Advances in AGM Battery Testing Methodologies

AUG 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

Absorbed Glass Mat (AGM) batteries have undergone significant evolution since their inception in the 1980s. Initially developed for military and aerospace applications, AGM technology has progressively found its way into various commercial and consumer sectors. The evolution of AGM batteries has been driven by the increasing demand for reliable, maintenance-free energy storage solutions with improved performance characteristics.

In the early stages of AGM battery development, the focus was primarily on enhancing the basic design to improve capacity and cycle life. Manufacturers experimented with different glass mat compositions and electrolyte formulations to optimize the battery's performance. These efforts led to the creation of AGM batteries with higher specific energy and power densities compared to traditional flooded lead-acid batteries.

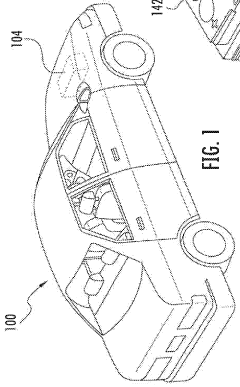

As the technology matured, attention shifted towards addressing specific application requirements. For automotive use, AGM batteries were engineered to withstand the high-current demands of start-stop systems in modern vehicles. This adaptation involved refining the internal structure of the battery to reduce internal resistance and improve charge acceptance rates.

The telecommunications industry also played a crucial role in driving AGM battery evolution. The need for reliable backup power in remote locations spurred the development of deep-cycle AGM batteries with enhanced durability and longer service life. These advancements included improvements in plate design and alloy composition to minimize grid corrosion and extend battery lifespan.

In recent years, the evolution of AGM batteries has been closely tied to the growth of renewable energy systems. The integration of AGM technology with solar and wind power installations has led to the development of batteries optimized for deep-cycle applications and frequent partial state of charge operation. This has resulted in AGM batteries with improved charge efficiency and reduced sulfation tendencies.

The pursuit of higher energy density has been a constant theme in AGM battery evolution. Researchers have explored various approaches, including the use of carbon additives in the negative plate to enhance charge acceptance and reduce sulfation. Additionally, advancements in manufacturing processes have enabled the production of thinner plates and separators, allowing for increased active material within the same battery volume.

Environmental concerns have also shaped the evolution of AGM batteries. Efforts to reduce the environmental impact of lead-acid batteries have led to improvements in recyclability and the development of AGM batteries with longer service lives, effectively reducing waste generation. Furthermore, research into alternative materials and designs aims to further enhance the sustainability of AGM technology.

As AGM battery technology continues to evolve, the focus is increasingly on integrating smart features and advanced monitoring capabilities. The incorporation of sensors and communication modules allows for real-time performance tracking and predictive maintenance, enhancing the overall reliability and efficiency of AGM battery systems.

In the early stages of AGM battery development, the focus was primarily on enhancing the basic design to improve capacity and cycle life. Manufacturers experimented with different glass mat compositions and electrolyte formulations to optimize the battery's performance. These efforts led to the creation of AGM batteries with higher specific energy and power densities compared to traditional flooded lead-acid batteries.

As the technology matured, attention shifted towards addressing specific application requirements. For automotive use, AGM batteries were engineered to withstand the high-current demands of start-stop systems in modern vehicles. This adaptation involved refining the internal structure of the battery to reduce internal resistance and improve charge acceptance rates.

The telecommunications industry also played a crucial role in driving AGM battery evolution. The need for reliable backup power in remote locations spurred the development of deep-cycle AGM batteries with enhanced durability and longer service life. These advancements included improvements in plate design and alloy composition to minimize grid corrosion and extend battery lifespan.

In recent years, the evolution of AGM batteries has been closely tied to the growth of renewable energy systems. The integration of AGM technology with solar and wind power installations has led to the development of batteries optimized for deep-cycle applications and frequent partial state of charge operation. This has resulted in AGM batteries with improved charge efficiency and reduced sulfation tendencies.

The pursuit of higher energy density has been a constant theme in AGM battery evolution. Researchers have explored various approaches, including the use of carbon additives in the negative plate to enhance charge acceptance and reduce sulfation. Additionally, advancements in manufacturing processes have enabled the production of thinner plates and separators, allowing for increased active material within the same battery volume.

