Evaluating AGM Battery Reliability in Sustainable Marine Transport

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in energy storage technology, particularly for marine applications. Initially developed in the 1970s for military aircraft, AGM batteries have undergone substantial improvements over the decades, making them increasingly suitable for sustainable marine transport.

In the early stages of AGM battery development, the focus was primarily on enhancing power density and reducing weight compared to traditional lead-acid batteries. This made them attractive for aviation and later for marine use, where space and weight constraints are critical factors. The 1980s and 1990s saw further refinements in the manufacturing process, leading to increased reliability and longer service life.

A key milestone in AGM battery evolution was the introduction of valve-regulated lead-acid (VRLA) technology in the late 1990s. This innovation allowed for a sealed, maintenance-free design, significantly reducing the risk of electrolyte leakage and improving safety in marine environments. The VRLA design also enabled AGM batteries to be mounted in various orientations without compromising performance, a crucial feature for marine applications.

The early 2000s marked a period of rapid advancement in AGM battery technology. Manufacturers began incorporating advanced lead alloys and optimizing the glass mat structure, resulting in improved charge acceptance and faster recharge rates. These enhancements made AGM batteries more suitable for the cyclical demands of marine propulsion systems and onboard electrical loads.

In recent years, the evolution of AGM batteries has been driven by the growing emphasis on sustainability in marine transport. This has led to the development of AGM batteries with higher energy density, longer cycle life, and improved resistance to deep discharge cycles. Modern AGM batteries now offer significantly better performance in terms of capacity retention and resistance to sulfation, addressing key reliability concerns in marine applications.

The latest advancements in AGM battery technology have focused on integrating smart battery management systems (BMS) and remote monitoring capabilities. These features allow for real-time performance tracking, predictive maintenance, and optimized charging strategies, further enhancing the reliability and longevity of AGM batteries in marine environments.

As the marine industry continues to prioritize sustainable transport solutions, the evolution of AGM batteries is likely to accelerate. Future developments may include the incorporation of nanomaterials to enhance electrode performance, advanced thermal management systems for improved efficiency in varying marine conditions, and the integration of AGM technology with hybrid propulsion systems for enhanced energy management in sustainable marine transport.

In the early stages of AGM battery development, the focus was primarily on enhancing power density and reducing weight compared to traditional lead-acid batteries. This made them attractive for aviation and later for marine use, where space and weight constraints are critical factors. The 1980s and 1990s saw further refinements in the manufacturing process, leading to increased reliability and longer service life.

A key milestone in AGM battery evolution was the introduction of valve-regulated lead-acid (VRLA) technology in the late 1990s. This innovation allowed for a sealed, maintenance-free design, significantly reducing the risk of electrolyte leakage and improving safety in marine environments. The VRLA design also enabled AGM batteries to be mounted in various orientations without compromising performance, a crucial feature for marine applications.

The early 2000s marked a period of rapid advancement in AGM battery technology. Manufacturers began incorporating advanced lead alloys and optimizing the glass mat structure, resulting in improved charge acceptance and faster recharge rates. These enhancements made AGM batteries more suitable for the cyclical demands of marine propulsion systems and onboard electrical loads.

In recent years, the evolution of AGM batteries has been driven by the growing emphasis on sustainability in marine transport. This has led to the development of AGM batteries with higher energy density, longer cycle life, and improved resistance to deep discharge cycles. Modern AGM batteries now offer significantly better performance in terms of capacity retention and resistance to sulfation, addressing key reliability concerns in marine applications.

The latest advancements in AGM battery technology have focused on integrating smart battery management systems (BMS) and remote monitoring capabilities. These features allow for real-time performance tracking, predictive maintenance, and optimized charging strategies, further enhancing the reliability and longevity of AGM batteries in marine environments.

