Reducing AGM Battery Overhead through Advanced Manufacturing Techniques

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in lead-acid battery technology. Originating in the 1970s, AGM batteries were initially developed for military aircraft, where their spill-proof design and high power density were crucial. The technology quickly found applications in other fields, including telecommunications and uninterruptible power supplies (UPS).

Throughout the 1980s and 1990s, AGM batteries gained popularity in the automotive industry, particularly for start-stop vehicles and high-performance cars. This adoption was driven by their superior cycle life, faster charging capabilities, and better resistance to vibration compared to traditional flooded lead-acid batteries. The evolution of AGM technology during this period focused on improving the glass mat's absorbency and optimizing the electrolyte distribution within the battery.

In the early 2000s, advancements in manufacturing techniques led to significant improvements in AGM battery performance. Enhanced plate design and more efficient production processes resulted in batteries with higher specific energy and power. These improvements made AGM batteries increasingly competitive with other battery technologies in various applications, including renewable energy storage systems.

Recent years have seen a focus on reducing the manufacturing overhead of AGM batteries while maintaining or improving their performance characteristics. This has involved innovations in materials science, such as the development of more efficient separators and improved active material formulations. Advanced manufacturing techniques, including automated assembly lines and precision control of electrolyte filling, have contributed to reducing production costs and improving consistency.

The current evolution of AGM battery technology is driven by the need for more sustainable and efficient energy storage solutions. Researchers are exploring ways to increase the recyclability of AGM batteries and reduce their environmental impact. Additionally, efforts are being made to extend the cycle life and improve the charge acceptance of AGM batteries, making them more suitable for emerging applications in electric vehicles and grid energy storage.

As we look towards the future, the evolution of AGM batteries is likely to continue along several paths. These include further improvements in energy density, faster charging capabilities, and enhanced temperature performance. The integration of smart battery management systems and the development of hybrid AGM-lithium technologies are also areas of active research, promising to extend the relevance of AGM batteries in an increasingly electrified world.

Throughout the 1980s and 1990s, AGM batteries gained popularity in the automotive industry, particularly for start-stop vehicles and high-performance cars. This adoption was driven by their superior cycle life, faster charging capabilities, and better resistance to vibration compared to traditional flooded lead-acid batteries. The evolution of AGM technology during this period focused on improving the glass mat's absorbency and optimizing the electrolyte distribution within the battery.

In the early 2000s, advancements in manufacturing techniques led to significant improvements in AGM battery performance. Enhanced plate design and more efficient production processes resulted in batteries with higher specific energy and power. These improvements made AGM batteries increasingly competitive with other battery technologies in various applications, including renewable energy storage systems.

Recent years have seen a focus on reducing the manufacturing overhead of AGM batteries while maintaining or improving their performance characteristics. This has involved innovations in materials science, such as the development of more efficient separators and improved active material formulations. Advanced manufacturing techniques, including automated assembly lines and precision control of electrolyte filling, have contributed to reducing production costs and improving consistency.

The current evolution of AGM battery technology is driven by the need for more sustainable and efficient energy storage solutions. Researchers are exploring ways to increase the recyclability of AGM batteries and reduce their environmental impact. Additionally, efforts are being made to extend the cycle life and improve the charge acceptance of AGM batteries, making them more suitable for emerging applications in electric vehicles and grid energy storage.

As we look towards the future, the evolution of AGM batteries is likely to continue along several paths. These include further improvements in energy density, faster charging capabilities, and enhanced temperature performance. The integration of smart battery management systems and the development of hybrid AGM-lithium technologies are also areas of active research, promising to extend the relevance of AGM batteries in an increasingly electrified world.

Market Demand Analysis

The market demand for advanced manufacturing techniques to reduce AGM (Absorbent Glass Mat) battery overhead is experiencing significant growth, driven by several key factors. The automotive industry, in particular, is a major driver of this demand as it shifts towards electrification and seeks more efficient energy storage solutions. AGM batteries, known for their high performance and reliability, are increasingly being used in start-stop systems and hybrid vehicles, creating a substantial market opportunity.

