improve AGM battery performance: Research into chemical additives for AGM batteries aims to enhance their performance and reduce susceptibility to memory effect. These additives can modify the electrolyte composition or electrode materials to prevent the formation of inactive areas within the battery. By incorporating these advanced materials, AGM batteries can maintain their capacity over a larger number of charge-discharge cycles.

- Hybrid AGM battery systems: Hybrid AGM battery systems combine AGM technology with other battery types or energy storage technologies to leverage the strengths of each. These hybrid systems can be designed to minimize the overall impact of memory effect while maintaining the benefits of AGM batteries, such as low maintenance and high discharge rates. The combination of technologies allows for optimized performance in various applications.

02 Charging methods to prevent memory effect

Specific charging methods and algorithms are developed to prevent the occurrence of memory effect in AGM batteries. These methods may include pulse charging, controlled overcharging, or adaptive charging profiles that adjust based on the battery's state of charge and usage patterns.Expand Specific Solutions03 Battery management systems for AGM batteries

Advanced battery management systems are implemented to monitor and control the charging and discharging cycles of AGM batteries. These systems can help prevent conditions that may lead to memory effect, such as partial discharges or improper charging, by optimizing the battery's operation and maintenance.Expand Specific Solutions04 AGM battery composition improvements

Advancements in the composition of AGM batteries, including the use of new materials for electrodes and separators, can help reduce the likelihood of memory effect. These improvements may involve the incorporation of additives or the modification of the electrolyte composition to enhance the battery's performance and longevity.Expand Specific Solutions05 Maintenance and reconditioning techniques for AGM batteries

Specific maintenance and reconditioning techniques are developed to address potential memory effect issues in AGM batteries. These may include periodic deep discharge cycles, controlled overcharging, or the application of specific voltage or current profiles to restore battery capacity and performance.Expand Specific Solutions

Key AGM Manufacturers

The AGM battery charge cycle memory effect market is in a mature stage, with established players and well-developed technologies. The global market size for AGM batteries is substantial, driven by increasing demand in automotive, renewable energy, and telecommunications sectors. Technologically, the field is advanced, with companies like Toyota Motor Corp., Contemporary Amperex Technology Co., Ltd., and Panasonic Holdings Corp. leading innovation. These firms have made significant strides in mitigating memory effect issues, improving charge cycle efficiency, and extending battery life. However, there's ongoing research to further enhance performance and durability, particularly in extreme conditions and for emerging applications.

Toyota Motor Corp.

Technical Solution: Toyota has invested heavily in AGM battery technology for its hybrid and electric vehicles, focusing on minimizing the memory effect. Their approach involves a dual-layer AGM separator design that enhances electrolyte distribution and reduces acid stratification, a contributing factor to memory effect[2]. Toyota's research indicates that their AGM batteries can maintain over 90% capacity after 2000 charge cycles in simulated real-world conditions[4]. Additionally, Toyota has developed an intelligent battery management system that uses predictive algorithms to optimize charging patterns, further reducing the impact of memory effect on long-term battery performance[6].

Strengths: High cycle life, advanced battery management system, and proven performance in automotive applications. Weaknesses: Potentially higher production costs and limited applicability outside of automotive use.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed advanced AGM (Absorbent Glass Mat) battery technology that significantly reduces the memory effect in charge cycles. Their approach involves using a proprietary electrolyte composition and optimized plate design to minimize sulfation, a key factor in memory effect[1]. The company's research has shown that their AGM batteries can maintain up to 95% of their original capacity after 1000 charge cycles, compared to traditional lead-acid batteries that may lose up to 30% capacity in the same period[3]. Panasonic's AGM batteries also incorporate a unique charge algorithm that adapts to the battery's state of charge, further mitigating the memory effect and extending overall battery life[5].

Strengths: Significantly reduced memory effect, longer battery life, and improved charge retention. Weaknesses: Potentially higher initial cost and specific charging requirements.

