Exploring Charge Duration Impact on AGM Battery Life

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

Absorbed Glass Mat (AGM) batteries have undergone significant evolution since their inception in the 1980s. Initially developed for military aircraft, these batteries quickly found applications in various industries due to their superior performance characteristics. The evolution of AGM batteries can be traced through several key stages, each marked by technological advancements and expanding use cases.

In the early stages, AGM batteries were primarily used in specialized applications such as aircraft and military vehicles. The focus was on improving the basic design to enhance safety and reliability. As the technology matured, manufacturers began to explore ways to increase the power density and cycle life of these batteries.

The 1990s saw a rapid expansion of AGM battery applications into the automotive sector. This period was characterized by improvements in manufacturing processes, leading to more consistent quality and lower production costs. The automotive industry's adoption of AGM batteries was driven by the increasing electrical demands of modern vehicles and the need for more reliable starting power.

By the early 2000s, AGM batteries had become a popular choice for uninterruptible power supplies (UPS) and renewable energy storage systems. This phase of evolution focused on enhancing the deep-cycle capabilities of AGM batteries, allowing for more efficient energy storage and longer service life in cyclic applications.

The mid-2000s to early 2010s marked a significant leap in AGM battery technology. Advancements in electrode design and electrolyte formulations led to batteries with higher specific energy and improved charge acceptance rates. These improvements made AGM batteries increasingly attractive for use in hybrid vehicles and start-stop systems, further solidifying their position in the automotive market.

Recent years have seen a focus on optimizing AGM batteries for specific applications. This includes the development of high-performance AGM batteries for racing and high-end vehicles, as well as specialized versions for renewable energy storage. Manufacturers have also been working on improving the environmental footprint of AGM batteries, exploring ways to enhance recyclability and reduce the use of harmful materials.

The latest trend in AGM battery evolution is the integration of smart technology. Modern AGM batteries are being equipped with sensors and monitoring systems that provide real-time data on battery health, state of charge, and performance. This development is particularly crucial for applications in electric vehicles and grid-scale energy storage, where precise battery management is essential.

As we look to the future, the evolution of AGM batteries is likely to continue along several paths. Research is ongoing to further increase energy density, improve charge acceptance rates, and extend cycle life. There is also a growing focus on developing AGM batteries that can operate efficiently in extreme temperature conditions, broadening their potential applications.

In the early stages, AGM batteries were primarily used in specialized applications such as aircraft and military vehicles. The focus was on improving the basic design to enhance safety and reliability. As the technology matured, manufacturers began to explore ways to increase the power density and cycle life of these batteries.

The 1990s saw a rapid expansion of AGM battery applications into the automotive sector. This period was characterized by improvements in manufacturing processes, leading to more consistent quality and lower production costs. The automotive industry's adoption of AGM batteries was driven by the increasing electrical demands of modern vehicles and the need for more reliable starting power.

By the early 2000s, AGM batteries had become a popular choice for uninterruptible power supplies (UPS) and renewable energy storage systems. This phase of evolution focused on enhancing the deep-cycle capabilities of AGM batteries, allowing for more efficient energy storage and longer service life in cyclic applications.

The mid-2000s to early 2010s marked a significant leap in AGM battery technology. Advancements in electrode design and electrolyte formulations led to batteries with higher specific energy and improved charge acceptance rates. These improvements made AGM batteries increasingly attractive for use in hybrid vehicles and start-stop systems, further solidifying their position in the automotive market.

Recent years have seen a focus on optimizing AGM batteries for specific applications. This includes the development of high-performance AGM batteries for racing and high-end vehicles, as well as specialized versions for renewable energy storage. Manufacturers have also been working on improving the environmental footprint of AGM batteries, exploring ways to enhance recyclability and reduce the use of harmful materials.

The latest trend in AGM battery evolution is the integration of smart technology. Modern AGM batteries are being equipped with sensors and monitoring systems that provide real-time data on battery health, state of charge, and performance. This development is particularly crucial for applications in electric vehicles and grid-scale energy storage, where precise battery management is essential.

