Advances in AGM Battery Control Algorithms

AUG 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) battery technology has been a significant journey in the field of energy storage. Initially developed in the 1970s for military aircraft, AGM batteries have since found widespread applications in various industries, particularly in automotive and renewable energy sectors.

The early AGM batteries were designed to address the limitations of traditional flooded lead-acid batteries, offering improved safety, reduced maintenance, and better performance in high-vibration environments. These batteries utilized a fiberglass mat separator to absorb and immobilize the electrolyte, allowing for a spill-proof and maintenance-free design.

As the technology matured, AGM batteries saw improvements in their energy density, cycle life, and charge acceptance rates. The 1990s marked a significant milestone with the introduction of valve-regulated lead-acid (VRLA) AGM batteries, which further enhanced safety and reduced gas emissions during charging.

The turn of the millennium brought about advancements in manufacturing processes, leading to more consistent quality and reduced production costs. This period also saw the integration of AGM batteries into start-stop vehicle systems, contributing to improved fuel efficiency in automotive applications.

In recent years, the focus has shifted towards optimizing AGM battery performance through advanced control algorithms. These algorithms aim to enhance battery life, improve charging efficiency, and provide more accurate state-of-charge estimations. The development of smart battery management systems (BMS) has been crucial in this regard, allowing for real-time monitoring and adaptive control of AGM batteries.

The latest advancements in AGM battery technology include the incorporation of carbon additives to improve charge acceptance and cycle life, as well as the development of hybrid AGM-lithium systems that combine the benefits of both chemistries. These innovations have expanded the application range of AGM batteries, making them more competitive in markets traditionally dominated by other battery technologies.

Looking ahead, the evolution of AGM batteries is likely to continue with a focus on sustainability, increased energy density, and further integration with renewable energy systems. Research into advanced materials and manufacturing techniques promises to push the boundaries of AGM battery performance, ensuring their relevance in an increasingly electrified world.

The early AGM batteries were designed to address the limitations of traditional flooded lead-acid batteries, offering improved safety, reduced maintenance, and better performance in high-vibration environments. These batteries utilized a fiberglass mat separator to absorb and immobilize the electrolyte, allowing for a spill-proof and maintenance-free design.

As the technology matured, AGM batteries saw improvements in their energy density, cycle life, and charge acceptance rates. The 1990s marked a significant milestone with the introduction of valve-regulated lead-acid (VRLA) AGM batteries, which further enhanced safety and reduced gas emissions during charging.

The turn of the millennium brought about advancements in manufacturing processes, leading to more consistent quality and reduced production costs. This period also saw the integration of AGM batteries into start-stop vehicle systems, contributing to improved fuel efficiency in automotive applications.

In recent years, the focus has shifted towards optimizing AGM battery performance through advanced control algorithms. These algorithms aim to enhance battery life, improve charging efficiency, and provide more accurate state-of-charge estimations. The development of smart battery management systems (BMS) has been crucial in this regard, allowing for real-time monitoring and adaptive control of AGM batteries.

The latest advancements in AGM battery technology include the incorporation of carbon additives to improve charge acceptance and cycle life, as well as the development of hybrid AGM-lithium systems that combine the benefits of both chemistries. These innovations have expanded the application range of AGM batteries, making them more competitive in markets traditionally dominated by other battery technologies.

Looking ahead, the evolution of AGM batteries is likely to continue with a focus on sustainability, increased energy density, and further integration with renewable energy systems. Research into advanced materials and manufacturing techniques promises to push the boundaries of AGM battery performance, ensuring their relevance in an increasingly electrified world.

Market Demand Analysis

The market demand for advanced AGM (Absorbent Glass Mat) battery control algorithms has been steadily increasing in recent years, driven by the growing adoption of AGM batteries in various applications. These batteries are widely used in automotive, renewable energy storage, and uninterruptible power supply (UPS) systems due to their superior performance characteristics compared to traditional lead-acid batteries.

In the automotive sector, the shift towards more sophisticated electrical systems and the rise of start-stop technology have significantly boosted the demand for AGM batteries. As vehicles become more electrified, the need for efficient battery management systems and control algorithms has become paramount. The global automotive AGM battery market is expected to grow substantially, with a particular focus on improving battery life, charge acceptance, and overall performance through advanced control algorithms.

The renewable energy sector has also emerged as a key driver for AGM battery control algorithm advancements. As solar and wind power installations continue to expand, the requirement for reliable energy storage solutions has intensified. AGM batteries, coupled with sophisticated control algorithms, play a crucial role in optimizing energy storage and distribution in off-grid and grid-tied systems. The market for these solutions is projected to experience robust growth, especially in regions with high renewable energy adoption rates.