Environmental concerns have also shaped the evolution of AGM batteries. Efforts to reduce the environmental impact of lead-acid batteries have led to improvements in recyclability and the development of AGM batteries with longer service lives, effectively reducing waste generation. Furthermore, research into alternative materials and designs aims to further enhance the sustainability of AGM technology.

As AGM battery technology continues to evolve, the focus is increasingly on integrating smart features and advanced monitoring capabilities. The incorporation of sensors and communication modules allows for real-time performance tracking and predictive maintenance, enhancing the overall reliability and efficiency of AGM battery systems.

Market Demand Analysis

The market demand for advanced AGM (Absorbent Glass Mat) battery testing methodologies has been steadily increasing in recent years, driven by the growing adoption of AGM batteries across various industries. The automotive sector, in particular, has been a significant contributor to this demand, as AGM batteries are increasingly preferred for start-stop systems and other advanced vehicle applications.

The global AGM battery market is experiencing robust growth, with projections indicating continued expansion in the coming years. This growth is primarily fueled by the rising demand for reliable and efficient energy storage solutions in automotive, telecommunications, and renewable energy sectors. As the market expands, the need for more sophisticated and accurate testing methodologies becomes paramount to ensure battery quality, performance, and safety.

In the automotive industry, the shift towards electric and hybrid vehicles has further intensified the demand for advanced battery testing methods. AGM batteries are often used in these vehicles for auxiliary power systems, and their performance directly impacts overall vehicle reliability. This has led to increased investment in research and development of testing methodologies that can accurately assess battery capacity, cycle life, and performance under various operating conditions.

The telecommunications sector is another key driver of market demand for AGM battery testing advancements. With the ongoing expansion of 5G networks and the increasing reliance on uninterrupted power supply for critical infrastructure, telecom companies are seeking more reliable and efficient battery solutions. This has created a need for testing methodologies that can accurately predict battery performance and lifespan in real-world telecom applications.

The renewable energy sector, particularly in solar and wind power installations, has also contributed to the growing demand for advanced AGM battery testing. As energy storage becomes increasingly crucial for grid stability and off-grid applications, the need for reliable battery performance has never been greater. This has led to a surge in demand for testing methodologies that can accurately assess battery performance under varying charge and discharge cycles, temperature conditions, and long-term usage scenarios.

Furthermore, the industrial sector, including material handling equipment and backup power systems, has shown a significant interest in improved AGM battery testing methodologies. The need for reliable power sources in critical operations has driven the demand for more accurate and comprehensive testing procedures to ensure optimal battery performance and longevity.

As environmental concerns continue to grow, there is an increasing focus on battery recycling and sustainability. This has created a new market segment for testing methodologies that can accurately assess the remaining life and potential reuse applications of AGM batteries, further driving innovation in this field.

The global AGM battery market is experiencing robust growth, with projections indicating continued expansion in the coming years. This growth is primarily fueled by the rising demand for reliable and efficient energy storage solutions in automotive, telecommunications, and renewable energy sectors. As the market expands, the need for more sophisticated and accurate testing methodologies becomes paramount to ensure battery quality, performance, and safety.

In the automotive industry, the shift towards electric and hybrid vehicles has further intensified the demand for advanced battery testing methods. AGM batteries are often used in these vehicles for auxiliary power systems, and their performance directly impacts overall vehicle reliability. This has led to increased investment in research and development of testing methodologies that can accurately assess battery capacity, cycle life, and performance under various operating conditions.

The telecommunications sector is another key driver of market demand for AGM battery testing advancements. With the ongoing expansion of 5G networks and the increasing reliance on uninterrupted power supply for critical infrastructure, telecom companies are seeking more reliable and efficient battery solutions. This has created a need for testing methodologies that can accurately predict battery performance and lifespan in real-world telecom applications.