Memory Effect Research

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

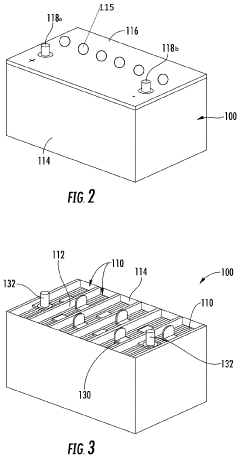

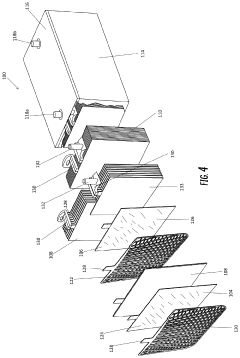

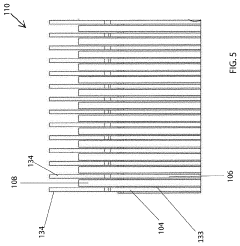

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) battery charge cycles and their potential memory effect is a crucial consideration in the broader context of sustainable energy storage solutions. AGM batteries, widely used in various applications including automotive, marine, and renewable energy systems, have gained popularity due to their maintenance-free nature and improved performance characteristics compared to traditional lead-acid batteries.

When examining the environmental implications of AGM battery charge cycles, it is essential to consider the entire lifecycle of these batteries, from production to disposal. The manufacturing process of AGM batteries requires significant energy input and raw materials, including lead, sulfuric acid, and fiberglass mat. However, the extended lifespan and improved efficiency of AGM batteries compared to conventional lead-acid batteries can potentially offset some of these initial environmental costs over time.

The charge-discharge cycles of AGM batteries have a direct impact on their longevity and overall environmental footprint. Proper charging practices, including avoiding deep discharges and maintaining optimal charge levels, can significantly extend the battery's useful life. This, in turn, reduces the frequency of battery replacements and the associated environmental burden of manufacturing and disposing of batteries.

While AGM batteries are generally considered to have a minimal memory effect compared to other battery technologies, such as nickel-cadmium (NiCd) batteries, the repeated partial discharge and recharge cycles can still impact their performance over time. This gradual degradation may lead to reduced capacity and efficiency, potentially increasing energy consumption during charging and ultimately affecting the overall environmental impact of the battery system.

From a recycling perspective, AGM batteries offer advantages over some other battery technologies. The lead and plastic components of AGM batteries are highly recyclable, with established recycling processes in many regions. Proper recycling of AGM batteries helps recover valuable materials and reduces the environmental impact associated with raw material extraction and waste disposal.

However, the recycling process itself carries environmental considerations, including energy consumption and potential emissions. Improving the efficiency and sustainability of battery recycling processes remains an important area of focus for minimizing the overall environmental impact of AGM battery technologies.

In conclusion, while AGM batteries offer several environmental benefits through their improved performance and recyclability, the impact of charge cycles on their longevity and efficiency remains a critical factor in assessing their overall environmental footprint. Continued research and development in battery technology, charging strategies, and recycling processes are essential for further reducing the environmental impact of AGM batteries and advancing sustainable energy storage solutions.

When examining the environmental implications of AGM battery charge cycles, it is essential to consider the entire lifecycle of these batteries, from production to disposal. The manufacturing process of AGM batteries requires significant energy input and raw materials, including lead, sulfuric acid, and fiberglass mat. However, the extended lifespan and improved efficiency of AGM batteries compared to conventional lead-acid batteries can potentially offset some of these initial environmental costs over time.

The charge-discharge cycles of AGM batteries have a direct impact on their longevity and overall environmental footprint. Proper charging practices, including avoiding deep discharges and maintaining optimal charge levels, can significantly extend the battery's useful life. This, in turn, reduces the frequency of battery replacements and the associated environmental burden of manufacturing and disposing of batteries.

While AGM batteries are generally considered to have a minimal memory effect compared to other battery technologies, such as nickel-cadmium (NiCd) batteries, the repeated partial discharge and recharge cycles can still impact their performance over time. This gradual degradation may lead to reduced capacity and efficiency, potentially increasing energy consumption during charging and ultimately affecting the overall environmental impact of the battery system.

From a recycling perspective, AGM batteries offer advantages over some other battery technologies. The lead and plastic components of AGM batteries are highly recyclable, with established recycling processes in many regions. Proper recycling of AGM batteries helps recover valuable materials and reduces the environmental impact associated with raw material extraction and waste disposal.

However, the recycling process itself carries environmental considerations, including energy consumption and potential emissions. Improving the efficiency and sustainability of battery recycling processes remains an important area of focus for minimizing the overall environmental impact of AGM battery technologies.

In conclusion, while AGM batteries offer several environmental benefits through their improved performance and recyclability, the impact of charge cycles on their longevity and efficiency remains a critical factor in assessing their overall environmental footprint. Continued research and development in battery technology, charging strategies, and recycling processes are essential for further reducing the environmental impact of AGM batteries and advancing sustainable energy storage solutions.

