AGM Battery Advances in Hyperloop Technology Energy Supply

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution and Hyperloop Energy Goals

The evolution of AGM (Absorbent Glass Mat) battery technology has been closely intertwined with the development of Hyperloop transportation systems, as both fields strive for high-performance, efficient, and sustainable energy solutions. AGM batteries, known for their high power density, low internal resistance, and maintenance-free operation, have emerged as a promising candidate for powering various components of the Hyperloop infrastructure.

In the context of Hyperloop technology, the primary energy goals revolve around providing reliable, high-capacity power for propulsion, levitation, and auxiliary systems while maintaining safety and efficiency. AGM batteries have undergone significant advancements to meet these demanding requirements, with researchers and engineers focusing on improving energy density, cycle life, and rapid charging capabilities.

The journey of AGM battery development for Hyperloop applications began with the adaptation of existing automotive and industrial battery designs. Early prototypes faced challenges in meeting the high power demands and extended operational cycles required for Hyperloop systems. However, continuous research and development efforts have led to notable improvements in electrode materials, electrolyte compositions, and battery management systems.

One of the key milestones in AGM battery evolution for Hyperloop technology has been the development of enhanced lead-carbon electrodes. These advanced materials have significantly increased the battery's power output and cycle life, addressing the need for sustained high-performance operation in Hyperloop pods and infrastructure. Additionally, the integration of nanotechnology in AGM battery design has further boosted energy density and charge acceptance rates, crucial for the rapid acceleration and deceleration cycles in Hyperloop systems.

The goals for AGM battery technology in Hyperloop applications continue to evolve, with a focus on achieving even higher energy densities, faster charging times, and improved thermal management. Researchers are exploring novel electrolyte additives and advanced separator materials to enhance battery performance under the unique operating conditions of Hyperloop systems, including high-speed travel and potential vacuum environments.

Furthermore, the integration of smart battery management systems has become a critical aspect of AGM battery development for Hyperloop technology. These systems aim to optimize battery performance, extend lifespan, and ensure safe operation under varying load conditions. The ultimate goal is to create a robust, efficient, and sustainable energy supply that can support the high-speed, long-distance travel envisioned for Hyperloop transportation.

In the context of Hyperloop technology, the primary energy goals revolve around providing reliable, high-capacity power for propulsion, levitation, and auxiliary systems while maintaining safety and efficiency. AGM batteries have undergone significant advancements to meet these demanding requirements, with researchers and engineers focusing on improving energy density, cycle life, and rapid charging capabilities.

The journey of AGM battery development for Hyperloop applications began with the adaptation of existing automotive and industrial battery designs. Early prototypes faced challenges in meeting the high power demands and extended operational cycles required for Hyperloop systems. However, continuous research and development efforts have led to notable improvements in electrode materials, electrolyte compositions, and battery management systems.

One of the key milestones in AGM battery evolution for Hyperloop technology has been the development of enhanced lead-carbon electrodes. These advanced materials have significantly increased the battery's power output and cycle life, addressing the need for sustained high-performance operation in Hyperloop pods and infrastructure. Additionally, the integration of nanotechnology in AGM battery design has further boosted energy density and charge acceptance rates, crucial for the rapid acceleration and deceleration cycles in Hyperloop systems.

The goals for AGM battery technology in Hyperloop applications continue to evolve, with a focus on achieving even higher energy densities, faster charging times, and improved thermal management. Researchers are exploring novel electrolyte additives and advanced separator materials to enhance battery performance under the unique operating conditions of Hyperloop systems, including high-speed travel and potential vacuum environments.

Furthermore, the integration of smart battery management systems has become a critical aspect of AGM battery development for Hyperloop technology. These systems aim to optimize battery performance, extend lifespan, and ensure safe operation under varying load conditions. The ultimate goal is to create a robust, efficient, and sustainable energy supply that can support the high-speed, long-distance travel envisioned for Hyperloop transportation.