The global AGM battery market is projected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is fueled by the rising adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), as well as the increasing demand for uninterruptible power supply (UPS) systems in various industries. The automotive sector alone accounts for a significant portion of this market, with AGM batteries being preferred for their ability to withstand frequent charge-discharge cycles and provide high cranking power.

Advanced manufacturing techniques that can reduce AGM battery overhead are in high demand due to their potential to lower production costs, improve battery performance, and enhance overall efficiency. These techniques include automated assembly processes, precision robotics, and advanced material handling systems. The market is particularly interested in solutions that can optimize the production of AGM battery separators, as these components play a crucial role in battery performance and longevity.

The renewable energy sector is another key driver of market demand for improved AGM battery manufacturing. As solar and wind power installations continue to grow globally, there is an increasing need for reliable energy storage solutions. AGM batteries are well-suited for these applications due to their deep-cycle capabilities and low maintenance requirements. Advanced manufacturing techniques that can enhance the production of AGM batteries for renewable energy storage are therefore highly sought after.

Industrial applications, including telecommunications and data centers, also contribute significantly to the market demand. These sectors require reliable backup power solutions, and AGM batteries are often the preferred choice due to their high energy density and long service life. Manufacturing techniques that can improve the production efficiency and reduce the overhead costs of AGM batteries for these applications are in high demand.

The market is also seeing increased interest from emerging economies, where rapid industrialization and urbanization are driving the need for reliable power sources. This presents a significant opportunity for advanced manufacturing techniques that can reduce AGM battery overhead, as these markets are often more price-sensitive and would benefit greatly from cost reductions in battery production.

The global AGM battery market is projected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is fueled by the rising adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), as well as the increasing demand for uninterruptible power supply (UPS) systems in various industries. The automotive sector alone accounts for a significant portion of this market, with AGM batteries being preferred for their ability to withstand frequent charge-discharge cycles and provide high cranking power.

Advanced manufacturing techniques that can reduce AGM battery overhead are in high demand due to their potential to lower production costs, improve battery performance, and enhance overall efficiency. These techniques include automated assembly processes, precision robotics, and advanced material handling systems. The market is particularly interested in solutions that can optimize the production of AGM battery separators, as these components play a crucial role in battery performance and longevity.

The renewable energy sector is another key driver of market demand for improved AGM battery manufacturing. As solar and wind power installations continue to grow globally, there is an increasing need for reliable energy storage solutions. AGM batteries are well-suited for these applications due to their deep-cycle capabilities and low maintenance requirements. Advanced manufacturing techniques that can enhance the production of AGM batteries for renewable energy storage are therefore highly sought after.

Industrial applications, including telecommunications and data centers, also contribute significantly to the market demand. These sectors require reliable backup power solutions, and AGM batteries are often the preferred choice due to their high energy density and long service life. Manufacturing techniques that can improve the production efficiency and reduce the overhead costs of AGM batteries for these applications are in high demand.

The market is also seeing increased interest from emerging economies, where rapid industrialization and urbanization are driving the need for reliable power sources. This presents a significant opportunity for advanced manufacturing techniques that can reduce AGM battery overhead, as these markets are often more price-sensitive and would benefit greatly from cost reductions in battery production.

Current Challenges

The current challenges in reducing AGM battery overhead through advanced manufacturing techniques are multifaceted and complex. One of the primary obstacles is the high cost associated with implementing new manufacturing processes. While these advanced techniques promise improved efficiency and reduced overhead, the initial investment required for equipment upgrades and workforce training can be substantial, deterring many manufacturers from adopting them.

Another significant challenge lies in the optimization of material usage. AGM batteries require precise amounts of absorbent glass mat and electrolyte to function optimally. Current manufacturing processes often result in material waste, contributing to increased overhead costs. Developing techniques that minimize waste while maintaining or improving battery performance is a delicate balance that researchers and manufacturers are still struggling to achieve.

Quality control presents another hurdle in the pursuit of reduced overhead. As manufacturing processes become more advanced and automated, ensuring consistent quality across large production volumes becomes increasingly complex. Implementing robust quality control measures that can keep pace with advanced manufacturing techniques without significantly increasing costs is a challenge that requires innovative solutions.

