AGM Battery Thermal Runaway Risks and Prevention Strategies

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution and Safety Objectives

Absorbed Glass Mat (AGM) batteries have undergone significant evolution since their inception in the 1980s, driven by the increasing demand for reliable and safe energy storage solutions. Initially developed for military and aviation applications, AGM batteries have found widespread use in various sectors, including automotive, telecommunications, and renewable energy systems. The primary objectives in AGM battery development have consistently focused on enhancing performance, longevity, and safety.

The evolution of AGM batteries has been marked by continuous improvements in electrode design, electrolyte composition, and manufacturing processes. Early iterations faced challenges related to capacity retention and cycle life. However, advancements in plate design, such as thinner and more uniform lead grids, have led to improved energy density and faster recharge capabilities. The introduction of high-purity lead alloys and optimized active material formulations has further enhanced battery performance and lifespan.

Safety has always been a paramount concern in AGM battery development. The inherent design of AGM batteries, with the electrolyte absorbed in a glass mat separator, already provides a significant safety advantage over flooded lead-acid batteries. This design minimizes the risk of electrolyte leakage and reduces the potential for hydrogen gas emission. However, as AGM batteries have been pushed to deliver higher power outputs and faster charging rates, new safety challenges have emerged, particularly concerning thermal management and the prevention of thermal runaway.

Recent safety objectives in AGM battery development have focused on addressing these emerging challenges. Key areas of improvement include the development of more stable separator materials that can withstand higher temperatures, implementation of advanced pressure relief valve designs to manage gas buildup, and the integration of smart battery management systems (BMS) to monitor and control charging processes more effectively.

The pursuit of enhanced safety has also led to innovations in battery casing materials and designs. Manufacturers have explored the use of flame-retardant additives in battery casings and investigated structural modifications to improve heat dissipation. Additionally, there has been a growing emphasis on developing more accurate and responsive temperature sensors to enable early detection of potential thermal issues.

As AGM batteries continue to evolve, the industry is increasingly focusing on balancing performance enhancements with rigorous safety standards. This includes the development of comprehensive testing protocols to simulate extreme conditions and validate the effectiveness of safety features. The ongoing research into new electrolyte additives and electrode materials aims not only to boost performance but also to inherently improve the thermal stability and overall safety profile of AGM batteries.

The evolution of AGM batteries has been marked by continuous improvements in electrode design, electrolyte composition, and manufacturing processes. Early iterations faced challenges related to capacity retention and cycle life. However, advancements in plate design, such as thinner and more uniform lead grids, have led to improved energy density and faster recharge capabilities. The introduction of high-purity lead alloys and optimized active material formulations has further enhanced battery performance and lifespan.

Safety has always been a paramount concern in AGM battery development. The inherent design of AGM batteries, with the electrolyte absorbed in a glass mat separator, already provides a significant safety advantage over flooded lead-acid batteries. This design minimizes the risk of electrolyte leakage and reduces the potential for hydrogen gas emission. However, as AGM batteries have been pushed to deliver higher power outputs and faster charging rates, new safety challenges have emerged, particularly concerning thermal management and the prevention of thermal runaway.

Recent safety objectives in AGM battery development have focused on addressing these emerging challenges. Key areas of improvement include the development of more stable separator materials that can withstand higher temperatures, implementation of advanced pressure relief valve designs to manage gas buildup, and the integration of smart battery management systems (BMS) to monitor and control charging processes more effectively.

The pursuit of enhanced safety has also led to innovations in battery casing materials and designs. Manufacturers have explored the use of flame-retardant additives in battery casings and investigated structural modifications to improve heat dissipation. Additionally, there has been a growing emphasis on developing more accurate and responsive temperature sensors to enable early detection of potential thermal issues.

As AGM batteries continue to evolve, the industry is increasingly focusing on balancing performance enhancements with rigorous safety standards. This includes the development of comprehensive testing protocols to simulate extreme conditions and validate the effectiveness of safety features. The ongoing research into new electrolyte additives and electrode materials aims not only to boost performance but also to inherently improve the thermal stability and overall safety profile of AGM batteries.

Market Demand for Safe AGM Batteries

The market demand for safe AGM (Absorbent Glass Mat) batteries has been steadily increasing due to their widespread applications in various industries and the growing emphasis on safety in energy storage systems. AGM batteries are extensively used in automotive, telecommunications, uninterruptible power supplies (UPS), and renewable energy storage sectors.

