AGM Battery Applications in Frozen Transport Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

AGM (Absorbent Glass Mat) batteries have undergone significant evolution since their inception in the 1980s, particularly in their application to frozen transport systems. Initially developed for military and aerospace use, AGM batteries have gradually found their way into various commercial and industrial applications, including cold chain logistics.

The early stages of AGM battery development focused on improving energy density and cycle life. Researchers worked on optimizing the glass mat separator, which is a key component in AGM batteries. This led to better electrolyte absorption and reduced internal resistance, resulting in improved performance in low-temperature environments.

As the technology matured, manufacturers began to tailor AGM batteries specifically for cold storage and transportation applications. This involved enhancing the battery's cold cranking amps (CCA) rating, which is crucial for starting engines in freezing conditions. The evolution of AGM batteries in this direction allowed for more reliable operation in sub-zero temperatures, making them increasingly attractive for frozen transport systems.

Another significant milestone in AGM battery evolution was the development of deep-cycle variants. These batteries were designed to withstand repeated discharge and recharge cycles, which is particularly important in transport systems that may require extended periods of operation without external power sources. This advancement greatly expanded the potential applications of AGM batteries in refrigerated trucks and containers.

The integration of smart battery management systems (BMS) marked a pivotal point in AGM battery evolution for frozen transport. These systems allowed for real-time monitoring of battery health, state of charge, and temperature, enabling more efficient use of the battery and prolonging its lifespan in harsh cold environments.

Recent advancements have focused on improving the environmental sustainability of AGM batteries. Manufacturers have been working on reducing the lead content and increasing the recyclability of these batteries, aligning with global trends towards greener technologies in the transportation sector.

The evolution of AGM batteries has also seen improvements in their charging efficiency and speed. This is particularly crucial for frozen transport systems, where minimizing downtime for battery charging is essential. Fast-charging capabilities have been developed, allowing for quicker turnaround times in logistics operations.

Looking towards the future, ongoing research is exploring the potential of hybrid systems that combine AGM batteries with other energy storage technologies, such as lithium-ion batteries or fuel cells. These hybrid solutions aim to leverage the strengths of different technologies to provide optimal performance in frozen transport applications.

The early stages of AGM battery development focused on improving energy density and cycle life. Researchers worked on optimizing the glass mat separator, which is a key component in AGM batteries. This led to better electrolyte absorption and reduced internal resistance, resulting in improved performance in low-temperature environments.

As the technology matured, manufacturers began to tailor AGM batteries specifically for cold storage and transportation applications. This involved enhancing the battery's cold cranking amps (CCA) rating, which is crucial for starting engines in freezing conditions. The evolution of AGM batteries in this direction allowed for more reliable operation in sub-zero temperatures, making them increasingly attractive for frozen transport systems.

Another significant milestone in AGM battery evolution was the development of deep-cycle variants. These batteries were designed to withstand repeated discharge and recharge cycles, which is particularly important in transport systems that may require extended periods of operation without external power sources. This advancement greatly expanded the potential applications of AGM batteries in refrigerated trucks and containers.

The integration of smart battery management systems (BMS) marked a pivotal point in AGM battery evolution for frozen transport. These systems allowed for real-time monitoring of battery health, state of charge, and temperature, enabling more efficient use of the battery and prolonging its lifespan in harsh cold environments.

Recent advancements have focused on improving the environmental sustainability of AGM batteries. Manufacturers have been working on reducing the lead content and increasing the recyclability of these batteries, aligning with global trends towards greener technologies in the transportation sector.

The evolution of AGM batteries has also seen improvements in their charging efficiency and speed. This is particularly crucial for frozen transport systems, where minimizing downtime for battery charging is essential. Fast-charging capabilities have been developed, allowing for quicker turnaround times in logistics operations.

Looking towards the future, ongoing research is exploring the potential of hybrid systems that combine AGM batteries with other energy storage technologies, such as lithium-ion batteries or fuel cells. These hybrid solutions aim to leverage the strengths of different technologies to provide optimal performance in frozen transport applications.

Frozen Transport Needs

The frozen transport industry faces unique challenges in maintaining the integrity of temperature-sensitive goods during transportation. As global trade in perishable items continues to grow, the demand for reliable and efficient frozen transport systems has become increasingly critical. These systems must maintain consistent sub-zero temperatures, often for extended periods, to prevent spoilage and ensure product quality.

