Aligning AGM Battery Production with Circular Economy Principles

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution and Sustainability Goals

Absorbed Glass Mat (AGM) batteries have undergone significant evolution since their inception in the 1980s. Initially developed for military and aerospace applications, AGM technology has progressively found its way into various sectors, including automotive, renewable energy storage, and telecommunications. The primary drivers behind this evolution have been the increasing demand for high-performance, maintenance-free batteries and the growing emphasis on sustainability in energy storage solutions.

The sustainability goals associated with AGM battery production have become increasingly prominent in recent years, aligning with broader circular economy principles. These goals encompass several key areas, including resource efficiency, waste reduction, and end-of-life management. As environmental concerns gain traction globally, battery manufacturers are under pressure to develop more sustainable production processes and products.

One of the primary sustainability objectives in AGM battery production is the reduction of raw material consumption. This involves optimizing the use of lead, sulfuric acid, and other components to minimize resource depletion. Additionally, there is a growing focus on incorporating recycled materials into the production process, thereby reducing the reliance on virgin resources and mitigating the environmental impact of mining activities.

Waste reduction is another critical aspect of aligning AGM battery production with circular economy principles. Manufacturers are increasingly adopting lean production techniques and implementing closed-loop systems to minimize waste generation throughout the manufacturing process. This includes efforts to recycle and reuse production scrap, as well as the development of more efficient manufacturing technologies that reduce material losses.

End-of-life management has emerged as a crucial sustainability goal in the AGM battery industry. The focus is on designing batteries that are easier to disassemble and recycle, as well as establishing robust collection and recycling infrastructure. This approach aims to recover valuable materials from spent batteries, reducing the need for raw material extraction and minimizing the environmental impact of battery disposal.

Energy efficiency in production processes is another key sustainability goal. Manufacturers are investing in more energy-efficient equipment and exploring renewable energy sources to power their production facilities. This not only reduces the carbon footprint of AGM battery production but also aligns with broader sustainability objectives in the energy sector.

As the AGM battery industry continues to evolve, there is an increasing emphasis on developing batteries with longer lifespans and improved performance characteristics. This aligns with circular economy principles by reducing the frequency of battery replacements and, consequently, the overall resource consumption and waste generation associated with battery production and disposal.

The sustainability goals associated with AGM battery production have become increasingly prominent in recent years, aligning with broader circular economy principles. These goals encompass several key areas, including resource efficiency, waste reduction, and end-of-life management. As environmental concerns gain traction globally, battery manufacturers are under pressure to develop more sustainable production processes and products.

One of the primary sustainability objectives in AGM battery production is the reduction of raw material consumption. This involves optimizing the use of lead, sulfuric acid, and other components to minimize resource depletion. Additionally, there is a growing focus on incorporating recycled materials into the production process, thereby reducing the reliance on virgin resources and mitigating the environmental impact of mining activities.

Waste reduction is another critical aspect of aligning AGM battery production with circular economy principles. Manufacturers are increasingly adopting lean production techniques and implementing closed-loop systems to minimize waste generation throughout the manufacturing process. This includes efforts to recycle and reuse production scrap, as well as the development of more efficient manufacturing technologies that reduce material losses.

End-of-life management has emerged as a crucial sustainability goal in the AGM battery industry. The focus is on designing batteries that are easier to disassemble and recycle, as well as establishing robust collection and recycling infrastructure. This approach aims to recover valuable materials from spent batteries, reducing the need for raw material extraction and minimizing the environmental impact of battery disposal.

Energy efficiency in production processes is another key sustainability goal. Manufacturers are investing in more energy-efficient equipment and exploring renewable energy sources to power their production facilities. This not only reduces the carbon footprint of AGM battery production but also aligns with broader sustainability objectives in the energy sector.

As the AGM battery industry continues to evolve, there is an increasing emphasis on developing batteries with longer lifespans and improved performance characteristics. This aligns with circular economy principles by reducing the frequency of battery replacements and, consequently, the overall resource consumption and waste generation associated with battery production and disposal.

Circular Economy Demand in Battery Industry

The circular economy concept has gained significant traction in the battery industry, driven by increasing environmental concerns and resource scarcity. This shift towards sustainable practices is particularly evident in the AGM (Absorbent Glass Mat) battery sector, where demand for circular economy principles is rapidly growing.