As we look to the future, the evolution of AGM batteries is likely to continue along several paths. Research is ongoing to further increase energy density, improve charge acceptance rates, and extend cycle life. There is also a growing focus on developing AGM batteries that can operate efficiently in extreme temperature conditions, broadening their potential applications.

Market Demand Analysis

The market demand for AGM (Absorbent Glass Mat) batteries has been steadily increasing due to their superior performance characteristics and versatility across various applications. In the automotive sector, AGM batteries are gaining traction as the preferred choice for start-stop systems in modern vehicles, which aim to improve fuel efficiency and reduce emissions. This trend is driven by stringent environmental regulations and consumer demand for more eco-friendly transportation options.

The renewable energy sector is another significant driver of AGM battery demand. As the adoption of solar and wind power continues to grow, the need for reliable energy storage solutions has become paramount. AGM batteries offer an attractive option for off-grid and grid-tied renewable energy systems due to their deep-cycle capabilities and maintenance-free operation.

In the telecommunications industry, AGM batteries are widely used as backup power sources for cell towers and other critical infrastructure. The rapid expansion of 5G networks worldwide is expected to further boost the demand for these batteries, as reliable power backup becomes increasingly crucial for maintaining network uptime and performance.

The marine and recreational vehicle markets also contribute to the growing demand for AGM batteries. Boating enthusiasts and RV owners appreciate the batteries' ability to withstand vibrations, their leak-proof design, and their capacity to provide consistent power for extended periods.

Market analysis indicates that the global AGM battery market is projected to experience substantial growth in the coming years. Factors such as increasing urbanization, rising disposable incomes, and growing awareness of energy-efficient technologies are expected to drive this expansion. Additionally, the ongoing electrification of various industries and the push towards smart grid systems are likely to create new opportunities for AGM battery applications.

However, the market also faces challenges. The emergence of lithium-ion batteries as a competing technology in some applications poses a potential threat to AGM battery market share. Lithium-ion batteries offer higher energy density and longer cycle life, which may make them more attractive for certain use cases.

Despite this competition, AGM batteries maintain several advantages, including lower initial cost, better performance in extreme temperatures, and a more established recycling infrastructure. These factors continue to support their strong market position and ongoing demand across various sectors.

As research into charge duration impact on AGM battery life progresses, the findings could significantly influence market dynamics. Improved understanding of optimal charging practices may lead to enhanced battery performance and longevity, potentially expanding the range of applications and increasing market penetration for AGM batteries.

The renewable energy sector is another significant driver of AGM battery demand. As the adoption of solar and wind power continues to grow, the need for reliable energy storage solutions has become paramount. AGM batteries offer an attractive option for off-grid and grid-tied renewable energy systems due to their deep-cycle capabilities and maintenance-free operation.

In the telecommunications industry, AGM batteries are widely used as backup power sources for cell towers and other critical infrastructure. The rapid expansion of 5G networks worldwide is expected to further boost the demand for these batteries, as reliable power backup becomes increasingly crucial for maintaining network uptime and performance.

The marine and recreational vehicle markets also contribute to the growing demand for AGM batteries. Boating enthusiasts and RV owners appreciate the batteries' ability to withstand vibrations, their leak-proof design, and their capacity to provide consistent power for extended periods.

Market analysis indicates that the global AGM battery market is projected to experience substantial growth in the coming years. Factors such as increasing urbanization, rising disposable incomes, and growing awareness of energy-efficient technologies are expected to drive this expansion. Additionally, the ongoing electrification of various industries and the push towards smart grid systems are likely to create new opportunities for AGM battery applications.

However, the market also faces challenges. The emergence of lithium-ion batteries as a competing technology in some applications poses a potential threat to AGM battery market share. Lithium-ion batteries offer higher energy density and longer cycle life, which may make them more attractive for certain use cases.

