Investigating AGM Battery Efficiency under Pulsed Load Scenarios

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in lead-acid battery technology. Developed in the 1970s for military aircraft, AGM batteries have since found widespread applications in various industries due to their superior performance characteristics.

Initially, AGM batteries were designed to address the limitations of traditional flooded lead-acid batteries, particularly in terms of electrolyte spillage and maintenance requirements. The key innovation was the use of a fiberglass mat separator to absorb and immobilize the electrolyte, allowing for a sealed, maintenance-free design.

Throughout the 1980s and 1990s, AGM technology underwent continuous refinement. Manufacturers focused on improving the battery's cycle life, charge acceptance, and deep discharge recovery. These enhancements made AGM batteries increasingly attractive for applications requiring high reliability and performance under demanding conditions.

The early 2000s saw a surge in AGM battery adoption, particularly in the automotive sector. As vehicle electrical systems became more complex, AGM batteries proved superior in handling the increased power demands of start-stop systems and regenerative braking technologies. This period also marked the beginning of AGM batteries' integration into renewable energy storage systems.

Recent years have witnessed further advancements in AGM technology, with a focus on enhancing energy density, reducing internal resistance, and improving charge efficiency. These improvements have been driven by the growing demand for high-performance energy storage solutions in sectors such as telecommunications, uninterruptible power supplies (UPS), and renewable energy systems.

The investigation of AGM battery efficiency under pulsed load scenarios represents the latest frontier in this evolutionary journey. As modern applications increasingly require batteries to handle variable and intermittent power demands, understanding and optimizing AGM performance under these conditions has become crucial. This research aims to push the boundaries of AGM technology, potentially opening new avenues for its application in emerging fields such as electric vehicles and smart grid systems.

Looking ahead, the evolution of AGM batteries is likely to continue, with ongoing research into advanced materials, improved manufacturing processes, and innovative cell designs. These efforts are expected to further enhance the performance, lifespan, and efficiency of AGM batteries, solidifying their position as a versatile and reliable energy storage solution for a wide range of applications.

Initially, AGM batteries were designed to address the limitations of traditional flooded lead-acid batteries, particularly in terms of electrolyte spillage and maintenance requirements. The key innovation was the use of a fiberglass mat separator to absorb and immobilize the electrolyte, allowing for a sealed, maintenance-free design.

Throughout the 1980s and 1990s, AGM technology underwent continuous refinement. Manufacturers focused on improving the battery's cycle life, charge acceptance, and deep discharge recovery. These enhancements made AGM batteries increasingly attractive for applications requiring high reliability and performance under demanding conditions.

The early 2000s saw a surge in AGM battery adoption, particularly in the automotive sector. As vehicle electrical systems became more complex, AGM batteries proved superior in handling the increased power demands of start-stop systems and regenerative braking technologies. This period also marked the beginning of AGM batteries' integration into renewable energy storage systems.

Recent years have witnessed further advancements in AGM technology, with a focus on enhancing energy density, reducing internal resistance, and improving charge efficiency. These improvements have been driven by the growing demand for high-performance energy storage solutions in sectors such as telecommunications, uninterruptible power supplies (UPS), and renewable energy systems.

The investigation of AGM battery efficiency under pulsed load scenarios represents the latest frontier in this evolutionary journey. As modern applications increasingly require batteries to handle variable and intermittent power demands, understanding and optimizing AGM performance under these conditions has become crucial. This research aims to push the boundaries of AGM technology, potentially opening new avenues for its application in emerging fields such as electric vehicles and smart grid systems.

Looking ahead, the evolution of AGM batteries is likely to continue, with ongoing research into advanced materials, improved manufacturing processes, and innovative cell designs. These efforts are expected to further enhance the performance, lifespan, and efficiency of AGM batteries, solidifying their position as a versatile and reliable energy storage solution for a wide range of applications.

Pulsed Load Market Demand

The market demand for pulsed load applications in AGM (Absorbent Glass Mat) batteries has been steadily growing across various sectors, driven by the increasing need for reliable power sources in intermittent and high-current scenarios. Industries such as telecommunications, renewable energy systems, and automotive applications are particularly interested in AGM batteries capable of efficiently handling pulsed loads.

