Evaluating AGM Battery System Redundancy for High-Reliability Applications

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) battery technology has been a significant advancement in the field of energy storage, particularly for high-reliability applications. AGM batteries emerged in the 1980s as a response to the limitations of traditional flooded lead-acid batteries, offering improved performance and safety characteristics.

Initially developed for military aircraft, AGM batteries quickly found applications in various sectors due to their unique construction. The key innovation was the use of a fiberglass mat separator that absorbs and immobilizes the electrolyte, allowing for a spill-proof and maintenance-free design. This design also enabled higher charge and discharge rates, better vibration resistance, and improved cycle life compared to conventional lead-acid batteries.

Throughout the 1990s and early 2000s, AGM technology continued to evolve, with manufacturers focusing on enhancing energy density, cycle life, and overall performance. The introduction of thinner plates and more efficient electrode designs allowed for higher power output and faster recharge capabilities. These improvements made AGM batteries increasingly attractive for use in uninterruptible power supplies (UPS), telecommunications systems, and other critical infrastructure applications where reliability is paramount.

In the context of high-reliability applications, the evolution of AGM batteries has been particularly noteworthy. The technology's inherent characteristics, such as low internal resistance and minimal gassing during operation, have made it well-suited for environments where consistent performance and safety are critical. As the demand for reliable backup power systems grew, AGM batteries became a preferred choice in data centers, hospitals, and industrial control systems.

The early 2010s saw further advancements in AGM technology, with a focus on extending battery life and improving performance in extreme temperatures. Manufacturers developed new alloy compositions and grid designs to reduce corrosion and enhance durability. These improvements resulted in AGM batteries capable of maintaining their capacity and performance over longer periods, even under challenging operating conditions.

More recently, the evolution of AGM batteries has been driven by the need for greater energy efficiency and environmental sustainability. Researchers have explored ways to optimize the recycling process for AGM batteries, making them a more eco-friendly option compared to other battery technologies. Additionally, advancements in charging algorithms and battery management systems have further enhanced the efficiency and lifespan of AGM batteries in high-reliability applications.

As the demand for reliable energy storage solutions continues to grow, AGM battery technology remains at the forefront of innovation. Current research focuses on integrating smart monitoring capabilities, improving thermal management, and developing hybrid systems that combine AGM batteries with other energy storage technologies to maximize performance and reliability in critical applications.

Initially developed for military aircraft, AGM batteries quickly found applications in various sectors due to their unique construction. The key innovation was the use of a fiberglass mat separator that absorbs and immobilizes the electrolyte, allowing for a spill-proof and maintenance-free design. This design also enabled higher charge and discharge rates, better vibration resistance, and improved cycle life compared to conventional lead-acid batteries.

Throughout the 1990s and early 2000s, AGM technology continued to evolve, with manufacturers focusing on enhancing energy density, cycle life, and overall performance. The introduction of thinner plates and more efficient electrode designs allowed for higher power output and faster recharge capabilities. These improvements made AGM batteries increasingly attractive for use in uninterruptible power supplies (UPS), telecommunications systems, and other critical infrastructure applications where reliability is paramount.

In the context of high-reliability applications, the evolution of AGM batteries has been particularly noteworthy. The technology's inherent characteristics, such as low internal resistance and minimal gassing during operation, have made it well-suited for environments where consistent performance and safety are critical. As the demand for reliable backup power systems grew, AGM batteries became a preferred choice in data centers, hospitals, and industrial control systems.

The early 2010s saw further advancements in AGM technology, with a focus on extending battery life and improving performance in extreme temperatures. Manufacturers developed new alloy compositions and grid designs to reduce corrosion and enhance durability. These improvements resulted in AGM batteries capable of maintaining their capacity and performance over longer periods, even under challenging operating conditions.

More recently, the evolution of AGM batteries has been driven by the need for greater energy efficiency and environmental sustainability. Researchers have explored ways to optimize the recycling process for AGM batteries, making them a more eco-friendly option compared to other battery technologies. Additionally, advancements in charging algorithms and battery management systems have further enhanced the efficiency and lifespan of AGM batteries in high-reliability applications.

As the demand for reliable energy storage solutions continues to grow, AGM battery technology remains at the forefront of innovation. Current research focuses on integrating smart monitoring capabilities, improving thermal management, and developing hybrid systems that combine AGM batteries with other energy storage technologies to maximize performance and reliability in critical applications.

