Evaluating AGM Battery Grounding Techniques for Safety

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Grounding Overview and Objectives

Absorbed Glass Mat (AGM) battery technology has revolutionized the energy storage landscape, offering enhanced performance and safety features compared to traditional lead-acid batteries. The evolution of AGM batteries has been driven by the increasing demand for reliable power sources in various applications, from automotive to renewable energy systems. As the technology continues to advance, ensuring proper grounding techniques has become a critical aspect of AGM battery safety and performance optimization.

The primary objective of evaluating AGM battery grounding techniques for safety is to mitigate potential risks associated with electrical faults, short circuits, and overcharging. Proper grounding serves as a fundamental safety measure, protecting both the battery system and its surrounding environment from hazardous electrical events. By establishing a reliable path for fault currents to dissipate, effective grounding techniques minimize the risk of electrical shocks, fires, and equipment damage.

Furthermore, the evaluation of grounding techniques aims to enhance the overall efficiency and longevity of AGM battery systems. Proper grounding contributes to the stability of electrical circuits, reducing electromagnetic interference and improving the battery's ability to maintain consistent voltage levels. This, in turn, leads to improved performance and extended battery life, which are crucial factors in various applications, particularly in automotive and renewable energy sectors.

The technological progression in AGM battery grounding has been marked by the development of innovative materials and design approaches. From basic metal-to-frame connections to sophisticated grounding mats and integrated grounding systems, the field has seen significant advancements. These improvements have been driven by the need to address the unique characteristics of AGM batteries, such as their sealed design and the potential for internal gas recombination.

As the industry moves towards more complex and high-powered battery systems, particularly in electric vehicles and grid-scale energy storage, the importance of robust grounding techniques has become increasingly apparent. The evaluation of these techniques must consider not only the immediate safety benefits but also the long-term implications for system reliability and performance. This includes assessing the impact of different grounding methods on battery capacity, charging efficiency, and overall system integration.

In the context of global efforts to transition towards cleaner energy sources, the safety and reliability of AGM batteries play a crucial role. Effective grounding techniques contribute to the broader goal of creating sustainable and dependable energy storage solutions. By ensuring the safe operation of AGM batteries, these techniques support the widespread adoption of renewable energy technologies and electric transportation systems, aligning with international environmental and energy security objectives.

The primary objective of evaluating AGM battery grounding techniques for safety is to mitigate potential risks associated with electrical faults, short circuits, and overcharging. Proper grounding serves as a fundamental safety measure, protecting both the battery system and its surrounding environment from hazardous electrical events. By establishing a reliable path for fault currents to dissipate, effective grounding techniques minimize the risk of electrical shocks, fires, and equipment damage.

Furthermore, the evaluation of grounding techniques aims to enhance the overall efficiency and longevity of AGM battery systems. Proper grounding contributes to the stability of electrical circuits, reducing electromagnetic interference and improving the battery's ability to maintain consistent voltage levels. This, in turn, leads to improved performance and extended battery life, which are crucial factors in various applications, particularly in automotive and renewable energy sectors.

The technological progression in AGM battery grounding has been marked by the development of innovative materials and design approaches. From basic metal-to-frame connections to sophisticated grounding mats and integrated grounding systems, the field has seen significant advancements. These improvements have been driven by the need to address the unique characteristics of AGM batteries, such as their sealed design and the potential for internal gas recombination.

As the industry moves towards more complex and high-powered battery systems, particularly in electric vehicles and grid-scale energy storage, the importance of robust grounding techniques has become increasingly apparent. The evaluation of these techniques must consider not only the immediate safety benefits but also the long-term implications for system reliability and performance. This includes assessing the impact of different grounding methods on battery capacity, charging efficiency, and overall system integration.

In the context of global efforts to transition towards cleaner energy sources, the safety and reliability of AGM batteries play a crucial role. Effective grounding techniques contribute to the broader goal of creating sustainable and dependable energy storage solutions. By ensuring the safe operation of AGM batteries, these techniques support the widespread adoption of renewable energy technologies and electric transportation systems, aligning with international environmental and energy security objectives.

