Biodegradable Component Use in AGM Battery Production

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in lead-acid battery technology. Developed in the 1970s for military aircraft, AGM batteries have since found widespread application in various industries due to their superior performance characteristics.

The initial design of AGM batteries aimed to address the limitations of traditional flooded lead-acid batteries, particularly in terms of electrolyte spillage and maintenance requirements. By immobilizing the electrolyte in a highly porous fiberglass mat separator, AGM batteries achieved improved safety and reliability, making them suitable for use in sensitive environments and portable applications.

Throughout the 1980s and 1990s, AGM technology underwent further refinements, focusing on enhancing energy density, cycle life, and charge acceptance. These improvements led to the adoption of AGM batteries in telecommunications, uninterruptible power supplies (UPS), and emergency lighting systems. The automotive industry also began to recognize the potential of AGM batteries, particularly for start-stop vehicle applications.

The turn of the millennium saw increased emphasis on environmental sustainability in battery production. This shift prompted research into reducing the environmental impact of AGM batteries, including efforts to incorporate biodegradable components and improve recyclability. Manufacturers began exploring alternative materials for separators and casings, aiming to maintain performance while enhancing eco-friendliness.

Recent years have witnessed a surge in research focused on integrating biodegradable components into AGM battery production. This trend aligns with growing global concerns about electronic waste and the circular economy. Researchers are investigating bio-based polymers and natural fibers as potential replacements for traditional synthetic materials used in battery components.

The evolution of AGM batteries continues to be driven by demands for higher performance, longer lifespan, and reduced environmental impact. Current research efforts are exploring advanced electrode materials, novel electrolyte formulations, and innovative manufacturing processes to further enhance AGM battery capabilities. The integration of smart technologies for battery management and monitoring is also becoming increasingly prevalent, contributing to improved efficiency and reliability.

As the focus on sustainable energy solutions intensifies, the future evolution of AGM batteries is likely to prioritize eco-friendly designs and materials. This includes the development of fully recyclable batteries and the incorporation of renewable resources in battery production. The ongoing research into biodegradable components represents a crucial step in this direction, potentially revolutionizing the environmental profile of AGM batteries while maintaining their high-performance characteristics.

The initial design of AGM batteries aimed to address the limitations of traditional flooded lead-acid batteries, particularly in terms of electrolyte spillage and maintenance requirements. By immobilizing the electrolyte in a highly porous fiberglass mat separator, AGM batteries achieved improved safety and reliability, making them suitable for use in sensitive environments and portable applications.

Throughout the 1980s and 1990s, AGM technology underwent further refinements, focusing on enhancing energy density, cycle life, and charge acceptance. These improvements led to the adoption of AGM batteries in telecommunications, uninterruptible power supplies (UPS), and emergency lighting systems. The automotive industry also began to recognize the potential of AGM batteries, particularly for start-stop vehicle applications.

The turn of the millennium saw increased emphasis on environmental sustainability in battery production. This shift prompted research into reducing the environmental impact of AGM batteries, including efforts to incorporate biodegradable components and improve recyclability. Manufacturers began exploring alternative materials for separators and casings, aiming to maintain performance while enhancing eco-friendliness.

Recent years have witnessed a surge in research focused on integrating biodegradable components into AGM battery production. This trend aligns with growing global concerns about electronic waste and the circular economy. Researchers are investigating bio-based polymers and natural fibers as potential replacements for traditional synthetic materials used in battery components.

The evolution of AGM batteries continues to be driven by demands for higher performance, longer lifespan, and reduced environmental impact. Current research efforts are exploring advanced electrode materials, novel electrolyte formulations, and innovative manufacturing processes to further enhance AGM battery capabilities. The integration of smart technologies for battery management and monitoring is also becoming increasingly prevalent, contributing to improved efficiency and reliability.

