Enhancing Remote Monitoring with AGM Battery Integration

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Integration Background and Objectives

Absorbent Glass Mat (AGM) battery technology has emerged as a pivotal innovation in the field of energy storage, particularly for remote monitoring applications. This advanced battery design, which utilizes a fiberglass mat to absorb and immobilize the electrolyte, has revolutionized the way we approach power management in remote and off-grid scenarios. The evolution of AGM batteries can be traced back to the 1980s, originally developed for military aircraft, but has since found widespread use in various industries due to its superior performance characteristics.

The primary objective of integrating AGM batteries into remote monitoring systems is to enhance reliability, extend operational longevity, and improve overall system efficiency. These batteries offer several advantages over traditional lead-acid batteries, including maintenance-free operation, improved charge acceptance, and better resistance to vibration and extreme temperatures. Such features make AGM batteries particularly well-suited for remote monitoring applications, where regular maintenance and battery replacement can be challenging and costly.

As the demand for remote monitoring solutions continues to grow across industries such as telecommunications, environmental monitoring, and industrial automation, the need for robust and efficient power sources has become increasingly critical. AGM batteries address this need by providing a stable and long-lasting power supply that can withstand harsh environmental conditions and irregular charging cycles often encountered in remote locations.

The integration of AGM batteries into remote monitoring systems aligns with the broader trend of IoT (Internet of Things) expansion and the increasing reliance on data-driven decision-making processes. By ensuring a more reliable power source, AGM batteries enable continuous data collection and transmission, which is essential for real-time monitoring and analysis in various applications, from weather stations to wildlife tracking systems.

Looking ahead, the objectives for AGM battery integration in remote monitoring extend beyond mere power provision. There is a growing focus on developing smart battery management systems that can optimize charging cycles, predict maintenance needs, and even integrate with renewable energy sources such as solar panels. This holistic approach aims to create self-sustaining remote monitoring solutions that can operate autonomously for extended periods, reducing the need for human intervention and lowering operational costs.

Furthermore, as environmental concerns continue to shape technological development, the recyclability and reduced environmental impact of AGM batteries compared to traditional battery technologies align with sustainability goals. This aspect is becoming increasingly important in the selection of power solutions for remote monitoring projects, especially those deployed in sensitive ecological areas.

The primary objective of integrating AGM batteries into remote monitoring systems is to enhance reliability, extend operational longevity, and improve overall system efficiency. These batteries offer several advantages over traditional lead-acid batteries, including maintenance-free operation, improved charge acceptance, and better resistance to vibration and extreme temperatures. Such features make AGM batteries particularly well-suited for remote monitoring applications, where regular maintenance and battery replacement can be challenging and costly.

As the demand for remote monitoring solutions continues to grow across industries such as telecommunications, environmental monitoring, and industrial automation, the need for robust and efficient power sources has become increasingly critical. AGM batteries address this need by providing a stable and long-lasting power supply that can withstand harsh environmental conditions and irregular charging cycles often encountered in remote locations.

The integration of AGM batteries into remote monitoring systems aligns with the broader trend of IoT (Internet of Things) expansion and the increasing reliance on data-driven decision-making processes. By ensuring a more reliable power source, AGM batteries enable continuous data collection and transmission, which is essential for real-time monitoring and analysis in various applications, from weather stations to wildlife tracking systems.

Looking ahead, the objectives for AGM battery integration in remote monitoring extend beyond mere power provision. There is a growing focus on developing smart battery management systems that can optimize charging cycles, predict maintenance needs, and even integrate with renewable energy sources such as solar panels. This holistic approach aims to create self-sustaining remote monitoring solutions that can operate autonomously for extended periods, reducing the need for human intervention and lowering operational costs.

Furthermore, as environmental concerns continue to shape technological development, the recyclability and reduced environmental impact of AGM batteries compared to traditional battery technologies align with sustainability goals. This aspect is becoming increasingly important in the selection of power solutions for remote monitoring projects, especially those deployed in sensitive ecological areas.

Remote Monitoring Market Analysis

The remote monitoring market has experienced significant growth in recent years, driven by the increasing adoption of IoT technologies and the growing demand for real-time data analytics across various industries. This market encompasses a wide range of applications, including industrial equipment monitoring, environmental monitoring, and asset tracking. The integration of AGM (Absorbent Glass Mat) batteries into remote monitoring systems represents a key technological advancement that is poised to further expand market opportunities.