The renewable energy sector, particularly in solar and wind power installations, has also contributed to the growing demand for advanced AGM battery testing. As energy storage becomes increasingly crucial for grid stability and off-grid applications, the need for reliable battery performance has never been greater. This has led to a surge in demand for testing methodologies that can accurately assess battery performance under varying charge and discharge cycles, temperature conditions, and long-term usage scenarios.

Furthermore, the industrial sector, including material handling equipment and backup power systems, has shown a significant interest in improved AGM battery testing methodologies. The need for reliable power sources in critical operations has driven the demand for more accurate and comprehensive testing procedures to ensure optimal battery performance and longevity.

As environmental concerns continue to grow, there is an increasing focus on battery recycling and sustainability. This has created a new market segment for testing methodologies that can accurately assess the remaining life and potential reuse applications of AGM batteries, further driving innovation in this field.

Testing Challenges

AGM (Absorbent Glass Mat) battery testing methodologies face several significant challenges that impact the accuracy, reliability, and efficiency of the testing process. One of the primary difficulties lies in accurately measuring the state of charge (SOC) and state of health (SOH) of AGM batteries. Traditional methods often rely on voltage measurements, which can be misleading due to the unique characteristics of AGM batteries, such as their low internal resistance and rapid charge acceptance.

The dynamic nature of AGM batteries during charge and discharge cycles presents another challenge. The internal chemical reactions and physical changes within the battery can lead to variations in performance that are difficult to capture with conventional testing methods. This variability necessitates more sophisticated testing approaches that can account for these dynamic changes and provide a more accurate representation of the battery's true capabilities.

Temperature sensitivity is a critical factor that complicates AGM battery testing. The performance of these batteries can vary significantly with temperature fluctuations, affecting both their capacity and lifespan. Developing testing methodologies that can accurately account for and control temperature effects is essential for obtaining reliable results across different environmental conditions.

The accelerated aging of AGM batteries during testing poses a unique challenge. Repeated charge and discharge cycles, especially under high-stress conditions, can lead to premature degradation of the battery, potentially skewing test results. Balancing the need for thorough testing with the preservation of battery life requires careful consideration and innovative testing strategies.

Standardization of testing protocols across different manufacturers and applications remains a significant hurdle. The lack of universally accepted testing standards for AGM batteries can lead to inconsistencies in reported performance metrics, making it difficult for consumers and industries to make informed comparisons and decisions.

The complexity of AGM battery systems, particularly in advanced applications like start-stop vehicles or renewable energy storage, introduces additional testing challenges. These systems often involve sophisticated battery management systems (BMS) and complex charge/discharge algorithms, which must be accounted for in the testing process to accurately reflect real-world performance.

Lastly, the time-consuming nature of comprehensive AGM battery testing presents practical challenges for manufacturers and researchers. Developing accelerated testing methods that can reliably predict long-term performance without compromising accuracy is an ongoing area of research and development in the field of AGM battery technology.

The dynamic nature of AGM batteries during charge and discharge cycles presents another challenge. The internal chemical reactions and physical changes within the battery can lead to variations in performance that are difficult to capture with conventional testing methods. This variability necessitates more sophisticated testing approaches that can account for these dynamic changes and provide a more accurate representation of the battery's true capabilities.

Temperature sensitivity is a critical factor that complicates AGM battery testing. The performance of these batteries can vary significantly with temperature fluctuations, affecting both their capacity and lifespan. Developing testing methodologies that can accurately account for and control temperature effects is essential for obtaining reliable results across different environmental conditions.

The accelerated aging of AGM batteries during testing poses a unique challenge. Repeated charge and discharge cycles, especially under high-stress conditions, can lead to premature degradation of the battery, potentially skewing test results. Balancing the need for thorough testing with the preservation of battery life requires careful consideration and innovative testing strategies.

Standardization of testing protocols across different manufacturers and applications remains a significant hurdle. The lack of universally accepted testing standards for AGM batteries can lead to inconsistencies in reported performance metrics, making it difficult for consumers and industries to make informed comparisons and decisions.

The complexity of AGM battery systems, particularly in advanced applications like start-stop vehicles or renewable energy storage, introduces additional testing challenges. These systems often involve sophisticated battery management systems (BMS) and complex charge/discharge algorithms, which must be accounted for in the testing process to accurately reflect real-world performance.