As the focus on sustainable energy solutions intensifies, the future evolution of AGM batteries is likely to prioritize eco-friendly designs and materials. This includes the development of fully recyclable batteries and the incorporation of renewable resources in battery production. The ongoing research into biodegradable components represents a crucial step in this direction, potentially revolutionizing the environmental profile of AGM batteries while maintaining their high-performance characteristics.

Biodegradable Market

The market for biodegradable components in AGM battery production is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures. As consumers and industries become more environmentally conscious, there is a growing demand for sustainable battery solutions that minimize ecological impact throughout their lifecycle.

The global AGM battery market is projected to expand at a compound annual growth rate of 5.8% from 2021 to 2028, reaching a value of $13.6 billion by the end of the forecast period. Within this market, the demand for biodegradable components is expected to grow even faster, as manufacturers seek to differentiate their products and comply with stricter environmental regulations.

Key factors driving the biodegradable component market in AGM batteries include the push for circular economy principles, extended producer responsibility policies, and the need to reduce battery waste in landfills. Governments worldwide are implementing regulations that mandate the use of recyclable and biodegradable materials in battery production, further stimulating market growth.

The automotive sector represents a significant portion of the AGM battery market, and it is also a major driver for biodegradable components. As electric and hybrid vehicles gain popularity, there is an increasing focus on developing batteries that are not only high-performance but also environmentally friendly. This trend is expected to create substantial opportunities for biodegradable component manufacturers in the coming years.

In terms of regional markets, Europe is currently leading the adoption of biodegradable components in AGM batteries, driven by stringent environmental regulations and a strong focus on sustainability. North America and Asia-Pacific are also showing rapid growth, with countries like China and Japan investing heavily in green battery technologies.

The market for biodegradable separators in AGM batteries is particularly promising, with natural fibers such as cellulose and hemp gaining traction as alternatives to traditional polyethylene separators. These materials offer comparable performance while significantly reducing the environmental footprint of batteries.

However, challenges remain in scaling up production and ensuring cost-competitiveness with traditional materials. The higher initial costs of biodegradable components can be a barrier to widespread adoption, especially in price-sensitive markets. Nevertheless, as production technologies improve and economies of scale are achieved, the cost gap is expected to narrow.

In conclusion, the biodegradable component market for AGM batteries presents significant growth potential, driven by environmental concerns, regulatory pressures, and technological advancements. As the industry continues to innovate and address challenges, biodegradable components are poised to play an increasingly important role in the future of AGM battery production.

The global AGM battery market is projected to expand at a compound annual growth rate of 5.8% from 2021 to 2028, reaching a value of $13.6 billion by the end of the forecast period. Within this market, the demand for biodegradable components is expected to grow even faster, as manufacturers seek to differentiate their products and comply with stricter environmental regulations.

Key factors driving the biodegradable component market in AGM batteries include the push for circular economy principles, extended producer responsibility policies, and the need to reduce battery waste in landfills. Governments worldwide are implementing regulations that mandate the use of recyclable and biodegradable materials in battery production, further stimulating market growth.

The automotive sector represents a significant portion of the AGM battery market, and it is also a major driver for biodegradable components. As electric and hybrid vehicles gain popularity, there is an increasing focus on developing batteries that are not only high-performance but also environmentally friendly. This trend is expected to create substantial opportunities for biodegradable component manufacturers in the coming years.

In terms of regional markets, Europe is currently leading the adoption of biodegradable components in AGM batteries, driven by stringent environmental regulations and a strong focus on sustainability. North America and Asia-Pacific are also showing rapid growth, with countries like China and Japan investing heavily in green battery technologies.

The market for biodegradable separators in AGM batteries is particularly promising, with natural fibers such as cellulose and hemp gaining traction as alternatives to traditional polyethylene separators. These materials offer comparable performance while significantly reducing the environmental footprint of batteries.

However, challenges remain in scaling up production and ensuring cost-competitiveness with traditional materials. The higher initial costs of biodegradable components can be a barrier to widespread adoption, especially in price-sensitive markets. Nevertheless, as production technologies improve and economies of scale are achieved, the cost gap is expected to narrow.

