Environmental and Social Impacts of AGM Battery Expansion

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

Absorbed Glass Mat (AGM) batteries have undergone significant evolution since their inception in the 1980s. Initially developed for military and aircraft applications, AGM technology has rapidly expanded into various sectors, including automotive, renewable energy storage, and telecommunications.

The early AGM batteries were primarily designed to provide high power output in short bursts, making them ideal for starting engines and powering aircraft systems. As the technology matured, manufacturers focused on improving energy density, cycle life, and overall performance. This led to the development of deep-cycle AGM batteries, which could withstand repeated discharge and recharge cycles, opening up new applications in renewable energy storage and backup power systems.

In the automotive sector, AGM batteries gained prominence with the introduction of start-stop technology in vehicles. Their ability to handle frequent charge-discharge cycles and provide reliable power for increasingly complex vehicle electronics made them a preferred choice over traditional flooded lead-acid batteries.

The evolution of AGM technology also saw improvements in manufacturing processes, resulting in enhanced durability and reduced production costs. This made AGM batteries more accessible for a wider range of applications, from small consumer electronics to large-scale industrial use.

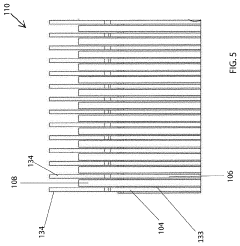

Recent advancements have focused on optimizing the internal structure of AGM batteries. Innovations in separator materials, electrode design, and electrolyte composition have led to increased energy density and longer service life. These improvements have made AGM batteries more competitive with other energy storage technologies, particularly in applications requiring high reliability and low maintenance.

The environmental impact of AGM batteries has also been a key focus area in their evolution. Manufacturers have made significant strides in reducing the use of harmful materials and improving recyclability. Modern AGM batteries are designed with easier disassembly in mind, facilitating more efficient recycling processes and reducing the environmental footprint of battery production and disposal.

As the demand for reliable energy storage solutions continues to grow, AGM battery technology is expected to evolve further. Current research is exploring ways to increase power density, improve charge acceptance rates, and extend cycle life even further. These advancements aim to meet the increasing energy demands of modern applications while addressing environmental concerns associated with battery production and disposal.

The early AGM batteries were primarily designed to provide high power output in short bursts, making them ideal for starting engines and powering aircraft systems. As the technology matured, manufacturers focused on improving energy density, cycle life, and overall performance. This led to the development of deep-cycle AGM batteries, which could withstand repeated discharge and recharge cycles, opening up new applications in renewable energy storage and backup power systems.

In the automotive sector, AGM batteries gained prominence with the introduction of start-stop technology in vehicles. Their ability to handle frequent charge-discharge cycles and provide reliable power for increasingly complex vehicle electronics made them a preferred choice over traditional flooded lead-acid batteries.

The evolution of AGM technology also saw improvements in manufacturing processes, resulting in enhanced durability and reduced production costs. This made AGM batteries more accessible for a wider range of applications, from small consumer electronics to large-scale industrial use.

Recent advancements have focused on optimizing the internal structure of AGM batteries. Innovations in separator materials, electrode design, and electrolyte composition have led to increased energy density and longer service life. These improvements have made AGM batteries more competitive with other energy storage technologies, particularly in applications requiring high reliability and low maintenance.

The environmental impact of AGM batteries has also been a key focus area in their evolution. Manufacturers have made significant strides in reducing the use of harmful materials and improving recyclability. Modern AGM batteries are designed with easier disassembly in mind, facilitating more efficient recycling processes and reducing the environmental footprint of battery production and disposal.

As the demand for reliable energy storage solutions continues to grow, AGM battery technology is expected to evolve further. Current research is exploring ways to increase power density, improve charge acceptance rates, and extend cycle life even further. These advancements aim to meet the increasing energy demands of modern applications while addressing environmental concerns associated with battery production and disposal.

Market Demand Analysis

The market demand for AGM (Absorbent Glass Mat) batteries has been experiencing significant growth in recent years, driven by several key factors. The automotive industry, particularly the start-stop vehicle segment, has been a major contributor to this increased demand. As more vehicles adopt start-stop technology to improve fuel efficiency and reduce emissions, the need for reliable and durable batteries capable of handling frequent charge-discharge cycles has surged.