Lastly, the time-consuming nature of comprehensive AGM battery testing presents practical challenges for manufacturers and researchers. Developing accelerated testing methods that can reliably predict long-term performance without compromising accuracy is an ongoing area of research and development in the field of AGM battery technology.

Current Test Solutions

01 Capacity and performance testing

AGM battery testing methodologies include capacity and performance tests to evaluate the battery's ability to store and deliver energy. These tests measure factors such as discharge capacity, charge acceptance, and cycle life under various conditions to assess the overall performance and longevity of the battery.- Capacity and performance testing methods: Various methodologies for testing the capacity and performance of AGM batteries, including discharge tests, charge acceptance tests, and cycle life tests. These methods help evaluate the battery's ability to store and deliver energy under different conditions.

- Internal resistance measurement techniques: Techniques for measuring the internal resistance of AGM batteries, which is crucial for assessing their state of health and performance. These methods may include AC impedance spectroscopy, DC current interruption, and pulse load testing.

- State of charge (SOC) estimation methods: Methodologies for accurately estimating the state of charge of AGM batteries, including coulomb counting, open-circuit voltage measurement, and machine learning-based approaches. These techniques are essential for battery management systems and optimizing battery usage.

- Accelerated aging and reliability testing: Methods for conducting accelerated aging tests and reliability assessments on AGM batteries. These tests simulate long-term usage conditions and help predict battery lifespan and performance degradation over time.

- Non-destructive testing and diagnostic techniques: Non-invasive methods for diagnosing AGM battery health and identifying potential issues without disassembling or damaging the battery. These techniques may include ultrasonic testing, thermal imaging, and electrochemical impedance spectroscopy.

02 Internal resistance measurement

Testing methods for AGM batteries involve measuring internal resistance, which is crucial for assessing the battery's health and efficiency. This includes techniques such as AC impedance spectroscopy and DC resistance measurements to evaluate the battery's ability to deliver power and identify potential degradation.Expand Specific Solutions03 Environmental and safety testing

AGM battery testing methodologies incorporate environmental and safety tests to ensure the battery's reliability and safety under various conditions. These tests include thermal cycling, vibration testing, and abuse tests to evaluate the battery's performance and safety in extreme situations.Expand Specific Solutions04 State of charge (SOC) and state of health (SOH) estimation

Testing methods for AGM batteries include techniques for estimating the state of charge and state of health. These involve advanced algorithms and sensor technologies to accurately determine the battery's remaining capacity and overall condition, which is crucial for battery management and maintenance.Expand Specific Solutions05 Automated testing systems

AGM battery testing methodologies utilize automated testing systems to improve efficiency and accuracy. These systems incorporate advanced data acquisition, control algorithms, and analysis tools to perform comprehensive battery tests, including charge-discharge cycles, capacity measurements, and performance evaluations.Expand Specific Solutions

Industry Leaders

The AGM battery testing methodologies market is in a growth phase, driven by increasing demand for reliable energy storage solutions across various industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Fengfan Co., Ltd., Tianneng Battery Group, and LG Energy Solution leading innovation. These firms are developing more sophisticated testing methods to improve battery performance, longevity, and safety. Established automotive giants such as BMW, Toyota, and Honda are also investing heavily in AGM battery research, indicating the technology's growing importance in the automotive sector. The competitive landscape is diverse, with both specialized battery manufacturers and large conglomerates vying for market share and technological leadership.

GM Global Technology Operations LLC

Technical Solution: GM has made significant advancements in AGM battery testing methodologies, particularly focusing on automotive applications. Their approach includes the development of a proprietary Battery Management System (BMS) that continuously monitors and analyzes battery performance in real-time[8]. This system incorporates machine learning algorithms to adapt to individual driving patterns and environmental conditions, optimizing battery life and performance. GM has also implemented a series of accelerated life cycle tests that simulate various driving scenarios and climate conditions, allowing for rapid assessment of long-term battery durability[10]. Furthermore, the company has developed advanced diagnostic tools that can detect subtle changes in battery chemistry, enabling early identification of potential issues before they impact vehicle performance[12].