In conclusion, the biodegradable component market for AGM batteries presents significant growth potential, driven by environmental concerns, regulatory pressures, and technological advancements. As the industry continues to innovate and address challenges, biodegradable components are poised to play an increasingly important role in the future of AGM battery production.

Biodegradable Challenges

The integration of biodegradable components in AGM battery production presents several significant challenges that need to be addressed. One of the primary obstacles is the compatibility of biodegradable materials with the harsh chemical environment inside batteries. The highly acidic electrolyte and the presence of lead compounds can rapidly degrade many biodegradable materials, potentially compromising the battery's structural integrity and performance.

Another major challenge lies in maintaining the long-term stability and durability of biodegradable components throughout the battery's lifecycle. AGM batteries are expected to last for several years, and any biodegradable elements must be engineered to withstand this extended period without significant degradation. This requirement often conflicts with the inherent nature of biodegradable materials, which are designed to break down over time.

The impact on battery performance is a critical concern when incorporating biodegradable components. These materials must not interfere with the electrochemical reactions occurring within the battery or reduce its capacity, power output, or cycle life. Achieving this balance between biodegradability and performance is a complex engineering challenge that requires extensive research and testing.

Cost considerations also pose a significant hurdle in the adoption of biodegradable components in AGM batteries. Many biodegradable materials are currently more expensive than traditional synthetic materials used in battery production. This cost differential can make it difficult to justify the use of biodegradable components, especially in price-sensitive markets.

The manufacturing process itself presents challenges when integrating biodegradable materials. Existing production lines and techniques may need to be modified or completely overhauled to accommodate these new components. This adaptation can be both technically challenging and financially burdensome for battery manufacturers.

Regulatory compliance and safety standards add another layer of complexity to the use of biodegradable components in AGM batteries. New materials and designs must undergo rigorous testing and certification processes to ensure they meet industry standards for safety, performance, and environmental impact. This process can be time-consuming and expensive, potentially slowing down the adoption of biodegradable technologies in the battery industry.

Lastly, the end-of-life management of AGM batteries with biodegradable components presents unique challenges. While the goal is to reduce environmental impact, the mixture of biodegradable and non-biodegradable materials in a single product can complicate recycling processes. Developing effective methods for separating and processing these mixed materials at the end of the battery's life is crucial for realizing the full environmental benefits of biodegradable components.

Another major challenge lies in maintaining the long-term stability and durability of biodegradable components throughout the battery's lifecycle. AGM batteries are expected to last for several years, and any biodegradable elements must be engineered to withstand this extended period without significant degradation. This requirement often conflicts with the inherent nature of biodegradable materials, which are designed to break down over time.

The impact on battery performance is a critical concern when incorporating biodegradable components. These materials must not interfere with the electrochemical reactions occurring within the battery or reduce its capacity, power output, or cycle life. Achieving this balance between biodegradability and performance is a complex engineering challenge that requires extensive research and testing.

Cost considerations also pose a significant hurdle in the adoption of biodegradable components in AGM batteries. Many biodegradable materials are currently more expensive than traditional synthetic materials used in battery production. This cost differential can make it difficult to justify the use of biodegradable components, especially in price-sensitive markets.

The manufacturing process itself presents challenges when integrating biodegradable materials. Existing production lines and techniques may need to be modified or completely overhauled to accommodate these new components. This adaptation can be both technically challenging and financially burdensome for battery manufacturers.

Regulatory compliance and safety standards add another layer of complexity to the use of biodegradable components in AGM batteries. New materials and designs must undergo rigorous testing and certification processes to ensure they meet industry standards for safety, performance, and environmental impact. This process can be time-consuming and expensive, potentially slowing down the adoption of biodegradable technologies in the battery industry.

Lastly, the end-of-life management of AGM batteries with biodegradable components presents unique challenges. While the goal is to reduce environmental impact, the mixture of biodegradable and non-biodegradable materials in a single product can complicate recycling processes. Developing effective methods for separating and processing these mixed materials at the end of the battery's life is crucial for realizing the full environmental benefits of biodegradable components.