Hyperloop Market Demand for Advanced Energy Solutions

The Hyperloop concept has sparked significant interest in advanced energy solutions, particularly in the realm of battery technology. As this revolutionary transportation system aims to achieve unprecedented speeds and efficiency, the demand for cutting-edge energy storage and supply systems has intensified. The market for advanced energy solutions in the Hyperloop sector is driven by several key factors.

Firstly, the need for high-power density batteries is paramount. Hyperloop pods require substantial energy to accelerate rapidly and maintain high speeds over long distances. This has created a strong demand for batteries that can deliver large amounts of power quickly and consistently. AGM (Absorbent Glass Mat) batteries have emerged as a promising candidate due to their ability to provide high current on demand and their robust construction.

Secondly, the market is seeking energy solutions with exceptional longevity and reliability. The Hyperloop system is designed to operate continuously with minimal downtime, necessitating batteries that can withstand frequent charge-discharge cycles without significant degradation. This requirement has fueled research and development into advanced AGM battery technologies that offer improved cycle life and durability.

Energy efficiency is another critical factor shaping market demand. Hyperloop systems aim to be highly energy-efficient, and this extends to their power supply. There is a growing interest in AGM batteries that offer high charge acceptance rates and low internal resistance, minimizing energy losses during operation and recharging processes.

Safety considerations also play a crucial role in driving market demand for advanced energy solutions. The high-speed nature of Hyperloop travel places stringent safety requirements on all components, including the power system. AGM batteries are favored for their sealed design and resistance to spilling or leaking, making them well-suited for the dynamic environment of Hyperloop pods.

Furthermore, the market is increasingly focused on sustainable and environmentally friendly energy solutions. This has led to a demand for AGM batteries with improved recyclability and reduced environmental impact. Manufacturers are exploring ways to enhance the recyclability of AGM batteries and reduce the use of harmful materials in their production.

The integration of smart battery management systems is another area of growing market demand. These systems optimize battery performance, extend lifespan, and provide real-time monitoring capabilities, which are essential for the efficient and safe operation of Hyperloop systems. The market is seeking AGM batteries that can seamlessly interface with advanced management systems to ensure optimal performance and reliability.

As Hyperloop technology continues to evolve, the market for advanced energy solutions is expected to expand rapidly. This growth is driven by the need for batteries that can meet the unique challenges of high-speed, long-distance transportation while adhering to strict safety and efficiency standards. The ongoing advancements in AGM battery technology are poised to play a crucial role in meeting these market demands and supporting the realization of the Hyperloop vision.

Firstly, the need for high-power density batteries is paramount. Hyperloop pods require substantial energy to accelerate rapidly and maintain high speeds over long distances. This has created a strong demand for batteries that can deliver large amounts of power quickly and consistently. AGM (Absorbent Glass Mat) batteries have emerged as a promising candidate due to their ability to provide high current on demand and their robust construction.

Secondly, the market is seeking energy solutions with exceptional longevity and reliability. The Hyperloop system is designed to operate continuously with minimal downtime, necessitating batteries that can withstand frequent charge-discharge cycles without significant degradation. This requirement has fueled research and development into advanced AGM battery technologies that offer improved cycle life and durability.

Energy efficiency is another critical factor shaping market demand. Hyperloop systems aim to be highly energy-efficient, and this extends to their power supply. There is a growing interest in AGM batteries that offer high charge acceptance rates and low internal resistance, minimizing energy losses during operation and recharging processes.

Safety considerations also play a crucial role in driving market demand for advanced energy solutions. The high-speed nature of Hyperloop travel places stringent safety requirements on all components, including the power system. AGM batteries are favored for their sealed design and resistance to spilling or leaking, making them well-suited for the dynamic environment of Hyperloop pods.

Furthermore, the market is increasingly focused on sustainable and environmentally friendly energy solutions. This has led to a demand for AGM batteries with improved recyclability and reduced environmental impact. Manufacturers are exploring ways to enhance the recyclability of AGM batteries and reduce the use of harmful materials in their production.

The integration of smart battery management systems is another area of growing market demand. These systems optimize battery performance, extend lifespan, and provide real-time monitoring capabilities, which are essential for the efficient and safe operation of Hyperloop systems. The market is seeking AGM batteries that can seamlessly interface with advanced management systems to ensure optimal performance and reliability.