Market Demand Analysis

The market demand for AGM (Absorbent Glass Mat) battery systems with high reliability and redundancy is experiencing significant growth across various sectors. This surge is primarily driven by the increasing need for uninterrupted power supply in critical applications, where even momentary power failures can lead to substantial financial losses or safety risks.

In the telecommunications industry, the deployment of 5G networks and the expansion of data centers have created a robust demand for reliable backup power systems. AGM batteries, known for their low maintenance requirements and high performance in standby applications, are becoming a preferred choice for these installations. The global telecom power systems market, which heavily relies on AGM batteries, is projected to grow steadily over the next five years.

The healthcare sector represents another key market for high-reliability AGM battery systems. Hospitals, clinics, and medical research facilities require continuous power supply for life-support systems, diagnostic equipment, and data storage. The COVID-19 pandemic has further highlighted the critical nature of uninterrupted power in healthcare settings, leading to increased investments in redundant power systems.

In the industrial automation sector, the trend towards Industry 4.0 and smart manufacturing is driving the need for reliable power backup solutions. AGM batteries are increasingly being integrated into uninterruptible power supply (UPS) systems to ensure continuous operation of sensitive equipment and prevent data loss during power outages.

The renewable energy sector, particularly solar and wind power installations, is another growing market for AGM batteries. As these intermittent energy sources become more prevalent, the demand for efficient energy storage solutions with high reliability is rising. AGM batteries are often used in off-grid and hybrid renewable energy systems, providing stable power output and long service life.

The transportation sector, especially in the realm of electric and hybrid vehicles, is also contributing to the market demand for AGM batteries. While lithium-ion batteries dominate the main power supply, AGM batteries are frequently used in auxiliary systems and for backup purposes due to their reliability and safety characteristics.

Government and military applications represent a niche but high-value market for redundant AGM battery systems. These sectors require extremely reliable power sources for critical infrastructure, communication systems, and defense applications. The stringent performance and safety standards in these areas align well with the capabilities of AGM battery systems.

As organizations across various industries increasingly recognize the importance of business continuity and risk mitigation, the market for redundant AGM battery systems is expected to continue its upward trajectory. The global focus on infrastructure resilience and the growing awareness of the economic impact of power disruptions are likely to sustain this demand in the foreseeable future.

In the telecommunications industry, the deployment of 5G networks and the expansion of data centers have created a robust demand for reliable backup power systems. AGM batteries, known for their low maintenance requirements and high performance in standby applications, are becoming a preferred choice for these installations. The global telecom power systems market, which heavily relies on AGM batteries, is projected to grow steadily over the next five years.

The healthcare sector represents another key market for high-reliability AGM battery systems. Hospitals, clinics, and medical research facilities require continuous power supply for life-support systems, diagnostic equipment, and data storage. The COVID-19 pandemic has further highlighted the critical nature of uninterrupted power in healthcare settings, leading to increased investments in redundant power systems.

In the industrial automation sector, the trend towards Industry 4.0 and smart manufacturing is driving the need for reliable power backup solutions. AGM batteries are increasingly being integrated into uninterruptible power supply (UPS) systems to ensure continuous operation of sensitive equipment and prevent data loss during power outages.

The renewable energy sector, particularly solar and wind power installations, is another growing market for AGM batteries. As these intermittent energy sources become more prevalent, the demand for efficient energy storage solutions with high reliability is rising. AGM batteries are often used in off-grid and hybrid renewable energy systems, providing stable power output and long service life.

The transportation sector, especially in the realm of electric and hybrid vehicles, is also contributing to the market demand for AGM batteries. While lithium-ion batteries dominate the main power supply, AGM batteries are frequently used in auxiliary systems and for backup purposes due to their reliability and safety characteristics.

Government and military applications represent a niche but high-value market for redundant AGM battery systems. These sectors require extremely reliable power sources for critical infrastructure, communication systems, and defense applications. The stringent performance and safety standards in these areas align well with the capabilities of AGM battery systems.

As organizations across various industries increasingly recognize the importance of business continuity and risk mitigation, the market for redundant AGM battery systems is expected to continue its upward trajectory. The global focus on infrastructure resilience and the growing awareness of the economic impact of power disruptions are likely to sustain this demand in the foreseeable future.

