Role of AGM Battery in Electrified Railway Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution in Rail

The evolution of Absorbent Glass Mat (AGM) batteries in rail systems has been a significant technological advancement in the electrification of railway transportation. Initially developed for military and aviation applications in the 1980s, AGM batteries have found their way into various sectors, including the rail industry, due to their superior performance characteristics.

In the early stages of rail electrification, lead-acid batteries were the primary energy storage solution. However, these traditional batteries faced limitations in terms of energy density, cycle life, and maintenance requirements. The introduction of AGM technology in the rail sector during the late 1990s marked a turning point in addressing these challenges.

AGM batteries offered several advantages over conventional lead-acid batteries, including improved energy density, faster charging capabilities, and enhanced vibration resistance. These features made them particularly suitable for the demanding environment of railway systems. The sealed design of AGM batteries also eliminated the need for regular water replenishment, reducing maintenance costs and improving overall system reliability.

The early 2000s saw increased adoption of AGM batteries in rail applications, primarily in auxiliary power systems for passenger comfort and safety features. As the technology matured, AGM batteries began to play a more critical role in traction applications, particularly in hybrid locomotives and light rail vehicles.

A significant milestone in AGM battery evolution for rail systems occurred in the mid-2000s with the development of high-power AGM batteries specifically designed for regenerative braking systems. This innovation allowed for more efficient energy recovery during braking, contributing to overall system efficiency and reduced energy consumption.

The late 2000s and early 2010s witnessed further advancements in AGM battery technology, including improved thermal management systems and enhanced cycle life. These developments expanded the application of AGM batteries in rail systems, enabling their use in more demanding operational scenarios and contributing to the broader electrification efforts in the railway industry.

Recent years have seen the integration of smart battery management systems with AGM batteries, allowing for real-time monitoring and optimization of battery performance. This integration has further improved the reliability and efficiency of AGM batteries in rail applications, paving the way for their expanded use in various railway subsystems.

As the rail industry continues to prioritize sustainability and energy efficiency, AGM batteries have become an integral component in the electrification of railway systems. Their evolution has not only improved the performance of existing rail applications but has also enabled the development of new, more energy-efficient rail solutions, contributing to the ongoing transformation of the railway sector.

In the early stages of rail electrification, lead-acid batteries were the primary energy storage solution. However, these traditional batteries faced limitations in terms of energy density, cycle life, and maintenance requirements. The introduction of AGM technology in the rail sector during the late 1990s marked a turning point in addressing these challenges.

AGM batteries offered several advantages over conventional lead-acid batteries, including improved energy density, faster charging capabilities, and enhanced vibration resistance. These features made them particularly suitable for the demanding environment of railway systems. The sealed design of AGM batteries also eliminated the need for regular water replenishment, reducing maintenance costs and improving overall system reliability.

The early 2000s saw increased adoption of AGM batteries in rail applications, primarily in auxiliary power systems for passenger comfort and safety features. As the technology matured, AGM batteries began to play a more critical role in traction applications, particularly in hybrid locomotives and light rail vehicles.

A significant milestone in AGM battery evolution for rail systems occurred in the mid-2000s with the development of high-power AGM batteries specifically designed for regenerative braking systems. This innovation allowed for more efficient energy recovery during braking, contributing to overall system efficiency and reduced energy consumption.

The late 2000s and early 2010s witnessed further advancements in AGM battery technology, including improved thermal management systems and enhanced cycle life. These developments expanded the application of AGM batteries in rail systems, enabling their use in more demanding operational scenarios and contributing to the broader electrification efforts in the railway industry.

Recent years have seen the integration of smart battery management systems with AGM batteries, allowing for real-time monitoring and optimization of battery performance. This integration has further improved the reliability and efficiency of AGM batteries in rail applications, paving the way for their expanded use in various railway subsystems.

As the rail industry continues to prioritize sustainability and energy efficiency, AGM batteries have become an integral component in the electrification of railway systems. Their evolution has not only improved the performance of existing rail applications but has also enabled the development of new, more energy-efficient rail solutions, contributing to the ongoing transformation of the railway sector.

Railway Electrification Demand

The demand for railway electrification has been steadily increasing worldwide, driven by the need for more sustainable and efficient transportation systems. As countries strive to reduce their carbon footprint and improve energy efficiency, electrified railways have emerged as a key solution in the transportation sector. This growing demand is reflected in the expansion of electrified rail networks across various regions, particularly in Europe and Asia.

