AGM Battery Cooling Solutions for Enhanced System Longevity

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Cooling Challenges and Objectives

Absorbed Glass Mat (AGM) batteries have become increasingly prevalent in various applications, particularly in automotive and renewable energy systems. As these batteries play a crucial role in powering critical systems, ensuring their longevity and optimal performance has become a paramount concern. The primary challenge in maintaining AGM batteries lies in managing their operating temperature, as excessive heat can significantly reduce their lifespan and efficiency.

The evolution of AGM battery technology has been marked by continuous improvements in energy density and cycle life. However, these advancements have also led to increased heat generation during charging and discharging cycles. This heat buildup can accelerate chemical reactions within the battery, leading to premature aging and reduced capacity. Consequently, the development of effective cooling solutions has emerged as a critical area of research in the AGM battery industry.

The primary objective of this research is to explore and evaluate various cooling strategies that can effectively manage the thermal characteristics of AGM batteries. By maintaining optimal operating temperatures, these solutions aim to extend battery life, improve performance, and enhance overall system reliability. The research seeks to address the unique challenges posed by AGM batteries, including their sealed construction and the need for uniform temperature distribution across all cells.

One of the key goals is to develop cooling systems that are not only effective but also energy-efficient and cost-effective. This involves exploring passive cooling techniques that leverage natural convection and conduction, as well as active cooling methods that employ forced air or liquid cooling. The research also aims to investigate the potential of advanced materials and novel designs that can enhance heat dissipation without compromising the battery's structural integrity or electrical performance.

Another critical objective is to develop intelligent thermal management systems that can dynamically adjust cooling parameters based on real-time battery conditions. This includes the integration of temperature sensors, predictive algorithms, and adaptive control systems to optimize cooling efficiency and prevent thermal runaway scenarios. The research also seeks to address the challenges of scaling cooling solutions for large battery banks and adapting them to diverse operating environments, from automotive applications to stationary energy storage systems.

Furthermore, the study aims to evaluate the long-term impact of various cooling strategies on AGM battery performance and lifespan. This involves conducting extensive cycle life testing under controlled thermal conditions to quantify the benefits of different cooling approaches. The research also seeks to develop standardized testing protocols and performance metrics to facilitate the comparison and evaluation of different cooling solutions across the industry.

Ultimately, this research endeavors to pave the way for the next generation of AGM battery systems that offer enhanced reliability, improved energy efficiency, and extended operational life. By addressing the critical challenge of thermal management, the findings of this study have the potential to significantly impact the adoption and performance of AGM batteries in a wide range of applications, from electric vehicles to renewable energy storage systems.

The evolution of AGM battery technology has been marked by continuous improvements in energy density and cycle life. However, these advancements have also led to increased heat generation during charging and discharging cycles. This heat buildup can accelerate chemical reactions within the battery, leading to premature aging and reduced capacity. Consequently, the development of effective cooling solutions has emerged as a critical area of research in the AGM battery industry.

The primary objective of this research is to explore and evaluate various cooling strategies that can effectively manage the thermal characteristics of AGM batteries. By maintaining optimal operating temperatures, these solutions aim to extend battery life, improve performance, and enhance overall system reliability. The research seeks to address the unique challenges posed by AGM batteries, including their sealed construction and the need for uniform temperature distribution across all cells.

One of the key goals is to develop cooling systems that are not only effective but also energy-efficient and cost-effective. This involves exploring passive cooling techniques that leverage natural convection and conduction, as well as active cooling methods that employ forced air or liquid cooling. The research also aims to investigate the potential of advanced materials and novel designs that can enhance heat dissipation without compromising the battery's structural integrity or electrical performance.

Another critical objective is to develop intelligent thermal management systems that can dynamically adjust cooling parameters based on real-time battery conditions. This includes the integration of temperature sensors, predictive algorithms, and adaptive control systems to optimize cooling efficiency and prevent thermal runaway scenarios. The research also seeks to address the challenges of scaling cooling solutions for large battery banks and adapting them to diverse operating environments, from automotive applications to stationary energy storage systems.