Despite this competition, AGM batteries maintain several advantages, including lower initial cost, better performance in extreme temperatures, and a more established recycling infrastructure. These factors continue to support their strong market position and ongoing demand across various sectors.

As research into charge duration impact on AGM battery life progresses, the findings could significantly influence market dynamics. Improved understanding of optimal charging practices may lead to enhanced battery performance and longevity, potentially expanding the range of applications and increasing market penetration for AGM batteries.

Technical Challenges

The exploration of charge duration impact on AGM (Absorbent Glass Mat) battery life faces several significant technical challenges. One of the primary obstacles is the complex interplay between charging parameters and battery degradation mechanisms. Prolonged charging at high voltages can lead to accelerated corrosion of the positive grid, while insufficient charging may result in sulfation, both of which severely impact battery longevity.

Accurately measuring and monitoring the state of charge (SOC) and state of health (SOH) of AGM batteries in real-time presents another formidable challenge. Current sensing technologies often lack the precision required to detect subtle changes in battery condition, especially as the battery ages. This limitation hampers the development of adaptive charging algorithms that could optimize charge duration based on the battery's current state.

The thermal management of AGM batteries during charging is a critical issue that demands innovative solutions. Extended charging periods can lead to increased heat generation, potentially causing thermal runaway and premature battery failure. Developing efficient cooling systems or charge protocols that minimize heat buildup without compromising charge efficiency remains a significant technical hurdle.

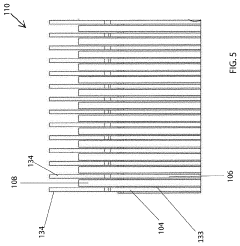

Another challenge lies in understanding and mitigating the effects of charge duration on the microstructure of the AGM separator. Prolonged exposure to charging currents may alter the glass mat's porosity and fiber structure, affecting its ability to retain electrolyte and maintain proper acid stratification. This phenomenon is not yet fully understood and requires advanced materials science research to address.

The variability in AGM battery manufacturing processes and materials introduces additional complexity to charge duration studies. Inconsistencies in plate composition, electrolyte distribution, and separator quality can lead to disparate results in charge duration experiments, making it difficult to establish universally applicable charging protocols.

Developing accelerated life testing methodologies that accurately simulate the long-term effects of various charge durations poses a significant challenge. Traditional cycling tests may not adequately capture the nuanced impacts of charge duration on battery life, necessitating the creation of more sophisticated testing regimes that can provide reliable predictions of battery performance over extended periods.

Lastly, the integration of advanced charging technologies, such as pulse charging or multi-stage charging algorithms, into existing battery management systems presents both technical and economic challenges. Balancing the potential benefits of these technologies with the increased complexity and cost of implementation requires careful consideration and extensive validation testing.

Accurately measuring and monitoring the state of charge (SOC) and state of health (SOH) of AGM batteries in real-time presents another formidable challenge. Current sensing technologies often lack the precision required to detect subtle changes in battery condition, especially as the battery ages. This limitation hampers the development of adaptive charging algorithms that could optimize charge duration based on the battery's current state.

The thermal management of AGM batteries during charging is a critical issue that demands innovative solutions. Extended charging periods can lead to increased heat generation, potentially causing thermal runaway and premature battery failure. Developing efficient cooling systems or charge protocols that minimize heat buildup without compromising charge efficiency remains a significant technical hurdle.

Another challenge lies in understanding and mitigating the effects of charge duration on the microstructure of the AGM separator. Prolonged exposure to charging currents may alter the glass mat's porosity and fiber structure, affecting its ability to retain electrolyte and maintain proper acid stratification. This phenomenon is not yet fully understood and requires advanced materials science research to address.

The variability in AGM battery manufacturing processes and materials introduces additional complexity to charge duration studies. Inconsistencies in plate composition, electrolyte distribution, and separator quality can lead to disparate results in charge duration experiments, making it difficult to establish universally applicable charging protocols.