Technical Challenges

The implementation of AGM (Absorbent Glass Mat) battery systems in high-reliability applications presents several technical challenges that must be addressed to ensure optimal performance and redundancy. One of the primary concerns is the management of thermal runaway, a critical issue that can lead to catastrophic failure if not properly controlled. AGM batteries are susceptible to this phenomenon, especially in high-temperature environments or during rapid charging cycles. Developing effective thermal management systems and implementing robust monitoring solutions are essential to mitigate this risk.

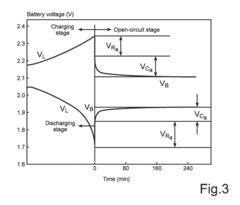

Another significant challenge lies in the accurate prediction of battery state-of-health (SOH) and state-of-charge (SOC). Unlike traditional lead-acid batteries, AGM batteries exhibit complex discharge characteristics that can make precise estimation difficult. This complexity is further compounded in redundant systems where multiple batteries are connected in parallel. Advanced algorithms and sensing technologies are required to provide real-time, accurate assessments of each battery's condition within the redundant array.

The design of an effective charge balancing system poses another technical hurdle. In redundant AGM battery configurations, ensuring uniform charging across all units is crucial for maximizing system lifespan and maintaining consistent performance. Variations in internal resistance and capacity between individual batteries can lead to imbalanced charging, potentially resulting in premature failure of certain units and compromising the overall reliability of the system.

Addressing the issue of self-discharge is also paramount in high-reliability applications. AGM batteries, while generally having lower self-discharge rates compared to flooded lead-acid batteries, still experience capacity loss over time. In redundant systems designed for long-term standby operation, this self-discharge can accumulate, potentially leading to unexpected capacity shortfalls during critical moments. Implementing intelligent charging strategies and periodic capacity testing regimes is necessary to counteract this effect.

The integration of AGM battery systems with power electronics and control systems presents its own set of challenges. Designing efficient power conversion and distribution architectures that can seamlessly switch between primary and redundant battery banks without interruption requires sophisticated control algorithms and fast-acting switching mechanisms. Additionally, ensuring electromagnetic compatibility (EMC) between the battery system and other sensitive electronic equipment in high-reliability applications is crucial to prevent interference and maintain system integrity.

Lastly, the environmental impact and end-of-life management of AGM batteries in redundant systems must be considered. While AGM batteries are sealed and generally considered maintenance-free, they still contain lead and sulfuric acid, which pose environmental risks. Developing safe and efficient recycling processes for these batteries, especially when dealing with large-scale redundant systems, is a technical challenge that intersects with environmental sustainability concerns.

Another significant challenge lies in the accurate prediction of battery state-of-health (SOH) and state-of-charge (SOC). Unlike traditional lead-acid batteries, AGM batteries exhibit complex discharge characteristics that can make precise estimation difficult. This complexity is further compounded in redundant systems where multiple batteries are connected in parallel. Advanced algorithms and sensing technologies are required to provide real-time, accurate assessments of each battery's condition within the redundant array.

The design of an effective charge balancing system poses another technical hurdle. In redundant AGM battery configurations, ensuring uniform charging across all units is crucial for maximizing system lifespan and maintaining consistent performance. Variations in internal resistance and capacity between individual batteries can lead to imbalanced charging, potentially resulting in premature failure of certain units and compromising the overall reliability of the system.

Addressing the issue of self-discharge is also paramount in high-reliability applications. AGM batteries, while generally having lower self-discharge rates compared to flooded lead-acid batteries, still experience capacity loss over time. In redundant systems designed for long-term standby operation, this self-discharge can accumulate, potentially leading to unexpected capacity shortfalls during critical moments. Implementing intelligent charging strategies and periodic capacity testing regimes is necessary to counteract this effect.

The integration of AGM battery systems with power electronics and control systems presents its own set of challenges. Designing efficient power conversion and distribution architectures that can seamlessly switch between primary and redundant battery banks without interruption requires sophisticated control algorithms and fast-acting switching mechanisms. Additionally, ensuring electromagnetic compatibility (EMC) between the battery system and other sensitive electronic equipment in high-reliability applications is crucial to prevent interference and maintain system integrity.

Lastly, the environmental impact and end-of-life management of AGM batteries in redundant systems must be considered. While AGM batteries are sealed and generally considered maintenance-free, they still contain lead and sulfuric acid, which pose environmental risks. Developing safe and efficient recycling processes for these batteries, especially when dealing with large-scale redundant systems, is a technical challenge that intersects with environmental sustainability concerns.