In the automotive industry, the shift towards more advanced electrical systems and the rise of start-stop technology have significantly boosted the demand for AGM batteries. These batteries offer superior performance in handling frequent charge-discharge cycles and provide better power delivery for modern vehicles with complex electrical systems.

The telecommunications sector has also been a major driver of AGM battery demand. As the global telecommunications infrastructure expands, particularly with the rollout of 5G networks, the need for reliable backup power solutions has increased. AGM batteries are preferred due to their maintenance-free operation and ability to perform well in diverse environmental conditions.

The UPS market, crucial for data centers and critical infrastructure, has seen a surge in demand for AGM batteries. The growing reliance on digital technologies and the expansion of cloud computing services have amplified the need for dependable power backup solutions. AGM batteries' quick response time and high-power density make them ideal for these applications.

In the renewable energy sector, AGM batteries play a vital role in energy storage systems for solar and wind power installations. As more countries invest in renewable energy sources, the demand for efficient and safe energy storage solutions has risen dramatically. AGM batteries' deep-cycle capabilities and low self-discharge rates make them suitable for these applications.

The market's focus on safety has become increasingly pronounced, especially in light of high-profile incidents involving lithium-ion batteries. This has led to a renewed interest in AGM technology as a safer alternative in certain applications. The non-spillable design and lower risk of thermal runaway in AGM batteries are particularly attractive features for industries where safety is paramount.

Furthermore, the global push towards electrification and the increasing adoption of electric vehicles have indirectly benefited the AGM battery market. While lithium-ion batteries dominate the EV sector, AGM batteries are still widely used in conventional vehicles and hybrid systems, maintaining a strong market presence.

In the automotive industry, the shift towards more advanced electrical systems and the rise of start-stop technology have significantly boosted the demand for AGM batteries. These batteries offer superior performance in handling frequent charge-discharge cycles and provide better power delivery for modern vehicles with complex electrical systems.

The telecommunications sector has also been a major driver of AGM battery demand. As the global telecommunications infrastructure expands, particularly with the rollout of 5G networks, the need for reliable backup power solutions has increased. AGM batteries are preferred due to their maintenance-free operation and ability to perform well in diverse environmental conditions.

The UPS market, crucial for data centers and critical infrastructure, has seen a surge in demand for AGM batteries. The growing reliance on digital technologies and the expansion of cloud computing services have amplified the need for dependable power backup solutions. AGM batteries' quick response time and high-power density make them ideal for these applications.

In the renewable energy sector, AGM batteries play a vital role in energy storage systems for solar and wind power installations. As more countries invest in renewable energy sources, the demand for efficient and safe energy storage solutions has risen dramatically. AGM batteries' deep-cycle capabilities and low self-discharge rates make them suitable for these applications.

The market's focus on safety has become increasingly pronounced, especially in light of high-profile incidents involving lithium-ion batteries. This has led to a renewed interest in AGM technology as a safer alternative in certain applications. The non-spillable design and lower risk of thermal runaway in AGM batteries are particularly attractive features for industries where safety is paramount.

Furthermore, the global push towards electrification and the increasing adoption of electric vehicles have indirectly benefited the AGM battery market. While lithium-ion batteries dominate the EV sector, AGM batteries are still widely used in conventional vehicles and hybrid systems, maintaining a strong market presence.

Thermal Runaway Challenges in AGM Batteries

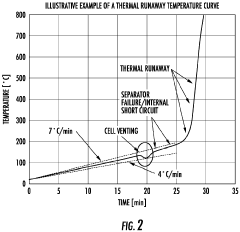

Thermal runaway in AGM (Absorbed Glass Mat) batteries presents a significant challenge in the field of energy storage and automotive applications. This phenomenon occurs when the battery's internal temperature rises uncontrollably, leading to a cascade of exothermic reactions that can result in catastrophic failure, fire, or explosion. The primary causes of thermal runaway in AGM batteries include overcharging, short circuits, mechanical damage, and manufacturing defects.

One of the main challenges in preventing thermal runaway is the difficulty in detecting early warning signs. AGM batteries, like other lead-acid batteries, can experience subtle changes in their internal chemistry that precede a thermal runaway event. These changes are often not easily detectable through conventional monitoring methods, making it challenging to implement preventive measures in a timely manner.