As Hyperloop technology continues to evolve, the market for advanced energy solutions is expected to expand rapidly. This growth is driven by the need for batteries that can meet the unique challenges of high-speed, long-distance transportation while adhering to strict safety and efficiency standards. The ongoing advancements in AGM battery technology are poised to play a crucial role in meeting these market demands and supporting the realization of the Hyperloop vision.

AGM Battery Technology: Current State and Challenges

AGM (Absorbent Glass Mat) battery technology has made significant strides in recent years, particularly in its application to Hyperloop energy supply systems. However, several challenges remain in fully realizing its potential for this cutting-edge transportation technology.

The current state of AGM batteries showcases impressive advancements in energy density, charge-discharge efficiency, and cycle life. These improvements have positioned AGM batteries as a viable option for powering Hyperloop systems, which require high-performance energy storage solutions. The sealed design of AGM batteries, which prevents electrolyte leakage and allows for flexible mounting orientations, is particularly advantageous in the confined spaces of Hyperloop pods.

One of the primary challenges facing AGM battery technology in Hyperloop applications is thermal management. The high-speed, low-pressure environment of Hyperloop systems generates significant heat, which can negatively impact battery performance and lifespan. Developing effective cooling systems that can operate efficiently in the unique Hyperloop environment remains a critical area of research and development.

Another challenge lies in optimizing the power-to-weight ratio of AGM batteries. While AGM technology offers better energy density compared to traditional lead-acid batteries, further improvements are necessary to meet the stringent weight requirements of Hyperloop systems. Researchers are exploring advanced materials and manufacturing techniques to enhance the power output while minimizing battery weight.

The durability and longevity of AGM batteries in the high-stress environment of Hyperloop operations also present ongoing challenges. The frequent acceleration and deceleration cycles, coupled with potential vibrations and G-forces, can strain battery components. Enhancing the structural integrity of AGM batteries without compromising their performance is a key focus area for engineers and material scientists.

Furthermore, the integration of AGM batteries with Hyperloop's regenerative braking systems poses both opportunities and challenges. While regenerative braking can help recharge batteries during operation, efficiently capturing and storing this energy within the AGM battery system requires sophisticated control algorithms and power management systems.

Lastly, the scalability of AGM battery technology for large-scale Hyperloop implementations remains a significant challenge. As Hyperloop systems move from prototypes to commercial applications, the ability to manufacture and deploy AGM batteries at scale, while maintaining consistent performance and reliability, will be crucial. This includes addressing issues related to raw material availability, production costs, and quality control in large-scale manufacturing processes.

The current state of AGM batteries showcases impressive advancements in energy density, charge-discharge efficiency, and cycle life. These improvements have positioned AGM batteries as a viable option for powering Hyperloop systems, which require high-performance energy storage solutions. The sealed design of AGM batteries, which prevents electrolyte leakage and allows for flexible mounting orientations, is particularly advantageous in the confined spaces of Hyperloop pods.

One of the primary challenges facing AGM battery technology in Hyperloop applications is thermal management. The high-speed, low-pressure environment of Hyperloop systems generates significant heat, which can negatively impact battery performance and lifespan. Developing effective cooling systems that can operate efficiently in the unique Hyperloop environment remains a critical area of research and development.

Another challenge lies in optimizing the power-to-weight ratio of AGM batteries. While AGM technology offers better energy density compared to traditional lead-acid batteries, further improvements are necessary to meet the stringent weight requirements of Hyperloop systems. Researchers are exploring advanced materials and manufacturing techniques to enhance the power output while minimizing battery weight.

The durability and longevity of AGM batteries in the high-stress environment of Hyperloop operations also present ongoing challenges. The frequent acceleration and deceleration cycles, coupled with potential vibrations and G-forces, can strain battery components. Enhancing the structural integrity of AGM batteries without compromising their performance is a key focus area for engineers and material scientists.

Furthermore, the integration of AGM batteries with Hyperloop's regenerative braking systems poses both opportunities and challenges. While regenerative braking can help recharge batteries during operation, efficiently capturing and storing this energy within the AGM battery system requires sophisticated control algorithms and power management systems.