The battery industry, traditionally characterized by linear production models, is now facing mounting pressure to adopt circular approaches. This demand stems from various factors, including regulatory requirements, consumer preferences, and the need for resource efficiency. Governments worldwide are implementing stricter regulations on battery production and disposal, pushing manufacturers to consider the entire lifecycle of their products.

In the AGM battery segment, circular economy demand is manifesting in several ways. There is a growing emphasis on designing batteries for longevity and recyclability. Manufacturers are exploring ways to extend battery life through improved materials and construction techniques, reducing the frequency of replacements. Additionally, there is a strong focus on developing efficient recycling processes to recover valuable materials from end-of-life batteries.

The market is also witnessing an increased demand for AGM batteries made from recycled materials. This trend is driven by both environmental consciousness and the potential for cost savings. As raw material prices fluctuate, the ability to source recycled components becomes increasingly attractive to manufacturers.

Another aspect of circular economy demand in the AGM battery industry is the growing interest in second-life applications. Batteries that no longer meet the performance requirements for their original use, such as in vehicles, are being repurposed for less demanding applications like energy storage systems. This approach extends the useful life of batteries and delays their entry into the waste stream.

The shift towards circular economy principles is also influencing business models in the AGM battery sector. There is a growing trend towards product-as-a-service models, where manufacturers retain ownership of the batteries and provide them to customers on a service basis. This model incentivizes manufacturers to design for durability and recyclability, as they remain responsible for the product throughout its lifecycle.

As the demand for circular economy practices in the AGM battery industry continues to grow, it is driving innovation in production processes, materials science, and recycling technologies. This evolution is not only addressing environmental concerns but also opening up new business opportunities and competitive advantages for companies that successfully align their operations with circular economy principles.

The battery industry, traditionally characterized by linear production models, is now facing mounting pressure to adopt circular approaches. This demand stems from various factors, including regulatory requirements, consumer preferences, and the need for resource efficiency. Governments worldwide are implementing stricter regulations on battery production and disposal, pushing manufacturers to consider the entire lifecycle of their products.

In the AGM battery segment, circular economy demand is manifesting in several ways. There is a growing emphasis on designing batteries for longevity and recyclability. Manufacturers are exploring ways to extend battery life through improved materials and construction techniques, reducing the frequency of replacements. Additionally, there is a strong focus on developing efficient recycling processes to recover valuable materials from end-of-life batteries.

The market is also witnessing an increased demand for AGM batteries made from recycled materials. This trend is driven by both environmental consciousness and the potential for cost savings. As raw material prices fluctuate, the ability to source recycled components becomes increasingly attractive to manufacturers.

Another aspect of circular economy demand in the AGM battery industry is the growing interest in second-life applications. Batteries that no longer meet the performance requirements for their original use, such as in vehicles, are being repurposed for less demanding applications like energy storage systems. This approach extends the useful life of batteries and delays their entry into the waste stream.

The shift towards circular economy principles is also influencing business models in the AGM battery sector. There is a growing trend towards product-as-a-service models, where manufacturers retain ownership of the batteries and provide them to customers on a service basis. This model incentivizes manufacturers to design for durability and recyclability, as they remain responsible for the product throughout its lifecycle.

As the demand for circular economy practices in the AGM battery industry continues to grow, it is driving innovation in production processes, materials science, and recycling technologies. This evolution is not only addressing environmental concerns but also opening up new business opportunities and competitive advantages for companies that successfully align their operations with circular economy principles.

AGM Battery Production Challenges

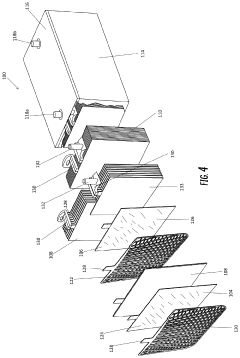

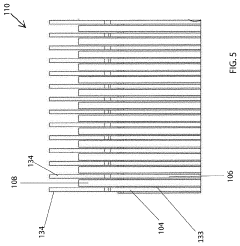

The production of Absorbent Glass Mat (AGM) batteries faces several significant challenges when aligning with circular economy principles. One of the primary issues is the complexity of the battery structure, which makes disassembly and recycling difficult. AGM batteries consist of multiple layers of glass fiber mats, lead plates, and electrolyte, all tightly compressed within a sealed case. This intricate design, while beneficial for performance, complicates end-of-life processing and material recovery.

