Comparative Operating Conditions for AGM Battery and Supercapacitors

AUG 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery and Supercapacitor Background

AGM (Absorbent Glass Mat) batteries and supercapacitors are two distinct energy storage technologies that have gained significant attention in various applications. AGM batteries, developed in the 1970s, are a type of lead-acid battery that uses a glass mat separator to hold the electrolyte. This design allows for a maintenance-free and spill-proof battery with improved performance characteristics compared to traditional flooded lead-acid batteries.

Supercapacitors, also known as ultracapacitors or electric double-layer capacitors (EDLCs), emerged in the 1950s but have seen rapid development in recent decades. These devices store energy through the separation of charges at the interface between an electrolyte and a high surface area electrode material, typically activated carbon.

The operating conditions for AGM batteries and supercapacitors differ significantly due to their distinct energy storage mechanisms. AGM batteries rely on chemical reactions to store and release energy, while supercapacitors store energy electrostatically. This fundamental difference leads to contrasting performance characteristics and operational requirements.

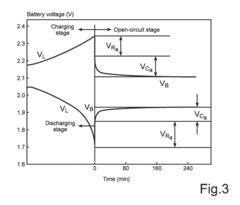

AGM batteries typically operate within a voltage range of 2.0 to 2.4 volts per cell, with a nominal voltage of 2.1 volts. They have a relatively narrow operating temperature range, generally between -20°C and 50°C, with optimal performance around 25°C. The cycle life of AGM batteries is typically in the range of 300 to 500 cycles, depending on depth of discharge and operating conditions.

In contrast, supercapacitors operate over a wider voltage range, typically from 0 to 2.7 volts for single cells, with some advanced designs reaching up to 3.0 volts. They can function effectively across a broader temperature range, from -40°C to 65°C or even higher in some cases. Supercapacitors boast an exceptionally long cycle life, often exceeding 500,000 cycles with minimal degradation.

The charging and discharging characteristics of these technologies also differ substantially. AGM batteries require careful charging protocols to prevent overcharging and sulfation, typically involving constant current followed by constant voltage phases. Supercapacitors, on the other hand, can be charged and discharged rapidly without the need for complex charging algorithms, making them suitable for high-power applications with frequent charge-discharge cycles.

Supercapacitors, also known as ultracapacitors or electric double-layer capacitors (EDLCs), emerged in the 1950s but have seen rapid development in recent decades. These devices store energy through the separation of charges at the interface between an electrolyte and a high surface area electrode material, typically activated carbon.

The operating conditions for AGM batteries and supercapacitors differ significantly due to their distinct energy storage mechanisms. AGM batteries rely on chemical reactions to store and release energy, while supercapacitors store energy electrostatically. This fundamental difference leads to contrasting performance characteristics and operational requirements.

AGM batteries typically operate within a voltage range of 2.0 to 2.4 volts per cell, with a nominal voltage of 2.1 volts. They have a relatively narrow operating temperature range, generally between -20°C and 50°C, with optimal performance around 25°C. The cycle life of AGM batteries is typically in the range of 300 to 500 cycles, depending on depth of discharge and operating conditions.

In contrast, supercapacitors operate over a wider voltage range, typically from 0 to 2.7 volts for single cells, with some advanced designs reaching up to 3.0 volts. They can function effectively across a broader temperature range, from -40°C to 65°C or even higher in some cases. Supercapacitors boast an exceptionally long cycle life, often exceeding 500,000 cycles with minimal degradation.

The charging and discharging characteristics of these technologies also differ substantially. AGM batteries require careful charging protocols to prevent overcharging and sulfation, typically involving constant current followed by constant voltage phases. Supercapacitors, on the other hand, can be charged and discharged rapidly without the need for complex charging algorithms, making them suitable for high-power applications with frequent charge-discharge cycles.

Market Analysis for Energy Storage Solutions

The energy storage solutions market has witnessed significant growth in recent years, driven by the increasing demand for reliable and efficient power management systems across various industries. This market encompasses a wide range of technologies, including AGM (Absorbent Glass Mat) batteries and supercapacitors, which are gaining prominence due to their unique operating characteristics and applications.