Lastly, the scalability of AGM battery technology for large-scale Hyperloop implementations remains a significant challenge. As Hyperloop systems move from prototypes to commercial applications, the ability to manufacture and deploy AGM batteries at scale, while maintaining consistent performance and reliability, will be crucial. This includes addressing issues related to raw material availability, production costs, and quality control in large-scale manufacturing processes.

Existing AGM Battery Solutions for Hyperloop Systems

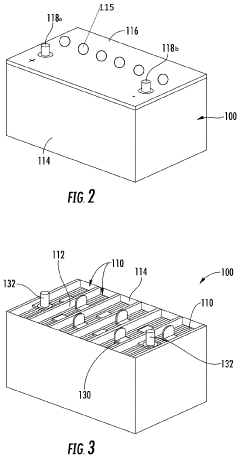

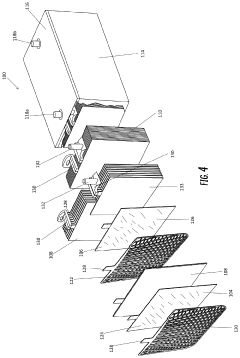

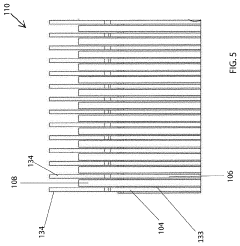

01 AGM battery design and structure

Advancements in Absorbent Glass Mat (AGM) battery design focus on improving energy density, cycle life, and overall performance. This includes optimizing electrode materials, separator design, and internal structure to enhance charge acceptance and discharge capabilities.- AGM battery structure and design: Advancements in Absorbent Glass Mat (AGM) battery design focus on improving energy density, cycle life, and overall performance. This includes optimizing electrode materials, separator design, and electrolyte composition to enhance charge acceptance and discharge capabilities.

- Battery management systems for AGM batteries: Intelligent battery management systems are developed to monitor and control AGM batteries, optimizing charging processes, balancing cell voltages, and extending battery life. These systems often incorporate advanced algorithms and sensors to ensure efficient energy supply and prevent overcharging or deep discharging.

- AGM battery applications in electric vehicles: AGM batteries are increasingly used in electric and hybrid vehicles due to their high power density and ability to handle frequent charge-discharge cycles. Innovations in this area focus on improving battery pack design, thermal management, and integration with vehicle systems to enhance overall energy supply efficiency.

- Energy storage solutions using AGM batteries: AGM batteries are utilized in various energy storage applications, including renewable energy systems and grid stabilization. Developments in this field aim to improve the scalability, reliability, and cost-effectiveness of AGM battery-based energy storage solutions, addressing challenges such as capacity retention and long-term performance.

- AGM battery charging technologies: Advanced charging technologies for AGM batteries focus on rapid charging capabilities while maintaining battery health. This includes the development of smart chargers, pulse charging techniques, and temperature-compensated charging algorithms to optimize the energy supply process and extend battery lifespan.

02 Battery management systems for AGM batteries

Intelligent battery management systems are developed to monitor and control AGM batteries, optimizing charging processes, balancing cell voltages, and extending battery life. These systems often incorporate advanced algorithms and sensors to ensure efficient energy supply and prevent overcharging or deep discharging.Expand Specific Solutions03 Integration of AGM batteries in energy storage systems

AGM batteries are increasingly integrated into larger energy storage systems, including renewable energy applications and grid stabilization. These systems combine multiple AGM batteries with power electronics and control systems to provide reliable and scalable energy supply solutions.Expand Specific Solutions04 Thermal management of AGM batteries

Effective thermal management techniques are developed to maintain optimal operating temperatures for AGM batteries, enhancing performance and longevity. This includes passive and active cooling systems, as well as insulation methods to protect against extreme environmental conditions.Expand Specific Solutions05 AGM battery recycling and environmental considerations

Innovations in AGM battery recycling processes aim to recover valuable materials and reduce environmental impact. This includes developing efficient disassembly methods, material separation techniques, and exploring ways to repurpose used AGM batteries for secondary applications.Expand Specific Solutions

