Performance Metrics for AGM Batteries in Healthcare Applications

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries has been a significant development in the field of energy storage, particularly for healthcare applications. Initially developed in the 1970s for military aircraft, AGM technology has since found its way into various sectors, including healthcare, due to its unique characteristics and performance advantages.

In the early stages of AGM battery development, the focus was primarily on improving the electrolyte retention and reducing maintenance requirements compared to traditional flooded lead-acid batteries. The use of a glass mat separator to absorb and immobilize the electrolyte was a key innovation, allowing for a spill-proof and maintenance-free design.

As the technology matured, manufacturers began to optimize AGM batteries for specific applications, including those in the healthcare sector. The evolution of AGM batteries for healthcare applications has been driven by the need for reliable, long-lasting, and safe power sources for critical medical equipment.

One of the significant milestones in AGM battery evolution for healthcare was the development of deep-cycle variants. These batteries were designed to withstand repeated discharge and recharge cycles, making them ideal for use in portable medical devices and backup power systems in hospitals and clinics.

The introduction of valve-regulated lead-acid (VRLA) technology in AGM batteries marked another important step in their evolution. This innovation allowed for better gas recombination within the battery, further reducing maintenance requirements and improving safety in healthcare settings where battery ventilation might be limited.

Advancements in manufacturing processes and materials have led to improvements in the energy density and cycle life of AGM batteries. This has resulted in smaller, lighter batteries that can deliver more power and last longer, which is crucial for mobile medical equipment and emergency backup systems.

In recent years, the focus of AGM battery evolution has shifted towards enhancing performance metrics specifically relevant to healthcare applications. This includes improving charge acceptance rates to ensure rapid recharging of medical devices, optimizing low-temperature performance for cold storage of medications and vaccines, and increasing resilience to partial state of charge operation, which is common in intermittently used medical equipment.

The integration of smart battery management systems (BMS) has been a recent trend in AGM battery evolution. These systems allow for real-time monitoring of battery health, state of charge, and performance metrics, which is critical for ensuring the reliability of life-supporting medical devices and minimizing downtime in healthcare facilities.

As environmental concerns have grown, efforts have been made to improve the recyclability and reduce the environmental impact of AGM batteries. This has led to the development of more eco-friendly manufacturing processes and materials, aligning with the healthcare sector's increasing focus on sustainability.

In the early stages of AGM battery development, the focus was primarily on improving the electrolyte retention and reducing maintenance requirements compared to traditional flooded lead-acid batteries. The use of a glass mat separator to absorb and immobilize the electrolyte was a key innovation, allowing for a spill-proof and maintenance-free design.

As the technology matured, manufacturers began to optimize AGM batteries for specific applications, including those in the healthcare sector. The evolution of AGM batteries for healthcare applications has been driven by the need for reliable, long-lasting, and safe power sources for critical medical equipment.

One of the significant milestones in AGM battery evolution for healthcare was the development of deep-cycle variants. These batteries were designed to withstand repeated discharge and recharge cycles, making them ideal for use in portable medical devices and backup power systems in hospitals and clinics.

The introduction of valve-regulated lead-acid (VRLA) technology in AGM batteries marked another important step in their evolution. This innovation allowed for better gas recombination within the battery, further reducing maintenance requirements and improving safety in healthcare settings where battery ventilation might be limited.

Advancements in manufacturing processes and materials have led to improvements in the energy density and cycle life of AGM batteries. This has resulted in smaller, lighter batteries that can deliver more power and last longer, which is crucial for mobile medical equipment and emergency backup systems.

In recent years, the focus of AGM battery evolution has shifted towards enhancing performance metrics specifically relevant to healthcare applications. This includes improving charge acceptance rates to ensure rapid recharging of medical devices, optimizing low-temperature performance for cold storage of medications and vaccines, and increasing resilience to partial state of charge operation, which is common in intermittently used medical equipment.

The integration of smart battery management systems (BMS) has been a recent trend in AGM battery evolution. These systems allow for real-time monitoring of battery health, state of charge, and performance metrics, which is critical for ensuring the reliability of life-supporting medical devices and minimizing downtime in healthcare facilities.