AGM batteries have established a strong presence in the market, particularly in automotive, marine, and backup power systems. Their popularity stems from their maintenance-free nature, high discharge rates, and improved safety compared to traditional lead-acid batteries. The global AGM battery market has been experiencing steady growth, with a notable increase in adoption for start-stop vehicle systems and renewable energy storage applications.

Supercapacitors, on the other hand, have been carving out their niche in the energy storage market, offering rapid charge and discharge capabilities, high power density, and long cycle life. These attributes make them particularly suitable for applications requiring quick bursts of power, such as regenerative braking systems in electric vehicles, grid stabilization, and consumer electronics.

The market dynamics for both AGM batteries and supercapacitors are influenced by several factors. The automotive sector, in particular, has been a significant driver for AGM batteries, with the growing adoption of start-stop technology in vehicles to improve fuel efficiency and reduce emissions. This trend is expected to continue as automotive manufacturers strive to meet stringent environmental regulations.

In the realm of renewable energy, both AGM batteries and supercapacitors play crucial roles in addressing the intermittency issues associated with solar and wind power generation. AGM batteries are often used for longer-term energy storage, while supercapacitors excel in managing short-term power fluctuations and improving grid stability.

The industrial sector presents another significant market opportunity for both technologies. AGM batteries are widely used in uninterruptible power supply (UPS) systems, while supercapacitors find applications in industrial machinery, robotics, and automation systems that require rapid energy delivery.

As the global focus on sustainability and energy efficiency intensifies, the market for advanced energy storage solutions is expected to expand further. This growth is likely to be fueled by ongoing research and development efforts aimed at improving the performance, cost-effectiveness, and environmental impact of both AGM batteries and supercapacitors.

AGM batteries have established a strong presence in the market, particularly in automotive, marine, and backup power systems. Their popularity stems from their maintenance-free nature, high discharge rates, and improved safety compared to traditional lead-acid batteries. The global AGM battery market has been experiencing steady growth, with a notable increase in adoption for start-stop vehicle systems and renewable energy storage applications.

Supercapacitors, on the other hand, have been carving out their niche in the energy storage market, offering rapid charge and discharge capabilities, high power density, and long cycle life. These attributes make them particularly suitable for applications requiring quick bursts of power, such as regenerative braking systems in electric vehicles, grid stabilization, and consumer electronics.

The market dynamics for both AGM batteries and supercapacitors are influenced by several factors. The automotive sector, in particular, has been a significant driver for AGM batteries, with the growing adoption of start-stop technology in vehicles to improve fuel efficiency and reduce emissions. This trend is expected to continue as automotive manufacturers strive to meet stringent environmental regulations.

In the realm of renewable energy, both AGM batteries and supercapacitors play crucial roles in addressing the intermittency issues associated with solar and wind power generation. AGM batteries are often used for longer-term energy storage, while supercapacitors excel in managing short-term power fluctuations and improving grid stability.

The industrial sector presents another significant market opportunity for both technologies. AGM batteries are widely used in uninterruptible power supply (UPS) systems, while supercapacitors find applications in industrial machinery, robotics, and automation systems that require rapid energy delivery.

As the global focus on sustainability and energy efficiency intensifies, the market for advanced energy storage solutions is expected to expand further. This growth is likely to be fueled by ongoing research and development efforts aimed at improving the performance, cost-effectiveness, and environmental impact of both AGM batteries and supercapacitors.

Technical Challenges in AGM and Supercapacitor Systems

AGM batteries and supercapacitors, while both energy storage devices, face distinct technical challenges in their operation and implementation. AGM batteries, known for their reliability and low maintenance, struggle with issues related to charge acceptance and cycle life. The primary challenge lies in optimizing the charge acceptance rate without compromising the battery's longevity. Rapid charging can lead to increased internal resistance and premature aging of the battery plates.

Supercapacitors, on the other hand, excel in rapid charge and discharge capabilities but face challenges in energy density and self-discharge rates. The main technical hurdle for supercapacitors is increasing their energy storage capacity while maintaining their high power density. Current supercapacitor technologies often suffer from significant self-discharge, which limits their effectiveness in long-term energy storage applications.

Both technologies face challenges in thermal management. AGM batteries are sensitive to temperature extremes, with performance degradation occurring at both high and low temperatures. This necessitates complex thermal management systems in applications where temperature control is critical. Supercapacitors, while generally more temperature-tolerant, can experience increased self-discharge rates and reduced capacitance at elevated temperatures.