Developing accelerated life testing methodologies that accurately simulate the long-term effects of various charge durations poses a significant challenge. Traditional cycling tests may not adequately capture the nuanced impacts of charge duration on battery life, necessitating the creation of more sophisticated testing regimes that can provide reliable predictions of battery performance over extended periods.

Lastly, the integration of advanced charging technologies, such as pulse charging or multi-stage charging algorithms, into existing battery management systems presents both technical and economic challenges. Balancing the potential benefits of these technologies with the increased complexity and cost of implementation requires careful consideration and extensive validation testing.

Current Charging Methods

01 Improved electrolyte composition

Enhancing the electrolyte composition in AGM batteries can significantly improve their lifespan. This includes optimizing the concentration of sulfuric acid, adding specific additives, or using gel electrolytes to reduce electrolyte stratification and minimize plate sulfation. These improvements can lead to better charge acceptance, reduced self-discharge, and overall longer battery life.- Improved electrolyte composition: Enhancing the electrolyte composition in AGM batteries can significantly improve their lifespan. This includes optimizing the concentration of sulfuric acid, adding specific additives, or using gel electrolytes to reduce electrolyte stratification and minimize internal resistance. These improvements can lead to better charge acceptance, reduced self-discharge, and overall longer battery life.

- Advanced plate design and materials: Implementing innovative plate designs and using high-performance materials can extend AGM battery life. This may involve using thicker plates, incorporating corrosion-resistant alloys, or utilizing advanced grid designs to improve current distribution and reduce plate degradation over time. These enhancements can result in increased cycle life and improved overall battery performance.

- Intelligent battery management systems: Integrating smart battery management systems can optimize charging and discharging processes, thereby extending AGM battery life. These systems can monitor battery parameters in real-time, adjust charging algorithms, and prevent overcharging or deep discharging. By maintaining optimal operating conditions, the battery's lifespan can be significantly increased.

- Temperature control and thermal management: Implementing effective temperature control and thermal management strategies can prolong AGM battery life. This may include using advanced cooling systems, heat-dissipating materials, or temperature-sensitive charging algorithms. Maintaining optimal operating temperatures can reduce chemical degradation, prevent thermal runaway, and extend the overall lifespan of the battery.

- Nanotechnology and advanced separators: Incorporating nanotechnology and advanced separator materials can enhance AGM battery performance and longevity. This may involve using nanostructured electrodes, carbon-based additives, or high-performance separator materials to improve charge transfer, reduce internal resistance, and prevent short circuits. These innovations can lead to increased cycle life and improved overall battery durability.

02 Advanced plate design and materials

Implementing innovative plate designs and using advanced materials can enhance the performance and longevity of AGM batteries. This may involve using high-purity lead alloys, optimizing grid structures, or incorporating nano-materials to improve conductivity and reduce corrosion. Such advancements can result in increased cycle life and improved capacity retention over time.Expand Specific Solutions03 Intelligent battery management systems

Integrating smart battery management systems can significantly extend AGM battery life. These systems can monitor battery parameters in real-time, optimize charging processes, and implement protective measures against overcharging or deep discharging. By maintaining optimal operating conditions, these systems help prevent premature battery degradation and extend overall lifespan.Expand Specific Solutions04 Thermal management techniques

Implementing effective thermal management techniques can greatly impact AGM battery life. This includes designing battery casings with improved heat dissipation properties, using phase-change materials for temperature regulation, or incorporating active cooling systems. Maintaining optimal operating temperatures helps prevent accelerated aging and degradation of battery components, thereby extending overall battery life.Expand Specific Solutions05 Charge optimization algorithms

Developing and implementing advanced charge optimization algorithms can significantly enhance AGM battery life. These algorithms can adapt charging profiles based on battery age, usage patterns, and environmental conditions. By optimizing charging rates, voltage levels, and charge durations, these algorithms can minimize stress on battery components, reduce capacity loss over time, and extend overall battery lifespan.Expand Specific Solutions