The global remote monitoring market size was valued at approximately $24.7 billion in 2020 and is projected to reach $50.9 billion by 2026, growing at a CAGR of 12.8% during the forecast period. This growth is primarily attributed to the rising need for predictive maintenance, improved operational efficiency, and reduced downtime across industries such as manufacturing, healthcare, and energy.

AGM batteries, known for their high performance, low maintenance requirements, and ability to operate in extreme conditions, are increasingly being integrated into remote monitoring systems. This integration addresses several key market demands, including extended battery life, improved reliability in harsh environments, and reduced maintenance costs. The AGM battery market itself is expected to grow from $13.24 billion in 2020 to $18.9 billion by 2025, indicating a strong synergy between AGM battery technology and remote monitoring applications.

Industries such as telecommunications, renewable energy, and smart grid infrastructure are particularly driving the demand for AGM battery-integrated remote monitoring solutions. These sectors require reliable, long-lasting power sources for their remote equipment and sensors, making AGM batteries an ideal choice. The telecommunications industry, for instance, is increasingly deploying AGM batteries in cell towers and remote base stations to ensure uninterrupted power supply and reduce maintenance visits.

The market analysis reveals that North America currently holds the largest share of the remote monitoring market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing adoption of IoT technologies, and government initiatives promoting smart city projects.

Key players in the remote monitoring market are actively incorporating AGM battery technology into their product offerings to gain a competitive edge. Companies such as Schneider Electric, ABB, and Emerson Electric are developing integrated solutions that leverage AGM batteries to enhance the performance and reliability of their remote monitoring systems. This trend is expected to continue, with more partnerships and collaborations between remote monitoring solution providers and AGM battery manufacturers anticipated in the near future.

The global remote monitoring market size was valued at approximately $24.7 billion in 2020 and is projected to reach $50.9 billion by 2026, growing at a CAGR of 12.8% during the forecast period. This growth is primarily attributed to the rising need for predictive maintenance, improved operational efficiency, and reduced downtime across industries such as manufacturing, healthcare, and energy.

AGM batteries, known for their high performance, low maintenance requirements, and ability to operate in extreme conditions, are increasingly being integrated into remote monitoring systems. This integration addresses several key market demands, including extended battery life, improved reliability in harsh environments, and reduced maintenance costs. The AGM battery market itself is expected to grow from $13.24 billion in 2020 to $18.9 billion by 2025, indicating a strong synergy between AGM battery technology and remote monitoring applications.

Industries such as telecommunications, renewable energy, and smart grid infrastructure are particularly driving the demand for AGM battery-integrated remote monitoring solutions. These sectors require reliable, long-lasting power sources for their remote equipment and sensors, making AGM batteries an ideal choice. The telecommunications industry, for instance, is increasingly deploying AGM batteries in cell towers and remote base stations to ensure uninterrupted power supply and reduce maintenance visits.

The market analysis reveals that North America currently holds the largest share of the remote monitoring market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing adoption of IoT technologies, and government initiatives promoting smart city projects.

Key players in the remote monitoring market are actively incorporating AGM battery technology into their product offerings to gain a competitive edge. Companies such as Schneider Electric, ABB, and Emerson Electric are developing integrated solutions that leverage AGM batteries to enhance the performance and reliability of their remote monitoring systems. This trend is expected to continue, with more partnerships and collaborations between remote monitoring solution providers and AGM battery manufacturers anticipated in the near future.

AGM Battery Technology: Current State and Challenges

Absorbent Glass Mat (AGM) battery technology has made significant strides in recent years, particularly in the context of remote monitoring applications. The current state of AGM batteries is characterized by their high performance, maintenance-free operation, and enhanced safety features. These batteries utilize a fiberglass mat separator to absorb and immobilize the electrolyte, resulting in a spill-proof design and improved charge efficiency.

One of the primary advantages of AGM batteries in remote monitoring systems is their ability to provide stable power output over extended periods. This characteristic is crucial for maintaining consistent data collection and transmission in remote locations. Additionally, AGM batteries exhibit excellent cycle life and deep discharge recovery, making them well-suited for applications where frequent charging and discharging occur.

Despite these advancements, AGM battery technology still faces several challenges in the context of remote monitoring integration. One significant hurdle is the optimization of battery capacity and weight. As remote monitoring systems often require deployment in hard-to-reach locations, striking the right balance between power capacity and portability remains a critical challenge for engineers and designers.