Voltage balancing presents another significant challenge, particularly in large-scale applications. For AGM batteries in series configurations, ensuring uniform charging across all cells is crucial to prevent overcharging and undercharging, which can lead to reduced overall system performance and lifespan. Supercapacitors face similar challenges, with voltage imbalances potentially leading to accelerated aging of individual cells and reduced system reliability.

The integration of these technologies into existing power systems poses additional challenges. AGM batteries often require specific charging profiles and management systems to optimize their performance and lifespan. Supercapacitors, due to their rapid charge and discharge characteristics, necessitate sophisticated power electronics to effectively manage energy flow and prevent system instabilities.

Lastly, both technologies face challenges in scalability and cost-effectiveness for large-scale energy storage applications. AGM batteries struggle with weight and space constraints in high-capacity installations, while supercapacitors face economic barriers due to their higher cost per unit of energy stored. Overcoming these challenges requires innovative approaches in materials science, manufacturing processes, and system integration strategies.

Supercapacitors, on the other hand, excel in rapid charge and discharge capabilities but face challenges in energy density and self-discharge rates. The main technical hurdle for supercapacitors is increasing their energy storage capacity while maintaining their high power density. Current supercapacitor technologies often suffer from significant self-discharge, which limits their effectiveness in long-term energy storage applications.

Both technologies face challenges in thermal management. AGM batteries are sensitive to temperature extremes, with performance degradation occurring at both high and low temperatures. This necessitates complex thermal management systems in applications where temperature control is critical. Supercapacitors, while generally more temperature-tolerant, can experience increased self-discharge rates and reduced capacitance at elevated temperatures.

Voltage balancing presents another significant challenge, particularly in large-scale applications. For AGM batteries in series configurations, ensuring uniform charging across all cells is crucial to prevent overcharging and undercharging, which can lead to reduced overall system performance and lifespan. Supercapacitors face similar challenges, with voltage imbalances potentially leading to accelerated aging of individual cells and reduced system reliability.

The integration of these technologies into existing power systems poses additional challenges. AGM batteries often require specific charging profiles and management systems to optimize their performance and lifespan. Supercapacitors, due to their rapid charge and discharge characteristics, necessitate sophisticated power electronics to effectively manage energy flow and prevent system instabilities.

Lastly, both technologies face challenges in scalability and cost-effectiveness for large-scale energy storage applications. AGM batteries struggle with weight and space constraints in high-capacity installations, while supercapacitors face economic barriers due to their higher cost per unit of energy stored. Overcoming these challenges requires innovative approaches in materials science, manufacturing processes, and system integration strategies.

Current AGM and Supercapacitor Solutions

01 Temperature management for AGM batteries and supercapacitors

Effective temperature management is crucial for optimal performance and longevity of AGM batteries and supercapacitors. This includes cooling systems, thermal management strategies, and temperature monitoring to maintain ideal operating conditions and prevent overheating or thermal runaway.- Temperature management for AGM batteries and supercapacitors: Effective temperature management is crucial for optimal performance and longevity of AGM batteries and supercapacitors. This includes cooling systems, thermal insulation, and temperature monitoring to maintain ideal operating conditions and prevent overheating or thermal runaway.

- Charge and discharge control strategies: Implementing advanced charge and discharge control strategies is essential for AGM batteries and supercapacitors. This involves optimizing charging rates, managing depth of discharge, and utilizing intelligent control algorithms to maximize efficiency and extend the lifespan of the energy storage devices.

- Integration of AGM batteries and supercapacitors in hybrid systems: Combining AGM batteries and supercapacitors in hybrid energy storage systems can leverage the strengths of both technologies. This integration requires careful design considerations, including power management, load balancing, and optimized energy flow between the two components to enhance overall system performance.

- Monitoring and diagnostics for AGM batteries and supercapacitors: Advanced monitoring and diagnostic systems are crucial for maintaining optimal operating conditions. These systems include real-time performance tracking, predictive maintenance algorithms, and fault detection mechanisms to ensure reliable operation and early identification of potential issues.

- Environmental and safety considerations: Addressing environmental and safety concerns is vital for AGM batteries and supercapacitors. This includes implementing protective measures against overcharging, short circuits, and thermal runaway, as well as considering the environmental impact of materials used and end-of-life disposal or recycling processes.