Market Analysis for AGM Battery Safety Solutions

The market for AGM battery safety solutions has experienced significant growth in recent years, driven by the increasing adoption of AGM batteries across various industries and the growing emphasis on safety in energy storage systems. The global AGM battery market is projected to reach $13.6 billion by 2026, with a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026. This growth is primarily attributed to the rising demand for reliable power sources in automotive, telecommunications, and renewable energy sectors.

In the automotive industry, AGM batteries are gaining popularity due to their superior performance in start-stop systems and hybrid vehicles. The increasing production of electric and hybrid vehicles is expected to further boost the demand for AGM batteries, consequently driving the need for advanced safety solutions. The automotive sector accounts for approximately 60% of the AGM battery market share, making it a key driver for safety solution innovations.

The telecommunications industry is another significant consumer of AGM batteries, particularly for backup power systems in cell towers and data centers. With the ongoing expansion of 5G networks and the increasing reliance on cloud computing, the demand for reliable and safe energy storage solutions is expected to grow substantially. This sector is projected to witness a CAGR of 6.8% in AGM battery adoption from 2021 to 2026, creating opportunities for safety solution providers.

Renewable energy applications, such as solar and wind power systems, are also contributing to the growth of the AGM battery safety solutions market. As more countries invest in clean energy infrastructure, the need for efficient and safe energy storage solutions becomes paramount. The renewable energy sector is expected to be the fastest-growing segment for AGM battery applications, with a projected CAGR of 7.5% from 2021 to 2026.

The market for AGM battery safety solutions is characterized by a focus on advanced grounding techniques, thermal management systems, and intelligent monitoring solutions. Key players in this market are investing heavily in research and development to enhance the safety features of AGM batteries, with a particular emphasis on preventing thermal runaway and improving overall system reliability.

Geographically, Asia-Pacific dominates the AGM battery market, accounting for approximately 40% of the global market share. This region is expected to maintain its leadership position due to the presence of major battery manufacturers and the rapid growth of end-use industries. North America and Europe follow closely, with significant investments in renewable energy and electric vehicle infrastructure driving the demand for AGM battery safety solutions.

In conclusion, the market for AGM battery safety solutions presents substantial growth opportunities across various industries. The increasing adoption of AGM batteries, coupled with stringent safety regulations and the need for reliable energy storage systems, is expected to drive innovation and market expansion in the coming years.

In the automotive industry, AGM batteries are gaining popularity due to their superior performance in start-stop systems and hybrid vehicles. The increasing production of electric and hybrid vehicles is expected to further boost the demand for AGM batteries, consequently driving the need for advanced safety solutions. The automotive sector accounts for approximately 60% of the AGM battery market share, making it a key driver for safety solution innovations.

The telecommunications industry is another significant consumer of AGM batteries, particularly for backup power systems in cell towers and data centers. With the ongoing expansion of 5G networks and the increasing reliance on cloud computing, the demand for reliable and safe energy storage solutions is expected to grow substantially. This sector is projected to witness a CAGR of 6.8% in AGM battery adoption from 2021 to 2026, creating opportunities for safety solution providers.

Renewable energy applications, such as solar and wind power systems, are also contributing to the growth of the AGM battery safety solutions market. As more countries invest in clean energy infrastructure, the need for efficient and safe energy storage solutions becomes paramount. The renewable energy sector is expected to be the fastest-growing segment for AGM battery applications, with a projected CAGR of 7.5% from 2021 to 2026.

The market for AGM battery safety solutions is characterized by a focus on advanced grounding techniques, thermal management systems, and intelligent monitoring solutions. Key players in this market are investing heavily in research and development to enhance the safety features of AGM batteries, with a particular emphasis on preventing thermal runaway and improving overall system reliability.