The renewable energy sector has also played a crucial role in boosting the demand for AGM batteries. With the growing adoption of solar and wind power systems, there is an increasing need for efficient energy storage solutions. AGM batteries have proven to be a popular choice due to their maintenance-free nature, high discharge rates, and ability to operate in a wide range of temperatures.

In the telecommunications industry, AGM batteries have found widespread application in backup power systems for cell towers and data centers. The reliability and long service life of these batteries make them ideal for ensuring uninterrupted power supply in critical infrastructure.

The marine and recreational vehicle markets have also contributed to the rising demand for AGM batteries. These batteries' resistance to vibration and ability to provide deep-cycle performance make them well-suited for use in boats, RVs, and other recreational vehicles.

However, the expansion of AGM battery production and use has raised concerns about its environmental and social impacts. The manufacturing process of AGM batteries involves the use of lead and other potentially harmful materials, which can pose risks to both the environment and human health if not properly managed. This has led to increased scrutiny of production practices and a growing demand for more sustainable battery technologies.

The disposal and recycling of AGM batteries at the end of their life cycle present another challenge. While these batteries are recyclable, the process requires specialized facilities and proper handling to prevent environmental contamination. As the number of AGM batteries in circulation increases, there is a growing need for improved recycling infrastructure and regulations to ensure responsible end-of-life management.

The social impacts of AGM battery expansion are also becoming more apparent. The increased demand has led to the creation of new jobs in manufacturing, recycling, and related industries. However, concerns have been raised about working conditions and safety standards in some production facilities, particularly in regions with less stringent labor regulations.

In response to these environmental and social concerns, there is a growing market demand for more sustainable battery technologies and improved production practices. This has spurred research and development efforts aimed at reducing the environmental footprint of AGM batteries and exploring alternative materials and designs that offer similar performance with fewer negative impacts.

The renewable energy sector has also played a crucial role in boosting the demand for AGM batteries. With the growing adoption of solar and wind power systems, there is an increasing need for efficient energy storage solutions. AGM batteries have proven to be a popular choice due to their maintenance-free nature, high discharge rates, and ability to operate in a wide range of temperatures.

In the telecommunications industry, AGM batteries have found widespread application in backup power systems for cell towers and data centers. The reliability and long service life of these batteries make them ideal for ensuring uninterrupted power supply in critical infrastructure.

The marine and recreational vehicle markets have also contributed to the rising demand for AGM batteries. These batteries' resistance to vibration and ability to provide deep-cycle performance make them well-suited for use in boats, RVs, and other recreational vehicles.

However, the expansion of AGM battery production and use has raised concerns about its environmental and social impacts. The manufacturing process of AGM batteries involves the use of lead and other potentially harmful materials, which can pose risks to both the environment and human health if not properly managed. This has led to increased scrutiny of production practices and a growing demand for more sustainable battery technologies.

The disposal and recycling of AGM batteries at the end of their life cycle present another challenge. While these batteries are recyclable, the process requires specialized facilities and proper handling to prevent environmental contamination. As the number of AGM batteries in circulation increases, there is a growing need for improved recycling infrastructure and regulations to ensure responsible end-of-life management.

The social impacts of AGM battery expansion are also becoming more apparent. The increased demand has led to the creation of new jobs in manufacturing, recycling, and related industries. However, concerns have been raised about working conditions and safety standards in some production facilities, particularly in regions with less stringent labor regulations.

In response to these environmental and social concerns, there is a growing market demand for more sustainable battery technologies and improved production practices. This has spurred research and development efforts aimed at reducing the environmental footprint of AGM batteries and exploring alternative materials and designs that offer similar performance with fewer negative impacts.

Technical Challenges

The expansion of Absorbent Glass Mat (AGM) battery technology presents several significant technical challenges that need to be addressed for its widespread adoption and sustainable implementation. One of the primary concerns is the environmental impact of AGM battery production and disposal. The manufacturing process requires substantial energy inputs and involves the use of potentially hazardous materials, including lead and sulfuric acid. Developing more energy-efficient production methods and finding safer alternatives to these materials are crucial challenges facing the industry.

Recycling and end-of-life management of AGM batteries pose another set of technical hurdles. While AGM batteries are recyclable, the process is complex and energy-intensive. Improving recycling technologies to make them more cost-effective and environmentally friendly is essential. Additionally, developing standardized recycling protocols and infrastructure to handle the increasing volume of spent AGM batteries is a pressing challenge.

