Analysis of AGM Battery Life Predictors in Varied Climates

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution and Objectives

Absorbed Glass Mat (AGM) batteries have undergone significant evolution since their inception in the 1980s. Initially developed for military and aerospace applications, AGM technology has progressively found its way into various sectors, including automotive, renewable energy storage, and telecommunications. The primary objective of AGM battery development has been to create a maintenance-free, high-performance energy storage solution capable of withstanding diverse environmental conditions.

The evolution of AGM batteries has been driven by the need for improved energy density, longer cycle life, and enhanced reliability in extreme temperatures. Early iterations focused on optimizing the glass mat separator and electrolyte absorption, leading to better charge acceptance and reduced internal resistance. Subsequent advancements targeted the electrode design and active material composition, resulting in higher specific energy and power capabilities.

A key milestone in AGM battery evolution was the introduction of valve-regulated lead-acid (VRLA) technology, which significantly reduced gas emissions and eliminated the need for regular water replenishment. This innovation expanded the application scope of AGM batteries, particularly in sealed environments and sensitive electronic equipment installations.

Recent developments in AGM technology have centered on enhancing battery life predictability across varied climatic conditions. This focus stems from the growing demand for reliable energy storage solutions in renewable energy systems and electric vehicles, where batteries are exposed to diverse environmental factors. The objective is to develop robust predictive models that can accurately estimate AGM battery lifespan under different temperature regimes, humidity levels, and charge-discharge patterns.

Current research aims to integrate advanced sensors and monitoring systems into AGM batteries, enabling real-time data collection on key performance indicators. This data-driven approach seeks to improve the accuracy of life prediction models by considering a broader range of environmental and operational variables. Additionally, efforts are underway to develop adaptive charging algorithms that can optimize battery performance based on ambient conditions, potentially extending battery life in challenging climates.

The overarching goal of AGM battery evolution is to create a more resilient and adaptable energy storage solution that can maintain consistent performance across diverse geographical locations and applications. By focusing on life prediction in varied climates, researchers and manufacturers aim to enhance the reliability and cost-effectiveness of AGM batteries, ultimately supporting the transition to more sustainable energy systems and electric mobility solutions.

The evolution of AGM batteries has been driven by the need for improved energy density, longer cycle life, and enhanced reliability in extreme temperatures. Early iterations focused on optimizing the glass mat separator and electrolyte absorption, leading to better charge acceptance and reduced internal resistance. Subsequent advancements targeted the electrode design and active material composition, resulting in higher specific energy and power capabilities.

A key milestone in AGM battery evolution was the introduction of valve-regulated lead-acid (VRLA) technology, which significantly reduced gas emissions and eliminated the need for regular water replenishment. This innovation expanded the application scope of AGM batteries, particularly in sealed environments and sensitive electronic equipment installations.

Recent developments in AGM technology have centered on enhancing battery life predictability across varied climatic conditions. This focus stems from the growing demand for reliable energy storage solutions in renewable energy systems and electric vehicles, where batteries are exposed to diverse environmental factors. The objective is to develop robust predictive models that can accurately estimate AGM battery lifespan under different temperature regimes, humidity levels, and charge-discharge patterns.

Current research aims to integrate advanced sensors and monitoring systems into AGM batteries, enabling real-time data collection on key performance indicators. This data-driven approach seeks to improve the accuracy of life prediction models by considering a broader range of environmental and operational variables. Additionally, efforts are underway to develop adaptive charging algorithms that can optimize battery performance based on ambient conditions, potentially extending battery life in challenging climates.

The overarching goal of AGM battery evolution is to create a more resilient and adaptable energy storage solution that can maintain consistent performance across diverse geographical locations and applications. By focusing on life prediction in varied climates, researchers and manufacturers aim to enhance the reliability and cost-effectiveness of AGM batteries, ultimately supporting the transition to more sustainable energy systems and electric mobility solutions.

Market Demand Analysis for AGM Batteries

The market demand for AGM (Absorbent Glass Mat) batteries has been steadily increasing, driven by their superior performance characteristics and growing applications across various industries. In the automotive sector, AGM batteries are gaining popularity due to their ability to support start-stop systems and advanced electrical systems in modern vehicles. The increasing adoption of electric and hybrid vehicles has further boosted the demand for high-performance batteries, including AGM technology.

The renewable energy sector has also contributed significantly to the market growth of AGM batteries. As solar and wind power installations continue to expand globally, the need for reliable energy storage solutions has increased. AGM batteries, with their deep-cycle capabilities and maintenance-free operation, have become a preferred choice for off-grid and grid-tied renewable energy systems.