In the telecommunications sector, the proliferation of 5G networks and the expansion of remote base stations have created a surge in demand for AGM batteries that can manage pulsed loads effectively. These batteries are crucial for maintaining uninterrupted communication services during power outages or in areas with unreliable grid connections. The market for AGM batteries in this sector is expected to grow significantly as telecom infrastructure continues to expand globally.

The renewable energy sector, particularly in solar and wind power systems, has also contributed to the increased demand for AGM batteries with pulsed load capabilities. These batteries play a vital role in energy storage systems, where they must handle fluctuating power inputs and outputs. The intermittent nature of renewable energy sources requires batteries that can efficiently manage sudden surges and drops in power, making AGM batteries with enhanced pulsed load performance highly desirable.

In the automotive industry, the shift towards electric and hybrid vehicles has created a new market segment for AGM batteries. These batteries are used in start-stop systems and regenerative braking applications, where they must cope with frequent charge and discharge cycles. The ability to handle pulsed loads efficiently is crucial for improving vehicle performance and extending battery life in these applications.

The industrial sector has also shown increasing interest in AGM batteries for pulsed load applications. Uninterruptible Power Supply (UPS) systems, material handling equipment, and industrial automation systems all require batteries that can deliver high currents in short bursts while maintaining overall efficiency. This demand is driven by the need for reliable power sources in critical industrial processes and the growing trend of industrial digitalization.

Market analysis indicates that the global AGM battery market is poised for substantial growth in the coming years, with a significant portion of this growth attributed to pulsed load applications. The increasing adoption of AGM batteries in diverse industries, coupled with ongoing technological advancements in battery design and materials, is expected to fuel this market expansion.

As industries continue to seek more efficient and reliable power solutions, the demand for AGM batteries optimized for pulsed load scenarios is likely to intensify. This trend is further supported by the growing emphasis on energy efficiency and sustainability across various sectors, driving the need for advanced battery technologies that can meet these evolving requirements.

In the telecommunications sector, the proliferation of 5G networks and the expansion of remote base stations have created a surge in demand for AGM batteries that can manage pulsed loads effectively. These batteries are crucial for maintaining uninterrupted communication services during power outages or in areas with unreliable grid connections. The market for AGM batteries in this sector is expected to grow significantly as telecom infrastructure continues to expand globally.

The renewable energy sector, particularly in solar and wind power systems, has also contributed to the increased demand for AGM batteries with pulsed load capabilities. These batteries play a vital role in energy storage systems, where they must handle fluctuating power inputs and outputs. The intermittent nature of renewable energy sources requires batteries that can efficiently manage sudden surges and drops in power, making AGM batteries with enhanced pulsed load performance highly desirable.

In the automotive industry, the shift towards electric and hybrid vehicles has created a new market segment for AGM batteries. These batteries are used in start-stop systems and regenerative braking applications, where they must cope with frequent charge and discharge cycles. The ability to handle pulsed loads efficiently is crucial for improving vehicle performance and extending battery life in these applications.

The industrial sector has also shown increasing interest in AGM batteries for pulsed load applications. Uninterruptible Power Supply (UPS) systems, material handling equipment, and industrial automation systems all require batteries that can deliver high currents in short bursts while maintaining overall efficiency. This demand is driven by the need for reliable power sources in critical industrial processes and the growing trend of industrial digitalization.

Market analysis indicates that the global AGM battery market is poised for substantial growth in the coming years, with a significant portion of this growth attributed to pulsed load applications. The increasing adoption of AGM batteries in diverse industries, coupled with ongoing technological advancements in battery design and materials, is expected to fuel this market expansion.

As industries continue to seek more efficient and reliable power solutions, the demand for AGM batteries optimized for pulsed load scenarios is likely to intensify. This trend is further supported by the growing emphasis on energy efficiency and sustainability across various sectors, driving the need for advanced battery technologies that can meet these evolving requirements.