Furthermore, the study aims to evaluate the long-term impact of various cooling strategies on AGM battery performance and lifespan. This involves conducting extensive cycle life testing under controlled thermal conditions to quantify the benefits of different cooling approaches. The research also seeks to develop standardized testing protocols and performance metrics to facilitate the comparison and evaluation of different cooling solutions across the industry.

Ultimately, this research endeavors to pave the way for the next generation of AGM battery systems that offer enhanced reliability, improved energy efficiency, and extended operational life. By addressing the critical challenge of thermal management, the findings of this study have the potential to significantly impact the adoption and performance of AGM batteries in a wide range of applications, from electric vehicles to renewable energy storage systems.

Market Analysis for Advanced AGM Battery Systems

The market for advanced AGM (Absorbent Glass Mat) battery systems has been experiencing significant growth in recent years, driven by the increasing demand for reliable and efficient energy storage solutions across various industries. The automotive sector, in particular, has been a major contributor to this growth, as AGM batteries are widely used in start-stop systems and other advanced vehicle applications.

The global AGM battery market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the rising adoption of electric and hybrid vehicles, as well as the increasing integration of advanced electronics in conventional vehicles.

In the automotive industry, AGM batteries are preferred for their superior performance in start-stop systems, which help reduce fuel consumption and emissions. As environmental regulations become more stringent worldwide, the demand for these systems is expected to surge, further boosting the AGM battery market.

Beyond automotive applications, AGM batteries are gaining traction in renewable energy storage systems, telecommunications, and uninterruptible power supply (UPS) units. The growing emphasis on sustainable energy solutions and the expansion of 5G networks are driving the demand for AGM batteries in these sectors.

However, the market faces challenges related to the high initial cost of AGM batteries compared to traditional lead-acid batteries. This cost factor may limit adoption in price-sensitive markets, particularly in developing regions. Additionally, the emergence of lithium-ion batteries as a competing technology poses a potential threat to the AGM battery market in certain applications.

Despite these challenges, the AGM battery market is expected to maintain its growth momentum due to several factors. The increasing focus on energy efficiency and sustainability across industries is likely to drive further adoption of AGM batteries. Moreover, ongoing research and development efforts aimed at improving AGM battery performance and reducing costs are expected to enhance their competitiveness in the market.

Geographically, North America and Europe currently lead the AGM battery market, owing to their advanced automotive industries and stringent environmental regulations. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing vehicle production, and growing investments in renewable energy projects.

The global AGM battery market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the rising adoption of electric and hybrid vehicles, as well as the increasing integration of advanced electronics in conventional vehicles.

In the automotive industry, AGM batteries are preferred for their superior performance in start-stop systems, which help reduce fuel consumption and emissions. As environmental regulations become more stringent worldwide, the demand for these systems is expected to surge, further boosting the AGM battery market.

Beyond automotive applications, AGM batteries are gaining traction in renewable energy storage systems, telecommunications, and uninterruptible power supply (UPS) units. The growing emphasis on sustainable energy solutions and the expansion of 5G networks are driving the demand for AGM batteries in these sectors.

However, the market faces challenges related to the high initial cost of AGM batteries compared to traditional lead-acid batteries. This cost factor may limit adoption in price-sensitive markets, particularly in developing regions. Additionally, the emergence of lithium-ion batteries as a competing technology poses a potential threat to the AGM battery market in certain applications.

Despite these challenges, the AGM battery market is expected to maintain its growth momentum due to several factors. The increasing focus on energy efficiency and sustainability across industries is likely to drive further adoption of AGM batteries. Moreover, ongoing research and development efforts aimed at improving AGM battery performance and reducing costs are expected to enhance their competitiveness in the market.

Geographically, North America and Europe currently lead the AGM battery market, owing to their advanced automotive industries and stringent environmental regulations. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing vehicle production, and growing investments in renewable energy projects.