Material selection presents another hurdle in achieving circularity. The lead used in AGM batteries, although highly recyclable, poses environmental and health risks if not handled properly. The glass fiber mats, which are essential for the battery's function, are challenging to separate and recycle effectively. Additionally, the electrolyte, typically sulfuric acid, requires careful management and neutralization during the recycling process.

Energy-intensive manufacturing processes further complicate the alignment with circular economy principles. The production of AGM batteries involves high-temperature lead smelting, plate formation, and assembly, all of which consume significant amounts of energy. Reducing the carbon footprint of these processes while maintaining product quality and performance is a major challenge for manufacturers.

The limited lifespan of AGM batteries also poses a challenge to circularity. Although they generally last longer than traditional lead-acid batteries, their finite cycle life means they still contribute to waste streams. Extending battery life through improved materials and design is crucial but must be balanced with performance requirements and cost considerations.

Waste management and recycling infrastructure present additional challenges. While lead recycling facilities are well-established in many regions, the specialized equipment and processes required for efficiently recycling AGM batteries are not as widespread. This gap in recycling capabilities can lead to improper disposal or inefficient recovery of materials.

Regulatory compliance and safety standards add another layer of complexity to AGM battery production. Stringent regulations governing the handling of lead and acid, as well as transportation and disposal of batteries, can sometimes conflict with circular economy goals. Balancing safety requirements with sustainable production practices requires careful navigation of regulatory landscapes.

Lastly, the economic viability of circular production models for AGM batteries remains a significant challenge. The costs associated with redesigning production processes, implementing take-back systems, and investing in advanced recycling technologies can be substantial. Manufacturers must find ways to make these circular approaches economically sustainable while remaining competitive in the market.

Material selection presents another hurdle in achieving circularity. The lead used in AGM batteries, although highly recyclable, poses environmental and health risks if not handled properly. The glass fiber mats, which are essential for the battery's function, are challenging to separate and recycle effectively. Additionally, the electrolyte, typically sulfuric acid, requires careful management and neutralization during the recycling process.

Energy-intensive manufacturing processes further complicate the alignment with circular economy principles. The production of AGM batteries involves high-temperature lead smelting, plate formation, and assembly, all of which consume significant amounts of energy. Reducing the carbon footprint of these processes while maintaining product quality and performance is a major challenge for manufacturers.

The limited lifespan of AGM batteries also poses a challenge to circularity. Although they generally last longer than traditional lead-acid batteries, their finite cycle life means they still contribute to waste streams. Extending battery life through improved materials and design is crucial but must be balanced with performance requirements and cost considerations.

Waste management and recycling infrastructure present additional challenges. While lead recycling facilities are well-established in many regions, the specialized equipment and processes required for efficiently recycling AGM batteries are not as widespread. This gap in recycling capabilities can lead to improper disposal or inefficient recovery of materials.

Regulatory compliance and safety standards add another layer of complexity to AGM battery production. Stringent regulations governing the handling of lead and acid, as well as transportation and disposal of batteries, can sometimes conflict with circular economy goals. Balancing safety requirements with sustainable production practices requires careful navigation of regulatory landscapes.

Lastly, the economic viability of circular production models for AGM batteries remains a significant challenge. The costs associated with redesigning production processes, implementing take-back systems, and investing in advanced recycling technologies can be substantial. Manufacturers must find ways to make these circular approaches economically sustainable while remaining competitive in the market.

Current Circular AGM Battery Solutions

01 AGM battery structure and design improvements

Advancements in AGM battery structure and design focus on enhancing performance and efficiency. These improvements include optimized plate arrangements, innovative separators, and refined internal configurations to increase capacity, reduce internal resistance, and improve overall battery life.- AGM battery structure and design improvements: Advancements in AGM battery structure and design focus on enhancing performance and efficiency. These improvements include optimized electrode configurations, innovative separator materials, and refined internal layouts to increase capacity, reduce internal resistance, and improve overall battery life.

- Electrolyte management and absorption techniques: Developments in electrolyte management for AGM batteries involve improved absorption methods and materials. These techniques aim to enhance electrolyte distribution, prevent leakage, and optimize the absorption of the electrolyte into the glass mat separator, leading to better battery performance and longevity.

- Thermal management and safety features: Innovations in thermal management and safety features for AGM batteries include advanced cooling systems, temperature monitoring devices, and protective mechanisms. These enhancements aim to prevent overheating, improve battery stability, and ensure safe operation under various conditions.