As the marine industry continues to prioritize sustainable transport solutions, the evolution of AGM batteries is likely to accelerate. Future developments may include the incorporation of nanomaterials to enhance electrode performance, advanced thermal management systems for improved efficiency in varying marine conditions, and the integration of AGM technology with hybrid propulsion systems for enhanced energy management in sustainable marine transport.

Marine Transport Market

The marine transport market has witnessed significant growth and transformation in recent years, driven by increasing global trade, technological advancements, and a growing focus on sustainability. As a crucial component of the global supply chain, marine transport plays a vital role in facilitating international commerce and economic development.

The market size of the marine transport industry is substantial, with container shipping alone accounting for a significant portion of global trade value. Major shipping routes connect key economic hubs across continents, with Asia-Europe, Transpacific, and Transatlantic routes being among the busiest. The industry has seen a trend towards larger vessels to achieve economies of scale, with mega-ships capable of carrying over 20,000 TEUs (Twenty-foot Equivalent Units) becoming more common.

In recent years, there has been a notable shift towards sustainable practices in marine transport. This change is driven by stricter environmental regulations, such as the International Maritime Organization's (IMO) 2020 sulfur cap and upcoming greenhouse gas emission reduction targets. As a result, the industry is exploring alternative fuels, energy-efficient technologies, and innovative propulsion systems to reduce its environmental footprint.

The adoption of digital technologies is another key trend shaping the marine transport market. Smart shipping solutions, including AI-powered route optimization, predictive maintenance, and autonomous vessel technologies, are gaining traction. These innovations aim to enhance operational efficiency, reduce costs, and improve safety in maritime operations.

The market landscape is characterized by a mix of established players and emerging companies. Traditional shipping giants continue to dominate, but new entrants specializing in sustainable solutions and digital technologies are making their mark. Collaborations between shipping companies, technology providers, and research institutions are becoming more common as the industry seeks to address complex challenges.

The COVID-19 pandemic has had a significant impact on the marine transport market, causing disruptions in global supply chains and fluctuations in demand. However, it has also accelerated certain trends, such as the adoption of digital solutions and the need for more resilient and flexible shipping networks.

Looking ahead, the marine transport market is expected to continue evolving, with a strong emphasis on sustainability, digitalization, and operational efficiency. The integration of renewable energy sources, advanced battery technologies, and smart systems will play a crucial role in shaping the future of the industry. As the sector navigates these changes, the reliability and performance of key components, such as AGM batteries, will be critical in ensuring the success of sustainable marine transport solutions.

The market size of the marine transport industry is substantial, with container shipping alone accounting for a significant portion of global trade value. Major shipping routes connect key economic hubs across continents, with Asia-Europe, Transpacific, and Transatlantic routes being among the busiest. The industry has seen a trend towards larger vessels to achieve economies of scale, with mega-ships capable of carrying over 20,000 TEUs (Twenty-foot Equivalent Units) becoming more common.

In recent years, there has been a notable shift towards sustainable practices in marine transport. This change is driven by stricter environmental regulations, such as the International Maritime Organization's (IMO) 2020 sulfur cap and upcoming greenhouse gas emission reduction targets. As a result, the industry is exploring alternative fuels, energy-efficient technologies, and innovative propulsion systems to reduce its environmental footprint.

The adoption of digital technologies is another key trend shaping the marine transport market. Smart shipping solutions, including AI-powered route optimization, predictive maintenance, and autonomous vessel technologies, are gaining traction. These innovations aim to enhance operational efficiency, reduce costs, and improve safety in maritime operations.

The market landscape is characterized by a mix of established players and emerging companies. Traditional shipping giants continue to dominate, but new entrants specializing in sustainable solutions and digital technologies are making their mark. Collaborations between shipping companies, technology providers, and research institutions are becoming more common as the industry seeks to address complex challenges.

The COVID-19 pandemic has had a significant impact on the marine transport market, causing disruptions in global supply chains and fluctuations in demand. However, it has also accelerated certain trends, such as the adoption of digital solutions and the need for more resilient and flexible shipping networks.