Geographically, Asia-Pacific dominates the AGM battery market, accounting for approximately 40% of the global market share. This region is expected to maintain its leadership position due to the presence of major battery manufacturers and the rapid growth of end-use industries. North America and Europe follow closely, with significant investments in renewable energy and electric vehicle infrastructure driving the demand for AGM battery safety solutions.

In conclusion, the market for AGM battery safety solutions presents substantial growth opportunities across various industries. The increasing adoption of AGM batteries, coupled with stringent safety regulations and the need for reliable energy storage systems, is expected to drive innovation and market expansion in the coming years.

Current Grounding Techniques and Challenges

The current landscape of AGM battery grounding techniques presents a mix of established methods and emerging challenges. Traditional grounding approaches for AGM batteries typically involve connecting the negative terminal to the vehicle's chassis or frame. This method has been widely adopted due to its simplicity and effectiveness in providing a return path for electrical current and ensuring safety.

However, as vehicle electrical systems become more complex, particularly with the integration of advanced electronics and hybrid powertrains, the conventional grounding techniques face new challenges. One significant issue is the potential for ground loops, which can introduce electrical noise and interfere with sensitive electronic components. This has led to the development of more sophisticated grounding strategies, such as isolated ground systems and multi-point grounding schemes.

Another challenge in AGM battery grounding is the management of high-current situations, especially during starting or rapid charging events. The grounding system must be capable of handling these peak loads without compromising safety or performance. This has prompted the use of enhanced grounding materials and designs, including larger cross-section conductors and improved connection methods to reduce resistance and heat generation.

Corrosion resistance remains a critical concern in battery grounding techniques. The harsh environment under the hood, combined with the potential for electrolyte leakage, can lead to degradation of grounding connections over time. To address this, manufacturers are exploring corrosion-resistant materials and protective coatings for grounding components.

The increasing adoption of start-stop technology in vehicles equipped with AGM batteries has introduced new challenges for grounding systems. These systems require rapid and frequent cycling of the battery, placing additional stress on the grounding connections. This has led to the development of more robust and durable grounding solutions capable of withstanding the increased cycling demands.

Electromagnetic compatibility (EMC) is another area of focus in current AGM battery grounding techniques. With the proliferation of electronic systems in modern vehicles, ensuring that the battery and its grounding system do not generate or are not susceptible to electromagnetic interference has become crucial. This has resulted in the implementation of shielding techniques and strategic placement of grounding points to minimize EMI issues.

As vehicle designs evolve towards more electric and hybrid powertrains, the integration of AGM batteries with high-voltage systems presents new safety challenges. Grounding techniques must now account for the potential interaction between low-voltage and high-voltage systems, necessitating advanced isolation and protection measures.

However, as vehicle electrical systems become more complex, particularly with the integration of advanced electronics and hybrid powertrains, the conventional grounding techniques face new challenges. One significant issue is the potential for ground loops, which can introduce electrical noise and interfere with sensitive electronic components. This has led to the development of more sophisticated grounding strategies, such as isolated ground systems and multi-point grounding schemes.

Another challenge in AGM battery grounding is the management of high-current situations, especially during starting or rapid charging events. The grounding system must be capable of handling these peak loads without compromising safety or performance. This has prompted the use of enhanced grounding materials and designs, including larger cross-section conductors and improved connection methods to reduce resistance and heat generation.

Corrosion resistance remains a critical concern in battery grounding techniques. The harsh environment under the hood, combined with the potential for electrolyte leakage, can lead to degradation of grounding connections over time. To address this, manufacturers are exploring corrosion-resistant materials and protective coatings for grounding components.

The increasing adoption of start-stop technology in vehicles equipped with AGM batteries has introduced new challenges for grounding systems. These systems require rapid and frequent cycling of the battery, placing additional stress on the grounding connections. This has led to the development of more robust and durable grounding solutions capable of withstanding the increased cycling demands.