The integration of new technologies into existing production lines also poses a significant challenge. Many manufacturers face difficulties in seamlessly incorporating advanced techniques into their established processes without disrupting ongoing production. This integration challenge often leads to temporary decreases in productivity and increases in overhead costs during the transition period.

Environmental concerns and regulatory compliance add another layer of complexity to the challenge of reducing AGM battery overhead. As environmental regulations become more stringent, manufacturers must find ways to implement cleaner, more sustainable production methods without significantly increasing costs. This includes addressing issues such as hazardous material handling, emissions reduction, and waste management.

Furthermore, the rapidly evolving nature of battery technology itself presents a challenge. As new battery chemistries and designs emerge, manufacturing techniques must adapt quickly. This constant need for innovation and flexibility in manufacturing processes can lead to increased overhead costs as manufacturers strive to stay competitive in a fast-changing market.

Lastly, the global supply chain disruptions experienced in recent years have highlighted the vulnerability of manufacturing processes to external factors. Developing resilient manufacturing techniques that can adapt to supply chain uncertainties while maintaining cost-effectiveness is a significant challenge that manufacturers must address to truly reduce AGM battery overhead in the long term.

Another significant challenge lies in the optimization of material usage. AGM batteries require precise amounts of absorbent glass mat and electrolyte to function optimally. Current manufacturing processes often result in material waste, contributing to increased overhead costs. Developing techniques that minimize waste while maintaining or improving battery performance is a delicate balance that researchers and manufacturers are still struggling to achieve.

Quality control presents another hurdle in the pursuit of reduced overhead. As manufacturing processes become more advanced and automated, ensuring consistent quality across large production volumes becomes increasingly complex. Implementing robust quality control measures that can keep pace with advanced manufacturing techniques without significantly increasing costs is a challenge that requires innovative solutions.

The integration of new technologies into existing production lines also poses a significant challenge. Many manufacturers face difficulties in seamlessly incorporating advanced techniques into their established processes without disrupting ongoing production. This integration challenge often leads to temporary decreases in productivity and increases in overhead costs during the transition period.

Environmental concerns and regulatory compliance add another layer of complexity to the challenge of reducing AGM battery overhead. As environmental regulations become more stringent, manufacturers must find ways to implement cleaner, more sustainable production methods without significantly increasing costs. This includes addressing issues such as hazardous material handling, emissions reduction, and waste management.

Furthermore, the rapidly evolving nature of battery technology itself presents a challenge. As new battery chemistries and designs emerge, manufacturing techniques must adapt quickly. This constant need for innovation and flexibility in manufacturing processes can lead to increased overhead costs as manufacturers strive to stay competitive in a fast-changing market.

Lastly, the global supply chain disruptions experienced in recent years have highlighted the vulnerability of manufacturing processes to external factors. Developing resilient manufacturing techniques that can adapt to supply chain uncertainties while maintaining cost-effectiveness is a significant challenge that manufacturers must address to truly reduce AGM battery overhead in the long term.

Overhead Reduction Methods

01 AGM battery design improvements

Various design improvements for AGM (Absorbent Glass Mat) batteries to enhance performance and reduce overhead. These include optimized electrode structures, improved electrolyte distribution systems, and advanced separator materials to increase efficiency and reduce internal resistance.- AGM battery structure and design improvements: Advancements in AGM battery structure and design focus on enhancing performance and reducing overhead. These improvements include optimized electrode configurations, improved separator materials, and innovative casing designs that contribute to better efficiency and reduced maintenance requirements.

- Thermal management systems for AGM batteries: Thermal management solutions are developed to address the overhead issues in AGM batteries. These systems include advanced cooling mechanisms, heat dissipation techniques, and temperature control strategies to maintain optimal operating conditions and extend battery life.

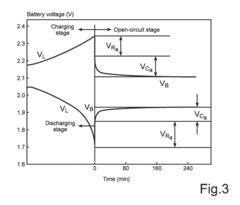

- Charging and discharging control strategies: Innovative charging and discharging control strategies are implemented to minimize overhead in AGM batteries. These include smart charging algorithms, adaptive current control, and state-of-charge monitoring systems that optimize battery performance and reduce energy losses during operation.