Current Cooling Technologies and Limitations

Current cooling technologies for AGM (Absorbent Glass Mat) batteries primarily focus on managing temperature to enhance system longevity. The most common approach is passive air cooling, which relies on natural convection to dissipate heat. This method is simple and cost-effective but often insufficient for high-performance applications or extreme environments.

Active air cooling systems, utilizing fans or blowers, offer improved heat dissipation. These systems can be thermostatically controlled to activate only when needed, conserving energy. However, they introduce moving parts that may require maintenance and can be susceptible to failure in harsh conditions.

Liquid cooling solutions have gained traction for their superior heat transfer capabilities. These systems circulate coolant through channels or plates in contact with the battery cells. While highly effective, liquid cooling systems are more complex, expensive, and carry the risk of coolant leaks, which could be catastrophic for electrical systems.

Phase change materials (PCMs) represent an innovative approach to thermal management. PCMs absorb excess heat during battery operation and release it during cooling periods, helping to maintain a more stable temperature. This technology is particularly useful for applications with intermittent high-power demands but faces challenges in long-duration temperature control.

Thermoelectric cooling, based on the Peltier effect, offers precise temperature control without moving parts. However, its efficiency is limited, and it can be energy-intensive, potentially offsetting the benefits for battery longevity.

Despite these advancements, current cooling technologies face several limitations. Thermal management systems often struggle to provide uniform cooling across all cells in a battery pack, leading to temperature gradients that can accelerate degradation in certain areas. The trade-off between cooling effectiveness and system complexity remains a significant challenge, particularly for mobile applications where weight and space are at a premium.

Energy efficiency is another critical concern. Active cooling systems consume power, which can reduce the overall efficiency of the battery system. This is especially problematic in electric vehicles, where every watt of power is crucial for extending range.

Scalability presents another hurdle. Cooling solutions that work well for small battery packs may not be easily scaled up for larger systems without significant redesign or loss of efficiency. This limitation impacts the adoption of AGM batteries in grid-scale energy storage and other large-scale applications.

Environmental factors also pose challenges. Cooling systems must be robust enough to function effectively across a wide range of ambient temperatures and humidity levels. Additionally, the environmental impact of cooling technologies, including the use of refrigerants in some systems, is an growing concern that needs to be addressed for sustainable battery solutions.

Active air cooling systems, utilizing fans or blowers, offer improved heat dissipation. These systems can be thermostatically controlled to activate only when needed, conserving energy. However, they introduce moving parts that may require maintenance and can be susceptible to failure in harsh conditions.

Liquid cooling solutions have gained traction for their superior heat transfer capabilities. These systems circulate coolant through channels or plates in contact with the battery cells. While highly effective, liquid cooling systems are more complex, expensive, and carry the risk of coolant leaks, which could be catastrophic for electrical systems.

Phase change materials (PCMs) represent an innovative approach to thermal management. PCMs absorb excess heat during battery operation and release it during cooling periods, helping to maintain a more stable temperature. This technology is particularly useful for applications with intermittent high-power demands but faces challenges in long-duration temperature control.

Thermoelectric cooling, based on the Peltier effect, offers precise temperature control without moving parts. However, its efficiency is limited, and it can be energy-intensive, potentially offsetting the benefits for battery longevity.

Despite these advancements, current cooling technologies face several limitations. Thermal management systems often struggle to provide uniform cooling across all cells in a battery pack, leading to temperature gradients that can accelerate degradation in certain areas. The trade-off between cooling effectiveness and system complexity remains a significant challenge, particularly for mobile applications where weight and space are at a premium.

Energy efficiency is another critical concern. Active cooling systems consume power, which can reduce the overall efficiency of the battery system. This is especially problematic in electric vehicles, where every watt of power is crucial for extending range.

Scalability presents another hurdle. Cooling solutions that work well for small battery packs may not be easily scaled up for larger systems without significant redesign or loss of efficiency. This limitation impacts the adoption of AGM batteries in grid-scale energy storage and other large-scale applications.