Electromagnetic compatibility (EMC) is another area of focus in current AGM battery grounding techniques. With the proliferation of electronic systems in modern vehicles, ensuring that the battery and its grounding system do not generate or are not susceptible to electromagnetic interference has become crucial. This has resulted in the implementation of shielding techniques and strategic placement of grounding points to minimize EMI issues.

As vehicle designs evolve towards more electric and hybrid powertrains, the integration of AGM batteries with high-voltage systems presents new safety challenges. Grounding techniques must now account for the potential interaction between low-voltage and high-voltage systems, necessitating advanced isolation and protection measures.

Existing AGM Battery Grounding Solutions

01 Proper grounding techniques for AGM batteries

Implementing proper grounding techniques is crucial for AGM battery safety. This includes using appropriate grounding materials, ensuring secure connections, and following manufacturer guidelines for grounding procedures. Proper grounding helps prevent electrical hazards and improves overall system stability.- Proper grounding techniques for AGM batteries: Implementing proper grounding techniques is crucial for AGM battery safety. This includes using appropriate grounding materials, ensuring secure connections, and following manufacturer guidelines for grounding procedures. Proper grounding helps prevent electrical hazards and improves overall system stability.

- Safety monitoring systems for AGM batteries: Incorporating safety monitoring systems can enhance AGM battery grounding safety. These systems may include voltage sensors, temperature monitors, and fault detection mechanisms. Real-time monitoring allows for quick identification and response to potential grounding issues, reducing the risk of accidents.

- Insulation and isolation techniques: Employing proper insulation and isolation techniques is essential for AGM battery grounding safety. This involves using appropriate insulating materials, implementing physical barriers, and ensuring adequate spacing between conductive components. These measures help prevent unintended electrical paths and reduce the risk of short circuits.

- Protective enclosures and housing designs: Designing protective enclosures and housings specifically for AGM batteries can improve grounding safety. These enclosures should incorporate features such as proper ventilation, corrosion-resistant materials, and secure mounting options. Well-designed housings help protect the battery and its grounding connections from environmental factors and physical damage.

- Regular maintenance and inspection procedures: Implementing regular maintenance and inspection procedures is crucial for ensuring the ongoing safety of AGM battery grounding systems. This includes periodic checks of grounding connections, cleaning of battery terminals, and assessment of insulation integrity. Routine maintenance helps identify and address potential issues before they escalate into safety hazards.

02 Safety monitoring systems for AGM batteries

Incorporating safety monitoring systems can enhance AGM battery grounding safety. These systems may include voltage sensors, temperature monitors, and fault detection mechanisms. Real-time monitoring helps identify potential issues early, allowing for prompt intervention and reducing safety risks.Expand Specific Solutions03 Insulation and protection measures

Implementing proper insulation and protection measures is essential for AGM battery grounding safety. This includes using insulating materials, protective covers, and barriers to prevent accidental contact with live components. These measures help reduce the risk of short circuits and electrical shocks.Expand Specific Solutions04 Ventilation and thermal management

Ensuring adequate ventilation and thermal management is crucial for AGM battery safety during grounding operations. Proper airflow and temperature control help prevent overheating and reduce the risk of thermal runaway. This may involve the use of cooling systems or strategic placement of batteries in well-ventilated areas.Expand Specific Solutions05 Regular maintenance and inspection protocols

Establishing regular maintenance and inspection protocols is vital for maintaining AGM battery grounding safety. This includes periodic checks of grounding connections, visual inspections for signs of wear or damage, and testing of safety systems. Regular maintenance helps identify and address potential issues before they become safety hazards.Expand Specific Solutions