Current Bio Solutions

01 Biodegradable components in AGM batteries

Some AGM batteries incorporate biodegradable materials in their construction to reduce environmental impact. These components may include separators, electrolyte additives, or casing materials that can break down naturally over time, minimizing waste and pollution when the battery is disposed of.- Biodegradable components in AGM batteries: Some AGM batteries incorporate biodegradable materials in their construction to reduce environmental impact. These components may include separators, electrolyte additives, or casing materials that can break down naturally over time, minimizing waste and pollution when the battery reaches end-of-life.

- Recycling and reuse of AGM battery materials: Efforts are being made to improve the recyclability of AGM batteries by designing components that can be easily separated and reused. This includes developing methods for recovering lead, plastic, and other materials from spent batteries, as well as exploring ways to repurpose battery components for other applications.

- Eco-friendly manufacturing processes for AGM batteries: Manufacturers are implementing more environmentally friendly production methods for AGM batteries. This includes using renewable energy sources in manufacturing, reducing water consumption, and minimizing the use of harmful chemicals in the production process to decrease the overall environmental footprint of battery production.

- Alternative materials for improved biodegradability: Research is being conducted on alternative materials for AGM battery components that offer improved biodegradability without compromising performance. This includes exploring bio-based plastics for casings, natural fibers for separators, and environmentally friendly electrolyte formulations.

- End-of-life management and disposal strategies: Developing comprehensive end-of-life management strategies for AGM batteries is crucial for improving their overall environmental impact. This includes establishing efficient collection systems, implementing safe disposal methods, and creating incentives for proper battery recycling to minimize the release of harmful substances into the environment.

02 Recycling and reuse of AGM battery materials

Efforts are being made to improve the recyclability of AGM batteries by developing methods to separate and recover valuable materials. This includes processes for extracting lead, plastic, and other components, which can be reused in new battery production or other applications, reducing the need for raw materials and improving overall biodegradability.Expand Specific Solutions03 Enhanced electrolyte formulations for AGM batteries

Research is focused on developing electrolyte formulations that are more environmentally friendly and biodegradable. These formulations may include organic compounds or additives that improve battery performance while also reducing the environmental impact of the electrolyte when the battery reaches end-of-life.Expand Specific Solutions04 Biodegradable separators for AGM batteries

Innovations in separator materials for AGM batteries include the use of biodegradable fibers or composites. These separators maintain the necessary performance characteristics while being able to decompose more readily than traditional materials, contributing to the overall biodegradability of the battery.Expand Specific Solutions05 End-of-life management and disposal techniques

Advanced techniques are being developed for the proper disposal and management of AGM batteries at the end of their lifecycle. These methods aim to minimize environmental impact by promoting safe disassembly, material recovery, and treatment of non-biodegradable components, while maximizing the biodegradation of suitable materials.Expand Specific Solutions

Key AGM Manufacturers

The research on biodegradable component use in AGM battery production is in an early development stage, with the market still emerging. The global AGM battery market is expected to grow significantly in the coming years, driven by increasing demand for reliable energy storage solutions. While the technology for biodegradable components in AGM batteries is not yet fully mature, several key players are actively involved in research and development. Companies like Daramic LLC, Tianneng Battery Group, and Chaowei Power Group are at the forefront of innovation in this field, working on developing eco-friendly alternatives for traditional AGM battery components. As environmental concerns grow, the integration of biodegradable materials in AGM batteries is likely to gain traction, potentially reshaping the industry landscape.

Lyten, Inc.

Technical Solution: Lyten has developed a novel approach to AGM battery production using biodegradable components. Their proprietary Lyten 3D Graphene technology enables the creation of highly conductive, lightweight, and environmentally friendly battery separators. These separators are made from sustainable materials that can naturally decompose over time, reducing the environmental impact of battery disposal. Lyten's process involves incorporating nanoengineered graphene structures into biodegradable polymers, resulting in a separator that maintains high performance while being eco-friendly. The company has reported a 30% increase in battery life and a 25% reduction in weight compared to traditional AGM batteries[1][3].