In the telecommunications industry, AGM batteries are widely used in backup power systems for cell towers and data centers. The rapid expansion of 5G networks and the growing reliance on cloud computing have led to an increased demand for reliable power backup solutions, further driving the market for AGM batteries.

The marine and recreational vehicle (RV) markets have also shown a strong demand for AGM batteries. Their spill-proof design, resistance to vibration, and ability to provide consistent power output make them ideal for use in boats, yachts, and RVs. The growing popularity of outdoor activities and recreational travel has contributed to the increased demand in these sectors.

Climate change and extreme weather events have highlighted the importance of reliable backup power systems for both residential and commercial applications. This has led to a rise in demand for AGM batteries in uninterruptible power supply (UPS) systems and emergency power backup solutions.

The industrial sector, including manufacturing and warehousing, has seen an uptick in AGM battery adoption for material handling equipment such as forklifts and pallet jacks. The batteries' fast-charging capabilities and long cycle life make them an attractive option for improving operational efficiency in these environments.

Market analysis indicates that the global AGM battery market is expected to continue its growth trajectory in the coming years. Factors such as increasing urbanization, technological advancements, and the growing focus on sustainable energy solutions are likely to drive further demand across various sectors.

The renewable energy sector has also contributed significantly to the market growth of AGM batteries. As solar and wind power installations continue to expand globally, the need for reliable energy storage solutions has increased. AGM batteries, with their deep-cycle capabilities and maintenance-free operation, have become a preferred choice for off-grid and grid-tied renewable energy systems.

In the telecommunications industry, AGM batteries are widely used in backup power systems for cell towers and data centers. The rapid expansion of 5G networks and the growing reliance on cloud computing have led to an increased demand for reliable power backup solutions, further driving the market for AGM batteries.

The marine and recreational vehicle (RV) markets have also shown a strong demand for AGM batteries. Their spill-proof design, resistance to vibration, and ability to provide consistent power output make them ideal for use in boats, yachts, and RVs. The growing popularity of outdoor activities and recreational travel has contributed to the increased demand in these sectors.

Climate change and extreme weather events have highlighted the importance of reliable backup power systems for both residential and commercial applications. This has led to a rise in demand for AGM batteries in uninterruptible power supply (UPS) systems and emergency power backup solutions.

The industrial sector, including manufacturing and warehousing, has seen an uptick in AGM battery adoption for material handling equipment such as forklifts and pallet jacks. The batteries' fast-charging capabilities and long cycle life make them an attractive option for improving operational efficiency in these environments.

Market analysis indicates that the global AGM battery market is expected to continue its growth trajectory in the coming years. Factors such as increasing urbanization, technological advancements, and the growing focus on sustainable energy solutions are likely to drive further demand across various sectors.

AGM Battery Challenges in Diverse Climates

AGM (Absorbent Glass Mat) batteries face significant challenges when operating in diverse climatic conditions. These batteries, widely used in various applications due to their reliability and maintenance-free nature, exhibit performance variations across different temperature ranges and environmental factors.

In cold climates, AGM batteries experience reduced chemical reaction rates, leading to decreased capacity and slower charging. The electrolyte's viscosity increases, impeding ion movement and potentially causing stratification. This can result in incomplete charging and reduced overall battery life. Additionally, cold temperatures may cause the battery to freeze if not properly maintained, leading to irreversible damage.

Conversely, hot climates present their own set of challenges for AGM batteries. Elevated temperatures accelerate chemical reactions within the battery, potentially increasing self-discharge rates and shortening the battery's lifespan. The heat can also cause water loss through evaporation, despite the sealed nature of AGM batteries, leading to increased internal resistance and reduced capacity over time.

Humidity levels in different climates also play a crucial role in AGM battery performance. High humidity environments can lead to increased corrosion of battery terminals and connections, potentially affecting the battery's overall performance and lifespan. In contrast, extremely dry conditions may contribute to faster water loss from the electrolyte, impacting the battery's long-term health.

Fluctuating temperatures, common in many regions, pose additional challenges. Rapid temperature changes can cause thermal stress on the battery components, potentially leading to physical damage or accelerated aging. This is particularly problematic in areas with significant day-night temperature variations or seasonal extremes.

The impact of altitude on AGM battery performance is another consideration in diverse climates. At higher altitudes, the reduced atmospheric pressure can affect the battery's charging characteristics and potentially lead to overcharging if not properly managed.