Key AGM Battery Manufacturers and Safety Innovators

The AGM battery grounding techniques market is in a growth phase, driven by increasing safety concerns in automotive and industrial applications. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is moderately mature, with ongoing innovations focused on enhancing safety and efficiency. Key players like Fengfan Co., Ltd., Tianneng Battery Group, and Hoppecke Batterien are investing in R&D to improve grounding techniques. Companies such as LG Energy Solution and Panasonic Holdings are leveraging their expertise in battery technology to develop advanced AGM battery solutions with improved grounding mechanisms. The competitive landscape is characterized by a mix of established battery manufacturers and specialized industrial technology firms, each striving to differentiate through technological advancements and safety features.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced AGM battery grounding techniques focusing on safety enhancement. Their approach includes a multi-layered grounding system that incorporates redundant pathways for electrical discharge[1]. This system utilizes high-conductivity materials and strategically placed grounding points to ensure rapid and efficient dissipation of any potential electrical buildup. Additionally, LG Chem has implemented smart sensors throughout the battery pack to continuously monitor grounding integrity and electrical potential differences[3]. These sensors are integrated with an advanced battery management system (BMS) that can instantly detect and respond to any grounding anomalies, initiating safety protocols as needed[5].

Strengths: Comprehensive multi-layered approach, advanced sensor integration, and real-time monitoring capabilities. Weaknesses: Potentially higher production costs and complexity in manufacturing and maintenance.

Hitachi Ltd.

Technical Solution: Hitachi has developed a holistic approach to AGM battery grounding that integrates advanced materials science with intelligent control systems. Their technique incorporates a novel composite material for battery casings that provides both structural integrity and enhanced electrical conductivity, serving as an integral part of the grounding system[12]. This is combined with a distributed network of micro-grounding points throughout the battery pack, ensuring uniform charge dissipation. Hitachi's system also features an AI-driven grounding management unit that continuously analyzes battery performance data, environmental conditions, and usage patterns to optimize grounding efficiency and safety parameters[14]. The system can detect subtle changes in grounding effectiveness and initiate preventive measures before critical issues arise.

Strengths: Innovative material integration, distributed grounding network, and AI-driven predictive maintenance. Weaknesses: Potentially higher production costs and complexity in manufacturing and quality control processes.

Innovative Grounding Technologies for AGM Batteries

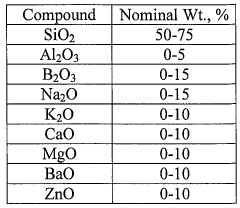

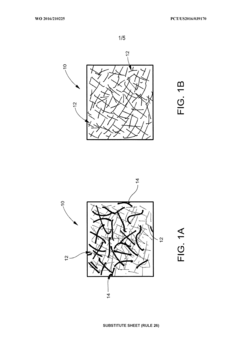

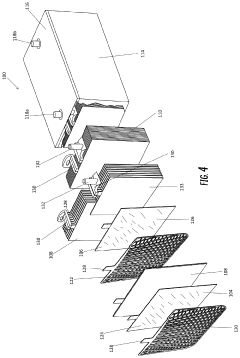

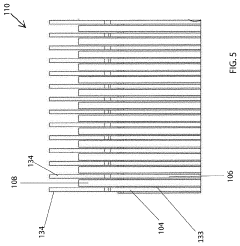

Improved absorbent glass mat separators, VRLA batteries, and related mehtods of manufacture and use

PatentWO2016210225A1

Innovation

- Incorporating soluble content such as fibers, flakes, or particles into the AGM separators that dissolve upon contact with water or sulfuric acid, creating additional pores and enhancing porosity, allowing for faster acid filling and improved wettability without compromising the separator's integrity.

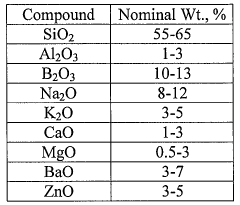

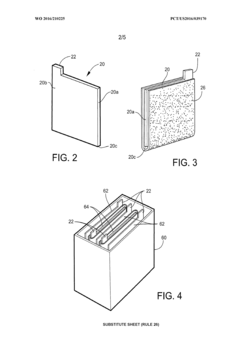

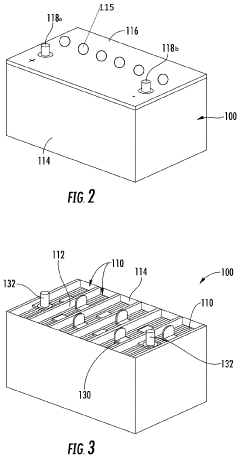

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Regulatory Framework for Battery Safety

The regulatory framework for battery safety is a critical aspect of evaluating AGM battery grounding techniques. Governments and industry organizations worldwide have established comprehensive guidelines and standards to ensure the safe operation of batteries, particularly in automotive and energy storage applications.