Looking ahead, the marine transport market is expected to continue evolving, with a strong emphasis on sustainability, digitalization, and operational efficiency. The integration of renewable energy sources, advanced battery technologies, and smart systems will play a crucial role in shaping the future of the industry. As the sector navigates these changes, the reliability and performance of key components, such as AGM batteries, will be critical in ensuring the success of sustainable marine transport solutions.

AGM Battery Challenges

AGM (Absorbent Glass Mat) batteries face several significant challenges in sustainable marine transport applications, primarily due to the unique and demanding environment of maritime operations. One of the foremost issues is the constant exposure to moisture and salt spray, which can accelerate corrosion and reduce battery life. This harsh marine environment necessitates robust sealing and protective measures to ensure longevity and reliability.

Another critical challenge is the need for consistent performance under varying temperature conditions. Marine vessels often operate in diverse climates, from tropical heat to arctic cold. AGM batteries must maintain their efficiency and capacity across this wide temperature range, which can be particularly challenging in extreme conditions. Temperature fluctuations can affect charging efficiency, discharge rates, and overall battery life.

The deep-cycle nature of marine applications poses another significant challenge. Unlike automotive batteries, which primarily provide short bursts of high current, marine batteries often need to deliver steady power over extended periods. This deep-cycling can lead to faster degradation of the battery's internal components if not properly managed, potentially reducing the overall lifespan of the battery.

Vibration and shock resistance are also crucial factors in marine environments. The constant motion of vessels, combined with occasional rough seas, can cause physical stress on battery components. AGM batteries must be designed to withstand these conditions without compromising their structural integrity or performance.

Weight and space constraints present additional challenges in marine applications. While AGM batteries are generally more compact than traditional flooded lead-acid batteries, there is ongoing pressure to further reduce size and weight without sacrificing power output or capacity. This is particularly important in smaller vessels where space is at a premium.

Charging efficiency and management in marine environments pose unique challenges. The variable power generation from onboard systems (such as solar panels or wind turbines) and the need for rapid recharging during short port stays require sophisticated charging systems. These systems must be capable of optimizing charging cycles to maximize battery life while ensuring sufficient power availability.

Lastly, the environmental impact of AGM batteries in marine applications is a growing concern. While they are sealed and spill-proof, which is advantageous in marine settings, the disposal and recycling of these batteries at the end of their life cycle present environmental challenges that need to be addressed for truly sustainable marine transport solutions.

Another critical challenge is the need for consistent performance under varying temperature conditions. Marine vessels often operate in diverse climates, from tropical heat to arctic cold. AGM batteries must maintain their efficiency and capacity across this wide temperature range, which can be particularly challenging in extreme conditions. Temperature fluctuations can affect charging efficiency, discharge rates, and overall battery life.

The deep-cycle nature of marine applications poses another significant challenge. Unlike automotive batteries, which primarily provide short bursts of high current, marine batteries often need to deliver steady power over extended periods. This deep-cycling can lead to faster degradation of the battery's internal components if not properly managed, potentially reducing the overall lifespan of the battery.

Vibration and shock resistance are also crucial factors in marine environments. The constant motion of vessels, combined with occasional rough seas, can cause physical stress on battery components. AGM batteries must be designed to withstand these conditions without compromising their structural integrity or performance.

Weight and space constraints present additional challenges in marine applications. While AGM batteries are generally more compact than traditional flooded lead-acid batteries, there is ongoing pressure to further reduce size and weight without sacrificing power output or capacity. This is particularly important in smaller vessels where space is at a premium.

Charging efficiency and management in marine environments pose unique challenges. The variable power generation from onboard systems (such as solar panels or wind turbines) and the need for rapid recharging during short port stays require sophisticated charging systems. These systems must be capable of optimizing charging cycles to maximize battery life while ensuring sufficient power availability.