Dust and particulate matter, prevalent in arid or industrial environments, can accumulate on battery surfaces, potentially interfering with heat dissipation and affecting overall performance. This issue is exacerbated in regions prone to sandstorms or heavy industrial pollution.

These varied climatic challenges necessitate the development of robust life prediction models for AGM batteries. Such models must account for the complex interplay of temperature, humidity, altitude, and environmental factors to accurately forecast battery performance and lifespan across diverse operating conditions.

In cold climates, AGM batteries experience reduced chemical reaction rates, leading to decreased capacity and slower charging. The electrolyte's viscosity increases, impeding ion movement and potentially causing stratification. This can result in incomplete charging and reduced overall battery life. Additionally, cold temperatures may cause the battery to freeze if not properly maintained, leading to irreversible damage.

Conversely, hot climates present their own set of challenges for AGM batteries. Elevated temperatures accelerate chemical reactions within the battery, potentially increasing self-discharge rates and shortening the battery's lifespan. The heat can also cause water loss through evaporation, despite the sealed nature of AGM batteries, leading to increased internal resistance and reduced capacity over time.

Humidity levels in different climates also play a crucial role in AGM battery performance. High humidity environments can lead to increased corrosion of battery terminals and connections, potentially affecting the battery's overall performance and lifespan. In contrast, extremely dry conditions may contribute to faster water loss from the electrolyte, impacting the battery's long-term health.

Fluctuating temperatures, common in many regions, pose additional challenges. Rapid temperature changes can cause thermal stress on the battery components, potentially leading to physical damage or accelerated aging. This is particularly problematic in areas with significant day-night temperature variations or seasonal extremes.

The impact of altitude on AGM battery performance is another consideration in diverse climates. At higher altitudes, the reduced atmospheric pressure can affect the battery's charging characteristics and potentially lead to overcharging if not properly managed.

Dust and particulate matter, prevalent in arid or industrial environments, can accumulate on battery surfaces, potentially interfering with heat dissipation and affecting overall performance. This issue is exacerbated in regions prone to sandstorms or heavy industrial pollution.

These varied climatic challenges necessitate the development of robust life prediction models for AGM batteries. Such models must account for the complex interplay of temperature, humidity, altitude, and environmental factors to accurately forecast battery performance and lifespan across diverse operating conditions.

Current AGM Battery Life Prediction Methods

01 Improved electrolyte composition

Enhancing the electrolyte composition in AGM batteries can significantly improve their lifespan. This includes using advanced additives, optimizing acid concentration, and incorporating gel-based electrolytes to reduce electrolyte stratification and improve charge acceptance.- Improved electrolyte composition: Enhancing the electrolyte composition in AGM batteries can significantly improve their lifespan. This includes optimizing the concentration of sulfuric acid, adding specific additives, or using gel electrolytes to reduce electrolyte stratification and minimize internal resistance. These improvements can lead to better charge acceptance, reduced self-discharge, and overall longer battery life.

- Advanced plate design and materials: Implementing innovative plate designs and using advanced materials for both positive and negative plates can enhance the AGM battery's performance and longevity. This may involve using high-purity lead alloys, optimizing grid structures, or incorporating nano-materials to improve conductivity and reduce corrosion. Such improvements can result in increased capacity retention and extended cycle life.

- Thermal management systems: Integrating effective thermal management systems in AGM batteries can help regulate temperature during charging and discharging cycles. This may include the use of heat-dissipating materials, improved case designs for better air circulation, or even active cooling mechanisms. Proper thermal management can prevent premature aging of battery components and extend overall battery life.

- Smart charging and monitoring systems: Incorporating intelligent charging algorithms and advanced monitoring systems can optimize the charging process and prevent overcharging or deep discharging. These systems can adapt to battery conditions, adjust charging parameters accordingly, and provide real-time data on battery health. By maintaining optimal operating conditions, smart systems can significantly extend AGM battery life.

- Separator technology improvements: Advancements in separator technology play a crucial role in enhancing AGM battery life. This includes developing high-performance glass fiber separators with improved porosity, wettability, and chemical stability. Enhanced separators can better retain the electrolyte, prevent short circuits, and maintain consistent performance over time, ultimately contributing to longer battery life.