In the United States, the Department of Transportation (DOT) and the National Highway Traffic Safety Administration (NHTSA) have implemented regulations governing the transportation and use of batteries. These regulations include specific requirements for battery grounding and insulation to prevent electrical hazards and short circuits.

The Society of Automotive Engineers (SAE) has developed several standards related to battery safety, including SAE J2464 for electric and hybrid vehicle rechargeable energy storage systems. This standard addresses safety performance and abuse testing of batteries, including grounding requirements to mitigate potential risks.

Internationally, the United Nations Economic Commission for Europe (UNECE) has established Regulation No. 100, which outlines safety requirements for electric power train vehicles. This regulation includes provisions for battery grounding and protection against electric shock.

The International Electrotechnical Commission (IEC) has published IEC 62619, which specifies safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard includes guidelines for battery management systems and grounding techniques to ensure safe operation.

In the European Union, the Battery Directive (2006/66/EC) sets requirements for battery manufacturers and importers, including safety measures and proper disposal procedures. While not specifically addressing grounding techniques, this directive emphasizes the importance of overall battery safety.

The Institute of Electrical and Electronics Engineers (IEEE) has developed IEEE 1725, a standard for rechargeable batteries in mobile devices. Although primarily focused on consumer electronics, this standard provides valuable insights into battery safety practices that can be applied to AGM batteries.

Compliance with these regulatory frameworks is essential for manufacturers and users of AGM batteries. Proper grounding techniques, as outlined in these regulations, play a crucial role in preventing electrical hazards, reducing the risk of fire or explosion, and ensuring the overall safety of battery systems.

As technology advances and new battery chemistries emerge, regulatory bodies continue to update and refine their safety standards. This ongoing process ensures that safety measures, including grounding techniques, remain effective in addressing evolving risks associated with battery technologies.

In the United States, the Department of Transportation (DOT) and the National Highway Traffic Safety Administration (NHTSA) have implemented regulations governing the transportation and use of batteries. These regulations include specific requirements for battery grounding and insulation to prevent electrical hazards and short circuits.

The Society of Automotive Engineers (SAE) has developed several standards related to battery safety, including SAE J2464 for electric and hybrid vehicle rechargeable energy storage systems. This standard addresses safety performance and abuse testing of batteries, including grounding requirements to mitigate potential risks.

Internationally, the United Nations Economic Commission for Europe (UNECE) has established Regulation No. 100, which outlines safety requirements for electric power train vehicles. This regulation includes provisions for battery grounding and protection against electric shock.

The International Electrotechnical Commission (IEC) has published IEC 62619, which specifies safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard includes guidelines for battery management systems and grounding techniques to ensure safe operation.

In the European Union, the Battery Directive (2006/66/EC) sets requirements for battery manufacturers and importers, including safety measures and proper disposal procedures. While not specifically addressing grounding techniques, this directive emphasizes the importance of overall battery safety.

The Institute of Electrical and Electronics Engineers (IEEE) has developed IEEE 1725, a standard for rechargeable batteries in mobile devices. Although primarily focused on consumer electronics, this standard provides valuable insights into battery safety practices that can be applied to AGM batteries.

Compliance with these regulatory frameworks is essential for manufacturers and users of AGM batteries. Proper grounding techniques, as outlined in these regulations, play a crucial role in preventing electrical hazards, reducing the risk of fire or explosion, and ensuring the overall safety of battery systems.