As environmental concerns have grown, efforts have been made to improve the recyclability and reduce the environmental impact of AGM batteries. This has led to the development of more eco-friendly manufacturing processes and materials, aligning with the healthcare sector's increasing focus on sustainability.

Healthcare Market Demand

The healthcare market demand for AGM (Absorbent Glass Mat) batteries has been steadily increasing due to the growing reliance on portable medical devices and equipment. As healthcare facilities strive to improve patient care and operational efficiency, the need for reliable and high-performance power sources has become paramount.

In recent years, there has been a significant shift towards mobile and portable medical devices, such as patient monitors, infusion pumps, and diagnostic equipment. These devices require dependable power sources that can withstand frequent use and provide consistent performance. AGM batteries have emerged as a preferred choice due to their sealed design, low maintenance requirements, and ability to deliver stable power output.

The aging population and the rise in chronic diseases have also contributed to the increased demand for AGM batteries in healthcare applications. As more patients require long-term care and monitoring, healthcare providers are investing in portable medical equipment that can be easily transported between different care settings. This trend has further fueled the need for reliable and long-lasting battery solutions.

Another factor driving the market demand is the growing emphasis on emergency preparedness in healthcare facilities. Hospitals and clinics are increasingly investing in backup power systems to ensure uninterrupted operation during power outages or natural disasters. AGM batteries, with their deep-cycle capabilities and quick recharge times, are well-suited for these critical applications.

The COVID-19 pandemic has also accelerated the adoption of telemedicine and remote patient monitoring solutions, which rely heavily on portable medical devices powered by AGM batteries. This shift towards remote healthcare delivery is expected to continue even after the pandemic, further driving the demand for reliable battery solutions in the healthcare sector.

Furthermore, the increasing focus on sustainability and environmental responsibility in healthcare has led to a preference for AGM batteries over traditional lead-acid batteries. AGM batteries are more environmentally friendly due to their sealed construction, which prevents acid spills and reduces the risk of environmental contamination.

As healthcare facilities continue to upgrade their equipment and expand their services, the demand for AGM batteries is expected to grow. The market is also seeing an increased interest in advanced battery management systems that can optimize battery performance and extend their lifespan, further enhancing the appeal of AGM batteries in healthcare applications.

In recent years, there has been a significant shift towards mobile and portable medical devices, such as patient monitors, infusion pumps, and diagnostic equipment. These devices require dependable power sources that can withstand frequent use and provide consistent performance. AGM batteries have emerged as a preferred choice due to their sealed design, low maintenance requirements, and ability to deliver stable power output.

The aging population and the rise in chronic diseases have also contributed to the increased demand for AGM batteries in healthcare applications. As more patients require long-term care and monitoring, healthcare providers are investing in portable medical equipment that can be easily transported between different care settings. This trend has further fueled the need for reliable and long-lasting battery solutions.

Another factor driving the market demand is the growing emphasis on emergency preparedness in healthcare facilities. Hospitals and clinics are increasingly investing in backup power systems to ensure uninterrupted operation during power outages or natural disasters. AGM batteries, with their deep-cycle capabilities and quick recharge times, are well-suited for these critical applications.

The COVID-19 pandemic has also accelerated the adoption of telemedicine and remote patient monitoring solutions, which rely heavily on portable medical devices powered by AGM batteries. This shift towards remote healthcare delivery is expected to continue even after the pandemic, further driving the demand for reliable battery solutions in the healthcare sector.

Furthermore, the increasing focus on sustainability and environmental responsibility in healthcare has led to a preference for AGM batteries over traditional lead-acid batteries. AGM batteries are more environmentally friendly due to their sealed construction, which prevents acid spills and reduces the risk of environmental contamination.

As healthcare facilities continue to upgrade their equipment and expand their services, the demand for AGM batteries is expected to grow. The market is also seeing an increased interest in advanced battery management systems that can optimize battery performance and extend their lifespan, further enhancing the appeal of AGM batteries in healthcare applications.