In the UPS market, AGM batteries are preferred for their maintenance-free operation and excellent cycle life. The demand for more efficient and intelligent UPS systems has led to increased interest in advanced battery control algorithms. These algorithms can significantly enhance battery performance, extend lifespan, and improve overall system reliability, which are critical factors in data centers, healthcare facilities, and industrial applications.

The telecommunications industry represents another significant market for AGM battery control algorithms. As 5G networks continue to expand, the need for reliable backup power solutions has grown. AGM batteries, managed by advanced control algorithms, are increasingly being deployed in cell towers and other telecommunications infrastructure to ensure uninterrupted service during power outages.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth in demand for AGM battery control algorithms. This is primarily due to the rapid industrialization, increasing automotive production, and substantial investments in renewable energy projects in countries like China and India. North America and Europe are also significant markets, driven by stringent environmental regulations and the push for energy-efficient solutions.

The market demand for AGM battery control algorithms is further fueled by the increasing focus on sustainability and energy efficiency across industries. As organizations strive to reduce their carbon footprint and optimize energy consumption, the role of advanced battery management systems becomes increasingly important. This trend is expected to continue driving innovation in control algorithms, with a focus on improving battery performance, extending lifespan, and enhancing overall system efficiency.

In the automotive sector, the shift towards more sophisticated electrical systems and the rise of start-stop technology have significantly boosted the demand for AGM batteries. As vehicles become more electrified, the need for efficient battery management systems and control algorithms has become paramount. The global automotive AGM battery market is expected to grow substantially, with a particular focus on improving battery life, charge acceptance, and overall performance through advanced control algorithms.

The renewable energy sector has also emerged as a key driver for AGM battery control algorithm advancements. As solar and wind power installations continue to expand, the requirement for reliable energy storage solutions has intensified. AGM batteries, coupled with sophisticated control algorithms, play a crucial role in optimizing energy storage and distribution in off-grid and grid-tied systems. The market for these solutions is projected to experience robust growth, especially in regions with high renewable energy adoption rates.

In the UPS market, AGM batteries are preferred for their maintenance-free operation and excellent cycle life. The demand for more efficient and intelligent UPS systems has led to increased interest in advanced battery control algorithms. These algorithms can significantly enhance battery performance, extend lifespan, and improve overall system reliability, which are critical factors in data centers, healthcare facilities, and industrial applications.

The telecommunications industry represents another significant market for AGM battery control algorithms. As 5G networks continue to expand, the need for reliable backup power solutions has grown. AGM batteries, managed by advanced control algorithms, are increasingly being deployed in cell towers and other telecommunications infrastructure to ensure uninterrupted service during power outages.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth in demand for AGM battery control algorithms. This is primarily due to the rapid industrialization, increasing automotive production, and substantial investments in renewable energy projects in countries like China and India. North America and Europe are also significant markets, driven by stringent environmental regulations and the push for energy-efficient solutions.

The market demand for AGM battery control algorithms is further fueled by the increasing focus on sustainability and energy efficiency across industries. As organizations strive to reduce their carbon footprint and optimize energy consumption, the role of advanced battery management systems becomes increasingly important. This trend is expected to continue driving innovation in control algorithms, with a focus on improving battery performance, extending lifespan, and enhancing overall system efficiency.

Current Challenges

AGM (Absorbent Glass Mat) battery control algorithms face several significant challenges in their current state of development. One of the primary issues is the accurate estimation of the battery's state of charge (SOC) and state of health (SOH). Traditional methods often fall short in providing precise measurements, especially in dynamic operating conditions. This inaccuracy can lead to suboptimal battery performance and reduced lifespan.

Another challenge lies in the thermal management of AGM batteries. As these batteries are sensitive to temperature fluctuations, maintaining an optimal operating temperature range is crucial. Current control algorithms struggle to effectively balance charging and discharging rates with thermal considerations, particularly in extreme environmental conditions.

The complexity of AGM battery chemistry poses additional difficulties for control algorithms. The non-linear behavior of these batteries, especially during rapid charge and discharge cycles, makes it challenging to develop accurate predictive models. This complexity is further compounded by the variations in battery characteristics due to manufacturing processes and aging.

Adapting to different usage patterns and applications remains a significant hurdle. AGM batteries are used in diverse scenarios, from automotive start-stop systems to renewable energy storage. Developing versatile algorithms that can optimize performance across these varied applications while maintaining battery longevity is an ongoing challenge.

