Durability of AGM Battery in High-Cyclic Load Conditions

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in lead-acid battery technology, particularly in addressing the challenges of durability under high-cyclic load conditions. AGM batteries emerged in the 1970s as a response to the limitations of traditional flooded lead-acid batteries, offering improved performance and reliability.

Initially developed for military and aircraft applications, AGM batteries quickly found their way into various industries due to their superior characteristics. The key innovation in AGM technology lies in the use of a fiberglass mat separator that absorbs and immobilizes the electrolyte, allowing for a sealed and maintenance-free design. This construction not only prevents electrolyte leakage but also enables the battery to be mounted in any orientation, expanding its versatility.

Throughout the 1980s and 1990s, AGM battery technology underwent significant refinements, focusing on enhancing cycle life and charge acceptance. Manufacturers introduced thinner plates and improved grid alloys, which led to reduced internal resistance and faster charging capabilities. These advancements made AGM batteries increasingly suitable for high-cyclic load applications, such as in renewable energy systems and uninterruptible power supplies (UPS).

The turn of the millennium saw a surge in AGM battery adoption across various sectors, including automotive, telecommunications, and renewable energy. This widespread use drove further innovations, particularly in the areas of deep-cycle performance and rapid charge recovery. Researchers and engineers focused on optimizing the electrolyte composition and improving the manufacturing processes to enhance the batteries' durability under frequent charge-discharge cycles.

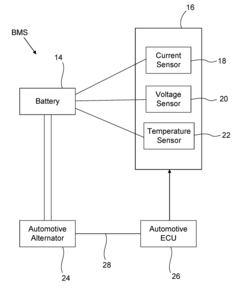

Recent years have witnessed the integration of smart battery management systems (BMS) with AGM technology. These systems monitor battery health, optimize charging patterns, and provide real-time data on battery performance. This integration has significantly extended the lifespan of AGM batteries in high-cyclic load environments by preventing overcharging and ensuring balanced cell performance.

The ongoing evolution of AGM batteries continues to address the challenges of durability in high-cyclic load conditions. Current research focuses on nano-enhanced electrode materials and advanced electrolyte formulations to further improve cycle life and charge efficiency. Additionally, efforts are being made to increase the energy density of AGM batteries while maintaining their robust performance characteristics.

As environmental concerns grow, the development of AGM batteries has also aligned with sustainability goals. Manufacturers are exploring ways to increase the recyclability of AGM batteries and reduce the environmental impact of their production. This eco-friendly approach, coupled with continuous performance improvements, ensures that AGM batteries remain a viable and evolving technology in the energy storage landscape.

Initially developed for military and aircraft applications, AGM batteries quickly found their way into various industries due to their superior characteristics. The key innovation in AGM technology lies in the use of a fiberglass mat separator that absorbs and immobilizes the electrolyte, allowing for a sealed and maintenance-free design. This construction not only prevents electrolyte leakage but also enables the battery to be mounted in any orientation, expanding its versatility.

Throughout the 1980s and 1990s, AGM battery technology underwent significant refinements, focusing on enhancing cycle life and charge acceptance. Manufacturers introduced thinner plates and improved grid alloys, which led to reduced internal resistance and faster charging capabilities. These advancements made AGM batteries increasingly suitable for high-cyclic load applications, such as in renewable energy systems and uninterruptible power supplies (UPS).

The turn of the millennium saw a surge in AGM battery adoption across various sectors, including automotive, telecommunications, and renewable energy. This widespread use drove further innovations, particularly in the areas of deep-cycle performance and rapid charge recovery. Researchers and engineers focused on optimizing the electrolyte composition and improving the manufacturing processes to enhance the batteries' durability under frequent charge-discharge cycles.

Recent years have witnessed the integration of smart battery management systems (BMS) with AGM technology. These systems monitor battery health, optimize charging patterns, and provide real-time data on battery performance. This integration has significantly extended the lifespan of AGM batteries in high-cyclic load environments by preventing overcharging and ensuring balanced cell performance.

The ongoing evolution of AGM batteries continues to address the challenges of durability in high-cyclic load conditions. Current research focuses on nano-enhanced electrode materials and advanced electrolyte formulations to further improve cycle life and charge efficiency. Additionally, efforts are being made to increase the energy density of AGM batteries while maintaining their robust performance characteristics.