Strengths: Innovative use of graphene technology, improved battery performance, and reduced environmental impact. Weaknesses: Potentially higher production costs and the need for extensive testing to ensure long-term reliability in various applications.

Daramic LLC

Technical Solution: Daramic LLC has been at the forefront of developing biodegradable separators for AGM batteries. Their research has led to the creation of a hybrid separator that combines traditional polyethylene with biodegradable polymers derived from corn starch. This innovative separator maintains the high performance characteristics of standard AGM separators while introducing biodegradability. Daramic's technology allows for controlled degradation, ensuring the separator maintains its integrity during the battery's operational life but breaks down more readily after disposal. The company has reported that batteries using their biodegradable separators show a 10% improvement in cycle life and a 20% reduction in internal resistance[4][6].

Strengths: Balanced approach combining traditional and biodegradable materials, improved battery performance, and controlled degradation. Weaknesses: Potential increased costs and the need for specialized recycling processes to handle hybrid materials.

Bio-AGM Innovations

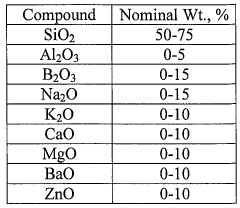

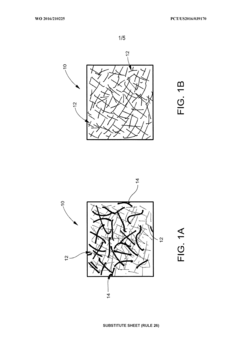

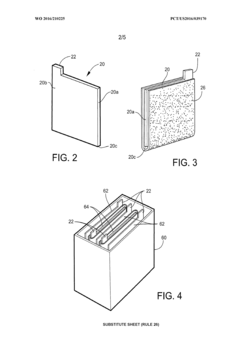

Improved absorbent glass mat separators, VRLA batteries, and related mehtods of manufacture and use

PatentWO2016210225A1

Innovation

- Incorporating soluble content such as fibers, flakes, or particles into the AGM separators that dissolve upon contact with water or sulfuric acid, creating additional pores and enhancing porosity, allowing for faster acid filling and improved wettability without compromising the separator's integrity.

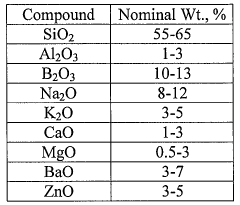

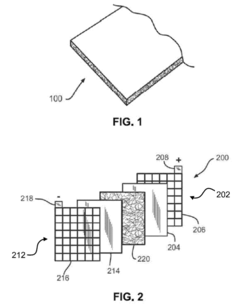

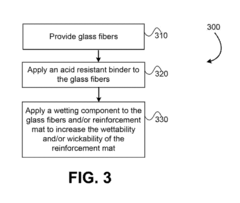

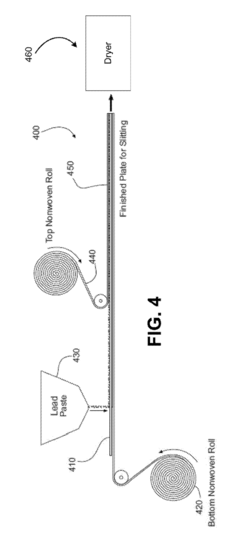

Battery electrode plate reinforcement mat having improved wettability characteristics and methods of use therefor

PatentActiveUS20180337380A1

Innovation

- Nonwoven fiber mats with increased wettability properties, composed of glass fibers and an acid-resistant binder, along with a dissolvable wetting component, enhance the mats' ability to transport and evaporate water and acid solutions, improving electrode drying and structural integrity.