Redundancy Solutions

01 Redundant AGM battery configuration

Implementing redundant AGM battery systems to ensure continuous power supply in critical applications. This configuration involves multiple AGM batteries connected in parallel or series-parallel arrangements to provide backup power in case of individual battery failure.- Redundant AGM battery configuration: Implementing redundant AGM battery systems to ensure continuous power supply in critical applications. This configuration involves multiple AGM batteries connected in parallel or series-parallel arrangements to provide backup power in case of individual battery failure.

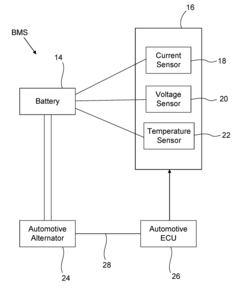

- Battery management system for AGM redundancy: Utilizing advanced battery management systems to monitor and control redundant AGM battery setups. These systems optimize battery performance, balance load distribution, and manage charging/discharging cycles to enhance overall system reliability and longevity.

- Modular AGM battery system design: Developing modular AGM battery systems that allow for easy replacement and scalability. This approach enables quick maintenance, reduces downtime, and facilitates system upgrades without compromising redundancy.

- Intelligent switching mechanisms for AGM redundancy: Incorporating intelligent switching mechanisms to seamlessly transition between primary and backup AGM batteries. These systems detect faults, isolate failing units, and automatically switch to redundant batteries to maintain uninterrupted power supply.

- Thermal management in redundant AGM systems: Implementing effective thermal management strategies for redundant AGM battery systems. This includes temperature monitoring, cooling systems, and heat dissipation techniques to prevent overheating and ensure optimal performance of the redundant battery setup.

02 Battery management system for redundancy

Utilizing advanced battery management systems to monitor and control redundant AGM battery setups. These systems optimize battery performance, balance load distribution, and enable seamless switching between primary and backup batteries to maintain system reliability.Expand Specific Solutions03 Modular AGM battery design for easy replacement

Developing modular AGM battery systems that allow for quick and easy replacement of individual battery units. This design enhances system redundancy by enabling hot-swapping of faulty batteries without interrupting power supply to critical loads.Expand Specific Solutions04 Intelligent charging and load balancing

Implementing intelligent charging algorithms and load balancing techniques to optimize the performance and lifespan of redundant AGM battery systems. These methods ensure even distribution of charge and discharge cycles across multiple batteries, enhancing overall system reliability.Expand Specific Solutions05 Integration with renewable energy sources

Combining AGM battery redundancy systems with renewable energy sources such as solar or wind power. This integration provides additional backup power options and improves overall system resilience, particularly in remote or off-grid applications.Expand Specific Solutions

Key Industry Players

The AGM battery system redundancy market for high-reliability applications is in a mature growth stage, with a significant global market size driven by increasing demand for reliable power solutions in critical sectors. The technology has reached a high level of maturity, with established players like Robert Bosch GmbH, Samsung SDI Co., Ltd., and Hitachi Ltd. leading innovation. These companies leverage their extensive R&D capabilities and industry experience to develop advanced AGM battery systems with improved redundancy features. Emerging players such as Fengfan Co., Ltd. and Tianneng Battery Group Co., Ltd. are also making strides in this space, focusing on cost-effective solutions and market expansion strategies to challenge the incumbents.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced AGM (Absorbent Glass Mat) battery system with built-in redundancy for high-reliability applications. Their approach involves using multiple AGM cells connected in parallel, each with its own monitoring and control system. This design allows for continued operation even if one or more cells fail. The system employs sophisticated algorithms to balance the load across cells, extending overall battery life and maintaining performance[1]. Bosch's solution also incorporates predictive maintenance capabilities, using machine learning to analyze battery performance data and predict potential failures before they occur[3].

Strengths: Robust redundancy, advanced monitoring, and predictive maintenance. Weaknesses: Potentially higher cost and complexity compared to simpler systems.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has engineered a high-reliability AGM battery system featuring a modular design for enhanced redundancy. Their system utilizes multiple independent battery modules, each containing AGM cells and a dedicated battery management system (BMS). The modular approach allows for hot-swapping of faulty modules without system downtime. Samsung's solution incorporates advanced thermal management techniques to ensure optimal operating conditions and extend battery lifespan[2]. Additionally, their system employs AI-driven load balancing algorithms to distribute power demands evenly across modules, further improving reliability and performance[4].