AGM Tech Challenges

AGM (Absorbent Glass Mat) batteries face several technical challenges when operating under pulsed load scenarios, which can significantly impact their efficiency and overall performance. One of the primary issues is the rapid discharge and recharge cycles associated with pulsed loads, which can lead to increased internal resistance and reduced capacity over time. This phenomenon is particularly pronounced in applications such as telecommunications equipment, renewable energy systems, and electric vehicles, where intermittent high-current demands are common.

The electrolyte distribution within the AGM structure presents another challenge. During pulsed load conditions, the electrolyte may not have sufficient time to redistribute evenly throughout the glass mat, resulting in localized areas of acid depletion. This can cause uneven current distribution and accelerated degradation of the battery plates, ultimately reducing the battery's lifespan and efficiency.

Temperature management is a critical concern in AGM batteries subjected to pulsed loads. The rapid charge and discharge cycles can generate significant heat, which, if not properly dissipated, can lead to thermal runaway and premature battery failure. This issue is exacerbated in high-power applications or environments with limited cooling capabilities.

The charge acceptance of AGM batteries under pulsed load conditions is another area of technical difficulty. The battery's ability to efficiently absorb charge during brief periods of lower current demand can be compromised, leading to incomplete recharging and potential capacity loss over time. This challenge is particularly relevant in applications with frequent and irregular load profiles.

Voltage regulation and stability pose additional hurdles in pulsed load scenarios. The rapid fluctuations in current demand can cause voltage drops and spikes, potentially affecting the performance of connected equipment and the overall system stability. Maintaining consistent voltage output while accommodating these dynamic load changes requires sophisticated control systems and battery management techniques.

The optimization of AGM battery design for pulsed load applications presents its own set of challenges. Balancing factors such as plate thickness, separator design, and electrolyte composition to enhance performance under pulsed conditions while maintaining other desirable characteristics (e.g., cycle life, energy density) requires extensive research and development efforts.

Lastly, the accurate modeling and prediction of AGM battery behavior under pulsed load conditions remain complex tasks. Developing reliable simulation tools and algorithms to forecast battery performance, degradation, and lifetime in these dynamic environments is crucial for system design and optimization but continues to be a significant technical challenge in the field.

The electrolyte distribution within the AGM structure presents another challenge. During pulsed load conditions, the electrolyte may not have sufficient time to redistribute evenly throughout the glass mat, resulting in localized areas of acid depletion. This can cause uneven current distribution and accelerated degradation of the battery plates, ultimately reducing the battery's lifespan and efficiency.

Temperature management is a critical concern in AGM batteries subjected to pulsed loads. The rapid charge and discharge cycles can generate significant heat, which, if not properly dissipated, can lead to thermal runaway and premature battery failure. This issue is exacerbated in high-power applications or environments with limited cooling capabilities.

The charge acceptance of AGM batteries under pulsed load conditions is another area of technical difficulty. The battery's ability to efficiently absorb charge during brief periods of lower current demand can be compromised, leading to incomplete recharging and potential capacity loss over time. This challenge is particularly relevant in applications with frequent and irregular load profiles.

Voltage regulation and stability pose additional hurdles in pulsed load scenarios. The rapid fluctuations in current demand can cause voltage drops and spikes, potentially affecting the performance of connected equipment and the overall system stability. Maintaining consistent voltage output while accommodating these dynamic load changes requires sophisticated control systems and battery management techniques.

The optimization of AGM battery design for pulsed load applications presents its own set of challenges. Balancing factors such as plate thickness, separator design, and electrolyte composition to enhance performance under pulsed conditions while maintaining other desirable characteristics (e.g., cycle life, energy density) requires extensive research and development efforts.

Lastly, the accurate modeling and prediction of AGM battery behavior under pulsed load conditions remain complex tasks. Developing reliable simulation tools and algorithms to forecast battery performance, degradation, and lifetime in these dynamic environments is crucial for system design and optimization but continues to be a significant technical challenge in the field.