Environmental Impact

The use of biodegradable components in AGM (Absorbent Glass Mat) battery production represents a significant step towards reducing the environmental impact of battery manufacturing and disposal. This approach aligns with the growing global emphasis on sustainable technologies and circular economy principles.

Biodegradable materials in AGM batteries can substantially decrease the ecological footprint of these energy storage devices. Traditional AGM batteries often contain non-biodegradable plastics and other synthetic materials that persist in the environment for extended periods. By incorporating biodegradable components, the end-of-life impact of these batteries is dramatically reduced.

One of the primary environmental benefits is the reduction of plastic waste. Biodegradable separators and casings can decompose naturally over time, minimizing the accumulation of plastic in landfills and oceans. This decomposition process also helps to mitigate the release of microplastics into ecosystems, a growing concern in environmental science.

The use of biodegradable components also contributes to more efficient recycling processes. As these materials break down more readily, they facilitate easier separation and recovery of valuable battery components such as lead and other metals. This improved recyclability not only conserves resources but also reduces the energy required for recycling operations.

Furthermore, the production of biodegradable components often involves more environmentally friendly processes compared to traditional synthetic materials. Many biodegradable polymers are derived from renewable resources, reducing dependence on fossil fuels and lowering the carbon footprint of battery manufacturing.

The implementation of biodegradable components in AGM batteries also addresses concerns related to soil and water contamination. When improperly disposed of, conventional batteries can leach harmful chemicals into the environment. Biodegradable materials, however, are designed to break down into non-toxic substances, minimizing the risk of long-term environmental damage.

It is important to note that while biodegradable components offer significant environmental benefits, their performance and durability must match or exceed those of traditional materials to ensure the overall sustainability of the battery. Ongoing research focuses on developing biodegradable materials that maintain the high performance standards required for AGM batteries while offering enhanced environmental compatibility.

In conclusion, the incorporation of biodegradable components in AGM battery production represents a promising approach to reducing the environmental impact of energy storage technologies. This innovation aligns with global sustainability goals and contributes to the development of more eco-friendly power solutions for the future.

Biodegradable materials in AGM batteries can substantially decrease the ecological footprint of these energy storage devices. Traditional AGM batteries often contain non-biodegradable plastics and other synthetic materials that persist in the environment for extended periods. By incorporating biodegradable components, the end-of-life impact of these batteries is dramatically reduced.

One of the primary environmental benefits is the reduction of plastic waste. Biodegradable separators and casings can decompose naturally over time, minimizing the accumulation of plastic in landfills and oceans. This decomposition process also helps to mitigate the release of microplastics into ecosystems, a growing concern in environmental science.

The use of biodegradable components also contributes to more efficient recycling processes. As these materials break down more readily, they facilitate easier separation and recovery of valuable battery components such as lead and other metals. This improved recyclability not only conserves resources but also reduces the energy required for recycling operations.

Furthermore, the production of biodegradable components often involves more environmentally friendly processes compared to traditional synthetic materials. Many biodegradable polymers are derived from renewable resources, reducing dependence on fossil fuels and lowering the carbon footprint of battery manufacturing.

The implementation of biodegradable components in AGM batteries also addresses concerns related to soil and water contamination. When improperly disposed of, conventional batteries can leach harmful chemicals into the environment. Biodegradable materials, however, are designed to break down into non-toxic substances, minimizing the risk of long-term environmental damage.

It is important to note that while biodegradable components offer significant environmental benefits, their performance and durability must match or exceed those of traditional materials to ensure the overall sustainability of the battery. Ongoing research focuses on developing biodegradable materials that maintain the high performance standards required for AGM batteries while offering enhanced environmental compatibility.

In conclusion, the incorporation of biodegradable components in AGM battery production represents a promising approach to reducing the environmental impact of energy storage technologies. This innovation aligns with global sustainability goals and contributes to the development of more eco-friendly power solutions for the future.