Strengths: Tailored for automotive applications; adaptive BMS technology. Weaknesses: May be less applicable to non-automotive AGM battery applications.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a novel AGM battery testing methodology that integrates artificial intelligence and big data analytics. Their system employs a network of IoT sensors to continuously monitor battery performance parameters during both laboratory testing and real-world usage[2]. This data is then processed using proprietary AI algorithms to identify subtle patterns indicative of potential battery issues or performance degradation. LG has also developed a unique "digital twin" approach, creating virtual models of each battery that can be subjected to simulated stress tests, allowing for predictive maintenance and optimization of battery management systems[4]. Furthermore, the company has implemented advanced electrochemical impedance spectroscopy techniques for non-invasive assessment of battery internal structure and aging processes[6].

Strengths: Cutting-edge AI and IoT integration; predictive maintenance capabilities. Weaknesses: Reliance on extensive data collection may raise privacy concerns; high complexity of implementation.

Key Innovations

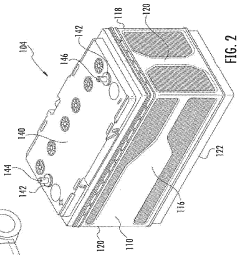

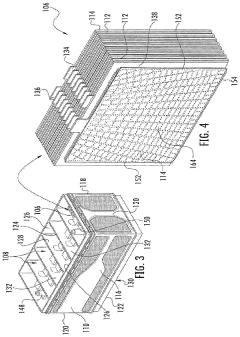

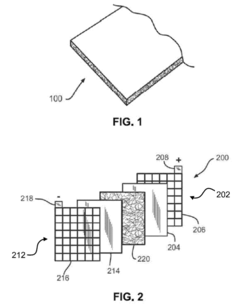

Battery, battery plate assembly, and method of assembly

PatentWO2011130514A1

Innovation

- A battery plate assembly using stamped electrically conductive grids with a grid pattern and highly absorbent separators, where the electrolyte is absorbed by the separators or active material, reducing the need for expanded metal grids and improving lead usage efficiency.

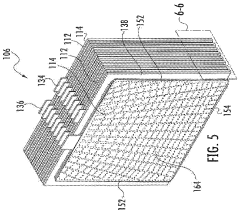

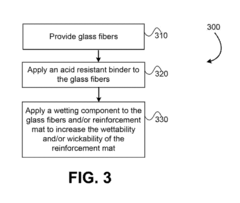

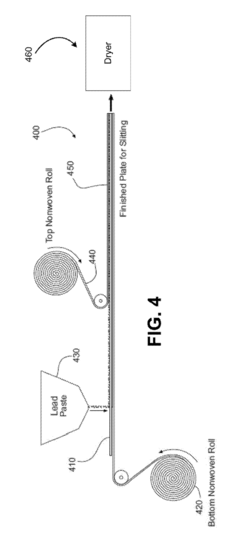

Battery electrode plate reinforcement mat having improved wettability characteristics and methods of use therefor

PatentActiveUS20180337380A1

Innovation

- Nonwoven fiber mats with increased wettability properties, composed of glass fibers and an acid-resistant binder, along with a dissolvable wetting component, enhance the mats' ability to transport and evaporate water and acid solutions, improving electrode drying and structural integrity.

Standardization Efforts

Standardization efforts in AGM battery testing methodologies have become increasingly crucial as the technology continues to evolve and gain widespread adoption across various industries. These efforts aim to establish consistent and reliable testing procedures, ensuring accurate performance evaluation and comparability of AGM batteries from different manufacturers.

One of the primary focuses of standardization has been the development of uniform cycling protocols. These protocols define specific charge and discharge rates, voltage limits, and temperature conditions for battery testing. By adhering to standardized cycling procedures, researchers and manufacturers can more effectively compare the performance and longevity of different AGM battery designs.