Environmental factors also pose challenges. Cooling systems must be robust enough to function effectively across a wide range of ambient temperatures and humidity levels. Additionally, the environmental impact of cooling technologies, including the use of refrigerants in some systems, is an growing concern that needs to be addressed for sustainable battery solutions.

Existing AGM Battery Cooling Solutions

01 Thermal management systems for AGM batteries

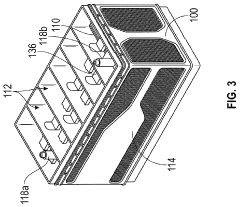

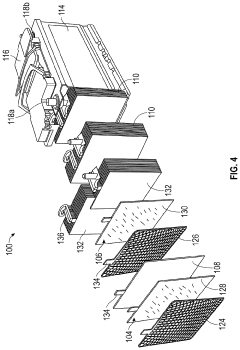

Advanced thermal management systems are crucial for maintaining optimal operating temperatures of AGM batteries, thereby extending their lifespan. These systems often incorporate cooling mechanisms such as liquid cooling, air cooling, or phase change materials to regulate battery temperature and prevent overheating during charging and discharging cycles.- Thermal management systems for AGM batteries: Advanced thermal management systems are crucial for maintaining optimal operating temperatures in AGM batteries. These systems often incorporate cooling mechanisms to prevent overheating, which can significantly extend battery life and improve overall performance. Effective cooling solutions may include liquid cooling, air cooling, or a combination of both, depending on the specific application and environmental conditions.

- Battery monitoring and control systems: Sophisticated monitoring and control systems play a vital role in AGM battery longevity. These systems continuously track battery parameters such as temperature, voltage, and current, allowing for real-time adjustments to optimize performance and prevent damage. Advanced algorithms and predictive analytics can be employed to anticipate potential issues and implement preventive measures, thereby extending battery lifespan.

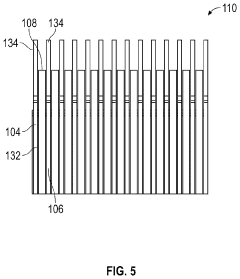

- Innovative cooling materials and designs: The development of novel cooling materials and designs can significantly enhance AGM battery cooling efficiency. This may include the use of advanced heat-dissipating materials, optimized cell layouts, and innovative cooling channel designs. These improvements can lead to more uniform temperature distribution within the battery pack, reducing hotspots and extending overall system longevity.

- Integration of renewable energy for cooling systems: Incorporating renewable energy sources, such as solar or wind power, to operate battery cooling systems can improve overall energy efficiency and reduce the environmental impact of AGM battery installations. This approach can be particularly beneficial for off-grid or remote applications, where traditional power sources may be limited or unreliable.

- Adaptive cooling strategies based on usage patterns: Implementing adaptive cooling strategies that adjust based on battery usage patterns and environmental conditions can optimize cooling efficiency and extend battery life. These strategies may involve machine learning algorithms that analyze historical data and predict future cooling needs, allowing for proactive temperature management and improved overall system longevity.

02 Battery monitoring and control systems

Sophisticated monitoring and control systems are employed to track battery performance, temperature, and state of charge. These systems use sensors and algorithms to optimize charging patterns, prevent overcharging, and manage thermal conditions, all of which contribute to prolonging the battery's operational life.Expand Specific Solutions03 Innovative cooling solutions for battery packs

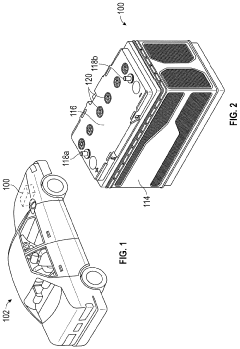

Novel cooling solutions are being developed for AGM battery packs, including the use of advanced materials and designs. These may involve heat-dissipating structures, coolant circulation systems, or intelligent airflow management to ensure uniform cooling across the battery pack, reducing hotspots and extending overall system longevity.Expand Specific Solutions04 Integration of battery cooling with vehicle systems

