Innovations in AGM Battery Internal Construction Methods

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in lead-acid battery technology. Originating in the 1980s, AGM batteries were initially developed for military aircraft, where their spill-proof design and high power output were crucial. The technology quickly found applications in other fields, including telecommunications and uninterruptible power supplies (UPS).

AGM batteries improved upon traditional flooded lead-acid batteries by immobilizing the electrolyte in a highly porous microfiber glass mat separator. This design change brought about several advantages, including better electrolyte retention, reduced internal resistance, and improved charge acceptance. These benefits led to increased cycle life, faster charging capabilities, and enhanced performance in deep-cycle applications.

Throughout the 1990s and early 2000s, AGM battery technology continued to evolve. Manufacturers focused on optimizing the internal construction to further improve performance and longevity. Key developments included refining the glass mat composition and structure to enhance electrolyte absorption and distribution. Additionally, advancements in grid alloys and active material formulations contributed to increased durability and capacity retention.

The automotive industry began adopting AGM batteries in the mid-2000s, particularly for start-stop vehicle systems. This application demanded batteries capable of frequent cycling and rapid charge acceptance, which AGM technology could provide. The integration of AGM batteries in vehicles drove further innovations in internal construction methods to meet the specific requirements of automotive applications.

Recent years have seen a focus on enhancing the environmental sustainability of AGM batteries. Efforts have been made to improve recyclability and reduce the use of harmful materials. Manufacturers have also worked on extending battery life through advanced internal construction techniques, such as optimized compression of the glass mat and improved plate designs.

The latest innovations in AGM battery internal construction methods aim to address the growing demand for higher energy density and faster charging capabilities. These include the development of thin plate pure lead (TPPL) technology, which utilizes ultra-thin, high-purity lead plates to increase power density and reduce weight. Another area of focus is the integration of carbon additives in the negative plates to enhance charge acceptance and cycle life.

As we look to the future, the evolution of AGM batteries continues to be driven by the need for more efficient, durable, and environmentally friendly energy storage solutions. Researchers are exploring novel materials and construction techniques to push the boundaries of AGM technology, aiming to meet the ever-increasing demands of various applications, from renewable energy storage to electric vehicles.

AGM batteries improved upon traditional flooded lead-acid batteries by immobilizing the electrolyte in a highly porous microfiber glass mat separator. This design change brought about several advantages, including better electrolyte retention, reduced internal resistance, and improved charge acceptance. These benefits led to increased cycle life, faster charging capabilities, and enhanced performance in deep-cycle applications.

Throughout the 1990s and early 2000s, AGM battery technology continued to evolve. Manufacturers focused on optimizing the internal construction to further improve performance and longevity. Key developments included refining the glass mat composition and structure to enhance electrolyte absorption and distribution. Additionally, advancements in grid alloys and active material formulations contributed to increased durability and capacity retention.

The automotive industry began adopting AGM batteries in the mid-2000s, particularly for start-stop vehicle systems. This application demanded batteries capable of frequent cycling and rapid charge acceptance, which AGM technology could provide. The integration of AGM batteries in vehicles drove further innovations in internal construction methods to meet the specific requirements of automotive applications.

Recent years have seen a focus on enhancing the environmental sustainability of AGM batteries. Efforts have been made to improve recyclability and reduce the use of harmful materials. Manufacturers have also worked on extending battery life through advanced internal construction techniques, such as optimized compression of the glass mat and improved plate designs.

The latest innovations in AGM battery internal construction methods aim to address the growing demand for higher energy density and faster charging capabilities. These include the development of thin plate pure lead (TPPL) technology, which utilizes ultra-thin, high-purity lead plates to increase power density and reduce weight. Another area of focus is the integration of carbon additives in the negative plates to enhance charge acceptance and cycle life.

As we look to the future, the evolution of AGM batteries continues to be driven by the need for more efficient, durable, and environmentally friendly energy storage solutions. Researchers are exploring novel materials and construction techniques to push the boundaries of AGM technology, aiming to meet the ever-increasing demands of various applications, from renewable energy storage to electric vehicles.