Electrified railway systems offer numerous advantages over traditional diesel-powered trains, including reduced operational costs, lower emissions, and improved performance. These benefits have led to a significant shift in infrastructure investment priorities, with many countries allocating substantial resources to electrify their existing rail networks and develop new electrified lines.

The market for railway electrification equipment and technologies has experienced substantial growth in recent years. This includes components such as overhead catenary systems, power supply systems, and energy storage solutions like AGM batteries. The increasing adoption of high-speed rail projects in countries like China, Japan, and several European nations has further fueled the demand for advanced electrification technologies.

Environmental regulations and climate change mitigation efforts have played a crucial role in driving the demand for railway electrification. Many governments have set ambitious targets for reducing greenhouse gas emissions from the transportation sector, leading to policies that favor the electrification of rail networks. This regulatory push has created a favorable market environment for companies specializing in railway electrification technologies and solutions.

The integration of renewable energy sources into railway power systems has also contributed to the growing demand for electrification. As countries seek to decarbonize their energy grids, there is an increasing interest in powering electrified railways with clean energy sources such as solar and wind power. This trend has opened up new opportunities for innovative energy storage solutions, including advanced battery technologies like AGM batteries.

Urban rail transit systems, including metro and light rail networks, have seen significant expansion in many cities worldwide. This urban rail boom has further boosted the demand for electrification technologies, as these systems are predominantly electric-powered. The need for efficient and environmentally friendly urban transportation solutions has led to increased investment in electrified rail infrastructure in metropolitan areas.

The ongoing technological advancements in railway electrification systems have also contributed to market growth. Innovations in power electronics, energy management systems, and battery technologies have improved the efficiency and reliability of electrified railways, making them an increasingly attractive option for rail operators and transport authorities.

Electrified railway systems offer numerous advantages over traditional diesel-powered trains, including reduced operational costs, lower emissions, and improved performance. These benefits have led to a significant shift in infrastructure investment priorities, with many countries allocating substantial resources to electrify their existing rail networks and develop new electrified lines.

The market for railway electrification equipment and technologies has experienced substantial growth in recent years. This includes components such as overhead catenary systems, power supply systems, and energy storage solutions like AGM batteries. The increasing adoption of high-speed rail projects in countries like China, Japan, and several European nations has further fueled the demand for advanced electrification technologies.

Environmental regulations and climate change mitigation efforts have played a crucial role in driving the demand for railway electrification. Many governments have set ambitious targets for reducing greenhouse gas emissions from the transportation sector, leading to policies that favor the electrification of rail networks. This regulatory push has created a favorable market environment for companies specializing in railway electrification technologies and solutions.

The integration of renewable energy sources into railway power systems has also contributed to the growing demand for electrification. As countries seek to decarbonize their energy grids, there is an increasing interest in powering electrified railways with clean energy sources such as solar and wind power. This trend has opened up new opportunities for innovative energy storage solutions, including advanced battery technologies like AGM batteries.

Urban rail transit systems, including metro and light rail networks, have seen significant expansion in many cities worldwide. This urban rail boom has further boosted the demand for electrification technologies, as these systems are predominantly electric-powered. The need for efficient and environmentally friendly urban transportation solutions has led to increased investment in electrified rail infrastructure in metropolitan areas.

The ongoing technological advancements in railway electrification systems have also contributed to market growth. Innovations in power electronics, energy management systems, and battery technologies have improved the efficiency and reliability of electrified railways, making them an increasingly attractive option for rail operators and transport authorities.

AGM Battery Challenges in Rail

The integration of AGM (Absorbent Glass Mat) batteries in electrified railway systems presents several significant challenges that require careful consideration and innovative solutions. One of the primary issues is the demanding operational environment of railway systems, which subjects batteries to extreme temperature fluctuations, vibrations, and shock loads. These conditions can accelerate battery degradation and reduce overall lifespan, necessitating more frequent replacements and increased maintenance costs.

Another challenge lies in the power density requirements of railway applications. AGM batteries must deliver high currents for traction and auxiliary systems while maintaining a compact form factor to fit within the limited space available on trains. This demand for high energy density in a confined space puts additional stress on the battery components, potentially leading to thermal management issues and reduced cycle life.