Key Players in AGM Battery and Hyperloop Industries

The AGM Battery Advances in Hyperloop Technology Energy Supply market is in its early development stage, characterized by ongoing research and limited commercial applications. The market size is relatively small but growing, driven by increasing interest in high-speed transportation solutions. Technologically, AGM batteries for Hyperloop are still evolving, with companies like Daramic LLC, Stryten Energy LLC, and FIAMM Energy Technology SpA leading in separator and battery technology development. Academic institutions such as Southwest Jiaotong University and Beijing Jiaotong University are contributing to research efforts. While the technology shows promise, it requires further refinement and testing to meet the demanding energy requirements of Hyperloop systems.

CRRC Qingdao Sifang Co., Ltd.

Technical Solution: CRRC Qingdao Sifang Co., Ltd. has developed advanced AGM (Absorbent Glass Mat) battery technology specifically tailored for Hyperloop energy supply systems. Their solution incorporates high-performance AGM batteries with enhanced energy density and rapid charge-discharge capabilities. The company has implemented a sophisticated battery management system that optimizes power distribution and extends battery life in the high-speed, low-pressure Hyperloop environment. Their AGM batteries feature improved thermal management to maintain optimal operating temperatures during high-speed travel[1]. Additionally, CRRC Qingdao Sifang has integrated regenerative braking technology to capture and store energy during deceleration, significantly improving overall system efficiency[3].

Strengths: Specialized design for Hyperloop applications, high energy density, rapid charge-discharge capabilities, and advanced thermal management. Weaknesses: Potential high costs associated with specialized production and limited real-world testing in operational Hyperloop systems.

Beijing Jiaotong University

Technical Solution: Beijing Jiaotong University has made significant strides in AGM battery technology for Hyperloop energy supply. Their research team has developed a novel electrolyte composition that enhances the battery's performance under the unique conditions of Hyperloop travel. This advanced electrolyte formulation improves ion conductivity and reduces internal resistance, resulting in higher power output and faster charging times[2]. The university has also pioneered a new electrode design that increases the active surface area, leading to improved energy storage capacity and longer battery life. Their AGM batteries incorporate nano-scale additives to enhance structural stability and prevent electrode degradation during rapid charge-discharge cycles[4].

Strengths: Cutting-edge research in electrolyte and electrode design, potential for significant performance improvements. Weaknesses: Technology may still be in the research phase, requiring further development for commercial application.

Core Innovations in AGM Battery for High-Speed Transit

Negative mass for lead-acid battery electrodes and lead-acid battery including same

PatentActiveUS20210336249A1

Innovation

- The introduction of additives such as fine particle barium sulfate, two organic compounds (oxylignins), and a carbonaceous material to the negative active material in lead-acid battery electrodes, which are pre-mixed to form a blended expander mixture, improving the homogeneity and dispersion of the battery paste and enhancing the battery's cycling performance and water retention.

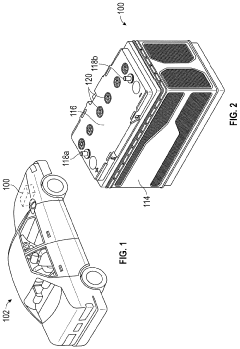

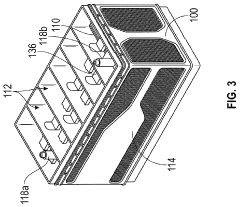

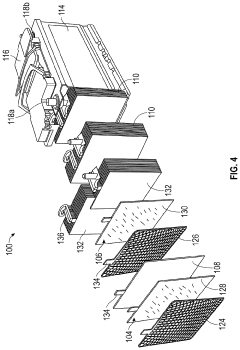

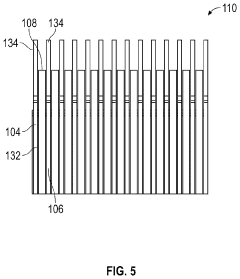

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Environmental Impact of AGM Batteries in Hyperloop

The environmental impact of AGM (Absorbent Glass Mat) batteries in Hyperloop technology is a crucial consideration as this innovative transportation system continues to develop. AGM batteries, known for their high performance and reliability, play a significant role in powering various systems within the Hyperloop infrastructure.