The integration of AGM battery control algorithms with broader energy management systems presents another area of difficulty. Ensuring seamless communication and coordination between battery management systems and other components of the energy ecosystem, such as power inverters or renewable energy sources, is crucial for optimal performance but remains technically challenging.

Furthermore, the rapid pace of technological advancements in battery technology creates a moving target for algorithm developers. As new materials and designs are introduced, control algorithms must be continuously updated and refined to leverage these improvements effectively.

Lastly, there is the challenge of balancing performance optimization with long-term reliability and safety. While pushing the boundaries of battery performance is desirable, it must not come at the cost of safety or accelerated degradation. Developing algorithms that can maintain this delicate balance under various operating conditions remains a significant challenge in the field of AGM battery control.

Another challenge lies in the thermal management of AGM batteries. As these batteries are sensitive to temperature fluctuations, maintaining an optimal operating temperature range is crucial. Current control algorithms struggle to effectively balance charging and discharging rates with thermal considerations, particularly in extreme environmental conditions.

The complexity of AGM battery chemistry poses additional difficulties for control algorithms. The non-linear behavior of these batteries, especially during rapid charge and discharge cycles, makes it challenging to develop accurate predictive models. This complexity is further compounded by the variations in battery characteristics due to manufacturing processes and aging.

Adapting to different usage patterns and applications remains a significant hurdle. AGM batteries are used in diverse scenarios, from automotive start-stop systems to renewable energy storage. Developing versatile algorithms that can optimize performance across these varied applications while maintaining battery longevity is an ongoing challenge.

The integration of AGM battery control algorithms with broader energy management systems presents another area of difficulty. Ensuring seamless communication and coordination between battery management systems and other components of the energy ecosystem, such as power inverters or renewable energy sources, is crucial for optimal performance but remains technically challenging.

Furthermore, the rapid pace of technological advancements in battery technology creates a moving target for algorithm developers. As new materials and designs are introduced, control algorithms must be continuously updated and refined to leverage these improvements effectively.

Lastly, there is the challenge of balancing performance optimization with long-term reliability and safety. While pushing the boundaries of battery performance is desirable, it must not come at the cost of safety or accelerated degradation. Developing algorithms that can maintain this delicate balance under various operating conditions remains a significant challenge in the field of AGM battery control.

Existing Control Methods

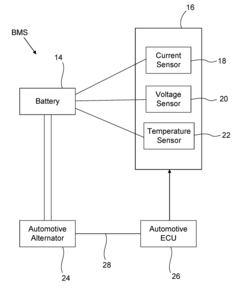

01 Battery Management System (BMS) for AGM Batteries

Advanced control algorithms implemented in Battery Management Systems (BMS) for AGM batteries. These systems monitor and optimize battery performance, including state of charge estimation, cell balancing, and thermal management to enhance battery life and efficiency.- Battery Management System (BMS) for AGM Batteries: Advanced Battery Management Systems are developed specifically for AGM batteries to optimize performance and lifespan. These systems monitor various parameters such as voltage, current, temperature, and state of charge to ensure efficient operation and prevent overcharging or deep discharging.

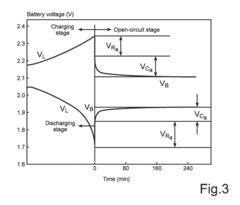

- Charging Algorithms for AGM Batteries: Specialized charging algorithms are designed for AGM batteries, taking into account their unique characteristics. These algorithms typically involve multi-stage charging processes, including bulk, absorption, and float stages, to maximize charging efficiency while minimizing damage to the battery.

- State of Charge (SOC) Estimation Techniques: Advanced techniques are employed to accurately estimate the State of Charge of AGM batteries. These methods may include coulomb counting, voltage-based estimation, and machine learning algorithms to provide real-time SOC information for better battery management and utilization.

- Thermal Management and Safety Controls: Control algorithms are developed to manage the thermal aspects of AGM batteries and ensure safe operation. These include temperature monitoring, cooling system control, and safety cutoffs to prevent overheating and potential hazards associated with battery operation.

- Adaptive Control Strategies for AGM Battery Systems: Intelligent and adaptive control strategies are implemented to optimize AGM battery performance under varying conditions. These algorithms can adjust charging and discharging parameters based on battery age, usage patterns, and environmental factors to extend battery life and maintain optimal performance.