Strengths: Modular design allows for easy maintenance and scalability. Advanced thermal management. Weaknesses: May require more space than traditional single-unit systems.

Innovative Technologies

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Over-Saturated Absorbed Glass Mat Valve Regulated Lead-Acid Battery Comprising Carbon Additives

PatentInactiveUS20140120386A1

Innovation

- An AGM VRLA battery design with a positive plate, negative plate containing a carbon additive, an AGM separator, and an electrolyte present in an amount ranging from 100 to 150% by volume based on the total pore volume of the separator, utilizing various carbon additives such as graphite, carbon black, activated carbon, and graphene to enhance charge acceptance and durability.

Reliability Standards

Reliability standards play a crucial role in evaluating AGM battery system redundancy for high-reliability applications. These standards provide a framework for assessing the performance, safety, and durability of battery systems in critical environments where uninterrupted power supply is essential.

One of the primary reliability standards applicable to AGM battery systems is IEC 60896-21/22, which specifically addresses stationary lead-acid batteries. This standard outlines testing methods and requirements for valve-regulated lead-acid batteries, including AGM types. It covers aspects such as capacity, charge retention, cycle life, and float service life, which are vital for determining the reliability of battery systems in redundant configurations.

The IEEE 1188 standard is another important reference for AGM battery systems in high-reliability applications. It provides guidelines for the maintenance, testing, and replacement of valve-regulated lead-acid batteries used in stationary applications. This standard helps ensure that battery systems maintain their performance over time, which is crucial for redundancy effectiveness.

For applications requiring extreme reliability, such as data centers or telecommunications facilities, the Uptime Institute's Tier Standard is often considered. While not specific to batteries, it provides a comprehensive framework for evaluating the reliability of data center infrastructure, including power systems. The Tier Standard's redundancy requirements often influence the design and implementation of AGM battery system redundancy.

The National Fire Protection Association (NFPA) 111 standard addresses emergency and standby power systems, which often incorporate AGM batteries. This standard provides requirements for the performance of battery systems in critical applications, ensuring they can reliably provide power during emergencies.

In the telecommunications sector, NEBS (Network Equipment-Building System) standards, particularly Telcordia GR-63-CORE and GR-1089-CORE, are relevant for AGM battery systems. These standards define criteria for equipment used in telecommunications facilities, including power systems and batteries, with a focus on reliability and environmental factors.

For automotive and transportation applications, SAE J2464 and J2929 standards are applicable to AGM batteries used in electric and hybrid vehicles. These standards address safety and abuse testing of rechargeable energy storage systems, which is crucial for ensuring reliability in mobile applications.

Compliance with these reliability standards is typically verified through rigorous testing procedures, often conducted by independent laboratories. These tests simulate various operational conditions, environmental factors, and potential failure modes to assess the battery system's performance and redundancy effectiveness.

One of the primary reliability standards applicable to AGM battery systems is IEC 60896-21/22, which specifically addresses stationary lead-acid batteries. This standard outlines testing methods and requirements for valve-regulated lead-acid batteries, including AGM types. It covers aspects such as capacity, charge retention, cycle life, and float service life, which are vital for determining the reliability of battery systems in redundant configurations.

The IEEE 1188 standard is another important reference for AGM battery systems in high-reliability applications. It provides guidelines for the maintenance, testing, and replacement of valve-regulated lead-acid batteries used in stationary applications. This standard helps ensure that battery systems maintain their performance over time, which is crucial for redundancy effectiveness.

For applications requiring extreme reliability, such as data centers or telecommunications facilities, the Uptime Institute's Tier Standard is often considered. While not specific to batteries, it provides a comprehensive framework for evaluating the reliability of data center infrastructure, including power systems. The Tier Standard's redundancy requirements often influence the design and implementation of AGM battery system redundancy.

The National Fire Protection Association (NFPA) 111 standard addresses emergency and standby power systems, which often incorporate AGM batteries. This standard provides requirements for the performance of battery systems in critical applications, ensuring they can reliably provide power during emergencies.

In the telecommunications sector, NEBS (Network Equipment-Building System) standards, particularly Telcordia GR-63-CORE and GR-1089-CORE, are relevant for AGM battery systems. These standards define criteria for equipment used in telecommunications facilities, including power systems and batteries, with a focus on reliability and environmental factors.