- Integration of AGM batteries in energy storage systems: AGM batteries are integrated into larger energy storage systems with improved efficiency. This integration involves advanced battery management systems, load balancing techniques, and intelligent power distribution strategies to reduce overall system overhead and enhance energy utilization.

- Maintenance and monitoring solutions for AGM batteries: Advanced maintenance and monitoring solutions are developed to reduce the operational overhead of AGM batteries. These include remote monitoring systems, predictive maintenance algorithms, and automated diagnostic tools that help identify and address potential issues before they lead to performance degradation or failure.

02 Thermal management systems

Implementation of thermal management systems to control and regulate the temperature of AGM batteries during operation. This includes cooling mechanisms, heat dissipation techniques, and temperature monitoring systems to prevent overheating and extend battery life.Expand Specific Solutions03 Battery management and monitoring

Advanced battery management and monitoring systems for AGM batteries to optimize performance and reduce overhead. These systems include state-of-charge estimation, voltage balancing, and predictive maintenance algorithms to improve overall efficiency and lifespan.Expand Specific Solutions04 Charging optimization techniques

Development of charging optimization techniques specifically for AGM batteries to reduce overhead and improve charging efficiency. This includes adaptive charging algorithms, pulse charging methods, and intelligent charging systems that adjust based on battery condition and usage patterns.Expand Specific Solutions05 Integration with renewable energy systems

Methods for integrating AGM batteries with renewable energy systems to optimize energy storage and reduce overall system overhead. This includes smart grid integration, load balancing techniques, and energy management strategies for solar and wind power applications.Expand Specific Solutions

Key Industry Players

The market for advanced AGM battery manufacturing techniques is in a growth phase, driven by increasing demand for high-performance energy storage solutions. The global market size is expanding rapidly, with key players like LG Energy Solution, Tianneng Battery Group, and Camel Group Battery Research Institute leading innovation efforts. The technology is maturing, with companies such as Hoppecke Batterien and FIAMM Energy Technology focusing on improving manufacturing processes to reduce overhead costs. Emerging players like Numbat GmbH and I-TEN SA are also contributing to technological advancements, indicating a competitive and dynamic landscape. As the industry progresses, collaboration between established manufacturers and innovative startups is likely to accelerate the development of more efficient AGM battery production techniques.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced manufacturing techniques to reduce AGM battery overhead. Their approach includes the use of precision coating technology for electrode production, which allows for thinner and more uniform active material layers[1]. This results in improved energy density and reduced material waste. Additionally, they have implemented automated assembly lines with real-time quality control systems, significantly reducing production errors and increasing overall efficiency[3]. The company has also invested in advanced formation and aging processes, utilizing AI-driven algorithms to optimize battery performance and lifespan[5].

Strengths: High-precision manufacturing, improved energy density, and reduced material waste. Weaknesses: High initial investment costs for advanced equipment and potential complexity in scaling up production.

Hoppecke Batterien GmbH & Co. KG

Technical Solution: Hoppecke has focused on reducing AGM battery overhead through innovative manufacturing processes. They have developed a proprietary grid design that optimizes current distribution and reduces internal resistance[2]. This design, combined with advanced lead alloy compositions, results in improved battery performance and longer cycle life. Hoppecke has also implemented a controlled gas recombination system that minimizes water loss and extends maintenance intervals[4]. Furthermore, they utilize a computer-controlled formation process that ensures consistent quality and reduces energy consumption during battery production[6].

Strengths: Improved battery performance, longer cycle life, and reduced maintenance requirements. Weaknesses: Potentially higher production costs and limited flexibility in battery design due to specialized components.