02 Charge and discharge control for hybrid energy storage systems

Advanced control strategies are implemented to manage the charge and discharge cycles of combined AGM battery and supercapacitor systems. These methods optimize power distribution, extend system lifespan, and improve overall energy efficiency in various applications such as electric vehicles and renewable energy storage.Expand Specific Solutions03 Integration of AGM batteries and supercapacitors in power systems

Innovative designs for integrating AGM batteries and supercapacitors in power systems are developed to leverage the strengths of both technologies. This includes novel circuit configurations, power management units, and system architectures that enhance energy density, power output, and system reliability.Expand Specific Solutions04 Monitoring and diagnostics for hybrid energy storage systems

Advanced monitoring and diagnostic techniques are employed to assess the health, performance, and state of charge of AGM batteries and supercapacitors in hybrid systems. These methods include real-time data analysis, predictive maintenance algorithms, and smart sensor technologies to optimize system operation and prevent failures.Expand Specific Solutions05 Environmental and safety considerations for AGM batteries and supercapacitors

Design and operational strategies are implemented to address environmental and safety concerns related to AGM batteries and supercapacitors. This includes the development of eco-friendly materials, safe disposal methods, and protective measures against potential hazards such as short circuits, overcharging, and electrolyte leakage.Expand Specific Solutions

Key Players in Energy Storage Industry

The comparative operating conditions for AGM batteries and supercapacitors reflect a dynamic and evolving market. The industry is in a growth phase, with increasing demand for energy storage solutions across various sectors. The global market size for these technologies is expanding rapidly, driven by applications in automotive, renewable energy, and consumer electronics. Technologically, both AGM batteries and supercapacitors are maturing, with companies like Shanghai Aowei Technology, Daramic LLC, and StoreDot Ltd leading innovations. Established players such as Panasonic Energy Co. Ltd and LG Chem Ltd are investing heavily in research and development, while newer entrants like Honeycomb Battery Co. are bringing fresh approaches to the field. The competition is intensifying as manufacturers strive to improve energy density, charging speeds, and overall performance.

Panasonic Energy Co. Ltd.

Technical Solution: Panasonic Energy has made significant advancements in both AGM battery and supercapacitor technologies. For AGM batteries, they have developed a high-performance line specifically designed for automotive applications, featuring enhanced durability and improved charge acceptance[4]. Their AGM batteries utilize advanced lead-calcium alloy grids and high-purity acid electrolyte to maximize performance and lifespan. In the supercapacitor domain, Panasonic has introduced a range of electric double-layer capacitors (EDLCs) with high power density and long cycle life[5]. These supercapacitors are designed to complement batteries in hybrid energy storage systems, providing rapid charge and discharge capabilities for applications such as regenerative braking in vehicles[6].

Strengths: Diverse product portfolio covering both AGM batteries and supercapacitors, enabling integrated energy storage solutions. Weaknesses: Supercapacitors have lower energy density compared to batteries, limiting their standalone use in some applications.

GM Global Technology Operations LLC

Technical Solution: GM has invested heavily in research and development of advanced energy storage technologies, including both AGM batteries and supercapacitors. For AGM batteries, GM has focused on optimizing performance for automotive applications, particularly in start-stop systems and mild hybrid vehicles. Their AGM batteries feature enhanced charge acceptance and improved cycle life compared to traditional lead-acid batteries[11]. In the supercapacitor domain, GM has explored the integration of supercapacitors with batteries to create hybrid energy storage systems. These systems leverage the high power density of supercapacitors to complement the high energy density of batteries, enabling improved performance in applications such as regenerative braking and power assist in hybrid vehicles[12].

Strengths: Extensive automotive expertise and ability to integrate energy storage solutions directly into vehicle designs. Weaknesses: Primary focus on automotive applications may limit advancements in other sectors.