The integration of AGM battery cooling systems with other vehicle systems, such as air conditioning or powertrain cooling, is being explored to improve overall efficiency. This approach allows for better heat management across the entire vehicle, potentially using waste heat from one system to benefit another, thereby enhancing the longevity of the battery system.Expand Specific Solutions05 Predictive maintenance and lifecycle management

Advanced algorithms and data analytics are being utilized to predict battery degradation and optimize maintenance schedules. These systems can analyze historical data, usage patterns, and environmental factors to forecast battery health, allowing for proactive interventions that can significantly extend the operational life of AGM batteries.Expand Specific Solutions

Key Players in AGM Battery Cooling Industry

The AGM battery cooling solutions market is in a growth phase, driven by increasing demand for electric vehicles and energy storage systems. Major players like GM, Tesla, and Hyundai are investing heavily in research and development to enhance battery performance and longevity. The market size is expanding rapidly, with projections indicating significant growth over the next decade. Technologically, the field is advancing quickly, with companies like LG Energy Solution and Contemporary Amperex Technology leading in innovation. Established automotive giants such as Toyota and Volkswagen are also making strides, while newer entrants like Rivian are bringing fresh perspectives. The competition is fierce, with a focus on developing more efficient, cost-effective, and environmentally friendly cooling solutions to address the critical challenge of thermal management in AGM batteries.

GM Global Technology Operations LLC

Technical Solution: GM's AGM battery cooling solution features an innovative immersion cooling system. This approach submerges battery cells in a dielectric fluid with excellent heat transfer properties. The fluid is circulated through the battery pack using a low-energy pump system, providing consistent and efficient cooling across all cells[6]. GM's solution also incorporates a heat exchanger that interfaces with the vehicle's existing HVAC system, allowing for both battery cooling and cabin climate control optimization[7]. The system is designed to operate in a wide range of environmental conditions, from extreme cold to high heat, ensuring consistent battery performance and longevity[8].

Strengths: Uniform cooling, integration with vehicle HVAC, wide operating temperature range. Weaknesses: Potential complexity in fluid management and maintenance.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a multi-layer AGM battery cooling solution that combines active and passive cooling techniques. The system utilizes a series of thermally conductive plates interspersed between battery cells, connected to a liquid cooling circuit. This design allows for efficient heat dissipation while maintaining a compact form factor[9]. Hyundai's solution also incorporates phase-change materials (PCMs) within the cooling plates, providing additional thermal buffering during high-load situations[10]. The system is controlled by an intelligent thermal management unit that optimizes cooling based on battery state of charge, ambient temperature, and vehicle operating conditions[11].

Strengths: Compact design, efficient heat dissipation, thermal buffering with PCMs. Weaknesses: Potential increased weight due to PCM integration.

Innovative Cooling Techniques for AGM Batteries

Negative mass for lead-acid battery electrodes and lead-acid battery including same

PatentActiveUS20210336249A1

Innovation

- The introduction of additives such as fine particle barium sulfate, two organic compounds (oxylignins), and a carbonaceous material to the negative active material in lead-acid battery electrodes, which are pre-mixed to form a blended expander mixture, improving the homogeneity and dispersion of the battery paste and enhancing the battery's cycling performance and water retention.

Over-Saturated Absorbed Glass Mat Valve Regulated Lead-Acid Battery Comprising Carbon Additives

PatentInactiveUS20140120386A1

Innovation

- An AGM VRLA battery design with a positive plate, negative plate containing a carbon additive, an AGM separator, and an electrolyte present in an amount ranging from 100 to 150% by volume based on the total pore volume of the separator, utilizing various carbon additives such as graphite, carbon black, activated carbon, and graphene to enhance charge acceptance and durability.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies for AGM batteries is a critical consideration in the development of sustainable energy storage solutions. Traditional cooling methods often rely on energy-intensive processes and materials that can have significant ecological consequences. Air cooling systems, while generally less harmful, may still contribute to increased energy consumption and noise pollution in large-scale applications.