02 Charging Control Algorithms for AGM Batteries

Specialized charging algorithms designed for AGM batteries to optimize charging efficiency and prolong battery life. These algorithms may include multi-stage charging processes, pulse charging techniques, and adaptive charging based on battery condition and temperature.Expand Specific Solutions03 State of Health (SOH) Estimation for AGM Batteries

Algorithms for accurately estimating the State of Health (SOH) of AGM batteries. These methods may involve analyzing voltage curves, internal resistance measurements, and capacity fade patterns to predict battery degradation and remaining useful life.Expand Specific Solutions04 Thermal Management Algorithms for AGM Batteries

Control algorithms focused on managing the thermal characteristics of AGM batteries. These may include temperature monitoring, cooling system control, and charge/discharge rate adjustments based on thermal conditions to optimize performance and prevent overheating.Expand Specific Solutions05 Adaptive Control Algorithms for AGM Battery Systems

Intelligent control algorithms that adapt to changing conditions and battery characteristics over time. These may incorporate machine learning techniques to optimize battery performance, predict failures, and adjust operating parameters based on usage patterns and environmental factors.Expand Specific Solutions

Innovative Algorithms

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Over-Saturated Absorbed Glass Mat Valve Regulated Lead-Acid Battery Comprising Carbon Additives

PatentInactiveUS20140120386A1

Innovation

- An AGM VRLA battery design with a positive plate, negative plate containing a carbon additive, an AGM separator, and an electrolyte present in an amount ranging from 100 to 150% by volume based on the total pore volume of the separator, utilizing various carbon additives such as graphite, carbon black, activated carbon, and graphene to enhance charge acceptance and durability.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) battery control algorithms is a critical consideration in the development and implementation of advanced energy storage systems. As these algorithms become more sophisticated, their potential to enhance battery performance and longevity also increases, which in turn can have significant positive effects on the environment.

One of the primary environmental benefits of improved AGM battery control algorithms is the extension of battery life. By optimizing charging and discharging cycles, these algorithms can reduce the frequency of battery replacements, thereby decreasing the demand for raw materials and energy required for battery production. This reduction in manufacturing needs translates to lower carbon emissions and less environmental stress associated with mining and processing battery components.

Furthermore, advanced control algorithms can enhance the efficiency of AGM batteries, allowing for better utilization of stored energy. This improved efficiency means that less energy is wasted during charge and discharge cycles, potentially reducing the overall energy consumption of systems relying on these batteries. In applications such as renewable energy storage or electric vehicles, this increased efficiency can contribute to a reduction in greenhouse gas emissions by maximizing the use of clean energy sources.

The optimization of battery performance through advanced algorithms also has implications for the recycling process. By maintaining battery health more effectively, these algorithms can help preserve the integrity of battery components, making them more suitable for recycling at the end of their lifecycle. This can lead to more efficient recycling processes and a higher percentage of materials that can be recovered and reused, further reducing the environmental impact of battery production.

In the context of grid-scale energy storage, improved AGM battery control algorithms can play a crucial role in supporting the integration of renewable energy sources. By enabling more precise and responsive energy management, these algorithms can help balance the intermittent nature of renewable energy generation, potentially reducing reliance on fossil fuel-based backup power systems. This capability is essential for accelerating the transition to cleaner energy grids and reducing overall carbon emissions from the power sector.

However, it is important to note that the environmental benefits of advanced AGM battery control algorithms are not without potential drawbacks. The increased complexity of these algorithms may require more powerful computing systems to operate, which could lead to higher energy consumption for battery management. Additionally, the development and implementation of these algorithms may involve electronic components that have their own environmental footprint. Therefore, a holistic approach is necessary when assessing the net environmental impact of these technological advancements.

One of the primary environmental benefits of improved AGM battery control algorithms is the extension of battery life. By optimizing charging and discharging cycles, these algorithms can reduce the frequency of battery replacements, thereby decreasing the demand for raw materials and energy required for battery production. This reduction in manufacturing needs translates to lower carbon emissions and less environmental stress associated with mining and processing battery components.

Furthermore, advanced control algorithms can enhance the efficiency of AGM batteries, allowing for better utilization of stored energy. This improved efficiency means that less energy is wasted during charge and discharge cycles, potentially reducing the overall energy consumption of systems relying on these batteries. In applications such as renewable energy storage or electric vehicles, this increased efficiency can contribute to a reduction in greenhouse gas emissions by maximizing the use of clean energy sources.

The optimization of battery performance through advanced algorithms also has implications for the recycling process. By maintaining battery health more effectively, these algorithms can help preserve the integrity of battery components, making them more suitable for recycling at the end of their lifecycle. This can lead to more efficient recycling processes and a higher percentage of materials that can be recovered and reused, further reducing the environmental impact of battery production.