Core Innovations in Energy Storage

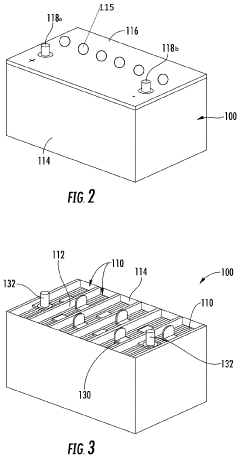

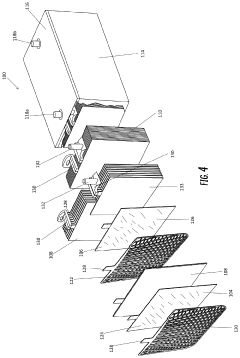

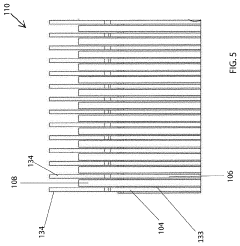

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

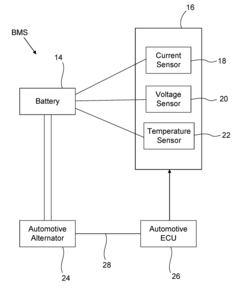

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Environmental Impact Assessment

The environmental impact assessment of AGM batteries and supercapacitors is crucial for understanding their sustainability and long-term viability. AGM batteries, while widely used, have several environmental concerns. The lead content in these batteries poses significant risks during production, use, and disposal. Lead mining and processing contribute to soil and water pollution, and improper disposal can lead to environmental contamination. However, AGM batteries have a high recycling rate, with up to 99% of lead-acid batteries being recyclable, which helps mitigate some of these concerns.

Supercapacitors, on the other hand, generally have a lower environmental impact compared to AGM batteries. They typically use carbon-based materials, which are less toxic and more environmentally friendly than lead. The production process for supercapacitors is generally less energy-intensive and produces fewer harmful emissions. Additionally, supercapacitors have a longer cycle life, which reduces the frequency of replacement and associated waste.

In terms of energy efficiency, supercapacitors outperform AGM batteries. They can charge and discharge rapidly with minimal energy loss, leading to better overall energy utilization. This efficiency translates to reduced energy consumption over the device's lifetime, indirectly lowering the carbon footprint associated with energy production.

The end-of-life management for both technologies differs significantly. While AGM batteries require careful handling due to their lead content, supercapacitors are generally easier and safer to dispose of. However, the recycling infrastructure for supercapacitors is less developed compared to that of lead-acid batteries, which may lead to more e-waste if proper recycling systems are not established.

When considering the operational lifespan, supercapacitors typically last longer than AGM batteries under similar conditions. This extended lifespan reduces the need for frequent replacements, thereby decreasing the overall environmental impact associated with manufacturing and disposal.

In conclusion, while both technologies have environmental implications, supercapacitors generally offer a more environmentally friendly alternative to AGM batteries. However, the full environmental impact depends on factors such as production methods, energy sources used during operation, and end-of-life management practices. As technology advances, improvements in both AGM battery and supercapacitor designs may further reduce their environmental footprints, making ongoing assessment and comparison necessary.

Supercapacitors, on the other hand, generally have a lower environmental impact compared to AGM batteries. They typically use carbon-based materials, which are less toxic and more environmentally friendly than lead. The production process for supercapacitors is generally less energy-intensive and produces fewer harmful emissions. Additionally, supercapacitors have a longer cycle life, which reduces the frequency of replacement and associated waste.

In terms of energy efficiency, supercapacitors outperform AGM batteries. They can charge and discharge rapidly with minimal energy loss, leading to better overall energy utilization. This efficiency translates to reduced energy consumption over the device's lifetime, indirectly lowering the carbon footprint associated with energy production.

The end-of-life management for both technologies differs significantly. While AGM batteries require careful handling due to their lead content, supercapacitors are generally easier and safer to dispose of. However, the recycling infrastructure for supercapacitors is less developed compared to that of lead-acid batteries, which may lead to more e-waste if proper recycling systems are not established.

When considering the operational lifespan, supercapacitors typically last longer than AGM batteries under similar conditions. This extended lifespan reduces the need for frequent replacements, thereby decreasing the overall environmental impact associated with manufacturing and disposal.

In conclusion, while both technologies have environmental implications, supercapacitors generally offer a more environmentally friendly alternative to AGM batteries. However, the full environmental impact depends on factors such as production methods, energy sources used during operation, and end-of-life management practices. As technology advances, improvements in both AGM battery and supercapacitor designs may further reduce their environmental footprints, making ongoing assessment and comparison necessary.