The performance and longevity of AGM batteries in various applications and environmental conditions present ongoing technical challenges. Enhancing the battery's cycle life, especially in deep discharge scenarios, and improving its performance in extreme temperatures are areas that require further research and development. Moreover, addressing issues related to sulfation, which can significantly reduce battery capacity over time, remains a critical technical challenge.

Safety concerns associated with AGM batteries, particularly in large-scale applications, need to be carefully managed. While AGM batteries are generally considered safer than flooded lead-acid batteries, they still carry risks of thermal runaway and gas emission under certain conditions. Developing advanced safety features, such as improved pressure relief valves and more robust casing materials, is crucial for mitigating these risks.

The scalability of AGM battery technology for grid-scale energy storage applications presents unique technical challenges. Optimizing the design and integration of large AGM battery systems, managing heat dissipation, and ensuring uniform charging and discharging across multiple cells are complex engineering problems that need to be solved for successful large-scale deployment.

Lastly, the social impacts of AGM battery expansion raise technical challenges related to resource management and supply chain sustainability. Ensuring a stable and ethically sourced supply of raw materials, particularly lead, is crucial. This involves developing more efficient mining and refining processes, as well as exploring alternative materials that can reduce dependence on scarce or environmentally problematic resources.

Recycling and end-of-life management of AGM batteries pose another set of technical hurdles. While AGM batteries are recyclable, the process is complex and energy-intensive. Improving recycling technologies to make them more cost-effective and environmentally friendly is essential. Additionally, developing standardized recycling protocols and infrastructure to handle the increasing volume of spent AGM batteries is a pressing challenge.

The performance and longevity of AGM batteries in various applications and environmental conditions present ongoing technical challenges. Enhancing the battery's cycle life, especially in deep discharge scenarios, and improving its performance in extreme temperatures are areas that require further research and development. Moreover, addressing issues related to sulfation, which can significantly reduce battery capacity over time, remains a critical technical challenge.

Safety concerns associated with AGM batteries, particularly in large-scale applications, need to be carefully managed. While AGM batteries are generally considered safer than flooded lead-acid batteries, they still carry risks of thermal runaway and gas emission under certain conditions. Developing advanced safety features, such as improved pressure relief valves and more robust casing materials, is crucial for mitigating these risks.

The scalability of AGM battery technology for grid-scale energy storage applications presents unique technical challenges. Optimizing the design and integration of large AGM battery systems, managing heat dissipation, and ensuring uniform charging and discharging across multiple cells are complex engineering problems that need to be solved for successful large-scale deployment.

Lastly, the social impacts of AGM battery expansion raise technical challenges related to resource management and supply chain sustainability. Ensuring a stable and ethically sourced supply of raw materials, particularly lead, is crucial. This involves developing more efficient mining and refining processes, as well as exploring alternative materials that can reduce dependence on scarce or environmentally problematic resources.

Current AGM Solutions

01 Environmental impact assessment of AGM batteries

AGM batteries are evaluated for their environmental impact throughout their lifecycle. This includes assessing the production process, use phase, and end-of-life disposal or recycling. The assessment considers factors such as resource consumption, energy efficiency, emissions, and waste generation. Environmental impact assessments help in identifying areas for improvement and developing more sustainable battery technologies.- Environmental impact assessment of AGM batteries: AGM (Absorbent Glass Mat) batteries are evaluated for their environmental impact throughout their lifecycle. This includes assessing the production process, use phase, and end-of-life disposal or recycling. The assessment considers factors such as resource consumption, energy efficiency, emissions, and potential for recycling or reuse of materials.

- Social implications of AGM battery production and use: The social aspects of AGM battery production and use are examined, including labor conditions in manufacturing, community impacts near production facilities, and the societal benefits of improved energy storage. This also encompasses the potential for job creation in the battery industry and the role of AGM batteries in supporting renewable energy adoption.

- Recycling and waste management of AGM batteries: Strategies for recycling and proper disposal of AGM batteries are crucial for minimizing environmental impact. This includes developing efficient recycling processes, establishing collection systems, and implementing policies to encourage responsible end-of-life management. The focus is on recovering valuable materials and reducing the amount of battery waste in landfills.