The cyclic nature of railway operations, with frequent starts and stops, poses a unique challenge for AGM batteries. These batteries must withstand numerous charge-discharge cycles daily, which can lead to accelerated capacity fade and reduced performance over time. The need for rapid charging during short stops further complicates battery management and may impact long-term reliability.

Safety considerations are paramount in railway applications, and AGM batteries must meet stringent safety standards to prevent thermal runaway, gas emissions, and potential fire hazards. The enclosed environments of train carriages amplify these safety concerns, requiring robust battery management systems and fail-safe mechanisms to mitigate risks.

The variability in power demand across different railway routes and operational scenarios presents another challenge. AGM batteries must be capable of adapting to diverse load profiles, from high-power acceleration phases to extended periods of low-power operation during coasting or station stops. This variability can lead to suboptimal battery utilization and potentially shortened lifespan if not properly managed.

Furthermore, the integration of AGM batteries with existing railway power systems and infrastructure poses technical challenges. Compatibility issues with charging systems, power converters, and control interfaces must be addressed to ensure seamless operation and maximize energy efficiency. The need for standardization across different train models and railway networks adds another layer of complexity to this integration process.

Lastly, the environmental impact and end-of-life management of AGM batteries in railway applications present ongoing challenges. The disposal and recycling of these batteries must be carefully managed to minimize environmental risks and comply with increasingly stringent regulations. Developing sustainable recycling processes and exploring second-life applications for retired railway batteries are critical areas that require ongoing research and development efforts.

Another challenge lies in the power density requirements of railway applications. AGM batteries must deliver high currents for traction and auxiliary systems while maintaining a compact form factor to fit within the limited space available on trains. This demand for high energy density in a confined space puts additional stress on the battery components, potentially leading to thermal management issues and reduced cycle life.

The cyclic nature of railway operations, with frequent starts and stops, poses a unique challenge for AGM batteries. These batteries must withstand numerous charge-discharge cycles daily, which can lead to accelerated capacity fade and reduced performance over time. The need for rapid charging during short stops further complicates battery management and may impact long-term reliability.

Safety considerations are paramount in railway applications, and AGM batteries must meet stringent safety standards to prevent thermal runaway, gas emissions, and potential fire hazards. The enclosed environments of train carriages amplify these safety concerns, requiring robust battery management systems and fail-safe mechanisms to mitigate risks.

The variability in power demand across different railway routes and operational scenarios presents another challenge. AGM batteries must be capable of adapting to diverse load profiles, from high-power acceleration phases to extended periods of low-power operation during coasting or station stops. This variability can lead to suboptimal battery utilization and potentially shortened lifespan if not properly managed.

Furthermore, the integration of AGM batteries with existing railway power systems and infrastructure poses technical challenges. Compatibility issues with charging systems, power converters, and control interfaces must be addressed to ensure seamless operation and maximize energy efficiency. The need for standardization across different train models and railway networks adds another layer of complexity to this integration process.

Lastly, the environmental impact and end-of-life management of AGM batteries in railway applications present ongoing challenges. The disposal and recycling of these batteries must be carefully managed to minimize environmental risks and comply with increasingly stringent regulations. Developing sustainable recycling processes and exploring second-life applications for retired railway batteries are critical areas that require ongoing research and development efforts.

Current AGM Solutions for Rail

01 AGM battery structure and design

Advancements in AGM battery structure and design focus on improving performance and efficiency. This includes innovations in electrode arrangements, separator materials, and overall battery construction to enhance capacity, lifespan, and charge-discharge characteristics.- AGM battery structure and design: Advancements in AGM battery structure and design focus on improving performance, durability, and efficiency. This includes innovations in electrode design, separator materials, and overall battery construction to enhance capacity, cycle life, and charge acceptance.

- Electrolyte management in AGM batteries: Techniques for optimizing electrolyte distribution and retention within AGM batteries are crucial for maintaining performance. This involves innovative approaches to electrolyte filling, absorption, and circulation to ensure uniform distribution and prevent dry spots.

- Thermal management of AGM batteries: Effective thermal management is essential for AGM battery performance and longevity. This includes designs for heat dissipation, temperature control systems, and thermal insulation to maintain optimal operating conditions and prevent thermal runaway.