Key Industry Players

The exploration of charge duration impact on AGM battery life is currently in a growth phase, with increasing market demand driven by automotive and renewable energy sectors. The global AGV battery market size is projected to reach significant growth in the coming years. Technologically, AGM batteries are relatively mature, but ongoing research focuses on improving their performance and lifespan. Companies like Fengfan Co., Ltd., Tianneng Battery Group, and Samsung SDI are at the forefront of AGM battery development, investing in R&D to enhance charge duration and overall battery efficiency. Other players such as Exide Technologies and Johnson Controls are also contributing to advancements in this field.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced AGM (Absorbent Glass Mat) battery technology that focuses on optimizing charge duration impact on battery life. Their approach involves using a proprietary electrolyte formulation that reduces sulfation during charging cycles[1]. This formulation allows for faster charge acceptance and helps maintain the battery's capacity over time. Samsung's AGM batteries also incorporate a unique plate design that enhances charge distribution, reducing localized stress on the battery components during charging[3]. Additionally, they have implemented an intelligent battery management system that monitors and adjusts charging parameters in real-time, ensuring optimal charge duration and minimizing degradation factors[5].

Strengths: Advanced electrolyte formulation reduces sulfation; Intelligent BMS for optimized charging; Improved plate design for better charge distribution. Weaknesses: Potentially higher cost due to advanced technologies; May require specialized charging equipment for optimal performance.

Stryten Energy LLC

Technical Solution: Stryten Energy has developed a novel approach to AGM battery technology that addresses charge duration impact on battery life. Their solution incorporates a patented carbon additive in the negative plates, which significantly improves charge acceptance and reduces the risk of sulfation during extended charging periods[2]. Stryten's AGM batteries also feature a proprietary separator material that enhances electrolyte distribution and retention, leading to more uniform charging across the battery cells[4]. Furthermore, they have implemented an advanced venting system that helps regulate internal pressure during charging, reducing the risk of dry-out and extending overall battery life[6].

Strengths: Patented carbon additive improves charge acceptance; Advanced separator material for uniform charging; Innovative venting system prolongs battery life. Weaknesses: May have higher initial costs; Potential compatibility issues with some existing charging systems.

Charge Duration Research

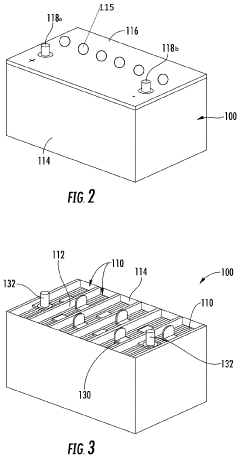

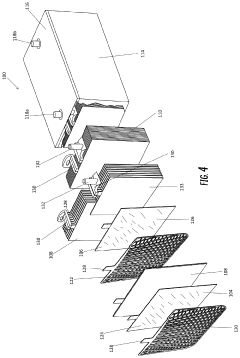

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Lead-acid battery and manufacture method

PatentWO2024047491A1

Innovation

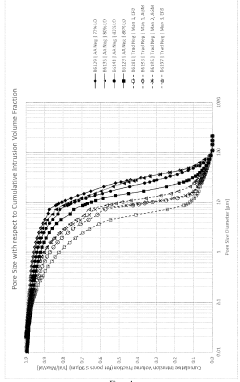

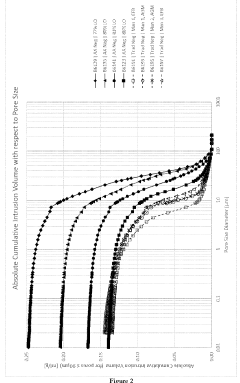

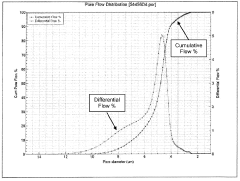

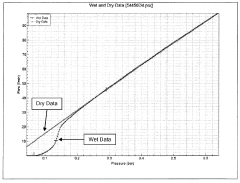

- A lead-acid battery design featuring a positive and negative electrode with a specific pore size diameter distribution, measured by mercury porosimetry, and a separator with a tailored pore size distribution, measured by capillary flow porometry, to enhance electrolyte immobilization and reduce water loss.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) batteries, particularly in relation to charge duration, is a critical aspect to consider in the broader context of sustainable energy storage solutions. AGM batteries, known for their low maintenance requirements and high performance, have gained popularity in various applications, including automotive, renewable energy systems, and backup power supplies.