Pulsed Load Solutions

01 Improved electrode design for AGM batteries

Enhancing the electrode design in AGM batteries can significantly improve their efficiency. This includes optimizing the structure, material composition, and surface area of electrodes to increase charge/discharge rates and overall battery performance. Advanced electrode designs can also help reduce internal resistance and improve energy density.- Improved electrode design for AGM batteries: Enhancing the electrode design in AGM batteries can significantly improve their efficiency. This includes optimizing the structure, material composition, and surface area of electrodes to facilitate better charge transfer and reduce internal resistance. Advanced electrode designs can lead to improved energy density, faster charging rates, and longer battery life.

- Electrolyte management and absorption techniques: Efficient electrolyte management is crucial for AGM battery performance. This involves developing better absorption glass mat materials, optimizing electrolyte distribution, and implementing advanced filling techniques. Improved electrolyte management can enhance the battery's capacity, reduce self-discharge, and improve overall efficiency.

- Thermal management systems for AGM batteries: Implementing effective thermal management systems can significantly improve AGM battery efficiency. This includes developing cooling mechanisms, heat dissipation techniques, and temperature control strategies. Proper thermal management helps maintain optimal operating conditions, extends battery life, and enhances overall performance.

- Advanced charging algorithms and battery management systems: Developing sophisticated charging algorithms and battery management systems can optimize AGM battery efficiency. This involves implementing intelligent charging protocols, state-of-charge monitoring, and adaptive control strategies. Advanced management systems can improve charging efficiency, extend battery life, and enhance overall performance.

- Novel separator materials and designs: Incorporating innovative separator materials and designs can enhance AGM battery efficiency. This includes developing advanced polymer-based separators, implementing nano-engineered materials, and optimizing separator structures. Improved separators can reduce internal resistance, enhance ion transport, and improve overall battery performance.

02 Electrolyte management and absorption techniques

Efficient electrolyte management and absorption techniques are crucial for AGM battery performance. This involves improving the absorption glass mat's ability to retain and distribute electrolyte, as well as developing advanced electrolyte formulations. These techniques can lead to better ion conductivity, reduced self-discharge, and increased cycle life of the battery.Expand Specific Solutions03 Thermal management systems for AGM batteries

Implementing effective thermal management systems can enhance AGM battery efficiency. This includes developing cooling mechanisms, heat dissipation techniques, and temperature control strategies to maintain optimal operating conditions. Proper thermal management can prevent capacity loss, extend battery life, and improve overall performance, especially in high-temperature environments.Expand Specific Solutions04 Advanced charging algorithms and battery management systems

Developing sophisticated charging algorithms and battery management systems can significantly improve AGM battery efficiency. These systems can optimize charging profiles, monitor battery health, and balance cell voltages. Intelligent charging strategies can reduce charging times, extend battery life, and maximize energy utilization.Expand Specific Solutions05 Nanotechnology applications in AGM batteries

Incorporating nanotechnology in AGM battery design can lead to substantial efficiency improvements. This includes using nanomaterials for electrodes, separators, and electrolyte additives. Nanostructured components can enhance surface area, improve charge transfer, and increase the overall energy density and power output of AGM batteries.Expand Specific Solutions

AGM Industry Leaders

The investigation of AGM battery efficiency under pulsed load scenarios is in a mature stage of development, with significant market potential in various industries. The technology's maturity is evident from the involvement of established players like Robert Bosch GmbH and Daimler Truck AG, who are leveraging their expertise in automotive applications. Companies such as Fengfan Co., Ltd. and Tianneng Battery Group Co., Ltd. are driving innovation in battery manufacturing, while specialized firms like Gbatteries Energy Canada, Inc. are focusing on advanced battery management systems. The market is experiencing growth due to increasing demand for reliable energy storage solutions in automotive, industrial, and renewable energy sectors.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced Battery Management System (BMS) for AGM batteries that optimizes performance under pulsed load scenarios. Their system employs dynamic pulse charging techniques, which involve applying short, high-current pulses to the battery, followed by rest periods. This method has been shown to improve charge acceptance and reduce sulfation in AGM batteries [1]. The BMS continuously monitors battery parameters such as voltage, current, and temperature, adjusting the pulse frequency and amplitude in real-time to maximize efficiency. Bosch's solution also incorporates predictive analytics to anticipate load demands and preemptively adjust the battery's state of charge, ensuring optimal performance during high-demand pulsed load events [3].