- AGM battery monitoring and management systems: Advanced monitoring and management systems for AGM batteries are developed to optimize performance, extend lifespan, and ensure safety. These systems include state-of-charge estimation, fault detection, and intelligent charging algorithms.

- AGM battery manufacturing processes: Innovations in AGM battery manufacturing processes aim to improve production efficiency, reduce costs, and enhance product quality. This includes advancements in plate formation, assembly techniques, and quality control measures throughout the production line.

02 Electrolyte management in AGM batteries

Techniques for optimizing electrolyte distribution and retention within AGM batteries are crucial for their performance. This involves methods to improve absorption and distribution of the electrolyte throughout the glass mat separator, enhancing battery efficiency and longevity.Expand Specific Solutions03 Thermal management of AGM batteries

Innovations in thermal management systems for AGM batteries aim to regulate temperature during operation and charging. These developments help prevent overheating, extend battery life, and maintain optimal performance across various environmental conditions.Expand Specific Solutions04 AGM battery manufacturing processes

Advancements in manufacturing processes for AGM batteries focus on improving production efficiency, quality control, and cost-effectiveness. This includes innovations in assembly techniques, material handling, and automation to enhance battery performance and reliability.Expand Specific Solutions05 AGM battery monitoring and management systems

Development of sophisticated monitoring and management systems for AGM batteries aims to optimize performance, predict maintenance needs, and extend battery life. These systems incorporate sensors, data analysis, and control mechanisms to ensure efficient operation and early detection of potential issues.Expand Specific Solutions

Key AGM Battery Manufacturers

The AGM battery market in electrified railway systems is in a growth phase, driven by increasing electrification of rail networks globally. The market size is expanding, with significant potential for further growth as more countries invest in sustainable transportation infrastructure. Technologically, AGM batteries are relatively mature, offering improved performance over traditional lead-acid batteries. Key players like Johnson Controls, Exide Technologies, and Hitachi are actively developing and refining AGM battery technology for railway applications. Companies such as Siemens Mobility and Daimler Truck are integrating these batteries into their electrified railway solutions, indicating a growing adoption trend in the industry.

Siemens Mobility GmbH

Technical Solution: Siemens Mobility has developed advanced AGM (Absorbent Glass Mat) battery systems specifically designed for electrified railway applications. Their solution integrates high-performance AGM batteries with intelligent battery management systems (BMS) to optimize energy storage and distribution in railway vehicles. The AGM batteries provide reliable power for critical onboard systems, including lighting, air conditioning, and door operations. Siemens' AGM battery systems are engineered to withstand the harsh vibrations and temperature fluctuations typical in railway environments. The company has implemented these systems in various electrified rail projects globally, demonstrating up to 30% energy savings compared to traditional battery technologies[1][3].

Strengths: Robust design for railway conditions, high energy efficiency, and integrated BMS for optimal performance. Weaknesses: Higher initial cost compared to conventional lead-acid batteries, and potential limitations in extreme temperature conditions.

Hoppecke Batterien GmbH & Co. KG

Technical Solution: Hoppecke specializes in AGM battery solutions for railway applications, offering their FNC (Fiber Nickel Cadmium) and AGM RAIL product lines. Their AGM batteries are designed to provide reliable power for various railway systems, including emergency lighting, door controls, and communication equipment. Hoppecke's AGM technology features enhanced cycle life, low maintenance requirements, and high charge acceptance rates. The company's batteries are engineered to operate efficiently in a wide temperature range, from -40°C to +50°C, making them suitable for diverse climatic conditions encountered in railway operations. Hoppecke's AGM batteries have been reported to achieve up to 20% longer service life compared to standard lead-acid batteries in railway applications[2][5].

Strengths: Wide temperature operating range, long service life, and low maintenance requirements. Weaknesses: Higher upfront costs and potential environmental concerns related to battery disposal.