- Charging and maintenance technologies: Advancements in charging and maintenance technologies for AGM batteries focus on intelligent charging algorithms, battery health monitoring systems, and automated maintenance procedures. These innovations aim to extend battery life, optimize charging efficiency, and reduce maintenance requirements.

- Integration with renewable energy systems: Developments in integrating AGM batteries with renewable energy systems involve optimizing battery performance for solar and wind power applications. These advancements include improved energy storage capabilities, faster charge and discharge rates, and enhanced compatibility with renewable energy sources.

02 Electrolyte management and absorption techniques

Developments in electrolyte management for AGM batteries involve improved absorption methods and materials. These techniques aim to enhance the electrolyte distribution within the battery, leading to better charge acceptance, reduced stratification, and improved cycle life.Expand Specific Solutions03 Thermal management and safety features

Innovations in thermal management and safety features for AGM batteries focus on preventing overheating and improving overall safety. These advancements include enhanced cooling systems, temperature-resistant materials, and protective mechanisms to ensure stable and safe operation under various conditions.Expand Specific Solutions04 Charging and maintenance technologies

Advancements in charging and maintenance technologies for AGM batteries aim to optimize charging efficiency and extend battery lifespan. These developments include smart charging algorithms, automated maintenance systems, and improved diagnostic tools for battery health monitoring.Expand Specific Solutions05 Integration with renewable energy systems

Innovations in integrating AGM batteries with renewable energy systems focus on improving energy storage capabilities and system efficiency. These advancements include optimized battery management systems, enhanced grid integration, and tailored designs for specific renewable energy applications.Expand Specific Solutions

Key AGM Battery Manufacturers and Recyclers

The market for AGM battery production aligned with circular economy principles is in a transitional phase, with growing interest but still evolving technologies. The global market size for sustainable batteries is expanding rapidly, driven by increasing environmental concerns and regulatory pressures. While the technology is maturing, there is still room for innovation and improvement in recycling processes and materials. Key players like Fengfan Co., Ltd., Chaowei Power Group, and Tianneng Battery Group are investing in research and development to enhance their AGM battery offerings and align with circular economy principles. Companies such as LG Chem and Contemporary Amperex Technology are also making significant strides in sustainable battery technologies, indicating a competitive and dynamic landscape.

LG Chem Ltd.

Technical Solution: LG Chem has implemented a comprehensive circular economy strategy for AGM battery production. They have developed a modular battery design that facilitates easier disassembly and recycling at the end of the battery's life[4]. The company utilizes AI-powered sorting systems to efficiently separate different battery components for recycling. LG Chem has also invested in hydrometallurgical recycling processes to recover high-purity materials from used batteries, including rare earth elements[5]. They have implemented a traceability system using blockchain technology to track the lifecycle of batteries and ensure proper recycling[6].

Strengths: Advanced recycling technologies, modular design approach, and innovative traceability systems. Weaknesses: Dependence on complex technologies and potential challenges in establishing a global recycling network.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has implemented a comprehensive circular economy strategy for AGM battery production. They have developed a battery pack design that allows for easy disassembly and material recovery at the end of life[10]. CATL utilizes advanced automation and robotics in their recycling facilities to efficiently separate and sort battery components. The company has also invested in hydrometallurgical processes to recover high-purity materials from used batteries, achieving recovery rates of up to 99% for some metals[11]. CATL has implemented a battery swapping system for electric vehicles, which extends battery life and facilitates easier recycling[12]. Additionally, they have developed a cloud-based battery management system that optimizes battery performance and longevity, reducing waste.

Strengths: Advanced recycling technologies, innovative battery swapping system, and high material recovery rates. Weaknesses: High initial investment costs and potential challenges in establishing a widespread battery swapping infrastructure.

Innovative AGM Battery Recycling Technologies

Improved absorbent glass mat separators, VRLA batteries, and related mehtods of manufacture and use

PatentWO2016210225A1

Innovation

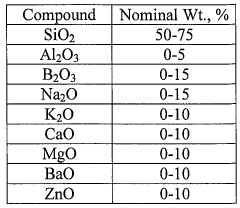

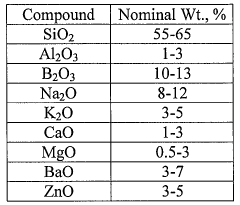

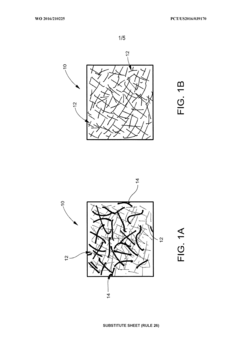

- Incorporating soluble content such as fibers, flakes, or particles into the AGM separators that dissolve upon contact with water or sulfuric acid, creating additional pores and enhancing porosity, allowing for faster acid filling and improved wettability without compromising the separator's integrity.