One of the primary needs in frozen transport is energy efficiency. Traditional refrigeration systems consume significant amounts of fuel, contributing to high operational costs and environmental concerns. The industry is actively seeking solutions that can provide long-lasting cooling power while minimizing energy consumption. This has led to a growing interest in advanced battery technologies, such as AGM (Absorbent Glass Mat) batteries, which offer potential improvements in energy storage and power delivery for refrigeration units.

Reliability is another crucial factor in frozen transport. Failures in cooling systems can result in substantial financial losses and compromised food safety. The industry requires power sources that can withstand the rigors of long-distance transportation, including vibrations, temperature fluctuations, and varying load demands. AGM batteries, known for their durability and resistance to shock and vibration, present a promising option to address these reliability concerns.

Space and weight optimization are also significant considerations in frozen transport. Vehicles need to maximize cargo capacity while accommodating necessary cooling equipment. Compact and lightweight power solutions that can support refrigeration systems without significantly impacting payload capacity are highly sought after. AGM batteries, with their high power density and flexible form factors, offer potential advantages in this regard.

Furthermore, the frozen transport sector is under increasing pressure to reduce its environmental footprint. This has led to a growing demand for eco-friendly technologies that can minimize greenhouse gas emissions and align with stricter environmental regulations. Battery-powered cooling systems, particularly those utilizing advanced technologies like AGM, are seen as a potential pathway to greener frozen transport operations.

Lastly, there is a need for intelligent power management systems in frozen transport. These systems should be capable of optimizing energy use, predicting maintenance requirements, and providing real-time monitoring of temperature and battery performance. The integration of AGM batteries with smart control systems could offer enhanced operational efficiency and improved cold chain management.

One of the primary needs in frozen transport is energy efficiency. Traditional refrigeration systems consume significant amounts of fuel, contributing to high operational costs and environmental concerns. The industry is actively seeking solutions that can provide long-lasting cooling power while minimizing energy consumption. This has led to a growing interest in advanced battery technologies, such as AGM (Absorbent Glass Mat) batteries, which offer potential improvements in energy storage and power delivery for refrigeration units.

Reliability is another crucial factor in frozen transport. Failures in cooling systems can result in substantial financial losses and compromised food safety. The industry requires power sources that can withstand the rigors of long-distance transportation, including vibrations, temperature fluctuations, and varying load demands. AGM batteries, known for their durability and resistance to shock and vibration, present a promising option to address these reliability concerns.

Space and weight optimization are also significant considerations in frozen transport. Vehicles need to maximize cargo capacity while accommodating necessary cooling equipment. Compact and lightweight power solutions that can support refrigeration systems without significantly impacting payload capacity are highly sought after. AGM batteries, with their high power density and flexible form factors, offer potential advantages in this regard.

Furthermore, the frozen transport sector is under increasing pressure to reduce its environmental footprint. This has led to a growing demand for eco-friendly technologies that can minimize greenhouse gas emissions and align with stricter environmental regulations. Battery-powered cooling systems, particularly those utilizing advanced technologies like AGM, are seen as a potential pathway to greener frozen transport operations.

Lastly, there is a need for intelligent power management systems in frozen transport. These systems should be capable of optimizing energy use, predicting maintenance requirements, and providing real-time monitoring of temperature and battery performance. The integration of AGM batteries with smart control systems could offer enhanced operational efficiency and improved cold chain management.

AGM Tech Challenges

AGM (Absorbent Glass Mat) batteries face several technical challenges when applied to frozen transport systems. The primary issue is their performance degradation in extremely low temperatures, which is a critical concern for cold chain logistics. At temperatures below freezing, the chemical reactions within the battery slow down significantly, reducing its capacity and power output. This can lead to insufficient energy supply for refrigeration units, potentially compromising the integrity of temperature-sensitive cargo.

Another challenge is the battery's charging efficiency in cold environments. AGM batteries typically require longer charging times and may not accept a full charge at very low temperatures, which can be problematic for transport systems that rely on frequent recharging cycles. This limitation can result in reduced operational time and increased downtime for charging, affecting the overall efficiency of frozen transport operations.

The thermal management of AGM batteries in frozen environments presents a significant technical hurdle. Without proper insulation and heating systems, the batteries may struggle to maintain optimal internal temperatures, leading to reduced lifespan and potential failure. Developing effective and energy-efficient thermal management solutions that can operate in extreme cold without significantly impacting the battery's performance is a complex engineering challenge.