Another key area of standardization involves capacity measurement techniques. Efforts have been made to establish consistent methods for determining the actual capacity of AGM batteries under various operating conditions. This includes standardizing the discharge rates and cut-off voltages used in capacity tests, as well as defining procedures for temperature compensation and state-of-charge estimation.

Safety testing standards have also been a significant focus of standardization efforts. Organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have developed comprehensive safety testing protocols for AGM batteries. These standards cover aspects such as thermal runaway prevention, short circuit protection, and overcharge resistance.

Efforts to standardize environmental testing procedures have gained momentum in recent years. This includes establishing uniform methods for evaluating AGM battery performance under extreme temperature conditions, vibration, and humidity. Standardized environmental testing helps ensure that batteries meet the rigorous requirements of diverse applications, from automotive to renewable energy storage.

Impedance spectroscopy has emerged as a powerful tool for AGM battery characterization, prompting efforts to standardize its application in battery testing. Standardization initiatives aim to define consistent measurement frequencies, excitation signals, and data analysis techniques for impedance-based battery diagnostics.

The development of standardized accelerated aging protocols has been another focus area. These protocols aim to simulate long-term battery degradation within a shorter timeframe, allowing for more rapid assessment of battery life and performance over extended periods. Standardization efforts in this area seek to establish agreed-upon stress factors and test durations that accurately reflect real-world aging processes.

Collaborative efforts between industry leaders, research institutions, and regulatory bodies have been instrumental in driving these standardization initiatives. Organizations such as the Battery Council International (BCI) and the European Committee for Electrotechnical Standardization (CENELEC) have played pivotal roles in coordinating and implementing standardized testing methodologies for AGM batteries.

One of the primary focuses of standardization has been the development of uniform cycling protocols. These protocols define specific charge and discharge rates, voltage limits, and temperature conditions for battery testing. By adhering to standardized cycling procedures, researchers and manufacturers can more effectively compare the performance and longevity of different AGM battery designs.

Another key area of standardization involves capacity measurement techniques. Efforts have been made to establish consistent methods for determining the actual capacity of AGM batteries under various operating conditions. This includes standardizing the discharge rates and cut-off voltages used in capacity tests, as well as defining procedures for temperature compensation and state-of-charge estimation.

Safety testing standards have also been a significant focus of standardization efforts. Organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have developed comprehensive safety testing protocols for AGM batteries. These standards cover aspects such as thermal runaway prevention, short circuit protection, and overcharge resistance.

Efforts to standardize environmental testing procedures have gained momentum in recent years. This includes establishing uniform methods for evaluating AGM battery performance under extreme temperature conditions, vibration, and humidity. Standardized environmental testing helps ensure that batteries meet the rigorous requirements of diverse applications, from automotive to renewable energy storage.

Impedance spectroscopy has emerged as a powerful tool for AGM battery characterization, prompting efforts to standardize its application in battery testing. Standardization initiatives aim to define consistent measurement frequencies, excitation signals, and data analysis techniques for impedance-based battery diagnostics.

The development of standardized accelerated aging protocols has been another focus area. These protocols aim to simulate long-term battery degradation within a shorter timeframe, allowing for more rapid assessment of battery life and performance over extended periods. Standardization efforts in this area seek to establish agreed-upon stress factors and test durations that accurately reflect real-world aging processes.

Collaborative efforts between industry leaders, research institutions, and regulatory bodies have been instrumental in driving these standardization initiatives. Organizations such as the Battery Council International (BCI) and the European Committee for Electrotechnical Standardization (CENELEC) have played pivotal roles in coordinating and implementing standardized testing methodologies for AGM batteries.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) battery testing methodologies is a critical consideration in the broader context of sustainable energy storage solutions. As testing procedures for AGM batteries advance, it is essential to evaluate their ecological footprint and potential consequences on the environment.

One of the primary environmental concerns associated with AGM battery testing is the disposal of used batteries and test samples. Traditional testing methods often require the destruction or disassembly of batteries, leading to increased waste generation. However, recent advancements in non-destructive testing techniques have significantly reduced this impact. These innovative approaches, such as electrochemical impedance spectroscopy and ultrasonic testing, allow for comprehensive battery assessment without compromising the integrity of the cells.