In the context of grid-scale energy storage, improved AGM battery control algorithms can play a crucial role in supporting the integration of renewable energy sources. By enabling more precise and responsive energy management, these algorithms can help balance the intermittent nature of renewable energy generation, potentially reducing reliance on fossil fuel-based backup power systems. This capability is essential for accelerating the transition to cleaner energy grids and reducing overall carbon emissions from the power sector.

However, it is important to note that the environmental benefits of advanced AGM battery control algorithms are not without potential drawbacks. The increased complexity of these algorithms may require more powerful computing systems to operate, which could lead to higher energy consumption for battery management. Additionally, the development and implementation of these algorithms may involve electronic components that have their own environmental footprint. Therefore, a holistic approach is necessary when assessing the net environmental impact of these technological advancements.

Safety Considerations

Safety considerations are paramount in the development and implementation of advanced AGM battery control algorithms. As these algorithms become more sophisticated, they must prioritize the protection of both the battery system and its users. One of the primary safety concerns is thermal management. AGM batteries can generate significant heat during charging and discharging cycles, and if not properly controlled, this can lead to thermal runaway, potentially resulting in fire or explosion. Advanced control algorithms must incorporate real-time temperature monitoring and adaptive charging strategies to prevent overheating.

Voltage regulation is another critical safety aspect. Overcharging or deep discharging can severely damage AGM batteries and pose safety risks. Control algorithms must maintain voltage levels within safe operating ranges, adjusting charging rates and cut-off points based on battery state and environmental conditions. This requires precise voltage sensing and predictive modeling to anticipate potential voltage excursions.

Current management is equally important for safety. Excessive current draw or charging rates can lead to internal damage, reduced battery life, and safety hazards. Advanced algorithms must implement intelligent current limiting functions, considering factors such as battery age, state of charge, and temperature to determine safe current thresholds.

Cell balancing is a crucial safety feature in multi-cell AGM battery systems. Uneven charge distribution among cells can lead to localized overcharging or undercharging, compromising overall battery health and safety. Control algorithms must incorporate active cell balancing techniques to ensure uniform charge distribution and prevent individual cell failures.

Fault detection and mitigation are essential components of safe AGM battery operation. Advanced algorithms should be capable of identifying potential failure modes, such as internal short circuits, cell degradation, or connection issues. Upon detection, these algorithms must initiate appropriate safety protocols, including load disconnection, charge termination, or system shutdown.

Environmental adaptability is another key safety consideration. AGM batteries may operate in diverse conditions, from extreme temperatures to high-vibration environments. Control algorithms must adjust their parameters based on environmental factors to maintain safe operation across various scenarios. This includes modifying charging profiles, adjusting safety thresholds, and implementing specialized protection measures for extreme conditions.

Human-machine interface safety is also crucial. Advanced control algorithms should provide clear, actionable information to users and maintenance personnel regarding battery status, potential issues, and required actions. This includes implementing fail-safe modes and user alerts to prevent unsafe operations or interventions.

Voltage regulation is another critical safety aspect. Overcharging or deep discharging can severely damage AGM batteries and pose safety risks. Control algorithms must maintain voltage levels within safe operating ranges, adjusting charging rates and cut-off points based on battery state and environmental conditions. This requires precise voltage sensing and predictive modeling to anticipate potential voltage excursions.

Current management is equally important for safety. Excessive current draw or charging rates can lead to internal damage, reduced battery life, and safety hazards. Advanced algorithms must implement intelligent current limiting functions, considering factors such as battery age, state of charge, and temperature to determine safe current thresholds.

Cell balancing is a crucial safety feature in multi-cell AGM battery systems. Uneven charge distribution among cells can lead to localized overcharging or undercharging, compromising overall battery health and safety. Control algorithms must incorporate active cell balancing techniques to ensure uniform charge distribution and prevent individual cell failures.

Fault detection and mitigation are essential components of safe AGM battery operation. Advanced algorithms should be capable of identifying potential failure modes, such as internal short circuits, cell degradation, or connection issues. Upon detection, these algorithms must initiate appropriate safety protocols, including load disconnection, charge termination, or system shutdown.

Environmental adaptability is another key safety consideration. AGM batteries may operate in diverse conditions, from extreme temperatures to high-vibration environments. Control algorithms must adjust their parameters based on environmental factors to maintain safe operation across various scenarios. This includes modifying charging profiles, adjusting safety thresholds, and implementing specialized protection measures for extreme conditions.

Human-machine interface safety is also crucial. Advanced control algorithms should provide clear, actionable information to users and maintenance personnel regarding battery status, potential issues, and required actions. This includes implementing fail-safe modes and user alerts to prevent unsafe operations or interventions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!