Lastly, the environmental impact of AGM batteries in marine applications is a growing concern. While they are sealed and spill-proof, which is advantageous in marine settings, the disposal and recycling of these batteries at the end of their life cycle present environmental challenges that need to be addressed for truly sustainable marine transport solutions.

AGM Battery Solutions

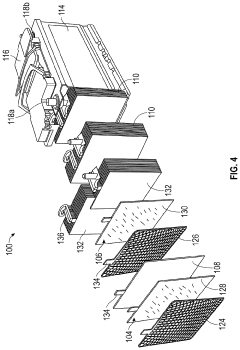

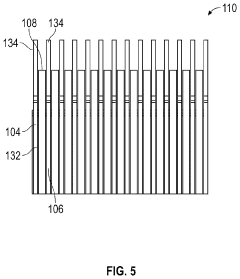

01 Improved electrolyte management

AGM batteries employ advanced electrolyte management techniques to enhance reliability. This includes optimized absorption and distribution of the electrolyte within the glass mat separator, reducing the risk of acid stratification and improving overall performance and longevity.- Improved electrolyte management: AGM batteries employ advanced electrolyte management techniques to enhance reliability. This includes optimized absorption and distribution of the electrolyte within the glass mat separator, reducing the risk of acid stratification and improving overall battery performance and longevity.

- Enhanced plate design and materials: Reliability of AGM batteries is improved through innovative plate designs and advanced materials. This includes the use of high-purity lead alloys, optimized grid structures, and corrosion-resistant coatings to extend battery life and maintain consistent performance over time.

- Advanced charging and monitoring systems: AGM battery reliability is enhanced through sophisticated charging and monitoring systems. These include intelligent charge controllers, temperature compensation, and real-time battery health monitoring, which help prevent overcharging, optimize charging cycles, and extend battery lifespan.

- Thermal management solutions: Improved thermal management techniques contribute to AGM battery reliability. This includes innovative heat dissipation designs, temperature-resistant materials, and thermal runaway prevention mechanisms, ensuring stable performance across various operating conditions.

- Manufacturing process enhancements: Reliability of AGM batteries is improved through advanced manufacturing processes. This includes precision assembly techniques, automated quality control systems, and stringent testing procedures to ensure consistent product quality and performance across production batches.

02 Enhanced plate design and materials

Innovations in plate design and materials contribute to increased AGM battery reliability. This involves using high-purity lead alloys, optimized grid structures, and advanced active material formulations to improve capacity, cycle life, and resistance to corrosion and sulfation.Expand Specific Solutions03 Thermal management systems

Implementing effective thermal management systems in AGM batteries helps maintain optimal operating temperatures, preventing overheating and extending battery life. This includes improved heat dissipation designs and temperature monitoring technologies.Expand Specific Solutions04 Advanced charging algorithms

Developing sophisticated charging algorithms tailored for AGM batteries enhances their reliability by optimizing the charging process. These algorithms help prevent overcharging, reduce water loss, and minimize grid corrosion, ultimately extending the battery's service life.Expand Specific Solutions05 Improved manufacturing processes

Enhancing AGM battery reliability through advanced manufacturing techniques, including precision assembly methods, quality control measures, and automated production processes. These improvements ensure consistent product quality and reduce the likelihood of manufacturing defects.Expand Specific Solutions

Marine Battery Players

The evaluation of AGM battery reliability in sustainable marine transport is currently in a growth phase, with increasing market size due to the rising demand for eco-friendly maritime solutions. The technology's maturity is advancing, as evidenced by the involvement of key players across various sectors. Companies like Fengfan Co., Ltd. and Tianneng Battery Group Co., Ltd. are leading in battery manufacturing, while LG Energy Solution Ltd. and Daramic LLC contribute to energy solutions and separator technologies. Academic institutions such as Tianjin University and Northwestern Polytechnical University are driving research and innovation. The competitive landscape is diverse, with traditional battery manufacturers competing alongside newer entrants and research institutions, indicating a dynamic and evolving market for AGM battery technology in marine applications.