02 Advanced plate design and materials

Utilizing innovative plate designs and materials can extend AGM battery life. This involves using high-purity lead alloys, implementing grid designs that resist corrosion, and incorporating carbon additives to enhance charge acceptance and reduce sulfation.Expand Specific Solutions03 Thermal management systems

Implementing effective thermal management systems can prolong AGM battery life by maintaining optimal operating temperatures. This includes using heat-dissipating materials, incorporating cooling channels, and designing battery casings that facilitate better heat distribution.Expand Specific Solutions04 Charge control and management

Advanced charge control and management systems can significantly extend AGM battery life. This involves implementing smart charging algorithms, voltage regulation techniques, and state-of-charge monitoring to prevent overcharging and deep discharging.Expand Specific Solutions05 Separator technology improvements

Enhancing separator technology can improve AGM battery life by preventing short circuits and reducing internal resistance. This includes using advanced materials for separators, optimizing pore size and distribution, and incorporating nano-scale additives to enhance separator performance.Expand Specific Solutions

Key AGM Battery Manufacturers and Suppliers

The analysis of AGM Battery Life Predictors in Varied Climates reveals a competitive landscape in a maturing industry. The market is experiencing steady growth, driven by increasing demand for reliable energy storage solutions across diverse sectors. Companies like Fengfan Co., Ltd., Daramic LLC, and Stryten Energy LLC are at the forefront, leveraging their expertise in battery technology. The technological maturity varies, with established players like GM Global Technology Operations LLC and Honda Motor Co., Ltd. investing in advanced predictive models, while newer entrants like ArcActive Ltd. focus on innovative lead-carbon technologies. The industry is seeing a shift towards more sophisticated life prediction methods, incorporating climate-specific factors to enhance battery performance and longevity across different environmental conditions.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced Battery Management System (BMS) for AGM batteries that incorporates machine learning algorithms to predict battery life in various climates. The system utilizes real-time data from temperature sensors, voltage monitors, and current measurements to create a comprehensive model of battery performance[1]. This model is continuously updated based on actual usage patterns and environmental conditions, allowing for more accurate predictions of battery degradation over time. GM's approach also includes a novel thermal management system that actively regulates battery temperature to optimize performance and longevity in extreme climates[3].

Strengths: Highly accurate prediction model, adaptive to different climates, integration with vehicle systems. Weaknesses: Complexity may increase costs, requires extensive data collection and processing.

Stryten Energy LLC

Technical Solution: Stryten Energy has developed a proprietary AGM battery life prediction system that combines electrochemical modeling with big data analytics. Their approach utilizes a network of IoT sensors embedded within the battery to monitor key parameters such as electrolyte levels, internal resistance, and charge/discharge cycles[2]. This data is then processed using advanced algorithms that account for various climatic factors, including temperature fluctuations and humidity levels. Stryten's system also incorporates historical performance data from similar batteries in comparable environments to refine its predictions[4].

Strengths: Comprehensive data collection, integration of historical data, scalable across different battery sizes. Weaknesses: Reliance on extensive sensor network may increase battery cost, potential privacy concerns with data collection.

Innovative AGM Battery Life Prediction Technologies

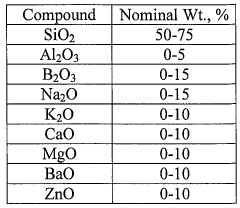

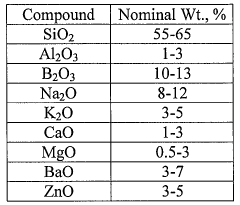

Improved absorbent glass mat separators, VRLA batteries, and related mehtods of manufacture and use

PatentWO2016210225A1

Innovation

- Incorporating soluble content such as fibers, flakes, or particles into the AGM separators that dissolve upon contact with water or sulfuric acid, creating additional pores and enhancing porosity, allowing for faster acid filling and improved wettability without compromising the separator's integrity.

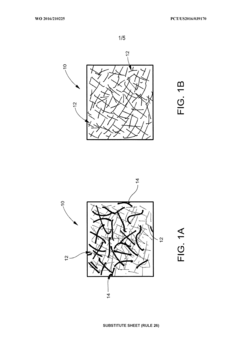

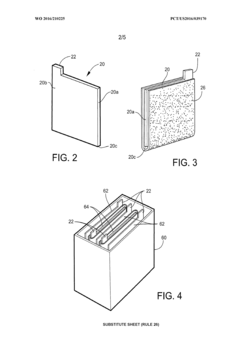

Multifunctional web for use in a lead-acid battery

PatentActiveHK1195399A

Innovation

- Incorporation of heat-sealable fibers alongside natural fibers in the multifunctional web, creating a persistent synthetic net structure after acid exposure.