Another significant challenge is the inherent design of AGM batteries. While the absorbed glass mat technology offers advantages in terms of electrolyte containment and reduced maintenance, it also presents unique thermal management issues. The compact design and limited electrolyte mobility can lead to localized heat buildup, potentially accelerating the onset of thermal runaway under certain conditions.

The high energy density of AGM batteries, while beneficial for many applications, also contributes to the severity of thermal runaway events. Once initiated, the energy released during a thermal runaway can be substantial, making containment and mitigation extremely difficult. This poses significant safety risks, particularly in enclosed spaces or when the batteries are part of larger energy storage systems.

Environmental factors also play a crucial role in the thermal runaway challenges of AGM batteries. Exposure to extreme temperatures, particularly high ambient temperatures, can significantly increase the risk of thermal runaway. This is particularly problematic in automotive applications where batteries may be subjected to a wide range of environmental conditions.

The chemical composition of AGM batteries presents another challenge in managing thermal runaway risks. The lead-acid chemistry, while well-established and cost-effective, is susceptible to side reactions that can generate heat and gases under certain conditions. Managing these chemical processes to prevent the initiation of thermal runaway requires sophisticated control systems and careful battery management.

Addressing these challenges requires a multifaceted approach, combining advances in battery design, improved monitoring technologies, and enhanced safety protocols. Developing more robust thermal management systems, implementing advanced early warning detection methods, and improving the overall resilience of AGM batteries to thermal stress are key areas of focus for researchers and manufacturers in the field.

One of the main challenges in preventing thermal runaway is the difficulty in detecting early warning signs. AGM batteries, like other lead-acid batteries, can experience subtle changes in their internal chemistry that precede a thermal runaway event. These changes are often not easily detectable through conventional monitoring methods, making it challenging to implement preventive measures in a timely manner.

Another significant challenge is the inherent design of AGM batteries. While the absorbed glass mat technology offers advantages in terms of electrolyte containment and reduced maintenance, it also presents unique thermal management issues. The compact design and limited electrolyte mobility can lead to localized heat buildup, potentially accelerating the onset of thermal runaway under certain conditions.

The high energy density of AGM batteries, while beneficial for many applications, also contributes to the severity of thermal runaway events. Once initiated, the energy released during a thermal runaway can be substantial, making containment and mitigation extremely difficult. This poses significant safety risks, particularly in enclosed spaces or when the batteries are part of larger energy storage systems.

Environmental factors also play a crucial role in the thermal runaway challenges of AGM batteries. Exposure to extreme temperatures, particularly high ambient temperatures, can significantly increase the risk of thermal runaway. This is particularly problematic in automotive applications where batteries may be subjected to a wide range of environmental conditions.

The chemical composition of AGM batteries presents another challenge in managing thermal runaway risks. The lead-acid chemistry, while well-established and cost-effective, is susceptible to side reactions that can generate heat and gases under certain conditions. Managing these chemical processes to prevent the initiation of thermal runaway requires sophisticated control systems and careful battery management.

Addressing these challenges requires a multifaceted approach, combining advances in battery design, improved monitoring technologies, and enhanced safety protocols. Developing more robust thermal management systems, implementing advanced early warning detection methods, and improving the overall resilience of AGM batteries to thermal stress are key areas of focus for researchers and manufacturers in the field.

Current Thermal Runaway Prevention Techniques

01 Thermal management systems for AGM batteries

Advanced thermal management systems are developed to prevent thermal runaway in AGM batteries. These systems include temperature monitoring, heat dissipation mechanisms, and cooling strategies to maintain optimal operating conditions and prevent overheating.- Thermal management systems for AGM batteries: Advanced thermal management systems are developed to prevent thermal runaway in AGM batteries. These systems include temperature monitoring, heat dissipation mechanisms, and intelligent cooling strategies to maintain optimal operating temperatures and prevent overheating.

- Safety features to prevent thermal runaway: Various safety features are incorporated into AGM battery designs to prevent thermal runaway. These may include pressure relief valves, thermal fuses, and separator materials with enhanced thermal stability to mitigate the risk of uncontrolled temperature increases.

- Advanced electrode and electrolyte materials: Research focuses on developing advanced electrode and electrolyte materials for AGM batteries that are more resistant to thermal runaway. These materials aim to improve thermal stability, reduce internal resistance, and enhance overall battery safety.