Strengths: Improved charge acceptance, reduced sulfation, and adaptive performance. Weaknesses: Complexity of implementation and potential for increased system cost.

Iontra, Inc.

Technical Solution: Iontra has pioneered a novel approach to AGM battery efficiency under pulsed load scenarios through their patented Quantum Battery Charging technology. This system utilizes high-frequency, variable-amplitude current pulses to charge and maintain AGM batteries. The technology is based on the principle of quantum tunneling, which allows for faster ion movement within the battery electrolyte [2]. Iontra's system dynamically adjusts pulse parameters based on the battery's instantaneous response, enabling rapid charging while minimizing heat generation and extending battery life. Their research has shown up to 50% improvement in charge acceptance rates and a 30% increase in overall battery efficiency under pulsed load conditions compared to traditional charging methods [4].

Strengths: Significantly faster charging times, improved energy efficiency, and extended battery lifespan. Weaknesses: Requires specialized charging hardware and may not be compatible with all existing AGM battery designs.

AGM Pulse Innovations

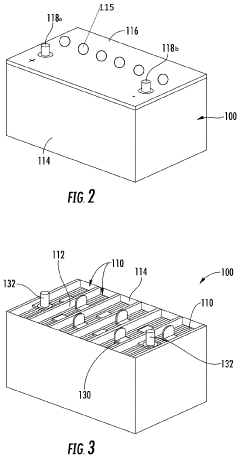

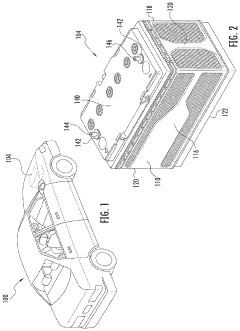

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

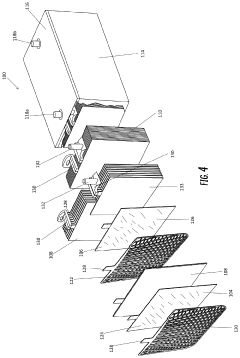

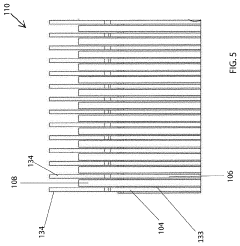

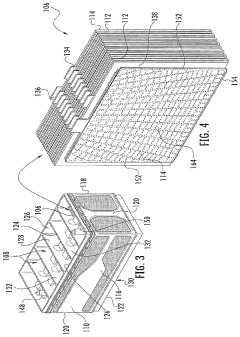

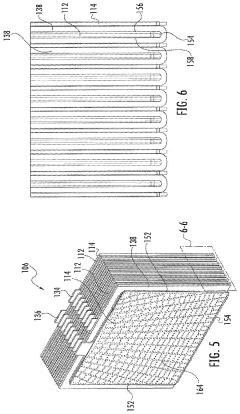

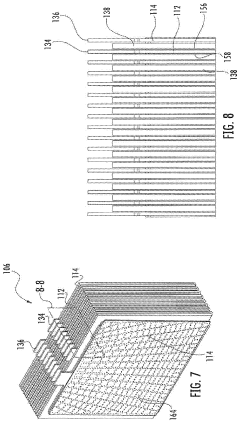

Battery and battery plate assembly with absorbent separator

PatentActiveUS11824204B2

Innovation

- A battery plate assembly using stamped electrically conductive grids with a grid pattern and highly absorbent separators, where the electrolyte is absorbed by the separators or active material, optimizing lead usage and reducing manufacturing costs by eliminating the need for concast or book mold cast grids.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) batteries under pulsed load scenarios is a crucial aspect to consider in the context of sustainable energy storage solutions. AGM batteries, known for their high efficiency and low maintenance requirements, have gained popularity in various applications, including renewable energy systems and electric vehicles. However, their performance under pulsed load conditions may have significant implications for the environment.