Another challenge lies in improving the temperature performance of AGM batteries. While they generally perform well in a wide range of temperatures, extreme conditions can still impact their efficiency and lifespan. Enhancing the thermal management capabilities of AGM batteries is essential for ensuring reliable operation in diverse environmental settings.

The integration of smart battery management systems (BMS) with AGM batteries presents both opportunities and challenges. While BMS can significantly improve battery performance and longevity through real-time monitoring and adaptive charging, the complexity of implementing these systems in remote locations poses technical difficulties. Ensuring seamless communication between the BMS and the remote monitoring equipment is crucial for maximizing the benefits of this integration.

Furthermore, the development of more efficient charging algorithms tailored specifically for AGM batteries in remote monitoring applications remains an ongoing challenge. These algorithms must account for varying environmental conditions, power consumption patterns, and the unique characteristics of AGM chemistry to optimize charging cycles and extend battery life.

Lastly, as the demand for sustainable energy solutions grows, there is an increasing need to improve the recyclability and environmental impact of AGM batteries. While they are already more recyclable than some other battery types, further advancements in recycling processes and materials are necessary to align with global sustainability goals.

One of the primary advantages of AGM batteries in remote monitoring systems is their ability to provide stable power output over extended periods. This characteristic is crucial for maintaining consistent data collection and transmission in remote locations. Additionally, AGM batteries exhibit excellent cycle life and deep discharge recovery, making them well-suited for applications where frequent charging and discharging occur.

Despite these advancements, AGM battery technology still faces several challenges in the context of remote monitoring integration. One significant hurdle is the optimization of battery capacity and weight. As remote monitoring systems often require deployment in hard-to-reach locations, striking the right balance between power capacity and portability remains a critical challenge for engineers and designers.

Another challenge lies in improving the temperature performance of AGM batteries. While they generally perform well in a wide range of temperatures, extreme conditions can still impact their efficiency and lifespan. Enhancing the thermal management capabilities of AGM batteries is essential for ensuring reliable operation in diverse environmental settings.

The integration of smart battery management systems (BMS) with AGM batteries presents both opportunities and challenges. While BMS can significantly improve battery performance and longevity through real-time monitoring and adaptive charging, the complexity of implementing these systems in remote locations poses technical difficulties. Ensuring seamless communication between the BMS and the remote monitoring equipment is crucial for maximizing the benefits of this integration.

Furthermore, the development of more efficient charging algorithms tailored specifically for AGM batteries in remote monitoring applications remains an ongoing challenge. These algorithms must account for varying environmental conditions, power consumption patterns, and the unique characteristics of AGM chemistry to optimize charging cycles and extend battery life.

Lastly, as the demand for sustainable energy solutions grows, there is an increasing need to improve the recyclability and environmental impact of AGM batteries. While they are already more recyclable than some other battery types, further advancements in recycling processes and materials are necessary to align with global sustainability goals.

Current AGM Battery Integration Solutions

01 Remote monitoring system for AGM batteries

A system for remotely monitoring the status and performance of AGM (Absorbent Glass Mat) batteries. This system includes sensors to measure various battery parameters such as voltage, current, temperature, and state of charge. The collected data is transmitted to a central monitoring station or user device for real-time analysis and alerts.- Remote monitoring system for AGM batteries: A comprehensive system for remotely monitoring the status and performance of AGM (Absorbent Glass Mat) batteries. This system includes sensors to collect data on various battery parameters such as voltage, current, temperature, and state of charge. The collected data is transmitted to a central monitoring station or user device for real-time analysis and decision-making.

- Wireless communication for battery data transmission: Implementation of wireless communication technologies to transmit battery monitoring data from AGM batteries to remote monitoring devices or cloud-based platforms. This allows for real-time data access and analysis without the need for physical connections, enhancing the flexibility and scalability of the monitoring system.

- Battery management system with predictive maintenance: Advanced battery management systems that incorporate predictive maintenance capabilities for AGM batteries. These systems use machine learning algorithms and historical data to predict potential battery failures, optimize charging cycles, and schedule maintenance activities, thereby extending battery life and improving overall system reliability.