As environmental concerns grow, the development of AGM batteries has also aligned with sustainability goals. Manufacturers are exploring ways to increase the recyclability of AGM batteries and reduce the environmental impact of their production. This eco-friendly approach, coupled with continuous performance improvements, ensures that AGM batteries remain a viable and evolving technology in the energy storage landscape.

High-Cyclic Load Market

The high-cyclic load market for AGM (Absorbent Glass Mat) batteries has experienced significant growth in recent years, driven by the increasing demand for reliable energy storage solutions in various applications. This market segment specifically caters to industries and sectors that require batteries capable of withstanding frequent charge-discharge cycles while maintaining performance and longevity.

One of the primary drivers of this market is the automotive industry, particularly in the realm of start-stop vehicle systems. As automotive manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, start-stop technology has become increasingly prevalent. AGM batteries are well-suited for these applications due to their ability to handle repeated cycling and provide the necessary power for frequent engine restarts.

The renewable energy sector also contributes substantially to the high-cyclic load market for AGM batteries. With the growing adoption of solar and wind power systems, there is a rising need for energy storage solutions that can efficiently manage the intermittent nature of these renewable sources. AGM batteries have proven to be a reliable choice for off-grid and grid-tied systems, offering the durability required for daily cycling in energy storage applications.

The telecommunications industry represents another significant market for high-cyclic load AGM batteries. As the global demand for uninterrupted communication services continues to rise, telecom companies rely on robust backup power systems to ensure network reliability. AGM batteries are widely used in cell tower installations and other critical infrastructure, where they must withstand frequent power outages and provide consistent performance.

In the industrial sector, AGM batteries find applications in material handling equipment, such as forklifts and electric pallet jacks. These batteries are subjected to multiple charge-discharge cycles throughout the workday, making durability a crucial factor. The ability of AGM batteries to maintain performance under high-cyclic load conditions has led to their widespread adoption in this field.

The marine industry also contributes to the market demand for high-cyclic load AGM batteries. Recreational boats and commercial vessels require reliable power sources for various onboard systems, including navigation equipment, lighting, and appliances. AGM batteries are favored for their ability to withstand the harsh marine environment while providing consistent power through numerous cycles.

As the market for high-cyclic load AGM batteries continues to expand, manufacturers are focusing on improving the technology to meet the evolving needs of various industries. Research and development efforts are aimed at enhancing cycle life, increasing energy density, and improving overall performance under demanding conditions. This ongoing innovation is expected to further drive market growth and open up new applications for AGM batteries in high-cyclic load environments.

One of the primary drivers of this market is the automotive industry, particularly in the realm of start-stop vehicle systems. As automotive manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, start-stop technology has become increasingly prevalent. AGM batteries are well-suited for these applications due to their ability to handle repeated cycling and provide the necessary power for frequent engine restarts.

The renewable energy sector also contributes substantially to the high-cyclic load market for AGM batteries. With the growing adoption of solar and wind power systems, there is a rising need for energy storage solutions that can efficiently manage the intermittent nature of these renewable sources. AGM batteries have proven to be a reliable choice for off-grid and grid-tied systems, offering the durability required for daily cycling in energy storage applications.

The telecommunications industry represents another significant market for high-cyclic load AGM batteries. As the global demand for uninterrupted communication services continues to rise, telecom companies rely on robust backup power systems to ensure network reliability. AGM batteries are widely used in cell tower installations and other critical infrastructure, where they must withstand frequent power outages and provide consistent performance.

In the industrial sector, AGM batteries find applications in material handling equipment, such as forklifts and electric pallet jacks. These batteries are subjected to multiple charge-discharge cycles throughout the workday, making durability a crucial factor. The ability of AGM batteries to maintain performance under high-cyclic load conditions has led to their widespread adoption in this field.

The marine industry also contributes to the market demand for high-cyclic load AGM batteries. Recreational boats and commercial vessels require reliable power sources for various onboard systems, including navigation equipment, lighting, and appliances. AGM batteries are favored for their ability to withstand the harsh marine environment while providing consistent power through numerous cycles.

As the market for high-cyclic load AGM batteries continues to expand, manufacturers are focusing on improving the technology to meet the evolving needs of various industries. Research and development efforts are aimed at enhancing cycle life, increasing energy density, and improving overall performance under demanding conditions. This ongoing innovation is expected to further drive market growth and open up new applications for AGM batteries in high-cyclic load environments.