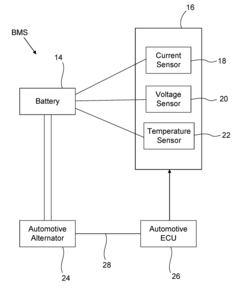

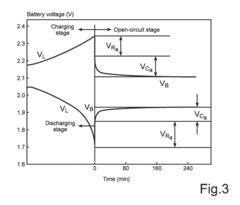

- Battery management systems for thermal runaway prevention: Sophisticated battery management systems are designed to monitor and control various parameters of AGM batteries. These systems use advanced algorithms to detect early signs of thermal runaway and implement preventive measures such as load balancing and charge control.

- Structural design improvements for thermal stability: Innovations in the structural design of AGM batteries focus on enhancing thermal stability. This includes optimized cell arrangements, improved heat dissipation pathways, and the use of thermally conductive materials to better manage heat distribution within the battery.

02 Safety mechanisms to prevent thermal runaway

Various safety mechanisms are implemented in AGM batteries to prevent thermal runaway. These include pressure relief valves, current interrupt devices, and thermal fuses that activate in response to abnormal temperature increases or pressure buildup.Expand Specific Solutions03 Advanced separator materials for AGM batteries

Innovative separator materials are developed to enhance the safety of AGM batteries. These materials have improved thermal stability, better electrolyte retention, and reduced risk of short circuits, contributing to the prevention of thermal runaway events.Expand Specific Solutions04 Battery management systems for thermal runaway prevention

Sophisticated battery management systems are designed to monitor and control AGM battery performance. These systems use advanced algorithms to detect early signs of thermal runaway, adjust charging parameters, and implement protective measures to maintain battery safety.Expand Specific Solutions05 Improved electrolyte formulations for AGM batteries

Novel electrolyte formulations are developed to enhance the thermal stability of AGM batteries. These formulations include additives that suppress gas generation, improve charge acceptance, and reduce the risk of thermal runaway under extreme conditions.Expand Specific Solutions

Key AGM Battery Manufacturers and Researchers

The AGM battery thermal runaway risk prevention market is in a growth phase, driven by increasing adoption of electric vehicles and energy storage systems. The market size is expanding rapidly, with major players like Tesla, BYD, and CATL investing heavily in research and development. Technological maturity varies, with established companies like Honeywell and IBM offering advanced solutions, while newer entrants like Microvast and EVE Energy focus on innovative approaches. The competitive landscape is diverse, featuring automotive manufacturers, battery producers, and technology firms, all striving to enhance safety and performance in AGM battery systems.

Tesla, Inc.

Technical Solution: Tesla has developed a multi-layered approach to prevent thermal runaway in their AGM batteries. They use a proprietary intumescent material between cells that expands when heated, creating a physical barrier to prevent fire spread[4]. Tesla's batteries also incorporate a state-of-the-art cooling system using a glycol-based coolant that flows through a serpentine network between cells[5]. Their BMS employs machine learning algorithms to continuously monitor cell temperatures and voltage, predicting potential issues before they occur[6].

Strengths: Advanced fire prevention, efficient cooling, and predictive maintenance. Weaknesses: Proprietary technology may limit wider industry adoption.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a novel battery cell-to-pack (CTP) technology that integrates cells directly into the battery pack, eliminating the need for modules. This design improves energy density and reduces the risk of thermal runaway by enhancing heat dissipation[1]. They have also implemented an advanced Battery Management System (BMS) that uses AI algorithms to predict and prevent potential thermal issues[2]. Additionally, CATL has introduced a liquid cooling system that circulates a non-conductive coolant directly around the cells, providing more efficient temperature control[3].

Strengths: High energy density, improved safety, and efficient cooling. Weaknesses: Potentially higher manufacturing complexity and cost.