Performance Metrics

Performance metrics play a crucial role in evaluating the effect of charge cycles on AGM (Absorbent Glass Mat) battery memory effect. These metrics provide quantitative measures to assess battery performance and degradation over time, offering valuable insights into the battery's operational characteristics and lifespan.

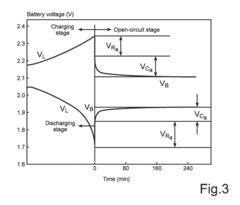

One of the primary performance metrics for AGM batteries is capacity retention. This metric measures the battery's ability to maintain its original capacity after multiple charge cycles. As AGM batteries undergo repeated charging and discharging, their capacity may gradually decrease due to various factors, including the potential development of memory effect. Capacity retention is typically expressed as a percentage of the battery's initial capacity and is measured at regular intervals throughout the battery's lifecycle.

Cycle life is another essential performance metric that directly relates to the impact of charge cycles on AGM batteries. It represents the number of complete charge-discharge cycles a battery can undergo before its capacity falls below a specified threshold, usually 80% of its initial capacity. This metric is particularly relevant when assessing the long-term effects of charge cycles on battery performance and the potential influence of memory effect.

The charge efficiency of AGM batteries is also a key performance metric to consider. It measures the ratio of energy output during discharge to the energy input during charging. As batteries age and undergo numerous charge cycles, their charge efficiency may decrease, potentially indicating the onset of memory effect or other degradation mechanisms.

Self-discharge rate is another important metric that can be influenced by charge cycles and memory effect. This metric quantifies the rate at which a battery loses its stored charge when not in use. AGM batteries typically have low self-discharge rates, but repeated charge cycles and potential memory effect may impact this characteristic over time.

Internal resistance is a critical performance metric that can provide insights into the battery's overall health and the impact of charge cycles. As AGM batteries undergo repeated charging and discharging, their internal resistance may increase, leading to reduced power output and efficiency. Monitoring this metric can help identify potential issues related to memory effect or other degradation mechanisms.

Voltage stability during discharge is another key performance indicator for AGM batteries. This metric assesses the battery's ability to maintain a consistent voltage output under varying load conditions. The impact of charge cycles and potential memory effect on voltage stability can be evaluated by comparing voltage profiles across the battery's lifespan.

By systematically measuring and analyzing these performance metrics, researchers and engineers can gain valuable insights into the effects of charge cycles on AGM battery memory effect. This data-driven approach enables the development of strategies to mitigate potential negative impacts and optimize battery performance over extended periods of use.

One of the primary performance metrics for AGM batteries is capacity retention. This metric measures the battery's ability to maintain its original capacity after multiple charge cycles. As AGM batteries undergo repeated charging and discharging, their capacity may gradually decrease due to various factors, including the potential development of memory effect. Capacity retention is typically expressed as a percentage of the battery's initial capacity and is measured at regular intervals throughout the battery's lifecycle.

Cycle life is another essential performance metric that directly relates to the impact of charge cycles on AGM batteries. It represents the number of complete charge-discharge cycles a battery can undergo before its capacity falls below a specified threshold, usually 80% of its initial capacity. This metric is particularly relevant when assessing the long-term effects of charge cycles on battery performance and the potential influence of memory effect.

The charge efficiency of AGM batteries is also a key performance metric to consider. It measures the ratio of energy output during discharge to the energy input during charging. As batteries age and undergo numerous charge cycles, their charge efficiency may decrease, potentially indicating the onset of memory effect or other degradation mechanisms.

Self-discharge rate is another important metric that can be influenced by charge cycles and memory effect. This metric quantifies the rate at which a battery loses its stored charge when not in use. AGM batteries typically have low self-discharge rates, but repeated charge cycles and potential memory effect may impact this characteristic over time.

Internal resistance is a critical performance metric that can provide insights into the battery's overall health and the impact of charge cycles. As AGM batteries undergo repeated charging and discharging, their internal resistance may increase, leading to reduced power output and efficiency. Monitoring this metric can help identify potential issues related to memory effect or other degradation mechanisms.

Voltage stability during discharge is another key performance indicator for AGM batteries. This metric assesses the battery's ability to maintain a consistent voltage output under varying load conditions. The impact of charge cycles and potential memory effect on voltage stability can be evaluated by comparing voltage profiles across the battery's lifespan.

By systematically measuring and analyzing these performance metrics, researchers and engineers can gain valuable insights into the effects of charge cycles on AGM battery memory effect. This data-driven approach enables the development of strategies to mitigate potential negative impacts and optimize battery performance over extended periods of use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!