AGM Durability Challenges

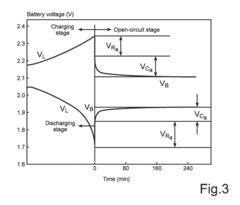

AGM (Absorbent Glass Mat) batteries face significant durability challenges when subjected to high-cyclic load conditions. These conditions, characterized by frequent charge and discharge cycles, place immense stress on the battery's internal components, leading to accelerated degradation and reduced lifespan.

One of the primary challenges is the gradual breakdown of the AGM separator material. The glass mat, which serves as both a separator and electrolyte reservoir, can deteriorate over time due to repeated compression and expansion during cycling. This degradation can lead to internal short circuits and reduced capacity retention.

The positive plate in AGM batteries is particularly vulnerable to high-cyclic loads. The active material on these plates can shed or become detached from the grid structure, a phenomenon known as "positive plate softening." This results in a loss of active material and a corresponding decrease in the battery's capacity and performance.

Sulfation presents another significant challenge to AGM battery durability. During high-cyclic use, especially if the battery is not fully recharged between cycles, lead sulfate crystals can form on the plates. These crystals reduce the battery's ability to accept and deliver charge, further diminishing its capacity and efficiency.

The constant cycling also puts stress on the battery's internal connections. Vibrations and thermal expansion/contraction can cause loosening of terminal connections or internal cell connections, leading to increased internal resistance and reduced overall performance.

Thermal management is a critical concern in high-cyclic applications. The frequent charge and discharge cycles generate heat, which can accelerate chemical reactions within the battery. Excessive heat can lead to premature aging of the battery components, including the separator and plate materials.

Electrolyte dry-out is another durability challenge faced by AGM batteries in high-cyclic conditions. Despite the sealed nature of AGM batteries, small amounts of electrolyte can be lost through venting during gas recombination, particularly under high-temperature or overcharging conditions. This gradual loss of electrolyte can impact the battery's performance and lifespan.

Addressing these durability challenges requires a multifaceted approach, including advanced materials science, improved battery management systems, and optimized charging strategies. Innovations in electrode and separator materials, enhanced thermal management techniques, and intelligent charging algorithms are crucial for extending the lifespan of AGM batteries in high-cyclic load applications.

One of the primary challenges is the gradual breakdown of the AGM separator material. The glass mat, which serves as both a separator and electrolyte reservoir, can deteriorate over time due to repeated compression and expansion during cycling. This degradation can lead to internal short circuits and reduced capacity retention.

The positive plate in AGM batteries is particularly vulnerable to high-cyclic loads. The active material on these plates can shed or become detached from the grid structure, a phenomenon known as "positive plate softening." This results in a loss of active material and a corresponding decrease in the battery's capacity and performance.

Sulfation presents another significant challenge to AGM battery durability. During high-cyclic use, especially if the battery is not fully recharged between cycles, lead sulfate crystals can form on the plates. These crystals reduce the battery's ability to accept and deliver charge, further diminishing its capacity and efficiency.

The constant cycling also puts stress on the battery's internal connections. Vibrations and thermal expansion/contraction can cause loosening of terminal connections or internal cell connections, leading to increased internal resistance and reduced overall performance.

Thermal management is a critical concern in high-cyclic applications. The frequent charge and discharge cycles generate heat, which can accelerate chemical reactions within the battery. Excessive heat can lead to premature aging of the battery components, including the separator and plate materials.

Electrolyte dry-out is another durability challenge faced by AGM batteries in high-cyclic conditions. Despite the sealed nature of AGM batteries, small amounts of electrolyte can be lost through venting during gas recombination, particularly under high-temperature or overcharging conditions. This gradual loss of electrolyte can impact the battery's performance and lifespan.

Addressing these durability challenges requires a multifaceted approach, including advanced materials science, improved battery management systems, and optimized charging strategies. Innovations in electrode and separator materials, enhanced thermal management techniques, and intelligent charging algorithms are crucial for extending the lifespan of AGM batteries in high-cyclic load applications.

Current AGM Solutions

01 Improved electrode design

Enhancing AGM battery durability through advanced electrode designs, including optimized grid structures and active material compositions. These improvements help reduce corrosion, increase charge acceptance, and extend overall battery life.- Improved electrode design: Enhancing AGM battery durability through advanced electrode designs, including optimized grid structures and active material compositions. These improvements help reduce corrosion, increase cycle life, and enhance overall battery performance.