Liquid cooling systems, which are more efficient in heat dissipation, present their own set of environmental challenges. The use of coolants, particularly those containing harmful chemicals, poses risks of leakage and contamination. Proper disposal and recycling of these coolants are essential to mitigate potential environmental hazards. Additionally, the production and transportation of specialized cooling fluids contribute to the overall carbon footprint of the battery system.

Phase change materials (PCMs) offer a promising alternative with potentially lower environmental impact. These materials absorb and release thermal energy during phase transitions, providing passive cooling without the need for energy-intensive mechanical systems. However, the long-term environmental effects of PCMs, including their biodegradability and potential for leaching, require further investigation.

The manufacturing processes for cooling components also have environmental implications. The production of heat sinks, cooling plates, and thermal management systems often involves energy-intensive processes and the use of raw materials with varying degrees of environmental impact. Efforts to utilize recycled materials and implement more sustainable manufacturing practices are crucial in reducing the overall ecological footprint of battery cooling solutions.

Energy efficiency is a key factor in assessing the environmental impact of cooling technologies. More efficient cooling systems not only extend battery life but also reduce the overall energy consumption of the battery system. This, in turn, leads to decreased demand on power grids and potentially lower greenhouse gas emissions associated with energy production.

As the adoption of AGM batteries in various applications continues to grow, the scalability of cooling solutions becomes increasingly important from an environmental perspective. Solutions that are environmentally sustainable at small scales may present unforeseen challenges when implemented in large-scale energy storage systems or electric vehicle fleets.

Lastly, the end-of-life considerations for cooling technologies must be addressed. The recyclability and proper disposal of cooling system components are crucial in minimizing waste and preventing the release of harmful substances into the environment. Developing circular economy approaches for these components can significantly reduce their long-term environmental impact.

Liquid cooling systems, which are more efficient in heat dissipation, present their own set of environmental challenges. The use of coolants, particularly those containing harmful chemicals, poses risks of leakage and contamination. Proper disposal and recycling of these coolants are essential to mitigate potential environmental hazards. Additionally, the production and transportation of specialized cooling fluids contribute to the overall carbon footprint of the battery system.

Phase change materials (PCMs) offer a promising alternative with potentially lower environmental impact. These materials absorb and release thermal energy during phase transitions, providing passive cooling without the need for energy-intensive mechanical systems. However, the long-term environmental effects of PCMs, including their biodegradability and potential for leaching, require further investigation.

The manufacturing processes for cooling components also have environmental implications. The production of heat sinks, cooling plates, and thermal management systems often involves energy-intensive processes and the use of raw materials with varying degrees of environmental impact. Efforts to utilize recycled materials and implement more sustainable manufacturing practices are crucial in reducing the overall ecological footprint of battery cooling solutions.

Energy efficiency is a key factor in assessing the environmental impact of cooling technologies. More efficient cooling systems not only extend battery life but also reduce the overall energy consumption of the battery system. This, in turn, leads to decreased demand on power grids and potentially lower greenhouse gas emissions associated with energy production.

As the adoption of AGM batteries in various applications continues to grow, the scalability of cooling solutions becomes increasingly important from an environmental perspective. Solutions that are environmentally sustainable at small scales may present unforeseen challenges when implemented in large-scale energy storage systems or electric vehicle fleets.

Lastly, the end-of-life considerations for cooling technologies must be addressed. The recyclability and proper disposal of cooling system components are crucial in minimizing waste and preventing the release of harmful substances into the environment. Developing circular economy approaches for these components can significantly reduce their long-term environmental impact.

Cost-Benefit Analysis of Cooling Solutions

The cost-benefit analysis of cooling solutions for AGM batteries is a critical aspect of enhancing system longevity. This analysis involves evaluating the financial implications of implementing various cooling methods against the potential benefits in terms of extended battery life and improved performance.