Innovative Thermal Management Solutions

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

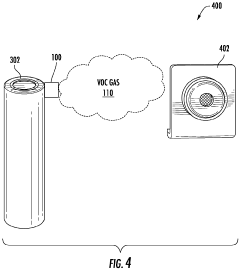

System and method for early-stage detection of thermal runaway in lithium-ion batteries

PatentPendingEP4366031A1

Innovation

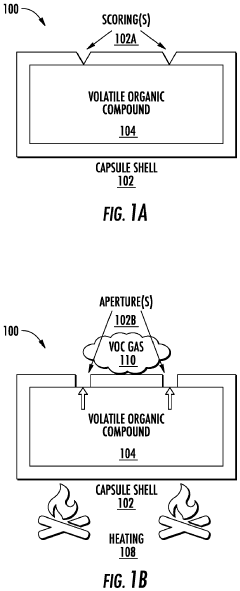

- A thermally reactive capsule coupled to battery cells, containing a volatile organic compound (VOC) with a boiling point below a threshold temperature, which vaporizes and opens pressure relief devices upon reaching this temperature, releasing gas detectable by a sensor to indicate potential thermal runaway before damage occurs.

Regulatory Framework for Battery Safety

The regulatory framework for battery safety plays a crucial role in mitigating the risks associated with AGM battery thermal runaway. Governments and international organizations have established comprehensive guidelines and standards to ensure the safe manufacturing, transportation, and use of batteries, including AGM batteries.

At the international level, the United Nations (UN) has developed regulations for the transport of dangerous goods, which include specific provisions for batteries. The UN Manual of Tests and Criteria outlines the requirements for lithium batteries, which can be applied to AGM batteries as well. These regulations cover aspects such as packaging, labeling, and testing procedures to prevent thermal runaway during transportation.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have implemented regulations based on the UN recommendations. These regulations, codified in 49 CFR Parts 171-180, provide detailed requirements for the safe transport of batteries, including AGM batteries, across various modes of transportation.

The European Union has also established a robust regulatory framework for battery safety. The EU Battery Directive (2006/66/EC) sets requirements for battery manufacturers, importers, and distributors to ensure the safe handling and disposal of batteries. Additionally, the EU has implemented specific regulations for the automotive industry, such as UN Regulation No. 100, which addresses the safety requirements for electric power train vehicles.

In the context of AGM battery thermal runaway prevention, regulatory bodies have focused on establishing safety standards for battery design, manufacturing processes, and quality control. For instance, the International Electrotechnical Commission (IEC) has developed standards such as IEC 62619, which specifies safety requirements for secondary lithium cells and batteries for use in industrial applications.

Regulatory frameworks also emphasize the importance of proper battery management systems (BMS) to prevent thermal runaway. Standards like UL 1973 and UL 2054 provide guidelines for the design and testing of BMS, ensuring that batteries operate within safe temperature and voltage ranges.

Furthermore, regulatory bodies have recognized the need for continuous improvement in battery safety standards. As new technologies and materials emerge, regulations are regularly updated to address potential risks and incorporate the latest safety measures. This adaptive approach ensures that the regulatory framework remains effective in preventing AGM battery thermal runaway incidents and promoting overall battery safety.

At the international level, the United Nations (UN) has developed regulations for the transport of dangerous goods, which include specific provisions for batteries. The UN Manual of Tests and Criteria outlines the requirements for lithium batteries, which can be applied to AGM batteries as well. These regulations cover aspects such as packaging, labeling, and testing procedures to prevent thermal runaway during transportation.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have implemented regulations based on the UN recommendations. These regulations, codified in 49 CFR Parts 171-180, provide detailed requirements for the safe transport of batteries, including AGM batteries, across various modes of transportation.

The European Union has also established a robust regulatory framework for battery safety. The EU Battery Directive (2006/66/EC) sets requirements for battery manufacturers, importers, and distributors to ensure the safe handling and disposal of batteries. Additionally, the EU has implemented specific regulations for the automotive industry, such as UN Regulation No. 100, which addresses the safety requirements for electric power train vehicles.

In the context of AGM battery thermal runaway prevention, regulatory bodies have focused on establishing safety standards for battery design, manufacturing processes, and quality control. For instance, the International Electrotechnical Commission (IEC) has developed standards such as IEC 62619, which specifies safety requirements for secondary lithium cells and batteries for use in industrial applications.

Regulatory frameworks also emphasize the importance of proper battery management systems (BMS) to prevent thermal runaway. Standards like UL 1973 and UL 2054 provide guidelines for the design and testing of BMS, ensuring that batteries operate within safe temperature and voltage ranges.