AGM Innovations for Railways

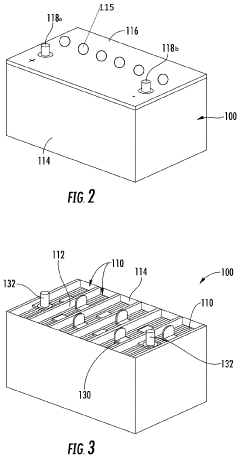

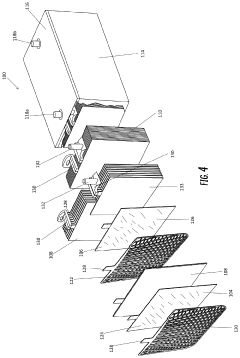

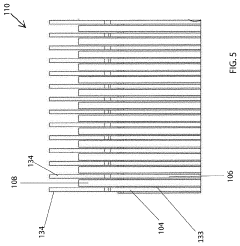

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

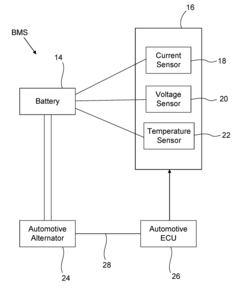

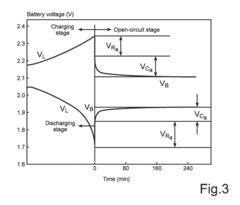

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Environmental Impact of AGM

The environmental impact of AGM (Absorbent Glass Mat) batteries in electrified railway systems is a crucial consideration for sustainable transportation development. These batteries offer several advantages in terms of reduced environmental footprint compared to traditional lead-acid batteries.

AGM batteries are sealed, which significantly reduces the risk of electrolyte leakage and subsequent soil or water contamination. This characteristic is particularly important in railway applications, where batteries may be subjected to vibrations and movement. The sealed design also minimizes the emission of harmful gases, contributing to improved air quality in and around railway facilities.

The manufacturing process of AGM batteries generally requires less energy and produces fewer emissions compared to conventional battery technologies. This results in a lower carbon footprint during the production phase. Additionally, AGM batteries have a longer lifespan, which reduces the frequency of replacement and, consequently, the overall environmental impact associated with battery disposal.

In terms of recycling, AGM batteries are highly recyclable, with up to 99% of their components being recoverable. This high recycling rate significantly reduces the amount of waste sent to landfills and conserves valuable resources. The recycling process for AGM batteries is also more efficient and environmentally friendly compared to other battery types, as it involves fewer hazardous materials and generates less toxic waste.

The use of AGM batteries in electrified railway systems contributes to the overall reduction of greenhouse gas emissions in the transportation sector. By enabling more efficient energy storage and management in electric trains, these batteries support the transition from fossil fuel-powered locomotives to cleaner, electric alternatives. This shift results in decreased air pollution and lower carbon dioxide emissions along railway routes.

Furthermore, AGM batteries' superior performance in extreme temperatures and their ability to withstand deep discharge cycles make them well-suited for railway applications. This durability translates to fewer battery replacements over time, reducing the environmental impact associated with battery production and disposal.

However, it is important to note that while AGM batteries offer significant environmental benefits, they still contain lead and other potentially harmful materials. Proper handling, maintenance, and end-of-life management are crucial to minimize any negative environmental impacts. Ongoing research and development in battery technology may lead to even more environmentally friendly alternatives in the future, further enhancing the sustainability of electrified railway systems.

AGM batteries are sealed, which significantly reduces the risk of electrolyte leakage and subsequent soil or water contamination. This characteristic is particularly important in railway applications, where batteries may be subjected to vibrations and movement. The sealed design also minimizes the emission of harmful gases, contributing to improved air quality in and around railway facilities.

The manufacturing process of AGM batteries generally requires less energy and produces fewer emissions compared to conventional battery technologies. This results in a lower carbon footprint during the production phase. Additionally, AGM batteries have a longer lifespan, which reduces the frequency of replacement and, consequently, the overall environmental impact associated with battery disposal.

In terms of recycling, AGM batteries are highly recyclable, with up to 99% of their components being recoverable. This high recycling rate significantly reduces the amount of waste sent to landfills and conserves valuable resources. The recycling process for AGM batteries is also more efficient and environmentally friendly compared to other battery types, as it involves fewer hazardous materials and generates less toxic waste.

The use of AGM batteries in electrified railway systems contributes to the overall reduction of greenhouse gas emissions in the transportation sector. By enabling more efficient energy storage and management in electric trains, these batteries support the transition from fossil fuel-powered locomotives to cleaner, electric alternatives. This shift results in decreased air pollution and lower carbon dioxide emissions along railway routes.