Cost-Benefit Analysis of AGM vs Supercapacitors

The cost-benefit analysis of AGM (Absorbent Glass Mat) batteries versus supercapacitors reveals significant differences in their economic and operational characteristics. This comparison is crucial for decision-makers in various industries, particularly in automotive, renewable energy, and consumer electronics sectors.

AGM batteries, known for their reliability and cost-effectiveness, offer a lower initial investment compared to supercapacitors. The average cost per kWh for AGM batteries ranges from $150 to $200, while supercapacitors can cost between $2,000 to $5,000 per kWh. This substantial price difference makes AGM batteries more attractive for applications where large energy storage capacity is required at a lower cost.

However, the long-term operational costs favor supercapacitors. AGM batteries typically have a lifespan of 3-7 years, depending on usage conditions, while supercapacitors can last 10-15 years or more. This extended lifespan translates to reduced replacement costs and maintenance expenses over time. Supercapacitors also offer superior cycle life, capable of hundreds of thousands of charge-discharge cycles compared to the few thousand cycles of AGM batteries.

Energy efficiency is another area where supercapacitors excel. They can achieve charge-discharge efficiencies of up to 95%, whereas AGM batteries typically range from 80-85%. This higher efficiency results in lower energy losses and potentially reduced operational costs, especially in applications with frequent charge-discharge cycles.

The power density of supercapacitors significantly outperforms AGM batteries. Supercapacitors can deliver high power bursts quickly, making them ideal for applications requiring rapid energy release. This characteristic can lead to improved system performance and potentially reduce the need for oversized energy storage systems in certain applications.

However, AGM batteries maintain an advantage in energy density, storing more energy per unit volume or weight. This makes them more suitable for applications where space is limited or weight is a concern, such as in portable devices or certain automotive applications.

Maintenance requirements also differ significantly. AGM batteries require periodic maintenance and may need electrolyte replacement, while supercapacitors are virtually maintenance-free. This difference can impact the total cost of ownership, particularly in large-scale installations or remote locations where maintenance access is challenging.

In conclusion, the choice between AGM batteries and supercapacitors depends on the specific application requirements and long-term cost considerations. While AGM batteries offer lower upfront costs and higher energy density, supercapacitors provide superior longevity, efficiency, and power density. A thorough analysis of the application's energy and power needs, lifecycle costs, and operational conditions is essential to determine the most cost-effective solution.

AGM batteries, known for their reliability and cost-effectiveness, offer a lower initial investment compared to supercapacitors. The average cost per kWh for AGM batteries ranges from $150 to $200, while supercapacitors can cost between $2,000 to $5,000 per kWh. This substantial price difference makes AGM batteries more attractive for applications where large energy storage capacity is required at a lower cost.

However, the long-term operational costs favor supercapacitors. AGM batteries typically have a lifespan of 3-7 years, depending on usage conditions, while supercapacitors can last 10-15 years or more. This extended lifespan translates to reduced replacement costs and maintenance expenses over time. Supercapacitors also offer superior cycle life, capable of hundreds of thousands of charge-discharge cycles compared to the few thousand cycles of AGM batteries.

Energy efficiency is another area where supercapacitors excel. They can achieve charge-discharge efficiencies of up to 95%, whereas AGM batteries typically range from 80-85%. This higher efficiency results in lower energy losses and potentially reduced operational costs, especially in applications with frequent charge-discharge cycles.

The power density of supercapacitors significantly outperforms AGM batteries. Supercapacitors can deliver high power bursts quickly, making them ideal for applications requiring rapid energy release. This characteristic can lead to improved system performance and potentially reduce the need for oversized energy storage systems in certain applications.

However, AGM batteries maintain an advantage in energy density, storing more energy per unit volume or weight. This makes them more suitable for applications where space is limited or weight is a concern, such as in portable devices or certain automotive applications.

Maintenance requirements also differ significantly. AGM batteries require periodic maintenance and may need electrolyte replacement, while supercapacitors are virtually maintenance-free. This difference can impact the total cost of ownership, particularly in large-scale installations or remote locations where maintenance access is challenging.

In conclusion, the choice between AGM batteries and supercapacitors depends on the specific application requirements and long-term cost considerations. While AGM batteries offer lower upfront costs and higher energy density, supercapacitors provide superior longevity, efficiency, and power density. A thorough analysis of the application's energy and power needs, lifecycle costs, and operational conditions is essential to determine the most cost-effective solution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!