One of the primary environmental concerns associated with AGM batteries is the potential for increased energy consumption during charging processes. Longer charge durations may lead to higher overall energy usage, which can indirectly contribute to increased carbon emissions if the electricity source is not renewable. This aspect becomes particularly significant in large-scale applications or in regions heavily reliant on fossil fuels for electricity generation.

However, it is important to note that AGM batteries generally have a longer lifespan compared to traditional lead-acid batteries when properly maintained. This extended life cycle can result in reduced waste generation and less frequent battery replacements, potentially offsetting some of the environmental impacts associated with manufacturing and disposal processes.

The recycling potential of AGM batteries is another crucial factor in assessing their environmental impact. These batteries are highly recyclable, with up to 99% of their components being recoverable and reusable. Efficient recycling processes can significantly reduce the demand for raw materials and minimize the environmental footprint associated with battery production.

When considering the charge duration's impact on AGM battery life, it is essential to recognize the potential for optimized charging strategies to enhance battery longevity. Implementing smart charging algorithms and advanced battery management systems can help minimize overcharging, which not only extends battery life but also reduces unnecessary energy consumption and associated environmental impacts.

Furthermore, the environmental implications of AGM batteries extend to their role in supporting renewable energy integration. By providing reliable energy storage solutions for intermittent renewable sources like solar and wind power, AGM batteries contribute to the broader goal of reducing reliance on fossil fuels and mitigating climate change impacts.

In conclusion, while the environmental impact of AGM batteries in relation to charge duration is a complex issue, it is clear that proper management and optimization of charging processes can significantly influence their overall ecological footprint. As technology continues to advance, further improvements in battery efficiency and charging strategies are likely to enhance the environmental performance of AGM batteries, solidifying their position as a key component in sustainable energy systems.

One of the primary environmental concerns associated with AGM batteries is the potential for increased energy consumption during charging processes. Longer charge durations may lead to higher overall energy usage, which can indirectly contribute to increased carbon emissions if the electricity source is not renewable. This aspect becomes particularly significant in large-scale applications or in regions heavily reliant on fossil fuels for electricity generation.

However, it is important to note that AGM batteries generally have a longer lifespan compared to traditional lead-acid batteries when properly maintained. This extended life cycle can result in reduced waste generation and less frequent battery replacements, potentially offsetting some of the environmental impacts associated with manufacturing and disposal processes.

The recycling potential of AGM batteries is another crucial factor in assessing their environmental impact. These batteries are highly recyclable, with up to 99% of their components being recoverable and reusable. Efficient recycling processes can significantly reduce the demand for raw materials and minimize the environmental footprint associated with battery production.

When considering the charge duration's impact on AGM battery life, it is essential to recognize the potential for optimized charging strategies to enhance battery longevity. Implementing smart charging algorithms and advanced battery management systems can help minimize overcharging, which not only extends battery life but also reduces unnecessary energy consumption and associated environmental impacts.

Furthermore, the environmental implications of AGM batteries extend to their role in supporting renewable energy integration. By providing reliable energy storage solutions for intermittent renewable sources like solar and wind power, AGM batteries contribute to the broader goal of reducing reliance on fossil fuels and mitigating climate change impacts.