Furthermore, AGM batteries' superior performance in extreme temperatures and their ability to withstand deep discharge cycles make them well-suited for railway applications. This durability translates to fewer battery replacements over time, reducing the environmental impact associated with battery production and disposal.

However, it is important to note that while AGM batteries offer significant environmental benefits, they still contain lead and other potentially harmful materials. Proper handling, maintenance, and end-of-life management are crucial to minimize any negative environmental impacts. Ongoing research and development in battery technology may lead to even more environmentally friendly alternatives in the future, further enhancing the sustainability of electrified railway systems.

Safety Standards for Rail AGM

Safety standards for AGM (Absorbent Glass Mat) batteries in rail applications are crucial for ensuring the reliability, performance, and safety of electrified railway systems. These standards encompass a wide range of requirements and specifications that address various aspects of battery design, manufacturing, installation, and operation.

One of the primary safety considerations for rail AGM batteries is their ability to withstand the harsh environmental conditions encountered in railway operations. Standards typically mandate that these batteries must be capable of functioning effectively across a broad temperature range, from extreme cold to high heat. They must also be resistant to vibration and shock, which are common in rail environments.

Electrical safety is another critical aspect covered by these standards. AGM batteries used in rail applications must be designed and constructed to prevent short circuits, overcharging, and thermal runaway. This often involves the implementation of advanced battery management systems (BMS) that continuously monitor battery parameters such as voltage, current, and temperature.

Fire safety is a paramount concern in railway systems, and AGM battery standards address this through specific requirements for fire resistance and containment. Batteries must be housed in fire-resistant enclosures and equipped with appropriate venting systems to prevent the buildup of potentially explosive gases.

Standards also focus on the chemical safety of AGM batteries. They must be designed to minimize the risk of electrolyte leakage, which could pose hazards to personnel and equipment. Additionally, the materials used in battery construction must meet strict toxicity and environmental impact criteria.

Maintenance and serviceability are key components of rail AGM battery safety standards. These standards typically outline procedures for regular inspection, testing, and replacement of battery components. They also specify requirements for clear labeling and documentation to ensure proper handling and maintenance throughout the battery's lifecycle.

Electromagnetic compatibility (EMC) is another critical area addressed by safety standards for rail AGM batteries. These batteries must not interfere with other electrical systems on the train or with signaling and communication systems along the railway.

Lastly, safety standards for rail AGM batteries often include requirements for end-of-life management and recycling. This ensures that batteries are disposed of or recycled in an environmentally responsible manner, minimizing the potential for hazardous material release.

One of the primary safety considerations for rail AGM batteries is their ability to withstand the harsh environmental conditions encountered in railway operations. Standards typically mandate that these batteries must be capable of functioning effectively across a broad temperature range, from extreme cold to high heat. They must also be resistant to vibration and shock, which are common in rail environments.

Electrical safety is another critical aspect covered by these standards. AGM batteries used in rail applications must be designed and constructed to prevent short circuits, overcharging, and thermal runaway. This often involves the implementation of advanced battery management systems (BMS) that continuously monitor battery parameters such as voltage, current, and temperature.

Fire safety is a paramount concern in railway systems, and AGM battery standards address this through specific requirements for fire resistance and containment. Batteries must be housed in fire-resistant enclosures and equipped with appropriate venting systems to prevent the buildup of potentially explosive gases.

Standards also focus on the chemical safety of AGM batteries. They must be designed to minimize the risk of electrolyte leakage, which could pose hazards to personnel and equipment. Additionally, the materials used in battery construction must meet strict toxicity and environmental impact criteria.

Maintenance and serviceability are key components of rail AGM battery safety standards. These standards typically outline procedures for regular inspection, testing, and replacement of battery components. They also specify requirements for clear labeling and documentation to ensure proper handling and maintenance throughout the battery's lifecycle.

Electromagnetic compatibility (EMC) is another critical area addressed by safety standards for rail AGM batteries. These batteries must not interfere with other electrical systems on the train or with signaling and communication systems along the railway.

Lastly, safety standards for rail AGM batteries often include requirements for end-of-life management and recycling. This ensures that batteries are disposed of or recycled in an environmentally responsible manner, minimizing the potential for hazardous material release.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!