Fengfan Co., Ltd.

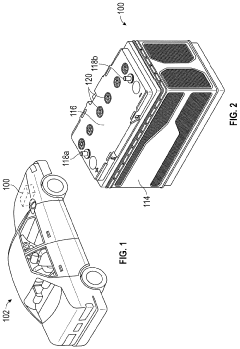

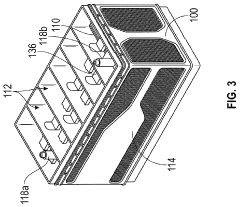

Technical Solution: Fengfan Co., Ltd. has developed AGM batteries designed for use in marine transport applications. Their technology focuses on enhancing battery life and reliability in harsh marine environments. Fengfan's AGM batteries utilize a proprietary grid alloy that improves corrosion resistance and reduces grid growth, leading to extended battery life in marine conditions[9]. The company has implemented an advanced plate formation process that enhances active material utilization and improves overall battery efficiency. Fengfan's batteries also feature a robust case design with reinforced terminals to withstand vibration and shock in marine applications. Additionally, they have developed a specialized electrolyte formulation that improves charge acceptance and reduces water loss, contributing to improved performance and reduced maintenance requirements in marine transport settings[10].

Strengths: Enhanced corrosion resistance, improved efficiency, robust design for marine use. Weaknesses: May have limited global presence compared to larger international competitors, potential for higher costs in some markets.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced AGM (Absorbent Glass Mat) batteries specifically designed for marine applications. Their technology incorporates high-purity lead alloys and advanced separator materials to enhance durability in harsh marine environments. The company's AGM batteries feature a proprietary electrolyte formulation that improves charge acceptance and reduces water loss, extending battery life in marine conditions[1]. LG's batteries also utilize a robust internal structure to withstand vibrations and shocks common in marine transport. Additionally, they have implemented smart battery management systems that monitor battery health and optimize performance, contributing to improved reliability and sustainability in marine applications[2].

Strengths: Advanced materials and design for marine-specific challenges, smart monitoring systems. Weaknesses: Potentially higher cost compared to traditional lead-acid batteries, limited long-term data on performance in extreme marine conditions.

AGM Battery Innovations

Negative mass for lead-acid battery electrodes and lead-acid battery including same

PatentActiveUS20210336249A1

Innovation

- The introduction of additives such as fine particle barium sulfate, two organic compounds (oxylignins), and a carbonaceous material to the negative active material in lead-acid battery electrodes, which are pre-mixed to form a blended expander mixture, improving the homogeneity and dispersion of the battery paste and enhancing the battery's cycling performance and water retention.

AGM battery recovery and capacity tester

PatentInactiveUS20110199058A1

Innovation

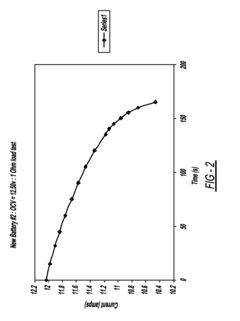

- A system comprising a battery charger, load test resistor, control relay, and electronic controller that automates the charging and load testing of AGM batteries, using a load test resistor to calculate capacity in ampere-hours and a recovery procedure involving constant current charging and discharging to restore battery capacity.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) batteries in sustainable marine transport is a critical consideration for the maritime industry's efforts to reduce its ecological footprint. AGM batteries, known for their high performance and reliability, offer several environmental advantages over traditional lead-acid batteries. These batteries are sealed and maintenance-free, significantly reducing the risk of acid spills and contamination in marine environments. The absence of liquid electrolyte also minimizes the potential for leakage during transportation and use, further protecting aquatic ecosystems.