In conclusion, while the environmental impact of AGM batteries in relation to charge duration is a complex issue, it is clear that proper management and optimization of charging processes can significantly influence their overall ecological footprint. As technology continues to advance, further improvements in battery efficiency and charging strategies are likely to enhance the environmental performance of AGM batteries, solidifying their position as a key component in sustainable energy systems.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of AGM (Absorbent Glass Mat) battery technology, particularly when exploring the impact of charge duration on battery life. As the energy storage industry continues to evolve, manufacturers and researchers must navigate a complex landscape of regulations and standards to ensure the safety, reliability, and environmental sustainability of their products.

In the United States, the Environmental Protection Agency (EPA) and the Department of Energy (DOE) have established guidelines for battery manufacturing and disposal. These regulations aim to minimize the environmental impact of battery production and end-of-life management. Manufacturers must adhere to strict protocols for handling and disposing of hazardous materials used in AGM batteries, such as lead and sulfuric acid.

The European Union has implemented the Battery Directive (2006/66/EC), which sets requirements for battery collection, recycling, and disposal. This directive also establishes limits on the use of certain hazardous substances in batteries. As research into charge duration and battery life progresses, manufacturers must ensure that any modifications to AGM battery design or charging protocols comply with these regulations.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide guidelines for battery performance testing and safety. The IEC 60896-21 and IEC 60896-22 standards specifically address valve-regulated lead-acid batteries, including AGM types. These standards outline test methods for determining battery capacity, cycle life, and other performance characteristics, which are essential when evaluating the impact of charge duration on battery life.

In the automotive sector, where AGM batteries are widely used, compliance with SAE (Society of Automotive Engineers) standards is crucial. SAE J537 and SAE J2185 provide specifications for lead-acid batteries used in vehicles, including performance requirements and testing procedures. As research into charge duration optimization continues, any findings must be validated against these industry standards to ensure compatibility with existing automotive systems.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, also impact AGM battery research and development. These regulations mandate proper handling procedures, personal protective equipment, and workplace safety measures when working with batteries and associated charging equipment.

As the focus on renewable energy and grid storage intensifies, new regulations are emerging to address large-scale battery installations. For instance, the National Fire Protection Association (NFPA) has developed NFPA 855, which provides safety standards for the installation of stationary energy storage systems, including those using AGM batteries. Researchers exploring charge duration impacts must consider these evolving standards to ensure their findings can be applied in real-world energy storage applications.

In the United States, the Environmental Protection Agency (EPA) and the Department of Energy (DOE) have established guidelines for battery manufacturing and disposal. These regulations aim to minimize the environmental impact of battery production and end-of-life management. Manufacturers must adhere to strict protocols for handling and disposing of hazardous materials used in AGM batteries, such as lead and sulfuric acid.

The European Union has implemented the Battery Directive (2006/66/EC), which sets requirements for battery collection, recycling, and disposal. This directive also establishes limits on the use of certain hazardous substances in batteries. As research into charge duration and battery life progresses, manufacturers must ensure that any modifications to AGM battery design or charging protocols comply with these regulations.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide guidelines for battery performance testing and safety. The IEC 60896-21 and IEC 60896-22 standards specifically address valve-regulated lead-acid batteries, including AGM types. These standards outline test methods for determining battery capacity, cycle life, and other performance characteristics, which are essential when evaluating the impact of charge duration on battery life.

In the automotive sector, where AGM batteries are widely used, compliance with SAE (Society of Automotive Engineers) standards is crucial. SAE J537 and SAE J2185 provide specifications for lead-acid batteries used in vehicles, including performance requirements and testing procedures. As research into charge duration optimization continues, any findings must be validated against these industry standards to ensure compatibility with existing automotive systems.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, also impact AGM battery research and development. These regulations mandate proper handling procedures, personal protective equipment, and workplace safety measures when working with batteries and associated charging equipment.

As the focus on renewable energy and grid storage intensifies, new regulations are emerging to address large-scale battery installations. For instance, the National Fire Protection Association (NFPA) has developed NFPA 855, which provides safety standards for the installation of stationary energy storage systems, including those using AGM batteries. Researchers exploring charge duration impacts must consider these evolving standards to ensure their findings can be applied in real-world energy storage applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!