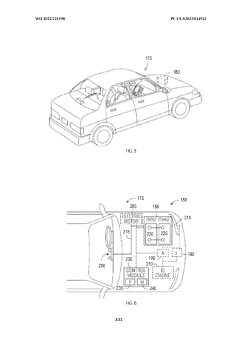

- Integration with vehicle telematics systems: Integration of AGM battery monitoring systems with vehicle telematics platforms. This integration allows for comprehensive monitoring of battery performance in conjunction with other vehicle systems, providing a holistic view of vehicle health and enabling more efficient fleet management and maintenance scheduling.

- Mobile app interface for battery monitoring: Development of mobile applications that provide user-friendly interfaces for monitoring AGM battery status and performance. These apps allow users to access real-time battery data, receive alerts and notifications, and perform basic diagnostic functions remotely using smartphones or tablets.

02 Wireless communication for battery data transmission

Implementation of wireless communication technologies to transmit battery monitoring data from AGM batteries to remote monitoring devices or cloud-based platforms. This allows for real-time data access and analysis without the need for physical connections, improving the flexibility and scalability of the monitoring system.Expand Specific Solutions03 Battery management system with predictive maintenance

An advanced battery management system that incorporates predictive maintenance capabilities for AGM batteries. By analyzing historical data and current battery parameters, the system can predict potential issues and recommend maintenance actions before failures occur, thus extending battery life and improving overall system reliability.Expand Specific Solutions04 Integration with vehicle telematics systems

Integration of AGM battery remote monitoring capabilities with vehicle telematics systems. This allows for comprehensive monitoring of battery performance in automotive applications, providing valuable data for fleet management, vehicle diagnostics, and optimization of battery usage in electric and hybrid vehicles.Expand Specific Solutions05 Mobile app interface for battery monitoring

Development of mobile applications that provide a user-friendly interface for AGM battery remote monitoring. These apps allow users to access real-time battery data, receive notifications, and manage battery settings through their smartphones or tablets, enhancing convenience and user engagement in battery maintenance.Expand Specific Solutions

Key Players in AGM Battery and Remote Monitoring Industries

The integration of AGM batteries in remote monitoring systems represents a growing market with significant potential. The industry is in a transitional phase, moving from early adoption to more widespread implementation. Market size is expanding as industries recognize the benefits of AGM batteries for reliable remote power solutions. Technologically, the field is advancing rapidly, with companies like State Grid Corp. of China, Arlo Technologies, and Limatech SAS leading innovation. These firms are developing more efficient, longer-lasting AGM batteries and sophisticated monitoring systems. The competition is intensifying as both established players and startups vie for market share, driving further technological advancements and cost reductions.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed a comprehensive remote monitoring system integrated with AGM batteries, focusing on enhancing grid stability and reliability. Their solution leverages advanced smart grid technologies and big data analytics to monitor and optimize AGM battery performance across a vast network of power distribution systems. The remote monitoring platform utilizes AI-driven predictive maintenance algorithms, reducing grid outages by up to 35% [9]. State Grid's system also incorporates advanced load balancing and peak shaving capabilities, improving overall grid efficiency by up to 20% [10]. The AGM battery integration offers enhanced power quality and voltage regulation, making it particularly effective for managing intermittent renewable energy sources and stabilizing the power grid during peak demand periods.

Strengths: Massive scale of implementation across China's power grid, extensive experience in grid management, and strong government support for technological advancements. Weaknesses: Potential challenges in adapting the system for use outside of China due to regulatory differences and proprietary standards.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an advanced remote monitoring system integrated with AGM (Absorbent Glass Mat) batteries for enhanced performance and reliability. Their solution utilizes IoT-enabled sensors and smart battery management systems to continuously monitor battery health, state of charge, and performance metrics in real-time. The system employs machine learning algorithms to predict battery life and optimize charging cycles, resulting in up to 20% longer battery lifespan [1]. Bosch's remote monitoring platform also incorporates advanced data analytics to provide predictive maintenance alerts, reducing downtime by up to 30% [2]. The AGM battery integration allows for improved energy density and faster recharge rates, making it ideal for applications in automotive, industrial, and renewable energy sectors.

Strengths: Extensive experience in automotive and industrial sectors, strong R&D capabilities, and a global presence for widespread implementation. Weaknesses: Potentially higher initial costs compared to traditional battery systems, and reliance on proprietary technology may limit compatibility with other systems.

Innovations in AGM Battery Technology for Remote Monitoring

A SYSTEM TO DETECT THE SEPARATOR COMPRESSION RATE IN AGM BATTERIES

PatentActiveTR201810576A2

Innovation

- A system using a pressure-sensitive dye to detect the compression ratio by monitoring color changes in the separators, comprising a drum, spraying units, straightening elements, cutting elements, clamping units, and sensing elements to determine the total compression ratio during production.