One of the primary considerations in this analysis is the initial investment required for different cooling solutions. Passive cooling systems, such as heat sinks and thermal pads, generally have lower upfront costs but may offer limited cooling efficiency. In contrast, active cooling systems like forced air circulation or liquid cooling tend to have higher initial costs due to the need for additional components such as fans, pumps, or heat exchangers.

Operating costs also play a significant role in the cost-benefit equation. Active cooling systems typically consume more energy, which can increase the overall power consumption of the battery system. This additional energy requirement must be weighed against the potential energy savings from improved battery efficiency and reduced self-discharge rates that effective cooling can provide.

Maintenance costs and system reliability are crucial factors to consider. Passive cooling systems often require minimal maintenance, resulting in lower long-term costs. However, active cooling systems may necessitate regular maintenance, such as filter replacements or coolant refills, which can add to the total cost of ownership over time.

The benefits of implementing cooling solutions can be substantial. Effective thermal management can significantly extend the lifespan of AGM batteries by reducing the rate of chemical degradation caused by high temperatures. This extension of battery life can lead to considerable cost savings by delaying the need for battery replacement and reducing the frequency of maintenance interventions.

Improved performance is another key benefit. Cooler operating temperatures can enhance the charge acceptance of AGM batteries, leading to faster charging times and potentially reducing downtime in applications where rapid recharging is critical. Additionally, maintaining optimal temperature ranges can increase the overall efficiency of the battery, potentially reducing energy consumption in the long run.

The analysis must also consider the specific application requirements. For instance, in high-power applications or environments with extreme temperature fluctuations, the benefits of advanced cooling solutions may far outweigh the costs. Conversely, in less demanding applications, the cost of sophisticated cooling systems might not be justified by the marginal improvements in battery performance.

Ultimately, the cost-benefit analysis should incorporate a lifecycle assessment of the battery system. This approach takes into account not only the immediate costs and benefits but also the long-term financial implications of different cooling strategies. Factors such as expected battery lifespan, replacement costs, and potential downtime due to battery failures should all be quantified and compared across various cooling solutions.

One of the primary considerations in this analysis is the initial investment required for different cooling solutions. Passive cooling systems, such as heat sinks and thermal pads, generally have lower upfront costs but may offer limited cooling efficiency. In contrast, active cooling systems like forced air circulation or liquid cooling tend to have higher initial costs due to the need for additional components such as fans, pumps, or heat exchangers.

Operating costs also play a significant role in the cost-benefit equation. Active cooling systems typically consume more energy, which can increase the overall power consumption of the battery system. This additional energy requirement must be weighed against the potential energy savings from improved battery efficiency and reduced self-discharge rates that effective cooling can provide.

Maintenance costs and system reliability are crucial factors to consider. Passive cooling systems often require minimal maintenance, resulting in lower long-term costs. However, active cooling systems may necessitate regular maintenance, such as filter replacements or coolant refills, which can add to the total cost of ownership over time.

The benefits of implementing cooling solutions can be substantial. Effective thermal management can significantly extend the lifespan of AGM batteries by reducing the rate of chemical degradation caused by high temperatures. This extension of battery life can lead to considerable cost savings by delaying the need for battery replacement and reducing the frequency of maintenance interventions.

Improved performance is another key benefit. Cooler operating temperatures can enhance the charge acceptance of AGM batteries, leading to faster charging times and potentially reducing downtime in applications where rapid recharging is critical. Additionally, maintaining optimal temperature ranges can increase the overall efficiency of the battery, potentially reducing energy consumption in the long run.

The analysis must also consider the specific application requirements. For instance, in high-power applications or environments with extreme temperature fluctuations, the benefits of advanced cooling solutions may far outweigh the costs. Conversely, in less demanding applications, the cost of sophisticated cooling systems might not be justified by the marginal improvements in battery performance.

Ultimately, the cost-benefit analysis should incorporate a lifecycle assessment of the battery system. This approach takes into account not only the immediate costs and benefits but also the long-term financial implications of different cooling strategies. Factors such as expected battery lifespan, replacement costs, and potential downtime due to battery failures should all be quantified and compared across various cooling solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!