Durability and cycle life of AGM batteries in frozen transport applications also pose concerns. The repeated exposure to extreme temperature fluctuations, from frozen conditions during transport to potentially warmer temperatures during loading and unloading, can accelerate battery degradation. This thermal cycling stress can lead to premature battery failure, increasing maintenance costs and reducing the reliability of the transport system.

Furthermore, the weight and space requirements of AGM batteries present design challenges for frozen transport vehicles. While AGM batteries are generally more compact than traditional lead-acid batteries, integrating them into existing vehicle designs while maintaining adequate power capacity for both propulsion and refrigeration can be challenging. This is particularly true for long-haul frozen transport, where extended range and prolonged cooling capabilities are essential.

Lastly, the environmental impact of AGM batteries in cold chain applications is an emerging concern. While these batteries are sealed and generally considered maintenance-free, their disposal at end-of-life presents environmental challenges, especially in regions with limited recycling infrastructure. Developing more sustainable and easily recyclable AGM battery technologies for frozen transport systems remains an important area for future research and development.

Another challenge is the battery's charging efficiency in cold environments. AGM batteries typically require longer charging times and may not accept a full charge at very low temperatures, which can be problematic for transport systems that rely on frequent recharging cycles. This limitation can result in reduced operational time and increased downtime for charging, affecting the overall efficiency of frozen transport operations.

The thermal management of AGM batteries in frozen environments presents a significant technical hurdle. Without proper insulation and heating systems, the batteries may struggle to maintain optimal internal temperatures, leading to reduced lifespan and potential failure. Developing effective and energy-efficient thermal management solutions that can operate in extreme cold without significantly impacting the battery's performance is a complex engineering challenge.

Durability and cycle life of AGM batteries in frozen transport applications also pose concerns. The repeated exposure to extreme temperature fluctuations, from frozen conditions during transport to potentially warmer temperatures during loading and unloading, can accelerate battery degradation. This thermal cycling stress can lead to premature battery failure, increasing maintenance costs and reducing the reliability of the transport system.

Furthermore, the weight and space requirements of AGM batteries present design challenges for frozen transport vehicles. While AGM batteries are generally more compact than traditional lead-acid batteries, integrating them into existing vehicle designs while maintaining adequate power capacity for both propulsion and refrigeration can be challenging. This is particularly true for long-haul frozen transport, where extended range and prolonged cooling capabilities are essential.

Lastly, the environmental impact of AGM batteries in cold chain applications is an emerging concern. While these batteries are sealed and generally considered maintenance-free, their disposal at end-of-life presents environmental challenges, especially in regions with limited recycling infrastructure. Developing more sustainable and easily recyclable AGM battery technologies for frozen transport systems remains an important area for future research and development.

AGM in Cold Chain

01 AGM battery structure and design

Innovations in the structure and design of AGM (Absorbent Glass Mat) batteries, including improvements in electrode arrangement, separator materials, and overall battery construction to enhance performance and efficiency.- AGM battery structure and design: Advancements in AGM battery structure and design focus on improving performance and efficiency. This includes innovations in electrode arrangements, separator materials, and overall battery construction to enhance capacity, lifespan, and charge-discharge characteristics.

- Electrolyte management in AGM batteries: Techniques for optimizing electrolyte distribution and retention within AGM batteries are crucial for their performance. This involves methods for improving absorption and distribution of the electrolyte within the glass mat separator, as well as strategies to prevent electrolyte loss and maintain proper saturation levels.

- Thermal management of AGM batteries: Effective thermal management is essential for AGM battery performance and longevity. Innovations in this area include heat dissipation techniques, temperature control systems, and designs that minimize thermal stress on battery components during operation and charging.

- AGM battery monitoring and management systems: Advanced monitoring and management systems for AGM batteries are being developed to optimize performance and extend battery life. These systems include sensors for real-time monitoring of battery parameters, intelligent charging algorithms, and diagnostic tools for predictive maintenance.

- AGM battery applications and integration: AGM batteries are being adapted and optimized for various applications, including automotive, renewable energy storage, and backup power systems. Innovations focus on integrating AGM batteries into different environments, improving their compatibility with specific systems, and enhancing their performance in diverse operating conditions.