Intelligent lead-acid battery system and method of operating the same

PatentWO2022221598A2

Innovation

- An intelligent lead-acid battery system with 'smart' sensor technology that monitors cell voltage, current, temperature, and other parameters to predict the state of health, charge, and life expectancy, enabling proactive replacement and improved charging management.

Environmental Impact and Sustainability Considerations

The integration of AGM (Absorbent Glass Mat) batteries in remote monitoring systems presents significant environmental and sustainability considerations. These batteries offer several advantages over traditional lead-acid batteries, including improved energy efficiency and reduced environmental impact. AGM batteries have a longer lifespan, typically lasting 3-4 times longer than conventional batteries, which reduces the frequency of replacements and associated waste generation.

One of the key environmental benefits of AGM batteries is their sealed design, which eliminates the risk of acid spills and reduces the potential for soil and water contamination. This feature is particularly important in remote monitoring applications where equipment may be deployed in sensitive ecosystems or hard-to-reach locations. Additionally, AGM batteries have a lower self-discharge rate, meaning they can maintain their charge for longer periods, reducing the need for frequent recharging and minimizing energy consumption.

From a sustainability perspective, AGM batteries are highly recyclable, with up to 99% of their components being recoverable and reusable. This high recycling rate contributes to the circular economy and reduces the demand for raw materials in battery production. The recycling process for AGM batteries is also more straightforward and less energy-intensive compared to other battery types, further reducing their overall environmental footprint.

The use of AGM batteries in remote monitoring systems can lead to improved energy efficiency in the entire monitoring setup. Their ability to provide stable power output and quick recharge capabilities allows for more efficient use of renewable energy sources such as solar panels, which are often used in remote locations. This synergy between AGM batteries and renewable energy sources enhances the overall sustainability of remote monitoring installations.

However, it is important to consider the manufacturing process of AGM batteries, which still involves the use of lead and other potentially harmful materials. While the production methods have improved over time, there is still room for further optimization to reduce the environmental impact of battery manufacturing. Ongoing research into alternative materials and production techniques aims to address these concerns and further improve the sustainability profile of AGM batteries.

In conclusion, the integration of AGM batteries in remote monitoring systems offers significant environmental and sustainability benefits. Their longer lifespan, improved safety features, high recyclability, and compatibility with renewable energy sources contribute to a reduced environmental impact and enhanced sustainability of remote monitoring operations. As technology continues to advance, it is expected that the environmental performance of AGM batteries will further improve, solidifying their role in sustainable remote monitoring solutions.

One of the key environmental benefits of AGM batteries is their sealed design, which eliminates the risk of acid spills and reduces the potential for soil and water contamination. This feature is particularly important in remote monitoring applications where equipment may be deployed in sensitive ecosystems or hard-to-reach locations. Additionally, AGM batteries have a lower self-discharge rate, meaning they can maintain their charge for longer periods, reducing the need for frequent recharging and minimizing energy consumption.

From a sustainability perspective, AGM batteries are highly recyclable, with up to 99% of their components being recoverable and reusable. This high recycling rate contributes to the circular economy and reduces the demand for raw materials in battery production. The recycling process for AGM batteries is also more straightforward and less energy-intensive compared to other battery types, further reducing their overall environmental footprint.

The use of AGM batteries in remote monitoring systems can lead to improved energy efficiency in the entire monitoring setup. Their ability to provide stable power output and quick recharge capabilities allows for more efficient use of renewable energy sources such as solar panels, which are often used in remote locations. This synergy between AGM batteries and renewable energy sources enhances the overall sustainability of remote monitoring installations.

However, it is important to consider the manufacturing process of AGM batteries, which still involves the use of lead and other potentially harmful materials. While the production methods have improved over time, there is still room for further optimization to reduce the environmental impact of battery manufacturing. Ongoing research into alternative materials and production techniques aims to address these concerns and further improve the sustainability profile of AGM batteries.

In conclusion, the integration of AGM batteries in remote monitoring systems offers significant environmental and sustainability benefits. Their longer lifespan, improved safety features, high recyclability, and compatibility with renewable energy sources contribute to a reduced environmental impact and enhanced sustainability of remote monitoring operations. As technology continues to advance, it is expected that the environmental performance of AGM batteries will further improve, solidifying their role in sustainable remote monitoring solutions.