- Electrolyte management: Implementing effective electrolyte management systems to maintain proper saturation levels and distribution within the AGM separator. This includes innovative filling techniques and pressure control mechanisms to prevent dry-out and extend battery life.

- Thermal management: Developing thermal management solutions to regulate battery temperature during operation and charging. This involves heat dissipation techniques and temperature-controlled charging algorithms to prevent thermal runaway and prolong battery lifespan.

- Separator technology: Utilizing advanced separator materials and designs to improve electrolyte retention, reduce internal resistance, and enhance overall battery performance. This includes the use of nano-fibers and composite materials to increase durability and cycle life.

- Charge control and monitoring: Implementing intelligent charge control systems and battery monitoring technologies to optimize charging processes and prevent overcharging or deep discharging. This includes the use of sensors and algorithms to adapt charging parameters based on battery condition and usage patterns.

02 Electrolyte management systems

Implementing sophisticated electrolyte management systems to maintain optimal acid distribution and prevent dry-out. This includes advanced separators, pressure control valves, and recombination technologies to enhance battery performance and longevity.Expand Specific Solutions03 Thermal management solutions

Developing effective thermal management solutions to regulate battery temperature and prevent degradation due to heat stress. This involves innovative cooling systems, heat-resistant materials, and temperature monitoring technologies to extend AGM battery lifespan.Expand Specific Solutions04 Advanced manufacturing processes

Utilizing cutting-edge manufacturing processes to improve AGM battery durability. This includes precision assembly techniques, quality control measures, and advanced curing methods to enhance overall battery construction and performance.Expand Specific Solutions05 Smart battery management systems

Incorporating intelligent battery management systems to optimize charging, discharging, and overall battery health. These systems use advanced algorithms and sensors to monitor battery conditions, predict failures, and adjust operating parameters for maximum durability.Expand Specific Solutions

Key AGM Manufacturers

The durability of AGM batteries in high-cyclic load conditions represents a mature technology within the energy storage sector, with a competitive landscape shaped by established players and emerging innovators. The market is in a growth phase, driven by increasing demand for reliable energy storage solutions across various industries. Key players like Johnson Controls, Daramic LLC, and Stryten Energy LLC are leading the field, leveraging their extensive experience and R&D capabilities. Emerging companies such as ArcActive Ltd. and Narada Power are introducing innovative technologies to enhance battery performance and longevity. The market size is substantial, with potential for further expansion as industries increasingly adopt AGM batteries for high-cyclic applications.

Zhejiang Narada Power Source Co., Ltd.

Technical Solution: Narada has developed a range of AGM batteries specifically engineered for high-cyclic load applications. Their technology focuses on optimizing the internal structure of the battery to enhance durability. Narada employs a high-purity lead alloy grid with additives that improve corrosion resistance and mechanical strength[1]. The company has also developed a proprietary paste formula that includes carbon nanotubes, which enhance the battery's charge acceptance and cycle life. Narada's AGM batteries feature a unique separator design with increased porosity and wettability, improving electrolyte distribution and reducing acid stratification. Additionally, they have implemented advanced valve-regulated technology to maintain optimal internal pressure, crucial for long-term performance in high-cyclic load conditions[2]. Narada reports that their AGM batteries can achieve up to 1200 cycles at 50% depth of discharge in demanding applications[3].

Strengths: High cycle life, improved charge acceptance, good performance in high-temperature environments. Weaknesses: Potentially higher cost due to advanced materials, may require specific charging algorithms for optimal performance.

Stryten Energy LLC

Technical Solution: Stryten Energy has focused on enhancing AGM battery durability through their EFB (Enhanced Flooded Battery) technology, which bridges the gap between traditional flooded batteries and AGM. Their approach involves using a carbon additive in the negative plate to improve charge acceptance and cycle life in high-cyclic load conditions[1]. Stryten's AGM batteries also incorporate a proprietary plate design that reduces grid growth and positive plate softening, two common failure modes in high-cycle applications. The company has implemented advanced manufacturing processes, including precision plate formation and automated assembly, to ensure consistent quality and performance. Stryten's batteries feature a robust case design and internal compression system to maintain plate-to-plate contact throughout the battery's life, crucial for withstanding the stresses of high-cyclic loads[2].

Strengths: Improved charge acceptance, reduced grid growth, consistent performance. Weaknesses: May not offer as long a cycle life as some pure AGM designs, potential for higher self-discharge rates.