Market Demand Analysis

The market demand for innovations in AGM (Absorbent Glass Mat) battery internal construction methods has been steadily increasing in recent years. This growth is primarily driven by the expanding applications of AGM batteries in various sectors, including automotive, renewable energy storage, and telecommunications.

In the automotive industry, the shift towards more fuel-efficient vehicles and the rise of start-stop technology have significantly boosted the demand for AGM batteries. These batteries are better suited to handle the frequent charge-discharge cycles associated with start-stop systems, leading to increased adoption by car manufacturers. The global automotive AGM battery market is expected to grow substantially over the next decade, as more vehicles incorporate this technology.

The renewable energy sector has also emerged as a key driver for AGM battery innovations. As solar and wind power installations continue to increase worldwide, the need for efficient and reliable energy storage solutions has grown correspondingly. AGM batteries, with their improved cycle life and maintenance-free operation, are becoming increasingly popular in off-grid and grid-tied renewable energy systems.

In the telecommunications industry, the ongoing expansion of 5G networks and the need for reliable backup power systems have created a strong demand for advanced AGM batteries. These batteries are preferred for their high performance in standby applications and their ability to operate in a wide range of temperatures, making them ideal for telecom tower installations.

The marine and recreational vehicle (RV) markets have also contributed to the growing demand for AGM batteries. Boaters and RV enthusiasts appreciate the spill-proof design and superior performance of AGM batteries in deep-cycle applications, driving manufacturers to innovate and improve their products.

Industrial applications, such as material handling equipment and uninterruptible power supplies (UPS), represent another significant market segment for AGM batteries. The need for reliable power sources in critical operations has led to increased adoption of AGM technology in these sectors.

As environmental concerns continue to grow, there is an increasing demand for more sustainable battery technologies. This has prompted research into improving the recyclability and environmental impact of AGM batteries, driving innovations in materials and construction methods.

The market is also seeing a trend towards higher energy density and longer cycle life in AGM batteries. Consumers and industries are demanding batteries that can store more energy in smaller packages and last longer, pushing manufacturers to develop new internal construction methods that can meet these requirements.

In the automotive industry, the shift towards more fuel-efficient vehicles and the rise of start-stop technology have significantly boosted the demand for AGM batteries. These batteries are better suited to handle the frequent charge-discharge cycles associated with start-stop systems, leading to increased adoption by car manufacturers. The global automotive AGM battery market is expected to grow substantially over the next decade, as more vehicles incorporate this technology.

The renewable energy sector has also emerged as a key driver for AGM battery innovations. As solar and wind power installations continue to increase worldwide, the need for efficient and reliable energy storage solutions has grown correspondingly. AGM batteries, with their improved cycle life and maintenance-free operation, are becoming increasingly popular in off-grid and grid-tied renewable energy systems.

In the telecommunications industry, the ongoing expansion of 5G networks and the need for reliable backup power systems have created a strong demand for advanced AGM batteries. These batteries are preferred for their high performance in standby applications and their ability to operate in a wide range of temperatures, making them ideal for telecom tower installations.

The marine and recreational vehicle (RV) markets have also contributed to the growing demand for AGM batteries. Boaters and RV enthusiasts appreciate the spill-proof design and superior performance of AGM batteries in deep-cycle applications, driving manufacturers to innovate and improve their products.

Industrial applications, such as material handling equipment and uninterruptible power supplies (UPS), represent another significant market segment for AGM batteries. The need for reliable power sources in critical operations has led to increased adoption of AGM technology in these sectors.

As environmental concerns continue to grow, there is an increasing demand for more sustainable battery technologies. This has prompted research into improving the recyclability and environmental impact of AGM batteries, driving innovations in materials and construction methods.

The market is also seeing a trend towards higher energy density and longer cycle life in AGM batteries. Consumers and industries are demanding batteries that can store more energy in smaller packages and last longer, pushing manufacturers to develop new internal construction methods that can meet these requirements.