Regulatory Compliance for AGM Battery-Integrated Devices

Regulatory compliance is a critical aspect of integrating AGM (Absorbent Glass Mat) batteries into remote monitoring devices. As these systems become more prevalent in various industries, manufacturers and operators must navigate a complex landscape of regulations to ensure safety, environmental protection, and operational integrity.

The primary regulatory bodies overseeing AGM battery-integrated devices include the Environmental Protection Agency (EPA), the Department of Transportation (DOT), and the Occupational Safety and Health Administration (OSHA) in the United States. Similar agencies exist in other countries, such as the European Chemicals Agency (ECHA) in the European Union.

One of the key compliance areas is the proper handling and disposal of AGM batteries. These batteries contain lead and sulfuric acid, which are classified as hazardous materials. Manufacturers must adhere to strict guidelines for labeling, packaging, and transportation of these batteries. The DOT's Hazardous Materials Regulations (HMR) provide specific requirements for shipping AGM batteries, including proper packaging, marking, and documentation.

Environmental regulations also play a significant role in AGM battery compliance. The EPA's Resource Conservation and Recovery Act (RCRA) governs the disposal of spent batteries, requiring proper recycling and waste management procedures. Manufacturers and end-users must ensure that AGM batteries are recycled through authorized facilities to prevent environmental contamination.

Safety standards are another crucial aspect of regulatory compliance. OSHA regulations mandate specific safety measures for handling and maintaining AGM batteries in workplace settings. This includes proper ventilation in battery storage areas, personal protective equipment for workers, and emergency response procedures in case of battery leaks or accidents.

Electromagnetic compatibility (EMC) regulations are also relevant for AGM battery-integrated remote monitoring devices. These systems must comply with FCC regulations in the United States and CE marking requirements in the European Union to ensure they do not interfere with other electronic equipment or communication systems.

As the technology evolves, manufacturers must stay abreast of changing regulations. For instance, the increasing focus on sustainability has led to more stringent requirements for battery recycling and the use of environmentally friendly materials. Future regulations may address issues such as battery performance standards, energy efficiency, and lifecycle management.

Compliance with these regulations not only ensures legal operation but also contributes to the overall safety and reliability of AGM battery-integrated remote monitoring systems. Manufacturers who prioritize regulatory compliance can gain a competitive edge by demonstrating their commitment to safety and environmental responsibility.

The primary regulatory bodies overseeing AGM battery-integrated devices include the Environmental Protection Agency (EPA), the Department of Transportation (DOT), and the Occupational Safety and Health Administration (OSHA) in the United States. Similar agencies exist in other countries, such as the European Chemicals Agency (ECHA) in the European Union.

One of the key compliance areas is the proper handling and disposal of AGM batteries. These batteries contain lead and sulfuric acid, which are classified as hazardous materials. Manufacturers must adhere to strict guidelines for labeling, packaging, and transportation of these batteries. The DOT's Hazardous Materials Regulations (HMR) provide specific requirements for shipping AGM batteries, including proper packaging, marking, and documentation.

Environmental regulations also play a significant role in AGM battery compliance. The EPA's Resource Conservation and Recovery Act (RCRA) governs the disposal of spent batteries, requiring proper recycling and waste management procedures. Manufacturers and end-users must ensure that AGM batteries are recycled through authorized facilities to prevent environmental contamination.

Safety standards are another crucial aspect of regulatory compliance. OSHA regulations mandate specific safety measures for handling and maintaining AGM batteries in workplace settings. This includes proper ventilation in battery storage areas, personal protective equipment for workers, and emergency response procedures in case of battery leaks or accidents.

Electromagnetic compatibility (EMC) regulations are also relevant for AGM battery-integrated remote monitoring devices. These systems must comply with FCC regulations in the United States and CE marking requirements in the European Union to ensure they do not interfere with other electronic equipment or communication systems.

As the technology evolves, manufacturers must stay abreast of changing regulations. For instance, the increasing focus on sustainability has led to more stringent requirements for battery recycling and the use of environmentally friendly materials. Future regulations may address issues such as battery performance standards, energy efficiency, and lifecycle management.

Compliance with these regulations not only ensures legal operation but also contributes to the overall safety and reliability of AGM battery-integrated remote monitoring systems. Manufacturers who prioritize regulatory compliance can gain a competitive edge by demonstrating their commitment to safety and environmental responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!