The energy consumption during AGM battery testing is another crucial environmental factor. Conventional testing procedures, particularly those involving repeated charge-discharge cycles, can be energy-intensive. Recent developments in accelerated testing protocols and more efficient testing equipment have led to reduced energy requirements. This not only decreases the carbon footprint of the testing process but also aligns with global efforts to minimize energy consumption in industrial processes.

Chemical emissions and potential leakage during AGM battery testing pose environmental risks that cannot be overlooked. Advanced testing methodologies now incorporate stringent safety measures and containment protocols to mitigate these risks. The use of specialized testing chambers with advanced filtration systems helps to capture and neutralize any potentially harmful emissions, thereby protecting air and water quality in the vicinity of testing facilities.

The lifecycle assessment of AGM battery testing equipment is an emerging area of focus. Manufacturers are increasingly adopting eco-friendly materials and designs for testing apparatus, considering the entire lifecycle from production to disposal. This holistic approach aims to reduce the overall environmental impact of the testing infrastructure.

Water usage in AGM battery testing, particularly in thermal management and safety systems, is another environmental concern. Innovations in cooling technologies and the implementation of closed-loop water systems have significantly reduced water consumption and potential contamination risks associated with battery testing processes.

As the demand for AGM batteries grows, particularly in renewable energy storage applications, the scale of testing operations is expected to increase. This expansion necessitates a proactive approach to environmental management. Advanced testing facilities are now being designed with environmental sustainability as a core principle, incorporating features such as renewable energy sources, waste heat recovery systems, and advanced recycling capabilities for test materials.

In conclusion, while AGM battery testing methodologies have historically posed various environmental challenges, recent advancements are steering the industry towards more sustainable practices. These improvements not only enhance the efficiency and accuracy of battery testing but also significantly reduce the ecological footprint of these essential processes in the energy storage sector.

One of the primary environmental concerns associated with AGM battery testing is the disposal of used batteries and test samples. Traditional testing methods often require the destruction or disassembly of batteries, leading to increased waste generation. However, recent advancements in non-destructive testing techniques have significantly reduced this impact. These innovative approaches, such as electrochemical impedance spectroscopy and ultrasonic testing, allow for comprehensive battery assessment without compromising the integrity of the cells.

The energy consumption during AGM battery testing is another crucial environmental factor. Conventional testing procedures, particularly those involving repeated charge-discharge cycles, can be energy-intensive. Recent developments in accelerated testing protocols and more efficient testing equipment have led to reduced energy requirements. This not only decreases the carbon footprint of the testing process but also aligns with global efforts to minimize energy consumption in industrial processes.

Chemical emissions and potential leakage during AGM battery testing pose environmental risks that cannot be overlooked. Advanced testing methodologies now incorporate stringent safety measures and containment protocols to mitigate these risks. The use of specialized testing chambers with advanced filtration systems helps to capture and neutralize any potentially harmful emissions, thereby protecting air and water quality in the vicinity of testing facilities.

The lifecycle assessment of AGM battery testing equipment is an emerging area of focus. Manufacturers are increasingly adopting eco-friendly materials and designs for testing apparatus, considering the entire lifecycle from production to disposal. This holistic approach aims to reduce the overall environmental impact of the testing infrastructure.

Water usage in AGM battery testing, particularly in thermal management and safety systems, is another environmental concern. Innovations in cooling technologies and the implementation of closed-loop water systems have significantly reduced water consumption and potential contamination risks associated with battery testing processes.

As the demand for AGM batteries grows, particularly in renewable energy storage applications, the scale of testing operations is expected to increase. This expansion necessitates a proactive approach to environmental management. Advanced testing facilities are now being designed with environmental sustainability as a core principle, incorporating features such as renewable energy sources, waste heat recovery systems, and advanced recycling capabilities for test materials.

In conclusion, while AGM battery testing methodologies have historically posed various environmental challenges, recent advancements are steering the industry towards more sustainable practices. These improvements not only enhance the efficiency and accuracy of battery testing but also significantly reduce the ecological footprint of these essential processes in the energy storage sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!