Current AGM Challenges

Absorbed Glass Mat (AGM) batteries have gained significant traction in healthcare applications due to their reliability and maintenance-free operation. However, several challenges persist in their performance metrics, particularly in the demanding healthcare environment.

One of the primary challenges is the accurate measurement and prediction of battery state-of-health (SOH) and state-of-charge (SOC) in real-time. Healthcare equipment often requires uninterrupted power supply, making precise SOH and SOC estimations crucial. Current methods for these estimations are often based on simplified models that may not account for the complex electrochemical processes within AGM batteries, leading to potential inaccuracies in predicting remaining battery life and capacity.

Temperature sensitivity presents another significant challenge for AGM batteries in healthcare settings. While AGM batteries generally perform well in a wide range of temperatures, extreme conditions can significantly impact their performance and lifespan. In healthcare facilities, where temperature control is critical for patient care and equipment operation, maintaining optimal battery temperature becomes an additional concern.

Cycle life and depth of discharge (DOD) management also pose challenges in healthcare applications. AGM batteries, while known for their deep-cycle capabilities, still face degradation with repeated deep discharges. Balancing the need for extended runtime with the preservation of battery lifespan requires sophisticated charge management systems, which are not always integrated into existing healthcare equipment.

The issue of self-discharge rates in AGM batteries is another area of concern. While generally lower than flooded lead-acid batteries, self-discharge can still impact the readiness of backup power systems in critical healthcare scenarios. This necessitates regular testing and maintenance protocols, which can be resource-intensive in busy healthcare environments.

Charging efficiency and the prevention of sulfation remain ongoing challenges. In healthcare settings, where batteries may undergo frequent partial charge-discharge cycles, ensuring complete and efficient charging is crucial to prevent capacity loss due to sulfation. However, implementing optimal charging strategies can be complicated by the diverse power demands of various medical devices.

Lastly, the environmental impact and end-of-life management of AGM batteries present growing concerns. As healthcare facilities strive for sustainability, the disposal and recycling of AGM batteries become important considerations. Developing more environmentally friendly recycling processes and extending battery lifespan are areas that require continued focus and innovation.

Addressing these challenges is crucial for improving the reliability and efficiency of AGM batteries in healthcare applications. Advances in battery management systems, materials science, and predictive analytics are key areas that could potentially overcome these limitations and enhance the performance metrics of AGM batteries in the healthcare sector.

One of the primary challenges is the accurate measurement and prediction of battery state-of-health (SOH) and state-of-charge (SOC) in real-time. Healthcare equipment often requires uninterrupted power supply, making precise SOH and SOC estimations crucial. Current methods for these estimations are often based on simplified models that may not account for the complex electrochemical processes within AGM batteries, leading to potential inaccuracies in predicting remaining battery life and capacity.

Temperature sensitivity presents another significant challenge for AGM batteries in healthcare settings. While AGM batteries generally perform well in a wide range of temperatures, extreme conditions can significantly impact their performance and lifespan. In healthcare facilities, where temperature control is critical for patient care and equipment operation, maintaining optimal battery temperature becomes an additional concern.

Cycle life and depth of discharge (DOD) management also pose challenges in healthcare applications. AGM batteries, while known for their deep-cycle capabilities, still face degradation with repeated deep discharges. Balancing the need for extended runtime with the preservation of battery lifespan requires sophisticated charge management systems, which are not always integrated into existing healthcare equipment.

The issue of self-discharge rates in AGM batteries is another area of concern. While generally lower than flooded lead-acid batteries, self-discharge can still impact the readiness of backup power systems in critical healthcare scenarios. This necessitates regular testing and maintenance protocols, which can be resource-intensive in busy healthcare environments.

Charging efficiency and the prevention of sulfation remain ongoing challenges. In healthcare settings, where batteries may undergo frequent partial charge-discharge cycles, ensuring complete and efficient charging is crucial to prevent capacity loss due to sulfation. However, implementing optimal charging strategies can be complicated by the diverse power demands of various medical devices.