- Dual functionality of the web: maintaining paste adhesion during production and reducing lead plate erosion during battery operation.

- Application in AGM batteries to maintain compression between lead plates, further reducing friction and erosion.

Environmental Impact of AGM Batteries

The environmental impact of AGM (Absorbent Glass Mat) batteries is a critical consideration in the context of their life cycle and performance in varied climates. These batteries, while offering numerous advantages, also present certain environmental challenges that must be addressed.

AGM batteries contain lead and sulfuric acid, which can be harmful to the environment if not properly managed. However, they have a significantly lower risk of leakage compared to traditional flooded lead-acid batteries, reducing the potential for soil and water contamination. This characteristic is particularly important in diverse climatic conditions, where temperature fluctuations and environmental stresses can affect battery integrity.

The production of AGM batteries requires energy and resources, contributing to their overall environmental footprint. However, their longer lifespan and improved efficiency in varied climates can offset some of these impacts over time. In colder climates, AGM batteries generally perform better than traditional lead-acid batteries, potentially reducing the frequency of replacements and associated environmental costs.

Recycling is a crucial aspect of mitigating the environmental impact of AGM batteries. These batteries are highly recyclable, with up to 99% of their components being recoverable. Efficient recycling processes can significantly reduce the demand for new raw materials and minimize waste. However, the effectiveness of recycling programs varies globally, and improving these systems remains an ongoing challenge.

Climate variations can affect the environmental impact of AGM batteries throughout their lifecycle. In hot climates, the batteries may experience accelerated degradation, potentially leading to shorter lifespans and increased replacement rates. Conversely, in moderate climates, AGM batteries tend to have extended lifespans, reducing the overall environmental impact associated with production and disposal.

The energy efficiency of AGM batteries in different climates also influences their environmental footprint. In applications where consistent power output is crucial, such as in renewable energy systems, AGM batteries can provide reliable performance across a range of temperatures. This reliability can contribute to the overall efficiency of renewable energy systems, indirectly reducing reliance on fossil fuels and associated emissions.

As climate change continues to affect global weather patterns, the adaptability of AGM batteries to varied environmental conditions becomes increasingly important. Their ability to maintain performance in extreme temperatures could play a role in climate resilience strategies, particularly in regions experiencing more frequent weather anomalies.

In conclusion, while AGM batteries present certain environmental challenges, their performance characteristics in varied climates, coupled with proper management and recycling, can contribute to a reduced overall environmental impact compared to some alternative battery technologies. Ongoing research into improving their efficiency and recyclability will be crucial in further minimizing their environmental footprint across diverse climatic conditions.

AGM batteries contain lead and sulfuric acid, which can be harmful to the environment if not properly managed. However, they have a significantly lower risk of leakage compared to traditional flooded lead-acid batteries, reducing the potential for soil and water contamination. This characteristic is particularly important in diverse climatic conditions, where temperature fluctuations and environmental stresses can affect battery integrity.

The production of AGM batteries requires energy and resources, contributing to their overall environmental footprint. However, their longer lifespan and improved efficiency in varied climates can offset some of these impacts over time. In colder climates, AGM batteries generally perform better than traditional lead-acid batteries, potentially reducing the frequency of replacements and associated environmental costs.

Recycling is a crucial aspect of mitigating the environmental impact of AGM batteries. These batteries are highly recyclable, with up to 99% of their components being recoverable. Efficient recycling processes can significantly reduce the demand for new raw materials and minimize waste. However, the effectiveness of recycling programs varies globally, and improving these systems remains an ongoing challenge.

Climate variations can affect the environmental impact of AGM batteries throughout their lifecycle. In hot climates, the batteries may experience accelerated degradation, potentially leading to shorter lifespans and increased replacement rates. Conversely, in moderate climates, AGM batteries tend to have extended lifespans, reducing the overall environmental impact associated with production and disposal.

The energy efficiency of AGM batteries in different climates also influences their environmental footprint. In applications where consistent power output is crucial, such as in renewable energy systems, AGM batteries can provide reliable performance across a range of temperatures. This reliability can contribute to the overall efficiency of renewable energy systems, indirectly reducing reliance on fossil fuels and associated emissions.

As climate change continues to affect global weather patterns, the adaptability of AGM batteries to varied environmental conditions becomes increasingly important. Their ability to maintain performance in extreme temperatures could play a role in climate resilience strategies, particularly in regions experiencing more frequent weather anomalies.