AGM batteries demonstrate improved energy efficiency compared to conventional batteries, which translates to reduced energy consumption and lower greenhouse gas emissions associated with battery charging. This efficiency is particularly beneficial in marine applications, where energy conservation is crucial for extending vessel range and reducing overall fuel consumption. Additionally, the longer lifespan of AGM batteries contributes to a decrease in battery replacement frequency, thereby reducing waste generation and the environmental impact of battery production and disposal.

The recyclability of AGM batteries is another significant environmental benefit. These batteries are highly recyclable, with up to 99% of their components being recoverable and reusable. This high recycling rate helps conserve natural resources and minimize the environmental impact of battery production. The recycling process for AGM batteries is also more straightforward and less hazardous compared to that of flooded lead-acid batteries, further reducing the potential for environmental contamination during end-of-life management.

However, it is important to note that the production of AGM batteries still involves the use of lead and other potentially harmful materials. While the sealed design mitigates many risks associated with these materials during use, proper handling and disposal procedures remain crucial to prevent environmental contamination. The maritime industry must ensure compliance with international regulations governing the transport and disposal of batteries to minimize potential negative impacts on marine ecosystems.

In the context of sustainable marine transport, the adoption of AGM batteries contributes to the overall reduction of vessel emissions and environmental impact. By providing reliable and efficient power storage, these batteries support the integration of renewable energy sources, such as solar and wind power, into marine propulsion systems. This integration is key to reducing the reliance on fossil fuels and decreasing the carbon footprint of maritime operations.

AGM batteries demonstrate improved energy efficiency compared to conventional batteries, which translates to reduced energy consumption and lower greenhouse gas emissions associated with battery charging. This efficiency is particularly beneficial in marine applications, where energy conservation is crucial for extending vessel range and reducing overall fuel consumption. Additionally, the longer lifespan of AGM batteries contributes to a decrease in battery replacement frequency, thereby reducing waste generation and the environmental impact of battery production and disposal.

The recyclability of AGM batteries is another significant environmental benefit. These batteries are highly recyclable, with up to 99% of their components being recoverable and reusable. This high recycling rate helps conserve natural resources and minimize the environmental impact of battery production. The recycling process for AGM batteries is also more straightforward and less hazardous compared to that of flooded lead-acid batteries, further reducing the potential for environmental contamination during end-of-life management.

However, it is important to note that the production of AGM batteries still involves the use of lead and other potentially harmful materials. While the sealed design mitigates many risks associated with these materials during use, proper handling and disposal procedures remain crucial to prevent environmental contamination. The maritime industry must ensure compliance with international regulations governing the transport and disposal of batteries to minimize potential negative impacts on marine ecosystems.

In the context of sustainable marine transport, the adoption of AGM batteries contributes to the overall reduction of vessel emissions and environmental impact. By providing reliable and efficient power storage, these batteries support the integration of renewable energy sources, such as solar and wind power, into marine propulsion systems. This integration is key to reducing the reliance on fossil fuels and decreasing the carbon footprint of maritime operations.

Safety Regulations

Safety regulations play a crucial role in ensuring the reliability and safe operation of AGM (Absorbent Glass Mat) batteries in sustainable marine transport. These regulations are designed to address the unique challenges posed by the marine environment and the specific characteristics of AGM batteries.

Maritime safety organizations, such as the International Maritime Organization (IMO) and classification societies, have established comprehensive guidelines for the use of batteries in marine applications. These regulations cover various aspects, including installation, maintenance, and emergency procedures. For AGM batteries, specific attention is given to their sealed design and the potential risks associated with hydrogen gas emission during charging.

One of the key safety requirements for AGM batteries in marine transport is proper ventilation. Although AGM batteries are considered sealed and maintenance-free, they can still produce small amounts of hydrogen gas during charging. Adequate ventilation systems must be in place to prevent the accumulation of potentially explosive gases in confined spaces.