Furthermore, regulatory bodies have recognized the need for continuous improvement in battery safety standards. As new technologies and materials emerge, regulations are regularly updated to address potential risks and incorporate the latest safety measures. This adaptive approach ensures that the regulatory framework remains effective in preventing AGM battery thermal runaway incidents and promoting overall battery safety.

Environmental Impact of AGM Battery Safety Measures

The implementation of safety measures for AGM (Absorbent Glass Mat) batteries, while crucial for preventing thermal runaway risks, carries significant environmental implications. These measures often involve the use of additional materials and components, which can impact the overall environmental footprint of battery production and disposal.

One of the primary environmental concerns is the increased use of flame-retardant materials in battery casings and separators. While these materials enhance safety, they often contain halogenated compounds that can be harmful to ecosystems if not properly managed at the end of the battery's life cycle. The production of these specialized materials also requires additional energy and resources, potentially increasing the carbon footprint of battery manufacturing.

The incorporation of advanced thermal management systems, such as phase change materials or active cooling systems, introduces new materials and components into the battery design. This complexity can make recycling more challenging, potentially reducing the overall recyclability of AGM batteries. However, these systems also contribute to extending battery life, which can offset some of the environmental impacts by reducing the frequency of battery replacements.

Safety-oriented design modifications may lead to increased battery size and weight, affecting the energy efficiency of vehicles or devices using these batteries. This could indirectly contribute to higher energy consumption and emissions in transportation applications. Conversely, improved safety measures can reduce the incidence of battery fires and thermal runaway events, which can have severe localized environmental impacts, including the release of toxic gases and contamination of soil and water resources.

The development and implementation of advanced battery management systems (BMS) for safety purposes involve the use of rare earth elements and precious metals in electronic components. The mining and processing of these materials have well-documented environmental consequences, including habitat destruction and water pollution. However, these systems also optimize battery performance and longevity, potentially reducing the overall demand for battery production and replacement.

From a lifecycle perspective, enhanced safety measures can lead to longer-lasting and more reliable AGM batteries. This longevity can significantly reduce the environmental impact associated with battery production and disposal over time. Additionally, safer batteries may encourage wider adoption of energy storage solutions, supporting the transition to renewable energy sources and potentially offsetting the environmental costs of safety measure implementation.

In conclusion, while AGM battery safety measures introduce new environmental challenges, they also offer opportunities for reducing long-term environmental impacts through improved battery performance and reduced safety incidents. Balancing these factors requires ongoing research and development to optimize safety technologies while minimizing their environmental footprint.

One of the primary environmental concerns is the increased use of flame-retardant materials in battery casings and separators. While these materials enhance safety, they often contain halogenated compounds that can be harmful to ecosystems if not properly managed at the end of the battery's life cycle. The production of these specialized materials also requires additional energy and resources, potentially increasing the carbon footprint of battery manufacturing.

The incorporation of advanced thermal management systems, such as phase change materials or active cooling systems, introduces new materials and components into the battery design. This complexity can make recycling more challenging, potentially reducing the overall recyclability of AGM batteries. However, these systems also contribute to extending battery life, which can offset some of the environmental impacts by reducing the frequency of battery replacements.

Safety-oriented design modifications may lead to increased battery size and weight, affecting the energy efficiency of vehicles or devices using these batteries. This could indirectly contribute to higher energy consumption and emissions in transportation applications. Conversely, improved safety measures can reduce the incidence of battery fires and thermal runaway events, which can have severe localized environmental impacts, including the release of toxic gases and contamination of soil and water resources.

The development and implementation of advanced battery management systems (BMS) for safety purposes involve the use of rare earth elements and precious metals in electronic components. The mining and processing of these materials have well-documented environmental consequences, including habitat destruction and water pollution. However, these systems also optimize battery performance and longevity, potentially reducing the overall demand for battery production and replacement.

From a lifecycle perspective, enhanced safety measures can lead to longer-lasting and more reliable AGM batteries. This longevity can significantly reduce the environmental impact associated with battery production and disposal over time. Additionally, safer batteries may encourage wider adoption of energy storage solutions, supporting the transition to renewable energy sources and potentially offsetting the environmental costs of safety measure implementation.

In conclusion, while AGM battery safety measures introduce new environmental challenges, they also offer opportunities for reducing long-term environmental impacts through improved battery performance and reduced safety incidents. Balancing these factors requires ongoing research and development to optimize safety technologies while minimizing their environmental footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!