02 Electrolyte management in AGM batteries

Advancements in electrolyte management systems for AGM batteries, focusing on optimizing electrolyte distribution, reducing electrolyte loss, and improving overall battery life and performance.Expand Specific Solutions03 Thermal management of AGM batteries

Development of thermal management solutions for AGM batteries, including heat dissipation mechanisms, temperature control systems, and thermal insulation techniques to maintain optimal operating conditions and extend battery lifespan.Expand Specific Solutions04 AGM battery manufacturing processes

Improvements in AGM battery manufacturing processes, including automated assembly techniques, quality control measures, and innovative production methods to enhance battery consistency and reduce manufacturing costs.Expand Specific Solutions05 AGM battery monitoring and management systems

Integration of advanced monitoring and management systems for AGM batteries, incorporating sensors, data analysis, and intelligent control mechanisms to optimize battery performance, predict maintenance needs, and extend overall battery life.Expand Specific Solutions

Key AGM Manufacturers

The AGM battery market for frozen transport systems is in a growth phase, driven by increasing demand for reliable cold chain logistics. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, AGM batteries are reaching maturity, offering improved performance and reliability in low-temperature environments. Key players like Fengfan Co., Ltd. and Amara Raja Energy & Mobility Ltd. are investing in R&D to enhance AGM battery capabilities for frozen transport applications. Companies such as Thermo King LLC and Cleantek Industries, Inc. are integrating these advanced batteries into their refrigerated transport solutions, indicating a competitive landscape with both battery manufacturers and system integrators vying for market share.

Thermo King LLC

Technical Solution: Thermo King has integrated AGM battery technology into their frozen transport systems, focusing on reliability and energy efficiency. Their solution incorporates AGM batteries with a high cycle life, capable of withstanding frequent charge-discharge cycles typical in refrigerated transport [1]. The company has developed a proprietary thermal management system that regulates battery temperature, ensuring optimal performance in both cold and hot environments [2]. Thermo King's AGM batteries are designed with a low internal resistance, allowing for rapid power delivery to start compressors and maintain cooling systems even in extreme cold [3]. They have also implemented an advanced charging algorithm that adapts to varying ambient temperatures, maximizing battery life and performance in diverse climatic conditions [4].

Strengths: High cycle life, efficient thermal management, rapid power delivery, and adaptive charging technology. Weaknesses: May require more frequent monitoring and potential higher maintenance costs in the long term.

Stryten Energy LLC

Technical Solution: Stryten Energy has developed advanced AGM (Absorbent Glass Mat) batteries specifically designed for frozen transport systems. Their technology incorporates enhanced electrolyte formulations that maintain performance in extreme cold conditions, typically down to -40°C [1]. The batteries feature a proprietary plate design that optimizes current flow and reduces internal resistance, resulting in improved cold-cranking performance and faster recharge rates [2]. Stryten's AGM batteries also utilize a robust case construction with reinforced internal components to withstand vibrations and shocks common in transport applications [3]. The company has implemented a smart battery management system that monitors battery health, predicts maintenance needs, and optimizes charging cycles to extend battery life in cold environments [4].

Strengths: Excellent cold weather performance, fast recharging, vibration resistance, and intelligent battery management. Weaknesses: Higher initial cost compared to traditional lead-acid batteries, and potential for overheating if not properly managed in warmer climates.