Electrical safety is another critical aspect addressed by regulations. AGM batteries must be installed with appropriate circuit protection devices, including fuses and circuit breakers, to prevent overcharging, short circuits, and other electrical faults. The battery management system (BMS) is also subject to regulatory scrutiny, as it plays a vital role in monitoring and controlling the battery's state of charge, temperature, and overall health.

Fire safety regulations are particularly stringent for marine applications. AGM batteries must be installed in fire-resistant enclosures and equipped with fire detection and suppression systems. The regulations also specify requirements for thermal runaway prevention and containment, as well as procedures for emergency response in case of battery-related incidents.

Environmental protection is an integral part of safety regulations for AGM batteries in marine transport. Guidelines are in place to ensure proper disposal and recycling of batteries at the end of their service life, minimizing the environmental impact of hazardous materials.

Regular inspection and maintenance protocols are mandated by safety regulations to ensure the ongoing reliability of AGM batteries. These include periodic capacity tests, visual inspections for signs of damage or corrosion, and verification of the battery management system's functionality.

Training requirements for crew members are also outlined in safety regulations. Personnel responsible for operating and maintaining AGM battery systems must receive specialized training on safety procedures, emergency response, and proper handling of battery-related equipment.

Compliance with these safety regulations is essential for vessel certification and insurance purposes. Shipowners and operators must demonstrate adherence to these standards through documentation, regular audits, and inspections by relevant authorities.

As technology evolves and more experience is gained with AGM batteries in marine applications, safety regulations continue to be updated and refined. This ongoing process ensures that the regulatory framework remains effective in addressing emerging risks and challenges associated with the use of AGM batteries in sustainable marine transport.

Maritime safety organizations, such as the International Maritime Organization (IMO) and classification societies, have established comprehensive guidelines for the use of batteries in marine applications. These regulations cover various aspects, including installation, maintenance, and emergency procedures. For AGM batteries, specific attention is given to their sealed design and the potential risks associated with hydrogen gas emission during charging.

One of the key safety requirements for AGM batteries in marine transport is proper ventilation. Although AGM batteries are considered sealed and maintenance-free, they can still produce small amounts of hydrogen gas during charging. Adequate ventilation systems must be in place to prevent the accumulation of potentially explosive gases in confined spaces.

Electrical safety is another critical aspect addressed by regulations. AGM batteries must be installed with appropriate circuit protection devices, including fuses and circuit breakers, to prevent overcharging, short circuits, and other electrical faults. The battery management system (BMS) is also subject to regulatory scrutiny, as it plays a vital role in monitoring and controlling the battery's state of charge, temperature, and overall health.

Fire safety regulations are particularly stringent for marine applications. AGM batteries must be installed in fire-resistant enclosures and equipped with fire detection and suppression systems. The regulations also specify requirements for thermal runaway prevention and containment, as well as procedures for emergency response in case of battery-related incidents.

Environmental protection is an integral part of safety regulations for AGM batteries in marine transport. Guidelines are in place to ensure proper disposal and recycling of batteries at the end of their service life, minimizing the environmental impact of hazardous materials.

Regular inspection and maintenance protocols are mandated by safety regulations to ensure the ongoing reliability of AGM batteries. These include periodic capacity tests, visual inspections for signs of damage or corrosion, and verification of the battery management system's functionality.

Training requirements for crew members are also outlined in safety regulations. Personnel responsible for operating and maintaining AGM battery systems must receive specialized training on safety procedures, emergency response, and proper handling of battery-related equipment.

Compliance with these safety regulations is essential for vessel certification and insurance purposes. Shipowners and operators must demonstrate adherence to these standards through documentation, regular audits, and inspections by relevant authorities.

As technology evolves and more experience is gained with AGM batteries in marine applications, safety regulations continue to be updated and refined. This ongoing process ensures that the regulatory framework remains effective in addressing emerging risks and challenges associated with the use of AGM batteries in sustainable marine transport.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!