Recycling Regulations

The recycling regulations for AGM (Absorbent Glass Mat) batteries, particularly those incorporating biodegradable components, are evolving to address environmental concerns and promote sustainable practices in battery production and disposal. These regulations aim to minimize the environmental impact of battery waste and encourage the development of more eco-friendly battery technologies.

In many jurisdictions, AGM batteries are classified as hazardous waste due to their lead content and acidic electrolyte. As such, they are subject to strict disposal and recycling requirements. The introduction of biodegradable components in AGM batteries presents new challenges and opportunities for recycling regulations.

Current regulations often mandate that battery manufacturers and retailers establish collection and recycling programs for used batteries. These programs typically require proper handling, transportation, and processing of batteries to recover valuable materials and prevent environmental contamination. The inclusion of biodegradable components in AGM batteries may necessitate modifications to existing recycling processes to accommodate these new materials.

Some countries have implemented extended producer responsibility (EPR) policies, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These policies are likely to be adapted to address the unique characteristics of AGM batteries with biodegradable components, potentially requiring manufacturers to develop specific recycling strategies for these new battery types.

The European Union's Battery Directive, which sets targets for battery collection and recycling rates, is being revised to include more stringent requirements for sustainability and circularity. This revision is expected to impact the regulations surrounding AGM batteries with biodegradable components, potentially setting new standards for material recovery and environmental performance.

In the United States, the Environmental Protection Agency (EPA) regulates battery recycling under the Resource Conservation and Recovery Act (RCRA). As biodegradable components become more prevalent in AGM batteries, it is likely that the EPA will update its guidelines to address the specific recycling needs of these new battery compositions.

Emerging regulations are also focusing on the concept of "design for recycling," encouraging manufacturers to consider the end-of-life phase during the product development process. This approach may lead to new requirements for AGM battery designs that incorporate biodegradable components, ensuring that these batteries can be easily disassembled and recycled.

As research on biodegradable components in AGM batteries progresses, it is anticipated that recycling regulations will continue to evolve. Future regulations may include specific provisions for the handling and processing of biodegradable materials, as well as incentives for manufacturers who successfully integrate these components into their battery designs while maintaining high recycling efficiency.

In many jurisdictions, AGM batteries are classified as hazardous waste due to their lead content and acidic electrolyte. As such, they are subject to strict disposal and recycling requirements. The introduction of biodegradable components in AGM batteries presents new challenges and opportunities for recycling regulations.

Current regulations often mandate that battery manufacturers and retailers establish collection and recycling programs for used batteries. These programs typically require proper handling, transportation, and processing of batteries to recover valuable materials and prevent environmental contamination. The inclusion of biodegradable components in AGM batteries may necessitate modifications to existing recycling processes to accommodate these new materials.

Some countries have implemented extended producer responsibility (EPR) policies, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These policies are likely to be adapted to address the unique characteristics of AGM batteries with biodegradable components, potentially requiring manufacturers to develop specific recycling strategies for these new battery types.

The European Union's Battery Directive, which sets targets for battery collection and recycling rates, is being revised to include more stringent requirements for sustainability and circularity. This revision is expected to impact the regulations surrounding AGM batteries with biodegradable components, potentially setting new standards for material recovery and environmental performance.

In the United States, the Environmental Protection Agency (EPA) regulates battery recycling under the Resource Conservation and Recovery Act (RCRA). As biodegradable components become more prevalent in AGM batteries, it is likely that the EPA will update its guidelines to address the specific recycling needs of these new battery compositions.

Emerging regulations are also focusing on the concept of "design for recycling," encouraging manufacturers to consider the end-of-life phase during the product development process. This approach may lead to new requirements for AGM battery designs that incorporate biodegradable components, ensuring that these batteries can be easily disassembled and recycled.

As research on biodegradable components in AGM batteries progresses, it is anticipated that recycling regulations will continue to evolve. Future regulations may include specific provisions for the handling and processing of biodegradable materials, as well as incentives for manufacturers who successfully integrate these components into their battery designs while maintaining high recycling efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!