Lastly, the environmental impact and end-of-life management of AGM batteries present growing concerns. As healthcare facilities strive for sustainability, the disposal and recycling of AGM batteries become important considerations. Developing more environmentally friendly recycling processes and extending battery lifespan are areas that require continued focus and innovation.

Addressing these challenges is crucial for improving the reliability and efficiency of AGM batteries in healthcare applications. Advances in battery management systems, materials science, and predictive analytics are key areas that could potentially overcome these limitations and enhance the performance metrics of AGM batteries in the healthcare sector.

AGM Performance Solutions

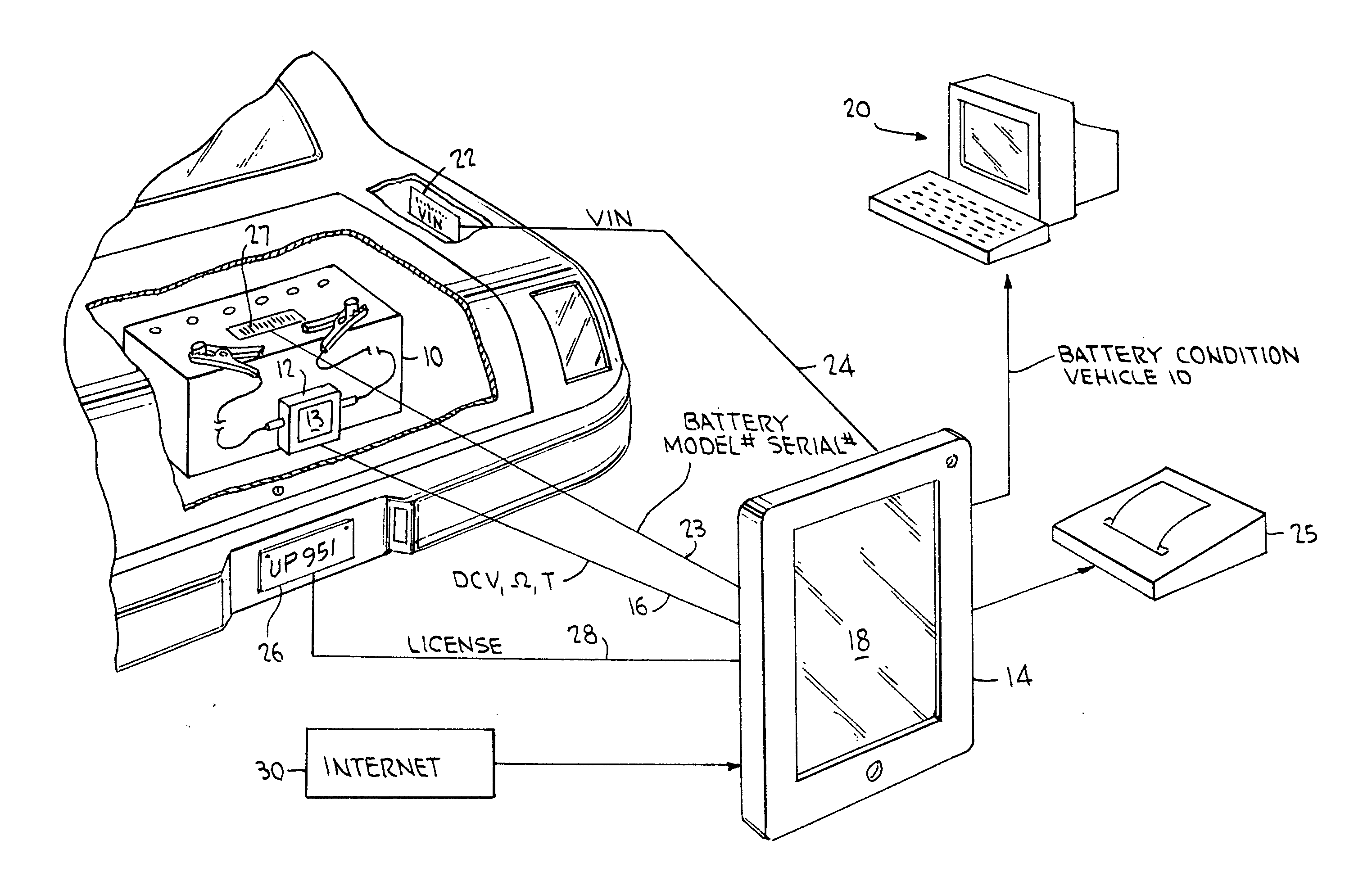

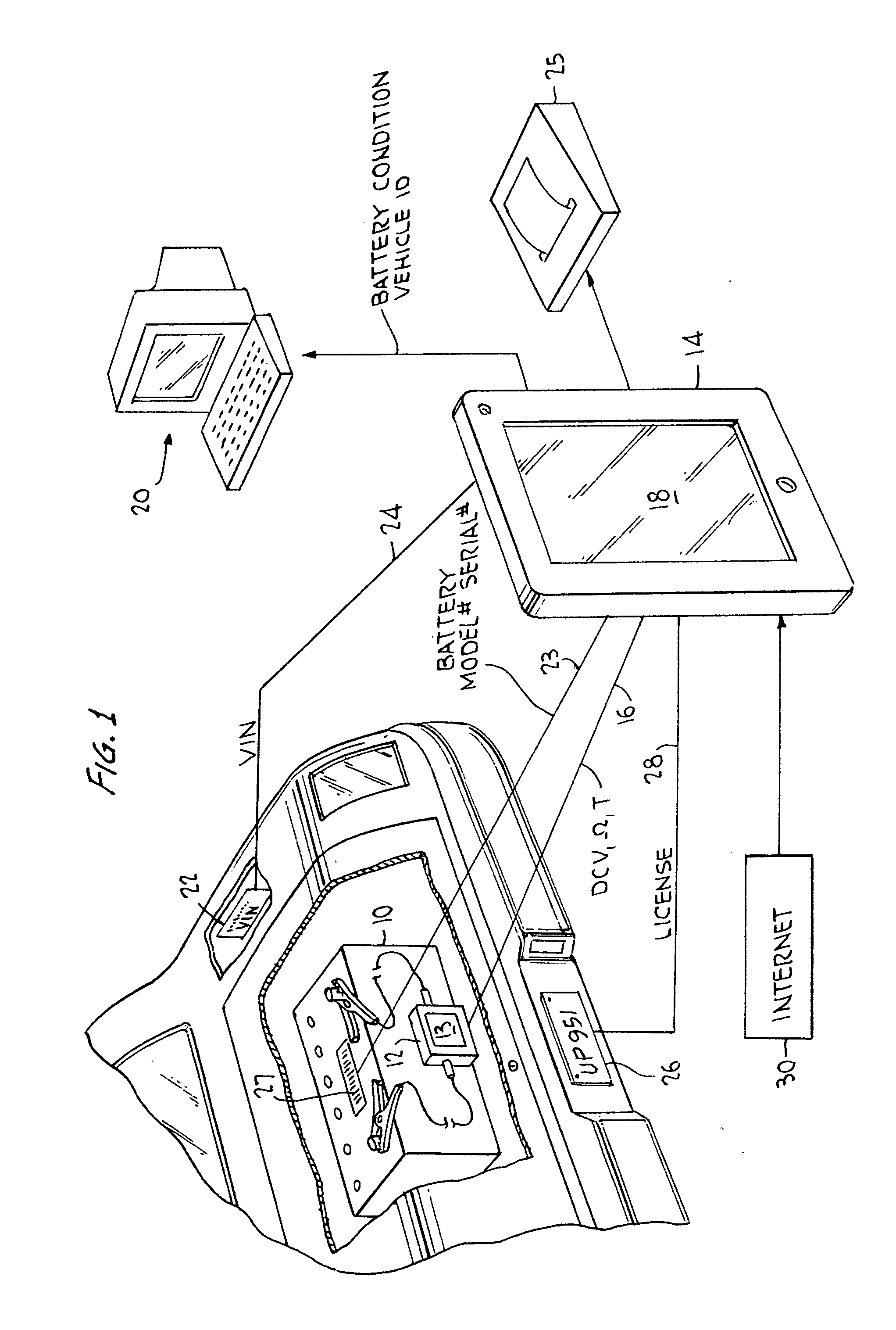

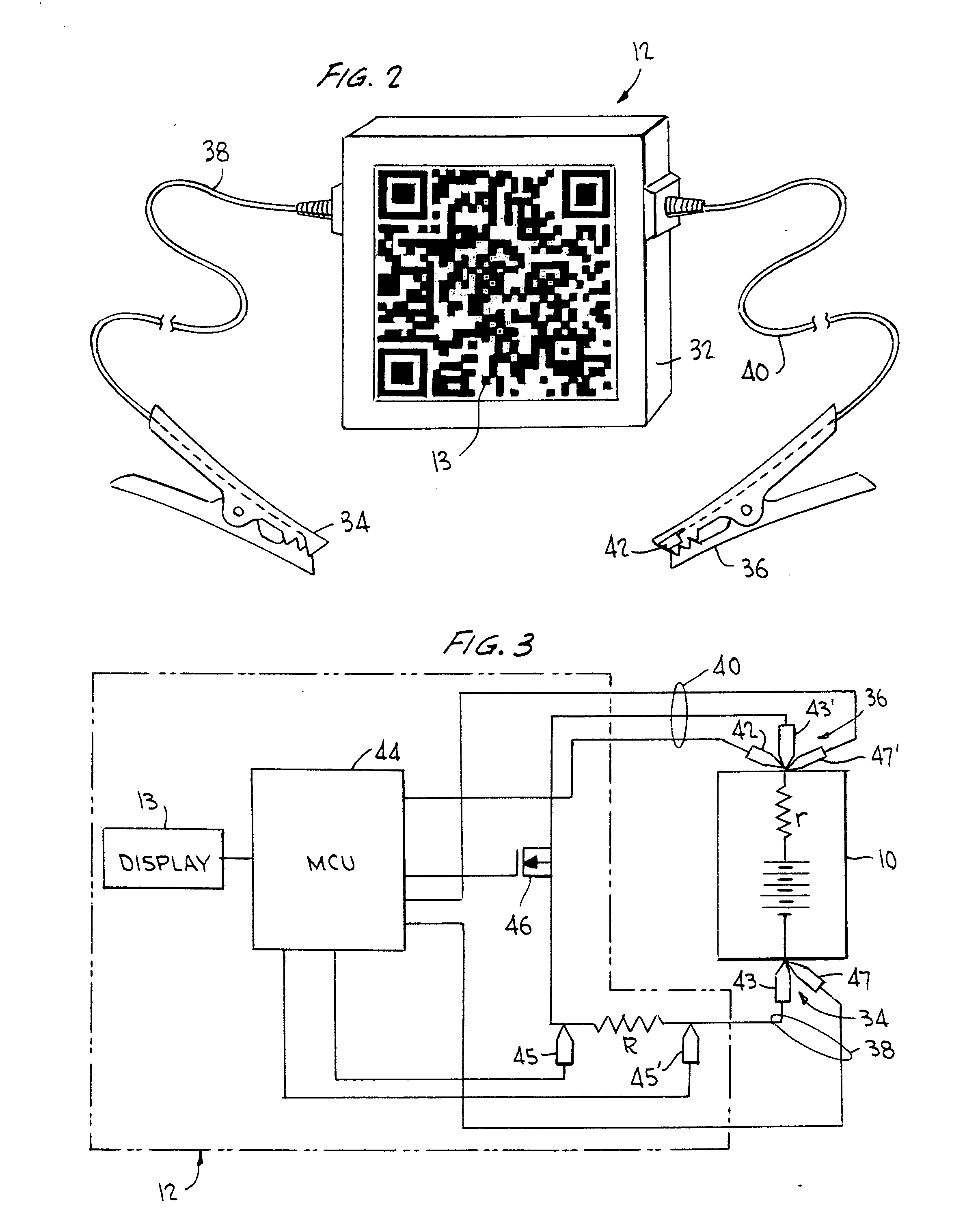

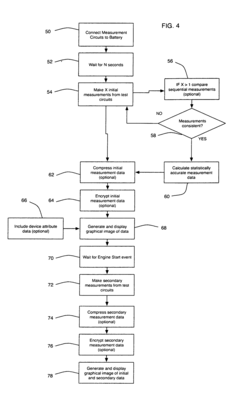

01 Battery performance monitoring and analysis

Systems and methods for monitoring and analyzing AGM battery performance metrics. This includes real-time data collection, performance tracking, and predictive analytics to assess battery health, efficiency, and lifespan. Advanced algorithms process the collected data to provide insights on battery condition and optimize operational parameters.