One of the primary environmental benefits of AGM batteries is their sealed design, which prevents electrolyte leakage and reduces the risk of soil and water contamination. This characteristic is particularly advantageous in pulsed load scenarios, where batteries may be subjected to frequent charge and discharge cycles. The sealed nature of AGM batteries ensures that even under these demanding conditions, the risk of environmental pollution due to electrolyte spillage remains minimal.

The efficiency of AGM batteries under pulsed load scenarios also contributes to their environmental impact. Higher efficiency translates to reduced energy waste, which in turn leads to lower greenhouse gas emissions associated with energy production. As pulsed loads can be more demanding on batteries, maintaining high efficiency under these conditions is crucial for minimizing the overall carbon footprint of the energy storage system.

Furthermore, the longevity of AGM batteries in pulsed load applications has environmental implications. Batteries that can withstand frequent charge-discharge cycles without significant degradation have a longer operational life, reducing the need for frequent replacements. This aspect not only conserves resources but also minimizes the environmental impact associated with battery manufacturing and disposal processes.

The recyclability of AGM batteries is another important environmental consideration. While these batteries are highly recyclable, with up to 99% of their components being recoverable, the impact of pulsed load scenarios on the recyclability of AGM batteries requires further investigation. It is essential to determine whether the stress induced by pulsed loads affects the recoverability of battery materials at the end of their life cycle.

In terms of raw material usage, AGM batteries typically require less lead compared to traditional flooded lead-acid batteries. This reduction in lead content is beneficial from an environmental perspective, as it decreases the demand for lead mining and processing. However, the performance of AGM batteries under pulsed load conditions may influence the optimal lead content, potentially affecting this environmental advantage.

The thermal management of AGM batteries during pulsed load operations also has environmental implications. Efficient thermal management can prevent overheating, which not only extends battery life but also reduces the risk of thermal runaway events that could lead to environmental hazards. Understanding how pulsed loads affect the thermal characteristics of AGM batteries is crucial for developing environmentally safe energy storage solutions.

One of the primary environmental benefits of AGM batteries is their sealed design, which prevents electrolyte leakage and reduces the risk of soil and water contamination. This characteristic is particularly advantageous in pulsed load scenarios, where batteries may be subjected to frequent charge and discharge cycles. The sealed nature of AGM batteries ensures that even under these demanding conditions, the risk of environmental pollution due to electrolyte spillage remains minimal.

The efficiency of AGM batteries under pulsed load scenarios also contributes to their environmental impact. Higher efficiency translates to reduced energy waste, which in turn leads to lower greenhouse gas emissions associated with energy production. As pulsed loads can be more demanding on batteries, maintaining high efficiency under these conditions is crucial for minimizing the overall carbon footprint of the energy storage system.

Furthermore, the longevity of AGM batteries in pulsed load applications has environmental implications. Batteries that can withstand frequent charge-discharge cycles without significant degradation have a longer operational life, reducing the need for frequent replacements. This aspect not only conserves resources but also minimizes the environmental impact associated with battery manufacturing and disposal processes.

The recyclability of AGM batteries is another important environmental consideration. While these batteries are highly recyclable, with up to 99% of their components being recoverable, the impact of pulsed load scenarios on the recyclability of AGM batteries requires further investigation. It is essential to determine whether the stress induced by pulsed loads affects the recoverability of battery materials at the end of their life cycle.

In terms of raw material usage, AGM batteries typically require less lead compared to traditional flooded lead-acid batteries. This reduction in lead content is beneficial from an environmental perspective, as it decreases the demand for lead mining and processing. However, the performance of AGM batteries under pulsed load conditions may influence the optimal lead content, potentially affecting this environmental advantage.