- Energy efficiency and performance improvements: Ongoing research and development efforts aim to enhance the energy efficiency and overall performance of AGM batteries. This includes improving charge-discharge cycles, extending battery life, and increasing energy density. These advancements contribute to reduced environmental impact through more efficient energy storage and decreased need for frequent replacements.

- Sustainable supply chain and manufacturing practices: The focus is on developing sustainable supply chains and manufacturing processes for AGM batteries. This involves sourcing raw materials responsibly, implementing cleaner production techniques, and reducing the carbon footprint of battery manufacturing. Efforts are also made to improve transparency and traceability in the supply chain to ensure ethical and environmentally friendly practices.

02 Social implications of AGM battery production and use

The production and use of AGM batteries have various social implications. These include job creation in manufacturing and recycling industries, impacts on local communities near production facilities, and the role of batteries in enabling renewable energy adoption. Social assessments also consider worker safety, labor conditions, and the broader societal benefits of improved energy storage technologies.Expand Specific Solutions03 Recycling and end-of-life management of AGM batteries

Proper recycling and end-of-life management of AGM batteries are crucial for minimizing environmental impact and recovering valuable materials. This involves developing efficient recycling processes, establishing collection systems, and implementing policies to encourage responsible disposal. Effective recycling can reduce the demand for raw materials and minimize the environmental footprint of battery production.Expand Specific Solutions04 Energy efficiency and performance optimization

Improving the energy efficiency and performance of AGM batteries can reduce their environmental impact during use. This includes developing advanced materials, optimizing charge-discharge cycles, and enhancing battery management systems. Better performance can lead to longer battery life, reduced energy consumption, and improved overall sustainability of battery-powered systems.Expand Specific Solutions05 Sustainable supply chain and production practices

Implementing sustainable supply chain and production practices for AGM batteries is essential for reducing their environmental and social impacts. This involves sourcing raw materials responsibly, minimizing waste in manufacturing processes, and ensuring ethical labor practices throughout the supply chain. Sustainable practices can improve the overall environmental footprint of AGM batteries and enhance their social acceptance.Expand Specific Solutions

Key Industry Players

The environmental and social impacts of AGM battery expansion are drawing increased attention as the industry evolves. The market is in a growth phase, driven by rising demand for reliable energy storage solutions across various sectors. The global AGM battery market size is projected to expand significantly in the coming years, reflecting the technology's maturity and widespread adoption. Companies like Daramic LLC, Fengfan Co., Ltd., and Stryten Energy LLC are at the forefront of this expansion, leveraging their expertise in battery technology and manufacturing. The industry is characterized by ongoing research and development efforts, with firms such as LG Energy Solution Ltd. and Amara Raja Energy & Mobility Ltd. investing in improving AGM battery performance and sustainability. As the technology matures, there is an increasing focus on addressing environmental concerns and enhancing recycling capabilities to mitigate potential negative impacts.

Stryten Energy LLC

Technical Solution: Stryten Energy has developed advanced AGM (Absorbent Glass Mat) battery technology that aims to minimize environmental impact while maximizing performance. Their approach includes using recycled materials in battery production, implementing a closed-loop recycling process, and improving energy density to reduce overall material usage. Stryten's AGM batteries feature enhanced charge acceptance and deeper cycling capabilities, which contribute to longer battery life and reduced waste [1]. The company has also invested in manufacturing processes that reduce energy consumption and emissions during production [2].

Strengths: Eco-friendly production, improved battery lifespan, and enhanced performance. Weaknesses: Potentially higher initial costs and limited market penetration compared to traditional lead-acid batteries.

Clarios Germany GmbH & Co. KG

Technical Solution: Clarios has developed a state-of-the-art AGM battery technology that focuses on sustainability and performance. Their approach includes implementing a circular economy model for battery production and recycling. Clarios' AGM batteries feature advanced lead alloys and optimized internal structures that improve charge acceptance and cycle life [3]. The company has also invested in energy-efficient manufacturing processes and has set ambitious targets for reducing its carbon footprint. Clarios is actively researching ways to further improve the recyclability of AGM batteries and reduce the environmental impact of their production [4].

Strengths: Strong focus on sustainability, well-established recycling infrastructure, and high-performance batteries. Weaknesses: Potential challenges in scaling up sustainable practices globally and competition from newer battery technologies.