- Battery performance monitoring and analysis: Systems and methods for monitoring and analyzing AGM battery performance metrics. This includes real-time data collection, performance tracking, and predictive analytics to assess battery health, efficiency, and lifespan. Advanced algorithms are used to process the collected data and provide insights for optimizing battery usage and maintenance.

- Capacity and charge/discharge characteristics: Evaluation of AGM battery capacity and charge/discharge characteristics. This involves measuring and analyzing factors such as energy density, power output, charging efficiency, and discharge rates. Techniques for improving these metrics through advanced materials and design optimizations are also explored.

- Thermal management and safety features: Development of thermal management systems and safety features for AGM batteries. This includes temperature monitoring, heat dissipation techniques, and fail-safe mechanisms to prevent overheating and ensure safe operation. Advanced sensors and control systems are implemented to maintain optimal operating conditions.

- Lifecycle assessment and durability testing: Methods for assessing AGM battery lifecycle and conducting durability tests. This involves accelerated aging techniques, cyclic testing, and long-term performance evaluations. The goal is to accurately predict battery lifespan and identify factors that impact longevity and reliability under various operating conditions.

- Integration with energy management systems: Techniques for integrating AGM batteries with broader energy management systems. This includes developing interfaces and protocols for seamless communication between batteries and power grids or renewable energy sources. Advanced algorithms are used to optimize energy storage and distribution, improving overall system efficiency.

02 Capacity and charge/discharge characteristics

Evaluation of AGM battery capacity and charge/discharge characteristics. This involves measuring and analyzing factors such as energy density, power output, charging efficiency, and discharge rates. Techniques for improving these metrics through advanced materials and design optimizations are also explored.Expand Specific Solutions03 Thermal management and safety features

Implementation of thermal management systems and safety features for AGM batteries. This includes temperature monitoring, heat dissipation techniques, and protective measures against overheating or thermal runaway. Advanced sensors and control systems are utilized to maintain optimal operating conditions and enhance battery longevity.Expand Specific Solutions04 Lifecycle assessment and degradation analysis

Methods for assessing AGM battery lifecycle and analyzing degradation patterns. This involves long-term performance testing, cycle life evaluation, and identification of factors affecting battery aging. Advanced diagnostic tools and machine learning algorithms are employed to predict battery lifespan and optimize maintenance schedules.Expand Specific Solutions05 Integration with energy management systems

Techniques for integrating AGM batteries with broader energy management systems. This includes optimizing battery performance in grid storage applications, renewable energy systems, and electric vehicles. Advanced control algorithms and communication protocols are developed to enhance overall system efficiency and reliability.Expand Specific Solutions

Key AGM Manufacturers

The performance metrics for AGM batteries in healthcare applications represent a mature yet evolving market. The industry is in a growth phase, with increasing demand for reliable power sources in medical devices. The global market size for medical batteries is projected to reach several billion dollars by 2025. Technologically, AGM batteries are well-established, but innovations continue to improve their performance and safety. Companies like Koninklijke Philips NV, Cardiac Pacemakers, Inc., and Roche Diabetes Care, Inc. are at the forefront, developing advanced AGM batteries for critical healthcare equipment. These industry leaders are focusing on enhancing energy density, longevity, and safety features to meet the stringent requirements of medical applications.