Innovative Technologies

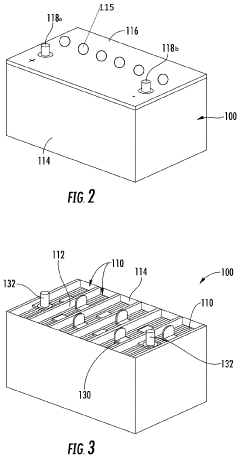

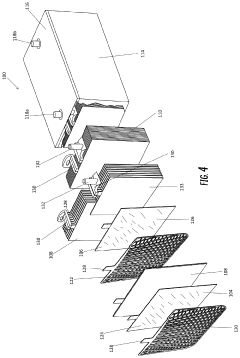

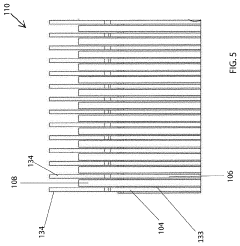

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

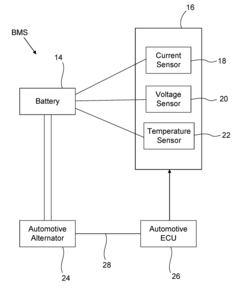

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) battery manufacturing and usage is a critical consideration in the pursuit of reducing battery overhead through advanced manufacturing techniques. As the demand for energy storage solutions continues to grow, it becomes increasingly important to address the ecological footprint of battery production and lifecycle.

AGM batteries, while more environmentally friendly than traditional lead-acid batteries, still pose significant environmental challenges. The manufacturing process involves the use of lead, sulfuric acid, and other potentially harmful materials. Advanced manufacturing techniques aim to minimize the environmental impact by optimizing resource utilization and reducing waste generation.

One key area of focus is the reduction of lead usage in AGM batteries. Advanced manufacturing techniques are being developed to create thinner, more efficient lead plates, which not only reduce the overall lead content but also improve battery performance. This approach not only lessens the environmental burden of lead mining and processing but also contributes to the reduction of battery weight and size.

Water consumption is another critical environmental factor in AGM battery production. Advanced manufacturing techniques are exploring ways to minimize water usage and implement closed-loop water recycling systems. These innovations can significantly reduce the water footprint of battery production, addressing concerns about water scarcity and pollution.

Energy efficiency in the manufacturing process is also a prime target for improvement. The implementation of smart manufacturing systems, automation, and energy-efficient equipment can substantially reduce the carbon footprint associated with AGM battery production. This not only contributes to environmental sustainability but also helps in reducing overall production costs.

End-of-life considerations are equally important in assessing the environmental impact of AGM batteries. Advanced manufacturing techniques are being developed to facilitate easier recycling and material recovery. This includes designing batteries with more easily separable components and using materials that are more readily recyclable.

The shift towards more sustainable raw materials is another aspect of reducing the environmental impact. Research is ongoing to find alternatives to traditional materials used in AGM batteries, focusing on abundant, non-toxic, and easily recyclable substances. This approach not only addresses environmental concerns but also helps in securing a more sustainable supply chain for battery production.

By addressing these environmental aspects through advanced manufacturing techniques, the AGM battery industry can significantly reduce its ecological footprint. This not only aligns with global sustainability goals but also enhances the overall value proposition of AGM batteries in an increasingly environmentally conscious market.

AGM batteries, while more environmentally friendly than traditional lead-acid batteries, still pose significant environmental challenges. The manufacturing process involves the use of lead, sulfuric acid, and other potentially harmful materials. Advanced manufacturing techniques aim to minimize the environmental impact by optimizing resource utilization and reducing waste generation.

One key area of focus is the reduction of lead usage in AGM batteries. Advanced manufacturing techniques are being developed to create thinner, more efficient lead plates, which not only reduce the overall lead content but also improve battery performance. This approach not only lessens the environmental burden of lead mining and processing but also contributes to the reduction of battery weight and size.

Water consumption is another critical environmental factor in AGM battery production. Advanced manufacturing techniques are exploring ways to minimize water usage and implement closed-loop water recycling systems. These innovations can significantly reduce the water footprint of battery production, addressing concerns about water scarcity and pollution.

Energy efficiency in the manufacturing process is also a prime target for improvement. The implementation of smart manufacturing systems, automation, and energy-efficient equipment can substantially reduce the carbon footprint associated with AGM battery production. This not only contributes to environmental sustainability but also helps in reducing overall production costs.

End-of-life considerations are equally important in assessing the environmental impact of AGM batteries. Advanced manufacturing techniques are being developed to facilitate easier recycling and material recovery. This includes designing batteries with more easily separable components and using materials that are more readily recyclable.