One of the primary environmental benefits of AGM batteries in Hyperloop technology is their contribution to overall energy efficiency. These batteries are capable of rapid charging and discharging, which aligns well with the Hyperloop's need for quick energy bursts during acceleration and deceleration. This efficiency translates to reduced energy consumption and, consequently, a lower carbon footprint compared to traditional transportation methods.

AGM batteries also have a longer lifespan compared to many other battery types, which reduces the frequency of battery replacements. This longevity contributes to a decrease in battery waste and the environmental impact associated with battery production and disposal. Additionally, AGM batteries are sealed and maintenance-free, minimizing the risk of electrolyte leakage and reducing the need for potentially harmful maintenance procedures.

However, the production of AGM batteries does have environmental implications. The manufacturing process involves the use of lead and other materials that can be environmentally hazardous if not properly managed. It is crucial for Hyperloop developers to work with battery manufacturers who adhere to strict environmental standards and employ sustainable production practices.

End-of-life considerations for AGM batteries in Hyperloop systems are also important. While these batteries are highly recyclable, with up to 99% of their components being recoverable, establishing efficient recycling processes and infrastructure specific to Hyperloop applications will be essential to maximize their environmental benefits.

The use of AGM batteries in Hyperloop technology also indirectly contributes to reduced environmental impact by supporting the shift away from fossil fuel-dependent transportation. As Hyperloop systems are designed to be powered by renewable energy sources, the integration of AGM batteries helps to stabilize and optimize the use of clean energy, further reducing the overall carbon emissions associated with transportation.

In conclusion, while AGM batteries offer significant environmental advantages in Hyperloop applications, their impact must be carefully managed throughout their lifecycle. Continued research and development in battery technology, coupled with sustainable manufacturing and recycling practices, will be key to maximizing the positive environmental impact of AGM batteries in Hyperloop systems.

One of the primary environmental benefits of AGM batteries in Hyperloop technology is their contribution to overall energy efficiency. These batteries are capable of rapid charging and discharging, which aligns well with the Hyperloop's need for quick energy bursts during acceleration and deceleration. This efficiency translates to reduced energy consumption and, consequently, a lower carbon footprint compared to traditional transportation methods.

AGM batteries also have a longer lifespan compared to many other battery types, which reduces the frequency of battery replacements. This longevity contributes to a decrease in battery waste and the environmental impact associated with battery production and disposal. Additionally, AGM batteries are sealed and maintenance-free, minimizing the risk of electrolyte leakage and reducing the need for potentially harmful maintenance procedures.

However, the production of AGM batteries does have environmental implications. The manufacturing process involves the use of lead and other materials that can be environmentally hazardous if not properly managed. It is crucial for Hyperloop developers to work with battery manufacturers who adhere to strict environmental standards and employ sustainable production practices.

End-of-life considerations for AGM batteries in Hyperloop systems are also important. While these batteries are highly recyclable, with up to 99% of their components being recoverable, establishing efficient recycling processes and infrastructure specific to Hyperloop applications will be essential to maximize their environmental benefits.

The use of AGM batteries in Hyperloop technology also indirectly contributes to reduced environmental impact by supporting the shift away from fossil fuel-dependent transportation. As Hyperloop systems are designed to be powered by renewable energy sources, the integration of AGM batteries helps to stabilize and optimize the use of clean energy, further reducing the overall carbon emissions associated with transportation.

In conclusion, while AGM batteries offer significant environmental advantages in Hyperloop applications, their impact must be carefully managed throughout their lifecycle. Continued research and development in battery technology, coupled with sustainable manufacturing and recycling practices, will be key to maximizing the positive environmental impact of AGM batteries in Hyperloop systems.

Safety Regulations for AGM Batteries in Hyperloop Systems

Safety regulations for AGM (Absorbent Glass Mat) batteries in Hyperloop systems are crucial to ensure the safe operation of this revolutionary transportation technology. These regulations address the unique challenges posed by the high-speed, low-pressure environment of Hyperloop systems and the specific characteristics of AGM batteries.