Technical Challenges

AGM (Absorbent Glass Mat) battery technology has made significant strides in recent years, yet several technical challenges persist in its internal construction methods. One of the primary obstacles is the optimization of electrolyte distribution within the glass mat separator. Achieving uniform saturation throughout the mat is crucial for battery performance, but current manufacturing processes struggle to ensure consistent distribution, leading to potential dry spots or oversaturation areas.

Another significant challenge lies in the reduction of internal resistance. While AGM batteries generally offer lower internal resistance compared to flooded lead-acid batteries, further improvements are necessary to enhance power output and efficiency. This involves refining the design of current collectors and optimizing the contact between the active material and the glass mat separator.

The management of gas recombination within AGM batteries presents an ongoing technical hurdle. Efficient oxygen recombination is essential for maintaining the battery's sealed nature and preventing electrolyte loss. However, achieving the right balance between gas generation and recombination rates across various operating conditions remains a complex task.

Thermal management is another critical area of concern. AGM batteries are sensitive to temperature fluctuations, which can significantly impact their performance and lifespan. Developing innovative internal construction methods that improve heat dissipation and maintain uniform temperature distribution throughout the battery is a pressing challenge.

The pursuit of higher energy density while maintaining structural integrity poses a significant technical dilemma. Increasing the amount of active material within the same battery volume can boost capacity, but it also risks compromising the mechanical stability of the internal components. Striking the right balance between energy density and structural robustness requires advanced material science and engineering solutions.

Lastly, the challenge of extending cycle life without sacrificing performance or increasing costs looms large. This involves developing new alloys for grids, improving the formulation of active materials, and enhancing the overall internal construction to minimize degradation mechanisms such as sulfation and grid corrosion.

Addressing these technical challenges requires a multidisciplinary approach, combining advancements in materials science, electrochemistry, and manufacturing processes. As the demand for high-performance energy storage solutions continues to grow, overcoming these hurdles in AGM battery internal construction methods will be crucial for the technology's future competitiveness and widespread adoption.

Another significant challenge lies in the reduction of internal resistance. While AGM batteries generally offer lower internal resistance compared to flooded lead-acid batteries, further improvements are necessary to enhance power output and efficiency. This involves refining the design of current collectors and optimizing the contact between the active material and the glass mat separator.

The management of gas recombination within AGM batteries presents an ongoing technical hurdle. Efficient oxygen recombination is essential for maintaining the battery's sealed nature and preventing electrolyte loss. However, achieving the right balance between gas generation and recombination rates across various operating conditions remains a complex task.

Thermal management is another critical area of concern. AGM batteries are sensitive to temperature fluctuations, which can significantly impact their performance and lifespan. Developing innovative internal construction methods that improve heat dissipation and maintain uniform temperature distribution throughout the battery is a pressing challenge.

The pursuit of higher energy density while maintaining structural integrity poses a significant technical dilemma. Increasing the amount of active material within the same battery volume can boost capacity, but it also risks compromising the mechanical stability of the internal components. Striking the right balance between energy density and structural robustness requires advanced material science and engineering solutions.

Lastly, the challenge of extending cycle life without sacrificing performance or increasing costs looms large. This involves developing new alloys for grids, improving the formulation of active materials, and enhancing the overall internal construction to minimize degradation mechanisms such as sulfation and grid corrosion.

Addressing these technical challenges requires a multidisciplinary approach, combining advancements in materials science, electrochemistry, and manufacturing processes. As the demand for high-performance energy storage solutions continues to grow, overcoming these hurdles in AGM battery internal construction methods will be crucial for the technology's future competitiveness and widespread adoption.