As technology advances and new battery chemistries emerge, regulatory bodies continue to update and refine their safety standards. This ongoing process ensures that safety measures, including grounding techniques, remain effective in addressing evolving risks associated with battery technologies.

Environmental Impact of AGM Battery Grounding

The environmental impact of AGM battery grounding techniques is a critical consideration in the overall safety evaluation of these systems. Proper grounding not only ensures operational safety but also plays a significant role in minimizing potential environmental hazards.

One of the primary environmental concerns related to AGM battery grounding is the risk of soil and water contamination. Improper grounding can lead to electrolyte leakage, which may contain harmful substances such as sulfuric acid. When these chemicals seep into the soil or water systems, they can cause long-term ecological damage, affecting plant life, aquatic organisms, and potentially entering the food chain.

Electromagnetic interference (EMI) is another environmental factor influenced by AGM battery grounding techniques. Inadequate grounding can result in increased EMI, which may disrupt nearby electronic systems and potentially affect wildlife communication patterns. Proper grounding helps mitigate these electromagnetic emissions, reducing the overall environmental electromagnetic pollution.

The choice of grounding materials also has environmental implications. Traditional grounding methods often rely on copper or other metallic components, which require resource-intensive mining and processing. Advanced grounding techniques that utilize more sustainable materials or reduce the overall material requirements can significantly lower the environmental footprint of AGM battery installations.

Energy efficiency is an indirect environmental benefit of effective grounding. Well-grounded AGM battery systems tend to operate more efficiently, reducing energy losses and, consequently, the overall energy demand. This efficiency translates to lower greenhouse gas emissions associated with power generation, contributing to broader environmental protection goals.

Recycling and end-of-life considerations are crucial aspects of the environmental impact assessment. Proper grounding design can facilitate easier and safer battery removal and recycling processes. This approach helps in reducing the amount of hazardous waste and promotes the recovery of valuable materials, aligning with circular economy principles.

Lastly, the environmental impact of AGM battery grounding extends to human health and safety. By preventing electrical accidents and fires, effective grounding techniques reduce the risk of releasing toxic fumes and chemicals into the atmosphere during potential incidents. This protection indirectly contributes to maintaining air quality and overall environmental health in the vicinity of AGM battery installations.

One of the primary environmental concerns related to AGM battery grounding is the risk of soil and water contamination. Improper grounding can lead to electrolyte leakage, which may contain harmful substances such as sulfuric acid. When these chemicals seep into the soil or water systems, they can cause long-term ecological damage, affecting plant life, aquatic organisms, and potentially entering the food chain.

Electromagnetic interference (EMI) is another environmental factor influenced by AGM battery grounding techniques. Inadequate grounding can result in increased EMI, which may disrupt nearby electronic systems and potentially affect wildlife communication patterns. Proper grounding helps mitigate these electromagnetic emissions, reducing the overall environmental electromagnetic pollution.

The choice of grounding materials also has environmental implications. Traditional grounding methods often rely on copper or other metallic components, which require resource-intensive mining and processing. Advanced grounding techniques that utilize more sustainable materials or reduce the overall material requirements can significantly lower the environmental footprint of AGM battery installations.

Energy efficiency is an indirect environmental benefit of effective grounding. Well-grounded AGM battery systems tend to operate more efficiently, reducing energy losses and, consequently, the overall energy demand. This efficiency translates to lower greenhouse gas emissions associated with power generation, contributing to broader environmental protection goals.

Recycling and end-of-life considerations are crucial aspects of the environmental impact assessment. Proper grounding design can facilitate easier and safer battery removal and recycling processes. This approach helps in reducing the amount of hazardous waste and promotes the recovery of valuable materials, aligning with circular economy principles.

Lastly, the environmental impact of AGM battery grounding extends to human health and safety. By preventing electrical accidents and fires, effective grounding techniques reduce the risk of releasing toxic fumes and chemicals into the atmosphere during potential incidents. This protection indirectly contributes to maintaining air quality and overall environmental health in the vicinity of AGM battery installations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!