AGM Battery Innovations

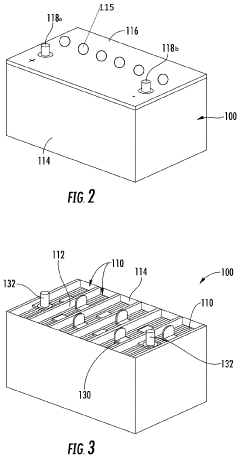

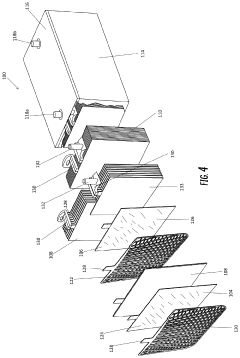

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Over-Saturated Absorbed Glass Mat Valve Regulated Lead-Acid Battery Comprising Carbon Additives

PatentInactiveUS20140120386A1

Innovation

- An AGM VRLA battery design with a positive plate, negative plate containing a carbon additive, an AGM separator, and an electrolyte present in an amount ranging from 100 to 150% by volume based on the total pore volume of the separator, utilizing various carbon additives such as graphite, carbon black, activated carbon, and graphene to enhance charge acceptance and durability.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) battery expansion is a critical consideration as these batteries gain popularity in various applications. AGM batteries, while offering several advantages over traditional lead-acid batteries, still pose significant environmental challenges throughout their lifecycle.

During the production phase, the manufacturing of AGM batteries requires substantial energy inputs and raw materials, including lead, sulfuric acid, and fiberglass. The extraction and processing of these materials can lead to habitat destruction, soil contamination, and water pollution if not properly managed. Additionally, the production process itself generates greenhouse gas emissions, contributing to climate change.

The use phase of AGM batteries generally has a lower environmental impact compared to traditional lead-acid batteries. AGM batteries are sealed, reducing the risk of acid spills and emissions. They also have a longer lifespan and better charge efficiency, which can lead to reduced energy consumption and fewer replacements over time. However, the increased demand for AGM batteries may result in a higher overall environmental footprint if not balanced by improved recycling and disposal practices.

End-of-life management presents both challenges and opportunities for AGM batteries. While these batteries are highly recyclable, with up to 99% of their components potentially recoverable, the recycling process itself can have environmental implications. Improper handling during recycling can release toxic substances, including lead and sulfuric acid, into the environment. However, effective recycling programs can significantly reduce the need for raw material extraction and minimize waste.

The expansion of AGM battery use may also lead to indirect environmental impacts. For instance, their application in renewable energy storage systems could facilitate the transition away from fossil fuels, potentially reducing overall carbon emissions. Conversely, if not properly managed, the increased production and disposal of AGM batteries could lead to new environmental challenges, such as increased electronic waste and the need for more recycling facilities.

To mitigate these environmental impacts, several strategies can be employed. These include improving manufacturing processes to reduce energy consumption and emissions, developing more efficient recycling technologies, and implementing robust take-back programs to ensure proper end-of-life management. Additionally, research into alternative materials and designs that maintain the benefits of AGM batteries while further reducing their environmental footprint is crucial for sustainable expansion of this technology.

During the production phase, the manufacturing of AGM batteries requires substantial energy inputs and raw materials, including lead, sulfuric acid, and fiberglass. The extraction and processing of these materials can lead to habitat destruction, soil contamination, and water pollution if not properly managed. Additionally, the production process itself generates greenhouse gas emissions, contributing to climate change.

The use phase of AGM batteries generally has a lower environmental impact compared to traditional lead-acid batteries. AGM batteries are sealed, reducing the risk of acid spills and emissions. They also have a longer lifespan and better charge efficiency, which can lead to reduced energy consumption and fewer replacements over time. However, the increased demand for AGM batteries may result in a higher overall environmental footprint if not balanced by improved recycling and disposal practices.

End-of-life management presents both challenges and opportunities for AGM batteries. While these batteries are highly recyclable, with up to 99% of their components potentially recoverable, the recycling process itself can have environmental implications. Improper handling during recycling can release toxic substances, including lead and sulfuric acid, into the environment. However, effective recycling programs can significantly reduce the need for raw material extraction and minimize waste.

The expansion of AGM battery use may also lead to indirect environmental impacts. For instance, their application in renewable energy storage systems could facilitate the transition away from fossil fuels, potentially reducing overall carbon emissions. Conversely, if not properly managed, the increased production and disposal of AGM batteries could lead to new environmental challenges, such as increased electronic waste and the need for more recycling facilities.