Current Construction

01 Electrode plate structure

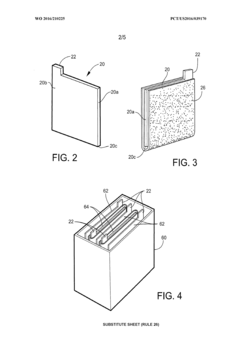

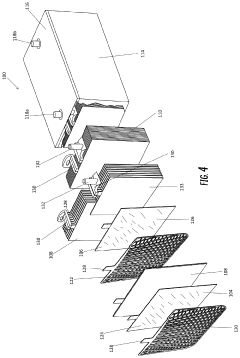

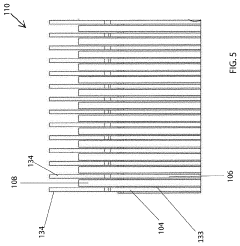

AGM batteries feature a unique electrode plate structure, typically consisting of positive and negative plates separated by an Absorbent Glass Mat (AGM) separator. This design allows for efficient electrolyte absorption and improved charge/discharge performance. The plates are often made of lead or lead alloys, with specific grid designs to enhance conductivity and durability.- Electrode plate structure: AGM batteries feature a unique electrode plate structure, typically consisting of positive and negative plates separated by an Absorbent Glass Mat (AGM) separator. This design allows for efficient electrolyte absorption and improved charge/discharge performance. The plates are often made of lead or lead alloys, with specific grid designs to enhance conductivity and durability.

- Electrolyte management system: AGM batteries incorporate an advanced electrolyte management system that utilizes the AGM separator to hold the electrolyte in a suspended state. This design prevents electrolyte stratification and allows for better gas recombination, resulting in maintenance-free operation and improved safety. The system also includes pressure relief valves to regulate internal pressure during charging and discharging cycles.

- Internal connection and current collection: The internal construction of AGM batteries includes a sophisticated network of connections between electrode plates and terminals. This system often employs lead-based connectors and busbars to ensure efficient current collection and distribution. The design aims to minimize internal resistance and enhance overall battery performance, particularly in high-current applications.

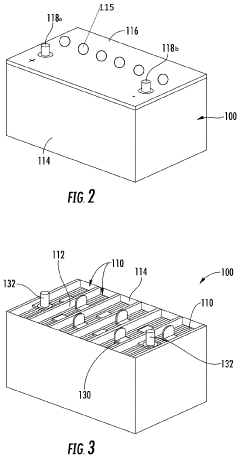

- Casing and sealing technology: AGM batteries utilize advanced casing and sealing technologies to ensure a leak-proof and maintenance-free design. The casing is typically made of durable materials such as polypropylene or ABS plastic, with reinforced structures to withstand internal pressure. Specialized sealing methods are employed to prevent electrolyte leakage and gas escape, contributing to the battery's long service life and safety features.

- Thermal management and safety features: AGM batteries incorporate various thermal management and safety features in their internal construction. These may include heat-dissipating materials, thermal sensors, and protective circuits to prevent overheating and thermal runaway. Additionally, internal pressure regulation mechanisms and flame-retardant separators are often integrated to enhance overall battery safety and reliability under various operating conditions.

02 Electrolyte management system

AGM batteries incorporate an advanced electrolyte management system that utilizes the AGM separator to hold the electrolyte in a suspended state. This design prevents electrolyte stratification and allows for better gas recombination, resulting in maintenance-free operation and improved safety. The system also includes pressure relief valves to regulate internal pressure during charging and discharging cycles.Expand Specific Solutions03 Terminal and connection design

The internal construction of AGM batteries includes specially designed terminals and connections to ensure optimal current flow and minimize internal resistance. These may include lead-alloy terminals, copper inserts, or other conductive materials. The connections between cells and terminals are engineered to withstand vibration and provide reliable performance throughout the battery's lifespan.Expand Specific Solutions04 Cell compression and case design

AGM batteries utilize a compressed cell design within a robust case to maintain proper contact between the plates and separator. This compression helps prevent plate shedding and improves overall battery life. The case is typically made of durable materials such as polypropylene or ABS plastic, designed to withstand internal pressure and provide protection against external factors.Expand Specific Solutions05 Gas recombination technology