In conclusion, while AGM batteries present certain environmental challenges, their performance characteristics in varied climates, coupled with proper management and recycling, can contribute to a reduced overall environmental impact compared to some alternative battery technologies. Ongoing research into improving their efficiency and recyclability will be crucial in further minimizing their environmental footprint across diverse climatic conditions.

AGM Battery Standards and Regulations

The regulatory landscape for AGM (Absorbent Glass Mat) batteries is complex and multifaceted, encompassing various standards and regulations across different regions and applications. In the context of analyzing AGM battery life predictors in varied climates, it is crucial to understand the existing standards that govern battery performance, safety, and environmental impact.

International standards such as IEC 60896-21/22 provide comprehensive guidelines for stationary lead-acid batteries, including AGM types. These standards outline testing procedures for capacity, durability, and safety, which are essential factors in predicting battery life across different climatic conditions. The IEEE 1188 standard specifically addresses the maintenance, testing, and replacement of valve-regulated lead-acid (VRLA) batteries, offering valuable insights into the long-term performance expectations of AGM batteries.

In the automotive sector, SAE J2185 sets forth performance requirements for heavy-duty AGM batteries, considering factors like vibration resistance and cold-cranking ability, which are particularly relevant when assessing battery life in extreme climates. The UN38.3 standard governs the transportation of lithium batteries but also impacts AGM batteries, especially in terms of safety regulations during shipping and handling in various environmental conditions.

Environmental regulations play a significant role in AGM battery standards. The European Union's Battery Directive (2006/66/EC) and its subsequent amendments outline requirements for battery collection, recycling, and disposal, which indirectly influence battery design and life cycle considerations. In the United States, the Environmental Protection Agency (EPA) regulates lead-acid battery recycling under the Resource Conservation and Recovery Act (RCRA).

Safety standards such as UL 1989 for standby batteries and UL 2054 for household and commercial batteries establish criteria for thermal runaway prevention, short circuit protection, and overall battery safety. These standards are particularly relevant when considering AGM battery performance and longevity in high-temperature environments.

Emerging standards are beginning to address the specific challenges of predicting battery life in varied climates. For instance, the development of accelerated life testing protocols that simulate diverse environmental conditions is gaining traction in the industry. These protocols aim to provide more accurate predictions of AGM battery performance across a range of temperatures and humidity levels.

As the focus on renewable energy storage intensifies, standards like IEC 61427-1 for photovoltaic energy systems are becoming increasingly relevant to AGM batteries used in off-grid applications. These standards consider the unique challenges posed by outdoor installations, including exposure to extreme temperatures and varying charge-discharge cycles.

International standards such as IEC 60896-21/22 provide comprehensive guidelines for stationary lead-acid batteries, including AGM types. These standards outline testing procedures for capacity, durability, and safety, which are essential factors in predicting battery life across different climatic conditions. The IEEE 1188 standard specifically addresses the maintenance, testing, and replacement of valve-regulated lead-acid (VRLA) batteries, offering valuable insights into the long-term performance expectations of AGM batteries.

In the automotive sector, SAE J2185 sets forth performance requirements for heavy-duty AGM batteries, considering factors like vibration resistance and cold-cranking ability, which are particularly relevant when assessing battery life in extreme climates. The UN38.3 standard governs the transportation of lithium batteries but also impacts AGM batteries, especially in terms of safety regulations during shipping and handling in various environmental conditions.

Environmental regulations play a significant role in AGM battery standards. The European Union's Battery Directive (2006/66/EC) and its subsequent amendments outline requirements for battery collection, recycling, and disposal, which indirectly influence battery design and life cycle considerations. In the United States, the Environmental Protection Agency (EPA) regulates lead-acid battery recycling under the Resource Conservation and Recovery Act (RCRA).

Safety standards such as UL 1989 for standby batteries and UL 2054 for household and commercial batteries establish criteria for thermal runaway prevention, short circuit protection, and overall battery safety. These standards are particularly relevant when considering AGM battery performance and longevity in high-temperature environments.

Emerging standards are beginning to address the specific challenges of predicting battery life in varied climates. For instance, the development of accelerated life testing protocols that simulate diverse environmental conditions is gaining traction in the industry. These protocols aim to provide more accurate predictions of AGM battery performance across a range of temperatures and humidity levels.

As the focus on renewable energy storage intensifies, standards like IEC 61427-1 for photovoltaic energy systems are becoming increasingly relevant to AGM batteries used in off-grid applications. These standards consider the unique challenges posed by outdoor installations, including exposure to extreme temperatures and varying charge-discharge cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!