The thermal management of AGM batteries during pulsed load operations also has environmental implications. Efficient thermal management can prevent overheating, which not only extends battery life but also reduces the risk of thermal runaway events that could lead to environmental hazards. Understanding how pulsed loads affect the thermal characteristics of AGM batteries is crucial for developing environmentally safe energy storage solutions.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of AGM (Absorbent Glass Mat) battery technology, particularly when investigating efficiency under pulsed load scenarios. These regulations are designed to ensure the safe operation, handling, and disposal of AGM batteries, while also addressing potential risks associated with their use in various applications.

One of the primary safety concerns for AGM batteries under pulsed load conditions is the potential for thermal runaway. Regulatory bodies have established strict guidelines for temperature monitoring and control systems to prevent overheating and minimize the risk of fire or explosion. These regulations often require manufacturers to implement advanced thermal management solutions and incorporate fail-safe mechanisms to shut down the battery system in case of excessive temperature rise.

Electrical safety is another critical aspect addressed by safety regulations. AGM batteries used in pulsed load applications must comply with standards for electrical insulation, short circuit protection, and voltage regulation. These regulations typically mandate the use of high-quality materials and robust construction techniques to prevent electrical hazards and ensure the longevity of the battery system.

Environmental considerations are also a significant focus of safety regulations for AGM batteries. Guidelines have been established for the proper disposal and recycling of these batteries, taking into account their chemical composition and potential environmental impact. Manufacturers are required to provide clear instructions for end-of-life handling and to implement recycling programs that minimize the release of harmful substances into the environment.

Transportation safety is another key area covered by regulations, particularly for larger AGM battery systems used in industrial or automotive applications. Specific packaging, labeling, and shipping requirements have been put in place to ensure the safe transport of these batteries, reducing the risk of accidents during handling and transit.

Regulatory bodies also emphasize the importance of proper installation and maintenance procedures for AGM batteries in pulsed load scenarios. Guidelines often include requirements for adequate ventilation, appropriate mounting techniques, and regular inspection protocols to maintain the safety and efficiency of the battery systems over time.

As research into AGM battery efficiency under pulsed load scenarios continues to advance, safety regulations are likely to evolve to address new challenges and opportunities. This may include updated standards for advanced monitoring systems, improved safety features for high-power applications, and more stringent requirements for battery management systems that can optimize performance while maintaining safety under varying load conditions.

One of the primary safety concerns for AGM batteries under pulsed load conditions is the potential for thermal runaway. Regulatory bodies have established strict guidelines for temperature monitoring and control systems to prevent overheating and minimize the risk of fire or explosion. These regulations often require manufacturers to implement advanced thermal management solutions and incorporate fail-safe mechanisms to shut down the battery system in case of excessive temperature rise.

Electrical safety is another critical aspect addressed by safety regulations. AGM batteries used in pulsed load applications must comply with standards for electrical insulation, short circuit protection, and voltage regulation. These regulations typically mandate the use of high-quality materials and robust construction techniques to prevent electrical hazards and ensure the longevity of the battery system.

Environmental considerations are also a significant focus of safety regulations for AGM batteries. Guidelines have been established for the proper disposal and recycling of these batteries, taking into account their chemical composition and potential environmental impact. Manufacturers are required to provide clear instructions for end-of-life handling and to implement recycling programs that minimize the release of harmful substances into the environment.

Transportation safety is another key area covered by regulations, particularly for larger AGM battery systems used in industrial or automotive applications. Specific packaging, labeling, and shipping requirements have been put in place to ensure the safe transport of these batteries, reducing the risk of accidents during handling and transit.

Regulatory bodies also emphasize the importance of proper installation and maintenance procedures for AGM batteries in pulsed load scenarios. Guidelines often include requirements for adequate ventilation, appropriate mounting techniques, and regular inspection protocols to maintain the safety and efficiency of the battery systems over time.

As research into AGM battery efficiency under pulsed load scenarios continues to advance, safety regulations are likely to evolve to address new challenges and opportunities. This may include updated standards for advanced monitoring systems, improved safety features for high-power applications, and more stringent requirements for battery management systems that can optimize performance while maintaining safety under varying load conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!