AGM Cold Performance

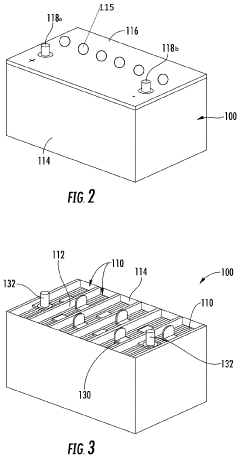

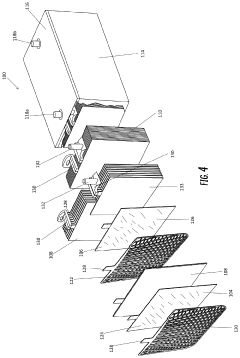

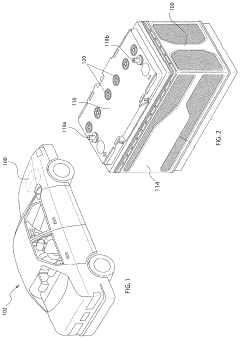

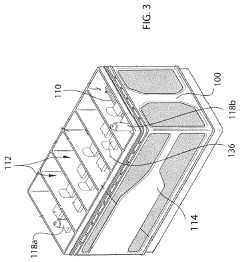

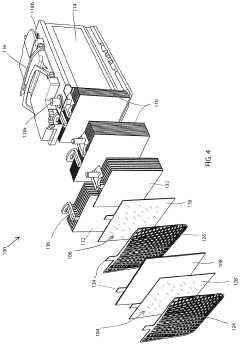

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

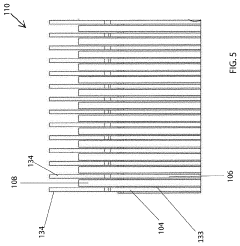

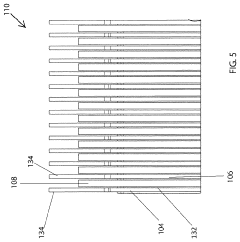

Absorbent glass mat battery

PatentActiveUS11936032B2

Innovation

- The development of a lead-acid battery with a negative electrode comprising a leady oxide, a synthetic organic expander, conductive carbons, and very fine particle barium sulfate, along with an absorbent glass mat separator, which enhances charge acceptance and cycling performance by improving the electrochemical active material composition and structure.

Cold Chain Regulations

Cold chain regulations play a crucial role in ensuring the safe and efficient transport of temperature-sensitive goods, particularly in the context of AGM battery applications in frozen transport systems. These regulations are designed to maintain product quality, safety, and efficacy throughout the entire supply chain.

The primary regulatory bodies governing cold chain practices include the World Health Organization (WHO), the Food and Drug Administration (FDA), and the European Union's Good Distribution Practice (GDP). These organizations set standards for temperature-controlled storage and distribution of perishable goods, including pharmaceuticals, food products, and certain types of batteries.

For AGM batteries used in frozen transport systems, compliance with cold chain regulations is essential to maintain their performance and longevity. The International Air Transport Association (IATA) and the International Maritime Organization (IMO) have specific guidelines for the transport of batteries, including temperature requirements during shipping and storage.

Key aspects of cold chain regulations relevant to AGM batteries in frozen transport systems include temperature monitoring, documentation, and risk management. Continuous temperature monitoring is mandatory to ensure that batteries are kept within the specified temperature range throughout the transport process. This often involves the use of data loggers and real-time monitoring systems.

Documentation requirements are stringent, with detailed records of temperature data, handling procedures, and any deviations from the prescribed conditions. This documentation serves as evidence of compliance and is crucial for quality assurance and regulatory inspections.

Risk management is another critical component of cold chain regulations. Companies must conduct thorough risk assessments to identify potential points of failure in the cold chain and implement appropriate mitigation strategies. This includes contingency plans for equipment failures, power outages, or unexpected delays in transit.

Regulatory bodies also emphasize the importance of personnel training in cold chain management. Employees involved in the handling, storage, and transport of AGM batteries must be adequately trained in cold chain procedures and the specific requirements for battery handling in frozen environments.

As technology advances, regulations are evolving to incorporate new methods of ensuring cold chain integrity. This includes the adoption of blockchain technology for enhanced traceability and the use of artificial intelligence for predictive maintenance of cold chain equipment.

Compliance with cold chain regulations not only ensures the quality and safety of AGM batteries in frozen transport systems but also helps companies avoid costly regulatory penalties and product losses. As such, staying abreast of regulatory changes and implementing robust cold chain management practices is essential for businesses operating in this sector.

The primary regulatory bodies governing cold chain practices include the World Health Organization (WHO), the Food and Drug Administration (FDA), and the European Union's Good Distribution Practice (GDP). These organizations set standards for temperature-controlled storage and distribution of perishable goods, including pharmaceuticals, food products, and certain types of batteries.

For AGM batteries used in frozen transport systems, compliance with cold chain regulations is essential to maintain their performance and longevity. The International Air Transport Association (IATA) and the International Maritime Organization (IMO) have specific guidelines for the transport of batteries, including temperature requirements during shipping and storage.

Key aspects of cold chain regulations relevant to AGM batteries in frozen transport systems include temperature monitoring, documentation, and risk management. Continuous temperature monitoring is mandatory to ensure that batteries are kept within the specified temperature range throughout the transport process. This often involves the use of data loggers and real-time monitoring systems.

Documentation requirements are stringent, with detailed records of temperature data, handling procedures, and any deviations from the prescribed conditions. This documentation serves as evidence of compliance and is crucial for quality assurance and regulatory inspections.

Risk management is another critical component of cold chain regulations. Companies must conduct thorough risk assessments to identify potential points of failure in the cold chain and implement appropriate mitigation strategies. This includes contingency plans for equipment failures, power outages, or unexpected delays in transit.