AGM batteries incorporate internal gas recombination technology to minimize water loss and eliminate the need for regular maintenance. This system allows oxygen generated at the positive plate to recombine with hydrogen at the negative plate, forming water. The design includes specific pathways and catalysts to facilitate this process, ensuring efficient operation and prolonging battery life.Expand Specific Solutions

Key Industry Players

The AGM battery internal construction methods market is in a growth phase, driven by increasing demand for reliable energy storage solutions. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technological maturity varies among key players, with companies like LG Chem, Hoppecke Batterien, and Daramic leading in innovation. These firms are investing heavily in R&D to improve battery performance, longevity, and safety. Emerging players such as ArcActive and American Battery Solutions are introducing novel approaches, challenging established manufacturers. The competitive landscape is characterized by a mix of large conglomerates and specialized battery technology firms, with Asian companies like Panasonic and NEC Corporation maintaining a strong presence in the global market.

LG Chem Ltd.

Technical Solution: LG Chem has developed innovative AGM battery construction methods, focusing on improving the internal structure for enhanced performance and longevity. Their approach includes the use of advanced separators with optimized pore structures to improve electrolyte distribution and reduce internal resistance[1]. They have also implemented a new grid design that enhances current collection and reduces corrosion, leading to improved cycle life[2]. LG Chem's AGM batteries feature a proprietary paste formulation that increases active material utilization and stability during cycling[3]. Additionally, they have introduced a novel compression technique that ensures optimal contact between the plates and separators, reducing the risk of short circuits and improving overall battery reliability[4].

Strengths: Advanced separator technology, improved grid design, and proprietary paste formulation lead to enhanced performance and longevity. Weaknesses: Potentially higher production costs due to advanced materials and manufacturing processes.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has made significant strides in AGM battery internal construction methods, focusing on enhancing energy density and cycle life. They have developed a new plate design that increases the surface area for improved charge acceptance and discharge performance[1]. Their innovative approach includes the use of nano-scale additives in the active material to enhance conductivity and reduce sulfation[2]. LG Energy Solution has also implemented advanced manufacturing techniques, such as precision casting and automated assembly, to ensure consistent quality and reduce internal defects[3]. Furthermore, they have introduced a novel electrolyte formulation that improves the battery's resistance to acid stratification, leading to more uniform current distribution and extended battery life[4].

Strengths: High energy density, improved cycle life, and advanced manufacturing techniques. Weaknesses: Potential for higher costs due to specialized materials and production processes.

Innovative Designs

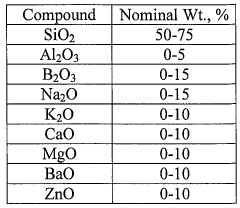

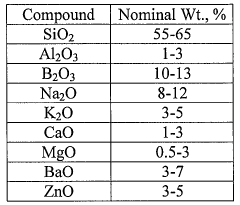

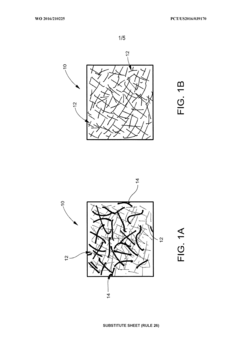

Improved absorbent glass mat separators, VRLA batteries, and related mehtods of manufacture and use

PatentWO2016210225A1

Innovation

- Incorporating soluble content such as fibers, flakes, or particles into the AGM separators that dissolve upon contact with water or sulfuric acid, creating additional pores and enhancing porosity, allowing for faster acid filling and improved wettability without compromising the separator's integrity.

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Material Advancements

Material advancements have played a crucial role in enhancing the performance and efficiency of AGM (Absorbent Glass Mat) batteries. Recent innovations in material science have led to significant improvements in the internal construction methods of these batteries, resulting in enhanced power output, longer lifespan, and improved safety features.

One of the key areas of material advancement is in the development of more efficient glass mat separators. Traditional AGM batteries use glass fiber mats to absorb and retain the electrolyte. However, new materials and manufacturing techniques have led to the creation of ultra-thin, highly porous glass mats that offer improved electrolyte absorption and retention capabilities. These advanced separators allow for better ion transfer between the positive and negative plates, resulting in improved battery performance and faster charging times.