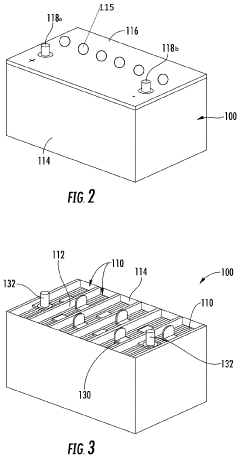

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

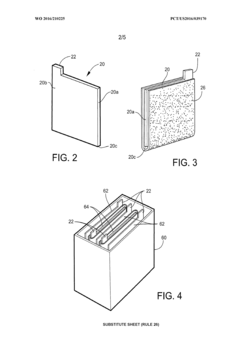

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Environmental Regulations for Battery Production

Environmental regulations play a crucial role in shaping the production processes of AGM (Absorbent Glass Mat) batteries, particularly in the context of aligning with circular economy principles. These regulations aim to minimize the environmental impact of battery production, promote resource efficiency, and ensure proper handling of hazardous materials throughout the battery lifecycle.

One of the key regulatory frameworks governing AGM battery production is the European Union's Battery Directive (2006/66/EC). This directive sets standards for battery collection, recycling, and disposal, as well as restrictions on the use of certain hazardous substances. It mandates that battery manufacturers implement eco-design principles to facilitate easier dismantling and recycling of batteries at the end of their life cycle.

In the United States, the Environmental Protection Agency (EPA) enforces regulations under the Resource Conservation and Recovery Act (RCRA) that apply to battery production. These regulations focus on the management of hazardous waste generated during manufacturing processes and the proper disposal of spent batteries. Additionally, the EPA's Clean Air Act and Clean Water Act impose limits on emissions and effluents from battery production facilities.

Many countries have implemented Extended Producer Responsibility (EPR) programs for batteries, which require manufacturers to take responsibility for the entire lifecycle of their products, including collection and recycling. These programs incentivize producers to design batteries with improved recyclability and to establish efficient take-back systems.

The growing emphasis on circular economy principles has led to the development of new regulations and standards specifically addressing the recyclability and reusability of battery components. For instance, the proposed EU Battery Regulation aims to enhance sustainability requirements for batteries, including targets for recycled content and material recovery efficiency.

Compliance with these environmental regulations often necessitates significant investments in cleaner production technologies, waste management systems, and recycling infrastructure. Manufacturers must also implement robust tracking and reporting systems to demonstrate compliance with various regulatory requirements.

As the regulatory landscape continues to evolve, AGM battery producers are increasingly focusing on developing innovative production methods that align with circular economy principles. This includes exploring alternative materials, improving energy efficiency in manufacturing processes, and designing batteries for easier disassembly and recycling.

The challenge for manufacturers lies in balancing regulatory compliance with maintaining cost-effectiveness and product performance. However, proactive adoption of environmentally friendly practices can lead to long-term benefits, including improved brand reputation, access to green markets, and potential cost savings through resource efficiency.

One of the key regulatory frameworks governing AGM battery production is the European Union's Battery Directive (2006/66/EC). This directive sets standards for battery collection, recycling, and disposal, as well as restrictions on the use of certain hazardous substances. It mandates that battery manufacturers implement eco-design principles to facilitate easier dismantling and recycling of batteries at the end of their life cycle.

In the United States, the Environmental Protection Agency (EPA) enforces regulations under the Resource Conservation and Recovery Act (RCRA) that apply to battery production. These regulations focus on the management of hazardous waste generated during manufacturing processes and the proper disposal of spent batteries. Additionally, the EPA's Clean Air Act and Clean Water Act impose limits on emissions and effluents from battery production facilities.

Many countries have implemented Extended Producer Responsibility (EPR) programs for batteries, which require manufacturers to take responsibility for the entire lifecycle of their products, including collection and recycling. These programs incentivize producers to design batteries with improved recyclability and to establish efficient take-back systems.

The growing emphasis on circular economy principles has led to the development of new regulations and standards specifically addressing the recyclability and reusability of battery components. For instance, the proposed EU Battery Regulation aims to enhance sustainability requirements for batteries, including targets for recycled content and material recovery efficiency.