AGM Durability Patents

Negative mass for lead-acid battery electrodes and lead-acid battery including same

PatentActiveUS20210336249A1

Innovation

- The introduction of additives such as fine particle barium sulfate, two organic compounds (oxylignins), and a carbonaceous material to the negative active material in lead-acid battery electrodes, which are pre-mixed to form a blended expander mixture, improving the homogeneity and dispersion of the battery paste and enhancing the battery's cycling performance and water retention.

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) batteries in high-cyclic load conditions is a crucial consideration for their widespread adoption and sustainable use. These batteries, while offering numerous advantages in terms of performance and reliability, also present certain environmental challenges that must be addressed.

One of the primary environmental concerns associated with AGM batteries is the potential for lead contamination. Although AGM batteries are sealed and designed to prevent leakage, the lead content remains a significant issue, particularly at the end of the battery's life cycle. Proper recycling and disposal procedures are essential to mitigate the risk of lead entering the environment and causing harm to ecosystems and human health.

The manufacturing process of AGM batteries also contributes to their environmental footprint. The production of lead plates and the glass mat material requires energy-intensive processes and raw material extraction, which can lead to increased carbon emissions and resource depletion. However, it is worth noting that AGM batteries generally have a longer lifespan compared to traditional lead-acid batteries, potentially reducing the overall environmental impact over time.

In high-cyclic load conditions, the durability of AGM batteries becomes particularly relevant from an environmental perspective. The ability of these batteries to withstand frequent charge and discharge cycles without significant degradation means they need to be replaced less often. This extended lifespan reduces the demand for new battery production and the associated environmental costs of manufacturing and disposal.

The recycling potential of AGM batteries is another important factor in assessing their environmental impact. The lead and plastic components of these batteries are highly recyclable, with established recycling processes in many countries. Efficient recycling not only reduces the need for raw material extraction but also minimizes the risk of hazardous materials entering landfills or contaminating soil and water resources.

Energy efficiency is a key environmental consideration for AGM batteries in high-cyclic load applications. These batteries typically offer higher charge acceptance rates and lower internal resistance compared to flooded lead-acid batteries, resulting in improved energy efficiency. This efficiency translates to reduced energy consumption during charging cycles, potentially lowering the overall carbon footprint associated with battery operation.

The use of AGM batteries in renewable energy systems, such as solar and wind power installations, further enhances their positive environmental impact. By enabling efficient energy storage and distribution, AGM batteries support the integration of clean energy sources into the grid, contributing to the reduction of greenhouse gas emissions and dependence on fossil fuels.

One of the primary environmental concerns associated with AGM batteries is the potential for lead contamination. Although AGM batteries are sealed and designed to prevent leakage, the lead content remains a significant issue, particularly at the end of the battery's life cycle. Proper recycling and disposal procedures are essential to mitigate the risk of lead entering the environment and causing harm to ecosystems and human health.

The manufacturing process of AGM batteries also contributes to their environmental footprint. The production of lead plates and the glass mat material requires energy-intensive processes and raw material extraction, which can lead to increased carbon emissions and resource depletion. However, it is worth noting that AGM batteries generally have a longer lifespan compared to traditional lead-acid batteries, potentially reducing the overall environmental impact over time.

In high-cyclic load conditions, the durability of AGM batteries becomes particularly relevant from an environmental perspective. The ability of these batteries to withstand frequent charge and discharge cycles without significant degradation means they need to be replaced less often. This extended lifespan reduces the demand for new battery production and the associated environmental costs of manufacturing and disposal.

The recycling potential of AGM batteries is another important factor in assessing their environmental impact. The lead and plastic components of these batteries are highly recyclable, with established recycling processes in many countries. Efficient recycling not only reduces the need for raw material extraction but also minimizes the risk of hazardous materials entering landfills or contaminating soil and water resources.

Energy efficiency is a key environmental consideration for AGM batteries in high-cyclic load applications. These batteries typically offer higher charge acceptance rates and lower internal resistance compared to flooded lead-acid batteries, resulting in improved energy efficiency. This efficiency translates to reduced energy consumption during charging cycles, potentially lowering the overall carbon footprint associated with battery operation.