To mitigate these environmental impacts, several strategies can be employed. These include improving manufacturing processes to reduce energy consumption and emissions, developing more efficient recycling technologies, and implementing robust take-back programs to ensure proper end-of-life management. Additionally, research into alternative materials and designs that maintain the benefits of AGM batteries while further reducing their environmental footprint is crucial for sustainable expansion of this technology.

Regulatory Framework

The regulatory framework surrounding AGM (Absorbent Glass Mat) battery expansion is complex and multifaceted, reflecting the growing concern for environmental protection and social responsibility in the energy storage sector. At the international level, several agreements and conventions guide the management of battery production and disposal, including the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal, which addresses the cross-border transportation of battery waste.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating AGM battery manufacturing and recycling through the Resource Conservation and Recovery Act (RCRA) and the Universal Waste Rule. These regulations aim to minimize environmental impacts by setting standards for hazardous waste management and promoting recycling initiatives. Additionally, the Department of Transportation (DOT) enforces strict guidelines for the safe transportation of AGM batteries, considering their potential hazards.

The European Union has implemented comprehensive regulations, such as the Battery Directive (2006/66/EC), which sets targets for battery collection and recycling, and restricts the use of certain hazardous substances in batteries. This directive has been instrumental in promoting eco-friendly battery designs and establishing extended producer responsibility schemes across EU member states.

In Asia, countries like China and Japan have also introduced stringent regulations. China's New Energy Vehicle (NEV) policy includes specific provisions for battery recycling and disposal, while Japan's Law for the Promotion of Effective Utilization of Resources mandates the collection and recycling of rechargeable batteries, including AGM types.

Emerging economies are increasingly adopting similar regulatory frameworks, recognizing the importance of sustainable battery management. For instance, India's Battery Management and Handling Rules focus on the proper disposal and recycling of lead-acid batteries, including AGM variants.

These regulatory measures often extend beyond environmental concerns to address social impacts. Labor laws and occupational health and safety regulations are being updated to protect workers involved in AGM battery production and recycling processes. Many jurisdictions now require manufacturers to conduct social impact assessments and implement community engagement programs in areas where battery production facilities are located.

As the AGM battery industry continues to expand, regulatory bodies are adapting their frameworks to address new challenges. This includes developing standards for the second-life applications of AGM batteries and implementing more stringent lifecycle assessment requirements. The evolving regulatory landscape aims to strike a balance between fostering innovation in energy storage technologies and mitigating the potential environmental and social risks associated with their widespread adoption.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating AGM battery manufacturing and recycling through the Resource Conservation and Recovery Act (RCRA) and the Universal Waste Rule. These regulations aim to minimize environmental impacts by setting standards for hazardous waste management and promoting recycling initiatives. Additionally, the Department of Transportation (DOT) enforces strict guidelines for the safe transportation of AGM batteries, considering their potential hazards.

The European Union has implemented comprehensive regulations, such as the Battery Directive (2006/66/EC), which sets targets for battery collection and recycling, and restricts the use of certain hazardous substances in batteries. This directive has been instrumental in promoting eco-friendly battery designs and establishing extended producer responsibility schemes across EU member states.

In Asia, countries like China and Japan have also introduced stringent regulations. China's New Energy Vehicle (NEV) policy includes specific provisions for battery recycling and disposal, while Japan's Law for the Promotion of Effective Utilization of Resources mandates the collection and recycling of rechargeable batteries, including AGM types.

Emerging economies are increasingly adopting similar regulatory frameworks, recognizing the importance of sustainable battery management. For instance, India's Battery Management and Handling Rules focus on the proper disposal and recycling of lead-acid batteries, including AGM variants.

These regulatory measures often extend beyond environmental concerns to address social impacts. Labor laws and occupational health and safety regulations are being updated to protect workers involved in AGM battery production and recycling processes. Many jurisdictions now require manufacturers to conduct social impact assessments and implement community engagement programs in areas where battery production facilities are located.

As the AGM battery industry continues to expand, regulatory bodies are adapting their frameworks to address new challenges. This includes developing standards for the second-life applications of AGM batteries and implementing more stringent lifecycle assessment requirements. The evolving regulatory landscape aims to strike a balance between fostering innovation in energy storage technologies and mitigating the potential environmental and social risks associated with their widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!