Compliance with these environmental regulations often necessitates significant investments in cleaner production technologies, waste management systems, and recycling infrastructure. Manufacturers must also implement robust tracking and reporting systems to demonstrate compliance with various regulatory requirements.

As the regulatory landscape continues to evolve, AGM battery producers are increasingly focusing on developing innovative production methods that align with circular economy principles. This includes exploring alternative materials, improving energy efficiency in manufacturing processes, and designing batteries for easier disassembly and recycling.

The challenge for manufacturers lies in balancing regulatory compliance with maintaining cost-effectiveness and product performance. However, proactive adoption of environmentally friendly practices can lead to long-term benefits, including improved brand reputation, access to green markets, and potential cost savings through resource efficiency.

Life Cycle Assessment of AGM Batteries

Life Cycle Assessment (LCA) of AGM batteries is a crucial tool for evaluating the environmental impact of these energy storage devices throughout their entire lifecycle. This comprehensive analysis encompasses raw material extraction, manufacturing processes, use phase, and end-of-life management. The assessment typically begins with the sourcing of materials such as lead, sulfuric acid, and glass fiber separators, considering the environmental implications of mining and processing these components.

The manufacturing stage of AGM batteries involves several energy-intensive processes, including grid casting, paste mixing, plate curing, and assembly. LCA studies focus on quantifying the energy consumption, emissions, and waste generation associated with these production steps. Additionally, the assessment examines the environmental footprint of transportation and packaging materials used in the distribution of finished batteries.

During the use phase, AGM batteries demonstrate relatively high efficiency and long service life compared to traditional flooded lead-acid batteries. LCA studies evaluate the energy losses during charging and discharging cycles, as well as the potential environmental benefits of their application in various sectors, such as automotive and renewable energy storage systems.

End-of-life management is a critical aspect of AGM battery LCA, given the hazardous nature of lead and sulfuric acid. The assessment examines the effectiveness of recycling processes in recovering valuable materials and reducing the environmental burden of disposal. Modern recycling techniques can recover up to 99% of the lead content, significantly mitigating the environmental impact of these batteries.

LCA studies also consider the potential for remanufacturing and second-life applications of AGM batteries, which can extend their useful life and improve overall sustainability. These assessments often employ standardized methodologies, such as ISO 14040 and 14044, to ensure consistency and comparability of results across different studies and battery technologies.

By conducting thorough Life Cycle Assessments, manufacturers and policymakers can identify hotspots of environmental impact throughout the AGM battery lifecycle. This information is invaluable for developing strategies to minimize negative environmental effects, optimize resource utilization, and align production processes with circular economy principles. Furthermore, LCA results can inform eco-design initiatives, guiding the development of more sustainable battery technologies and supporting the transition towards a more environmentally responsible energy storage sector.

The manufacturing stage of AGM batteries involves several energy-intensive processes, including grid casting, paste mixing, plate curing, and assembly. LCA studies focus on quantifying the energy consumption, emissions, and waste generation associated with these production steps. Additionally, the assessment examines the environmental footprint of transportation and packaging materials used in the distribution of finished batteries.

During the use phase, AGM batteries demonstrate relatively high efficiency and long service life compared to traditional flooded lead-acid batteries. LCA studies evaluate the energy losses during charging and discharging cycles, as well as the potential environmental benefits of their application in various sectors, such as automotive and renewable energy storage systems.

End-of-life management is a critical aspect of AGM battery LCA, given the hazardous nature of lead and sulfuric acid. The assessment examines the effectiveness of recycling processes in recovering valuable materials and reducing the environmental burden of disposal. Modern recycling techniques can recover up to 99% of the lead content, significantly mitigating the environmental impact of these batteries.

LCA studies also consider the potential for remanufacturing and second-life applications of AGM batteries, which can extend their useful life and improve overall sustainability. These assessments often employ standardized methodologies, such as ISO 14040 and 14044, to ensure consistency and comparability of results across different studies and battery technologies.

By conducting thorough Life Cycle Assessments, manufacturers and policymakers can identify hotspots of environmental impact throughout the AGM battery lifecycle. This information is invaluable for developing strategies to minimize negative environmental effects, optimize resource utilization, and align production processes with circular economy principles. Furthermore, LCA results can inform eco-design initiatives, guiding the development of more sustainable battery technologies and supporting the transition towards a more environmentally responsible energy storage sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!