Another significant advancement is in the composition of the battery plates. Researchers have developed new alloys and coatings that enhance the corrosion resistance of the plates, thereby extending the overall lifespan of the battery. For instance, the use of lead-calcium-tin alloys in positive plates has shown promising results in reducing grid growth and improving cycle life. Additionally, the incorporation of carbon additives in the negative plates has led to improved charge acceptance and reduced sulfation, addressing common issues in traditional AGM batteries.

The electrolyte formulation has also seen notable improvements. Advanced electrolyte additives have been developed to minimize water loss and reduce the rate of internal corrosion. These additives help maintain the battery's performance over time and contribute to its overall durability. Furthermore, the use of gel electrolytes in some AGM battery designs has shown potential in improving thermal stability and reducing the risk of electrolyte leakage.

Innovations in manufacturing processes have also contributed to material advancements. Precision casting techniques for grid production have resulted in more uniform and thinner grids, allowing for higher energy density within the same battery footprint. Moreover, advanced paste mixing and application methods have led to more consistent and durable active material coatings on the battery plates, enhancing overall performance and reliability.

The integration of nanomaterials in AGM battery construction has opened up new possibilities for performance enhancement. Nanostructured materials, such as carbon nanotubes and graphene, are being explored for their potential to improve the conductivity and surface area of battery components. These materials show promise in increasing the battery's power density and charge/discharge rates, potentially revolutionizing the capabilities of AGM batteries in high-performance applications.

In conclusion, material advancements have significantly contributed to the evolution of AGM battery internal construction methods. These innovations have not only improved the performance characteristics of AGM batteries but have also addressed long-standing challenges in battery technology. As research in material science continues to progress, we can expect further breakthroughs that will shape the future of AGM battery technology and expand its applications across various industries.

One of the key areas of material advancement is in the development of more efficient glass mat separators. Traditional AGM batteries use glass fiber mats to absorb and retain the electrolyte. However, new materials and manufacturing techniques have led to the creation of ultra-thin, highly porous glass mats that offer improved electrolyte absorption and retention capabilities. These advanced separators allow for better ion transfer between the positive and negative plates, resulting in improved battery performance and faster charging times.

Another significant advancement is in the composition of the battery plates. Researchers have developed new alloys and coatings that enhance the corrosion resistance of the plates, thereby extending the overall lifespan of the battery. For instance, the use of lead-calcium-tin alloys in positive plates has shown promising results in reducing grid growth and improving cycle life. Additionally, the incorporation of carbon additives in the negative plates has led to improved charge acceptance and reduced sulfation, addressing common issues in traditional AGM batteries.

The electrolyte formulation has also seen notable improvements. Advanced electrolyte additives have been developed to minimize water loss and reduce the rate of internal corrosion. These additives help maintain the battery's performance over time and contribute to its overall durability. Furthermore, the use of gel electrolytes in some AGM battery designs has shown potential in improving thermal stability and reducing the risk of electrolyte leakage.

Innovations in manufacturing processes have also contributed to material advancements. Precision casting techniques for grid production have resulted in more uniform and thinner grids, allowing for higher energy density within the same battery footprint. Moreover, advanced paste mixing and application methods have led to more consistent and durable active material coatings on the battery plates, enhancing overall performance and reliability.

The integration of nanomaterials in AGM battery construction has opened up new possibilities for performance enhancement. Nanostructured materials, such as carbon nanotubes and graphene, are being explored for their potential to improve the conductivity and surface area of battery components. These materials show promise in increasing the battery's power density and charge/discharge rates, potentially revolutionizing the capabilities of AGM batteries in high-performance applications.

In conclusion, material advancements have significantly contributed to the evolution of AGM battery internal construction methods. These innovations have not only improved the performance characteristics of AGM batteries but have also addressed long-standing challenges in battery technology. As research in material science continues to progress, we can expect further breakthroughs that will shape the future of AGM battery technology and expand its applications across various industries.