The shift towards more sustainable raw materials is another aspect of reducing the environmental impact. Research is ongoing to find alternatives to traditional materials used in AGM batteries, focusing on abundant, non-toxic, and easily recyclable substances. This approach not only addresses environmental concerns but also helps in securing a more sustainable supply chain for battery production.

By addressing these environmental aspects through advanced manufacturing techniques, the AGM battery industry can significantly reduce its ecological footprint. This not only aligns with global sustainability goals but also enhances the overall value proposition of AGM batteries in an increasingly environmentally conscious market.

Cost-Benefit Analysis

The cost-benefit analysis of reducing AGM battery overhead through advanced manufacturing techniques reveals significant potential for long-term savings and improved efficiency. Initial investments in advanced manufacturing equipment and processes may be substantial, ranging from $500,000 to $2 million depending on the scale of operations. However, these upfront costs are offset by the considerable reduction in production expenses over time.

One of the primary benefits is the decrease in material waste. Advanced manufacturing techniques, such as precision cutting and automated assembly, can reduce material waste by up to 15-20%. This translates to substantial savings in raw material costs, which typically account for 40-50% of the total production expenses for AGM batteries.

Labor costs also see a significant reduction with the implementation of advanced manufacturing techniques. Automation and streamlined processes can decrease labor requirements by 30-40%, leading to lower operational costs and increased productivity. This not only reduces direct labor expenses but also minimizes the potential for human error, further improving overall quality and reducing rework costs.

Energy efficiency is another area where advanced manufacturing techniques provide substantial benefits. Modern equipment and optimized processes can reduce energy consumption by 20-25%, resulting in lower utility costs and a smaller carbon footprint. This aligns with sustainability goals and can potentially lead to additional cost savings through energy incentives or carbon credits.

The improved precision and consistency of advanced manufacturing techniques also contribute to higher product quality. This results in fewer defects and returns, reducing warranty and replacement costs by an estimated 10-15%. Additionally, the enhanced product reliability can lead to increased customer satisfaction and brand loyalty, potentially driving sales growth and market share expansion.

Long-term cost projections indicate that the initial investment in advanced manufacturing techniques can be recouped within 2-3 years, depending on production volume and market conditions. After this break-even point, the ongoing cost savings and efficiency gains continue to provide a competitive advantage, with potential annual savings of 15-20% in overall production costs.

Furthermore, the flexibility and scalability of advanced manufacturing systems allow for easier adaptation to market demands and technological advancements. This agility can result in faster time-to-market for new products and the ability to quickly adjust production volumes, providing additional strategic and financial benefits in the dynamic battery market.

One of the primary benefits is the decrease in material waste. Advanced manufacturing techniques, such as precision cutting and automated assembly, can reduce material waste by up to 15-20%. This translates to substantial savings in raw material costs, which typically account for 40-50% of the total production expenses for AGM batteries.

Labor costs also see a significant reduction with the implementation of advanced manufacturing techniques. Automation and streamlined processes can decrease labor requirements by 30-40%, leading to lower operational costs and increased productivity. This not only reduces direct labor expenses but also minimizes the potential for human error, further improving overall quality and reducing rework costs.

Energy efficiency is another area where advanced manufacturing techniques provide substantial benefits. Modern equipment and optimized processes can reduce energy consumption by 20-25%, resulting in lower utility costs and a smaller carbon footprint. This aligns with sustainability goals and can potentially lead to additional cost savings through energy incentives or carbon credits.

The improved precision and consistency of advanced manufacturing techniques also contribute to higher product quality. This results in fewer defects and returns, reducing warranty and replacement costs by an estimated 10-15%. Additionally, the enhanced product reliability can lead to increased customer satisfaction and brand loyalty, potentially driving sales growth and market share expansion.

Long-term cost projections indicate that the initial investment in advanced manufacturing techniques can be recouped within 2-3 years, depending on production volume and market conditions. After this break-even point, the ongoing cost savings and efficiency gains continue to provide a competitive advantage, with potential annual savings of 15-20% in overall production costs.

Furthermore, the flexibility and scalability of advanced manufacturing systems allow for easier adaptation to market demands and technological advancements. This agility can result in faster time-to-market for new products and the ability to quickly adjust production volumes, providing additional strategic and financial benefits in the dynamic battery market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!