The use of AGM batteries in renewable energy systems, such as solar and wind power installations, further enhances their positive environmental impact. By enabling efficient energy storage and distribution, AGM batteries support the integration of clean energy sources into the grid, contributing to the reduction of greenhouse gas emissions and dependence on fossil fuels.

Safety Regulations

Safety regulations play a crucial role in ensuring the durability and reliability of AGM (Absorbent Glass Mat) batteries in high-cyclic load conditions. These regulations are designed to protect users, equipment, and the environment from potential hazards associated with battery operation and failure.

One of the primary safety concerns for AGM batteries in high-cyclic load applications is thermal management. Regulatory bodies such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have established standards for temperature limits and thermal runaway prevention. These standards typically require manufacturers to implement robust thermal management systems and conduct rigorous testing to ensure batteries can withstand repeated charge-discharge cycles without overheating.

Electrical safety is another key aspect addressed by regulations. Standards such as UL 1989 and IEC 60896-21 outline requirements for protection against short circuits, overcharging, and deep discharging. These regulations mandate the inclusion of safety features like pressure relief valves, flame-retardant materials, and proper insulation to prevent electrical hazards and potential explosions.

Environmental considerations are also incorporated into safety regulations for AGM batteries. The European Union's Battery Directive (2006/66/EC) and similar regulations in other regions set guidelines for the proper disposal and recycling of batteries. These regulations aim to minimize the environmental impact of battery production and disposal, particularly concerning the release of hazardous materials.

Transportation safety is a critical concern, especially for larger AGM batteries used in industrial applications. Regulations such as the UN Manual of Tests and Criteria and the IATA Dangerous Goods Regulations provide specific requirements for packaging, labeling, and shipping of batteries to prevent accidents during transit.

Workplace safety regulations, including those set by OSHA in the United States, address the handling and maintenance of AGM batteries in industrial settings. These regulations cover aspects such as proper ventilation, personal protective equipment, and emergency response procedures in case of battery-related incidents.

As AGM battery technology continues to evolve, safety regulations are regularly updated to address new challenges and improvements. For instance, recent updates to IEC 62619 have introduced more stringent requirements for lithium-ion batteries, which may influence future regulations for AGM batteries in high-cyclic load applications.

Compliance with these safety regulations is not only a legal requirement but also a critical factor in ensuring the long-term durability and reliability of AGM batteries in demanding applications. Manufacturers and users must stay informed about the latest regulatory updates and incorporate them into their design, production, and operational processes to maximize battery performance and safety in high-cyclic load conditions.

One of the primary safety concerns for AGM batteries in high-cyclic load applications is thermal management. Regulatory bodies such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have established standards for temperature limits and thermal runaway prevention. These standards typically require manufacturers to implement robust thermal management systems and conduct rigorous testing to ensure batteries can withstand repeated charge-discharge cycles without overheating.

Electrical safety is another key aspect addressed by regulations. Standards such as UL 1989 and IEC 60896-21 outline requirements for protection against short circuits, overcharging, and deep discharging. These regulations mandate the inclusion of safety features like pressure relief valves, flame-retardant materials, and proper insulation to prevent electrical hazards and potential explosions.

Environmental considerations are also incorporated into safety regulations for AGM batteries. The European Union's Battery Directive (2006/66/EC) and similar regulations in other regions set guidelines for the proper disposal and recycling of batteries. These regulations aim to minimize the environmental impact of battery production and disposal, particularly concerning the release of hazardous materials.

Transportation safety is a critical concern, especially for larger AGM batteries used in industrial applications. Regulations such as the UN Manual of Tests and Criteria and the IATA Dangerous Goods Regulations provide specific requirements for packaging, labeling, and shipping of batteries to prevent accidents during transit.

Workplace safety regulations, including those set by OSHA in the United States, address the handling and maintenance of AGM batteries in industrial settings. These regulations cover aspects such as proper ventilation, personal protective equipment, and emergency response procedures in case of battery-related incidents.

As AGM battery technology continues to evolve, safety regulations are regularly updated to address new challenges and improvements. For instance, recent updates to IEC 62619 have introduced more stringent requirements for lithium-ion batteries, which may influence future regulations for AGM batteries in high-cyclic load applications.

Compliance with these safety regulations is not only a legal requirement but also a critical factor in ensuring the long-term durability and reliability of AGM batteries in demanding applications. Manufacturers and users must stay informed about the latest regulatory updates and incorporate them into their design, production, and operational processes to maximize battery performance and safety in high-cyclic load conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!