Regulatory bodies also emphasize the importance of personnel training in cold chain management. Employees involved in the handling, storage, and transport of AGM batteries must be adequately trained in cold chain procedures and the specific requirements for battery handling in frozen environments.

As technology advances, regulations are evolving to incorporate new methods of ensuring cold chain integrity. This includes the adoption of blockchain technology for enhanced traceability and the use of artificial intelligence for predictive maintenance of cold chain equipment.

Compliance with cold chain regulations not only ensures the quality and safety of AGM batteries in frozen transport systems but also helps companies avoid costly regulatory penalties and product losses. As such, staying abreast of regulatory changes and implementing robust cold chain management practices is essential for businesses operating in this sector.

AGM Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) batteries in frozen transport systems is a critical consideration for sustainable logistics and cold chain management. These batteries, while offering significant advantages in low-temperature environments, also present unique environmental challenges throughout their lifecycle.

AGM batteries used in frozen transport systems typically have a longer lifespan compared to traditional lead-acid batteries, reducing the frequency of replacement and associated waste. This longevity is particularly beneficial in cold environments where battery performance is often compromised. However, the production of AGM batteries involves energy-intensive processes and the use of materials that can have environmental implications.

The lead content in AGM batteries remains a primary environmental concern. Although these batteries are sealed and maintenance-free, improper disposal can lead to lead contamination in soil and water systems. This risk is mitigated by well-established recycling processes, with lead being one of the most recycled materials globally. The recycling rate for lead-acid batteries, including AGM types, often exceeds 95% in many developed countries.

In the context of frozen transport systems, AGM batteries contribute to improved energy efficiency. Their ability to perform well in cold temperatures reduces the need for energy-intensive heating systems to maintain battery function. This indirectly lowers the overall carbon footprint of refrigerated transport operations.

The manufacturing process of AGM batteries has seen improvements in recent years, with many manufacturers adopting cleaner production methods. These include reducing harmful emissions, implementing water recycling systems, and optimizing energy use in production facilities. However, the production of glass mats and the absorption of electrolytes still involve processes that require careful environmental management.

When considering the end-of-life phase, AGM batteries in frozen transport systems present both challenges and opportunities. The sealed nature of these batteries makes them safer to handle during recycling processes compared to flooded lead-acid batteries. However, the complex composition of AGM batteries, including the glass mat separators, requires specialized recycling facilities to ensure maximum material recovery and minimal environmental impact.

In the broader context of sustainable transportation, the use of AGM batteries in frozen transport systems aligns with efforts to reduce the environmental impact of cold chain logistics. By enabling more efficient and reliable operation of refrigeration units, these batteries contribute to reducing food waste – a significant source of greenhouse gas emissions when disposed of in landfills.

AGM batteries used in frozen transport systems typically have a longer lifespan compared to traditional lead-acid batteries, reducing the frequency of replacement and associated waste. This longevity is particularly beneficial in cold environments where battery performance is often compromised. However, the production of AGM batteries involves energy-intensive processes and the use of materials that can have environmental implications.

The lead content in AGM batteries remains a primary environmental concern. Although these batteries are sealed and maintenance-free, improper disposal can lead to lead contamination in soil and water systems. This risk is mitigated by well-established recycling processes, with lead being one of the most recycled materials globally. The recycling rate for lead-acid batteries, including AGM types, often exceeds 95% in many developed countries.

In the context of frozen transport systems, AGM batteries contribute to improved energy efficiency. Their ability to perform well in cold temperatures reduces the need for energy-intensive heating systems to maintain battery function. This indirectly lowers the overall carbon footprint of refrigerated transport operations.

The manufacturing process of AGM batteries has seen improvements in recent years, with many manufacturers adopting cleaner production methods. These include reducing harmful emissions, implementing water recycling systems, and optimizing energy use in production facilities. However, the production of glass mats and the absorption of electrolytes still involve processes that require careful environmental management.

When considering the end-of-life phase, AGM batteries in frozen transport systems present both challenges and opportunities. The sealed nature of these batteries makes them safer to handle during recycling processes compared to flooded lead-acid batteries. However, the complex composition of AGM batteries, including the glass mat separators, requires specialized recycling facilities to ensure maximum material recovery and minimal environmental impact.

In the broader context of sustainable transportation, the use of AGM batteries in frozen transport systems aligns with efforts to reduce the environmental impact of cold chain logistics. By enabling more efficient and reliable operation of refrigeration units, these batteries contribute to reducing food waste – a significant source of greenhouse gas emissions when disposed of in landfills.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!