One of the primary safety concerns is thermal management. AGM batteries, while generally safer than traditional lead-acid batteries, can still generate heat during charging and discharging cycles. In the enclosed environment of a Hyperloop pod, heat dissipation becomes critical. Regulations mandate the implementation of advanced cooling systems and thermal monitoring to prevent overheating and potential thermal runaway.

Pressure-related safety measures are another key aspect of the regulations. The low-pressure environment inside Hyperloop tubes can affect battery performance and safety. Regulations require that AGM batteries used in Hyperloop systems undergo rigorous testing to ensure they can maintain structural integrity and performance under varying pressure conditions.

Containment and isolation protocols form an essential part of the safety regulations. In the event of a battery failure, it is crucial to prevent any potential fire or chemical release from spreading to other parts of the Hyperloop system. Regulations specify the use of fire-resistant materials for battery enclosures and the implementation of isolation systems to contain any potential incidents.

Electrical safety is a paramount concern addressed by the regulations. The high-voltage systems used in Hyperloop technology require stringent safeguards against electrical faults. Regulations mandate the use of advanced circuit protection devices, insulation systems, and regular electrical safety inspections to minimize the risk of electrical failures or short circuits.

Emergency response procedures are also a critical component of the safety regulations. These include protocols for rapid pod evacuation, fire suppression systems specifically designed for battery fires, and emergency power cut-off mechanisms. Regulations require regular drills and training for Hyperloop staff to ensure quick and effective responses to any battery-related emergencies.

Maintenance and inspection protocols are detailed in the regulations to ensure the ongoing safety and reliability of AGM batteries in Hyperloop systems. These include regular capacity testing, visual inspections for signs of damage or degradation, and scheduled replacement cycles based on usage and environmental factors.

The regulations also address the environmental aspects of AGM battery use in Hyperloop systems. This includes guidelines for the proper disposal and recycling of batteries at the end of their lifecycle, as well as measures to prevent and contain any potential environmental contamination in case of a battery failure.

One of the primary safety concerns is thermal management. AGM batteries, while generally safer than traditional lead-acid batteries, can still generate heat during charging and discharging cycles. In the enclosed environment of a Hyperloop pod, heat dissipation becomes critical. Regulations mandate the implementation of advanced cooling systems and thermal monitoring to prevent overheating and potential thermal runaway.

Pressure-related safety measures are another key aspect of the regulations. The low-pressure environment inside Hyperloop tubes can affect battery performance and safety. Regulations require that AGM batteries used in Hyperloop systems undergo rigorous testing to ensure they can maintain structural integrity and performance under varying pressure conditions.

Containment and isolation protocols form an essential part of the safety regulations. In the event of a battery failure, it is crucial to prevent any potential fire or chemical release from spreading to other parts of the Hyperloop system. Regulations specify the use of fire-resistant materials for battery enclosures and the implementation of isolation systems to contain any potential incidents.

Electrical safety is a paramount concern addressed by the regulations. The high-voltage systems used in Hyperloop technology require stringent safeguards against electrical faults. Regulations mandate the use of advanced circuit protection devices, insulation systems, and regular electrical safety inspections to minimize the risk of electrical failures or short circuits.

Emergency response procedures are also a critical component of the safety regulations. These include protocols for rapid pod evacuation, fire suppression systems specifically designed for battery fires, and emergency power cut-off mechanisms. Regulations require regular drills and training for Hyperloop staff to ensure quick and effective responses to any battery-related emergencies.

Maintenance and inspection protocols are detailed in the regulations to ensure the ongoing safety and reliability of AGM batteries in Hyperloop systems. These include regular capacity testing, visual inspections for signs of damage or degradation, and scheduled replacement cycles based on usage and environmental factors.

The regulations also address the environmental aspects of AGM battery use in Hyperloop systems. This includes guidelines for the proper disposal and recycling of batteries at the end of their lifecycle, as well as measures to prevent and contain any potential environmental contamination in case of a battery failure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!