Environmental Impact

The environmental impact of innovations in AGM battery internal construction methods is a critical consideration in the development and adoption of these technologies. As the demand for energy storage solutions continues to grow, particularly in renewable energy and electric vehicle sectors, the environmental footprint of battery production and disposal becomes increasingly significant.

Recent advancements in AGM battery construction have focused on improving the sustainability of these power sources. One key area of innovation is the reduction of lead content in AGM batteries. By optimizing the internal structure and using advanced materials, manufacturers have been able to decrease the amount of lead required while maintaining or even enhancing battery performance. This reduction in lead usage not only conserves resources but also minimizes the potential for environmental contamination during the battery's lifecycle.

Another important aspect of environmental impact is the improvement in battery lifespan. Innovations in electrode design and electrolyte composition have led to AGM batteries with longer operational lives. This extended durability reduces the frequency of battery replacements, thereby decreasing the overall environmental burden associated with battery production and disposal.

Recycling efficiency has also seen significant improvements due to innovations in AGM battery construction. New designs facilitate easier disassembly and material recovery, increasing the percentage of battery components that can be recycled. This circular approach to battery manufacturing helps to conserve raw materials and reduce waste, aligning with global sustainability goals.

Energy efficiency during the battery's operational phase has been enhanced through innovations in internal construction. Improved charge acceptance and lower internal resistance result in less energy loss during charging and discharging cycles. This increased efficiency translates to reduced energy consumption over the battery's lifetime, indirectly lowering the carbon footprint associated with its use.

The use of more environmentally friendly materials in AGM battery construction is another area of focus. Researchers are exploring alternatives to traditional toxic components, such as replacing certain additives with bio-based or less harmful substances. These efforts aim to reduce the environmental impact of battery production and mitigate potential risks in case of improper disposal.

Innovations in manufacturing processes for AGM batteries have also contributed to reducing their environmental impact. More efficient production techniques, such as advanced forming processes and precision assembly methods, have led to decreased energy consumption and waste generation during manufacturing. Additionally, some manufacturers are implementing closed-loop water systems and energy recovery technologies in their production facilities, further minimizing the environmental footprint of battery production.

Recent advancements in AGM battery construction have focused on improving the sustainability of these power sources. One key area of innovation is the reduction of lead content in AGM batteries. By optimizing the internal structure and using advanced materials, manufacturers have been able to decrease the amount of lead required while maintaining or even enhancing battery performance. This reduction in lead usage not only conserves resources but also minimizes the potential for environmental contamination during the battery's lifecycle.

Another important aspect of environmental impact is the improvement in battery lifespan. Innovations in electrode design and electrolyte composition have led to AGM batteries with longer operational lives. This extended durability reduces the frequency of battery replacements, thereby decreasing the overall environmental burden associated with battery production and disposal.

Recycling efficiency has also seen significant improvements due to innovations in AGM battery construction. New designs facilitate easier disassembly and material recovery, increasing the percentage of battery components that can be recycled. This circular approach to battery manufacturing helps to conserve raw materials and reduce waste, aligning with global sustainability goals.

Energy efficiency during the battery's operational phase has been enhanced through innovations in internal construction. Improved charge acceptance and lower internal resistance result in less energy loss during charging and discharging cycles. This increased efficiency translates to reduced energy consumption over the battery's lifetime, indirectly lowering the carbon footprint associated with its use.

The use of more environmentally friendly materials in AGM battery construction is another area of focus. Researchers are exploring alternatives to traditional toxic components, such as replacing certain additives with bio-based or less harmful substances. These efforts aim to reduce the environmental impact of battery production and mitigate potential risks in case of improper disposal.

Innovations in manufacturing processes for AGM batteries have also contributed to reducing their environmental impact. More efficient production techniques, such as advanced forming processes and precision assembly methods, have led to decreased energy consumption and waste generation during manufacturing. Additionally, some manufacturers are implementing closed-loop water systems and energy recovery technologies in their production facilities, further minimizing the environmental footprint of battery production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!