For automotive and transportation applications, SAE J2464 and J2929 standards are applicable to AGM batteries used in electric and hybrid vehicles. These standards address safety and abuse testing of rechargeable energy storage systems, which is crucial for ensuring reliability in mobile applications.

Compliance with these reliability standards is typically verified through rigorous testing procedures, often conducted by independent laboratories. These tests simulate various operational conditions, environmental factors, and potential failure modes to assess the battery system's performance and redundancy effectiveness.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) battery systems in high-reliability applications is a crucial consideration for organizations seeking to balance performance with sustainability. These battery systems, while offering significant advantages in terms of reliability and efficiency, also present unique environmental challenges throughout their lifecycle.

AGM batteries typically have a longer lifespan compared to traditional lead-acid batteries, which can reduce the frequency of replacements and, consequently, the overall environmental footprint. This extended service life translates to fewer batteries being manufactured and disposed of over time, potentially decreasing the demand for raw materials and energy associated with production processes.

However, the manufacturing of AGM batteries still involves the use of lead and other potentially hazardous materials. While the sealed design of AGM batteries reduces the risk of acid spills during operation, proper handling and disposal at the end of their life cycle remain critical to prevent environmental contamination. The recycling infrastructure for AGM batteries is well-established in many regions, with high recovery rates for lead and other components, which helps mitigate their environmental impact.

In high-reliability applications, the redundancy of AGM battery systems often leads to the installation of multiple batteries or battery banks. This redundancy, while essential for ensuring uninterrupted power supply, can increase the overall material footprint of the system. Organizations must carefully balance the need for reliability with the goal of minimizing resource consumption and waste generation.

Energy efficiency is another important aspect of AGM battery systems' environmental impact. These batteries generally offer improved charge acceptance and lower internal resistance compared to flooded lead-acid batteries, potentially reducing energy losses during charging and discharging cycles. This efficiency can contribute to lower overall energy consumption in backup power systems, indirectly reducing the carbon footprint associated with power generation.

The controlled environment often required for AGM battery systems in high-reliability applications can also have indirect environmental implications. Temperature management systems may be necessary to maintain optimal battery performance and longevity, potentially increasing energy consumption. However, the precise control over operating conditions can extend battery life, offsetting some of these energy costs over time.

As organizations increasingly prioritize sustainability, the environmental impact of AGM battery systems in redundant configurations is becoming a key factor in system design and procurement decisions. Innovations in battery technology, such as the development of more environmentally friendly materials and improved recycling processes, are ongoing efforts to further reduce the ecological footprint of these critical power systems.

AGM batteries typically have a longer lifespan compared to traditional lead-acid batteries, which can reduce the frequency of replacements and, consequently, the overall environmental footprint. This extended service life translates to fewer batteries being manufactured and disposed of over time, potentially decreasing the demand for raw materials and energy associated with production processes.

However, the manufacturing of AGM batteries still involves the use of lead and other potentially hazardous materials. While the sealed design of AGM batteries reduces the risk of acid spills during operation, proper handling and disposal at the end of their life cycle remain critical to prevent environmental contamination. The recycling infrastructure for AGM batteries is well-established in many regions, with high recovery rates for lead and other components, which helps mitigate their environmental impact.

In high-reliability applications, the redundancy of AGM battery systems often leads to the installation of multiple batteries or battery banks. This redundancy, while essential for ensuring uninterrupted power supply, can increase the overall material footprint of the system. Organizations must carefully balance the need for reliability with the goal of minimizing resource consumption and waste generation.

Energy efficiency is another important aspect of AGM battery systems' environmental impact. These batteries generally offer improved charge acceptance and lower internal resistance compared to flooded lead-acid batteries, potentially reducing energy losses during charging and discharging cycles. This efficiency can contribute to lower overall energy consumption in backup power systems, indirectly reducing the carbon footprint associated with power generation.

The controlled environment often required for AGM battery systems in high-reliability applications can also have indirect environmental implications. Temperature management systems may be necessary to maintain optimal battery performance and longevity, potentially increasing energy consumption. However, the precise control over operating conditions can extend battery life, offsetting some of these energy costs over time.

As organizations increasingly prioritize sustainability, the environmental impact of AGM battery systems in redundant configurations is becoming a key factor in system design and procurement decisions. Innovations in battery technology, such as the development of more environmentally friendly materials and improved recycling processes, are ongoing efforts to further reduce the ecological footprint of these critical power systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!