Cardiac Pacemakers, Inc.

Technical Solution: Cardiac Pacemakers, Inc. has developed advanced AGM (Absorbent Glass Mat) batteries specifically designed for implantable medical devices such as pacemakers. Their technology focuses on optimizing energy density and longevity while maintaining a small form factor. The company employs a proprietary electrolyte formulation that enhances charge retention and reduces self-discharge rates, crucial for long-term implantable devices[1]. They have also implemented advanced separator technology that improves ion transfer efficiency, leading to better overall battery performance in medical applications[2]. Their AGM batteries undergo rigorous testing protocols to ensure reliability and safety under various physiological conditions, including temperature fluctuations and mechanical stress[3].

Strengths: Specialized in medical-grade batteries, high energy density, long lifespan, and proven safety record. Weaknesses: Limited to specific medical applications, potentially higher cost due to specialized manufacturing.

Koninklijke Philips NV

Technical Solution: Philips has developed a range of AGM batteries optimized for healthcare applications, particularly in portable medical devices and monitoring equipment. Their approach focuses on balancing power output with weight reduction and extended cycle life. Philips' AGM batteries incorporate advanced plate designs that maximize surface area for improved charge acceptance and discharge performance[4]. They have also implemented smart battery management systems that monitor and optimize battery health, extending the operational life of medical devices[5]. Philips' AGM batteries feature rapid charging capabilities, crucial for medical equipment that requires minimal downtime[6]. The company has also invested in improving the thermal management of their batteries to ensure stable performance across various healthcare environments.

Strengths: Wide range of healthcare-specific applications, integrated smart management systems, and rapid charging capabilities. Weaknesses: May be more expensive than generic AGM batteries, potential over-reliance on proprietary technologies.

AGM Battery Innovations

Tester for equipment, apparatus or component with distributed processing function

PatentActiveUS20140374475A1

Innovation

- A simplified testing device that measures basic battery parameters and transmits raw data to a smart device for analysis, leveraging the smart device's user interface, memory, and communication capabilities to input context information and perform qualitative analysis, thereby reducing the need for complex user interfaces and dedicated analysis hardware.

Over-Saturated Absorbed Glass Mat Valve Regulated Lead-Acid Battery Comprising Carbon Additives

PatentInactiveUS20140120386A1

Innovation

- An AGM VRLA battery design with a positive plate, negative plate containing a carbon additive, an AGM separator, and an electrolyte present in an amount ranging from 100 to 150% by volume based on the total pore volume of the separator, utilizing various carbon additives such as graphite, carbon black, activated carbon, and graphene to enhance charge acceptance and durability.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing AGM (Absorbent Glass Mat) batteries in healthcare applications. The healthcare industry is subject to stringent regulations to ensure patient safety and the reliability of medical equipment. For AGM batteries used in medical devices, compliance with various standards and guidelines is mandatory.

One of the primary regulatory bodies overseeing medical devices in the United States is the Food and Drug Administration (FDA). The FDA's Center for Devices and Radiological Health (CDRH) is responsible for regulating medical devices, including those powered by AGM batteries. Manufacturers must adhere to the FDA's Quality System Regulation (QSR) and obtain necessary clearances or approvals before marketing their devices.

In Europe, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) set the standards for medical devices. These regulations require manufacturers to demonstrate the safety and performance of their devices, including the battery components. Compliance with these regulations involves rigorous testing and documentation processes.

International standards such as IEC 60601-1 for medical electrical equipment safety and IEC 62133 for secondary cells and batteries safety are crucial for AGM batteries in healthcare applications. These standards outline specific requirements for battery performance, safety features, and testing procedures.

Environmental regulations also play a role in AGM battery compliance. The European Union's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous materials in electrical and electronic equipment, including batteries. Similarly, the Battery Directive (2006/66/EC) sets requirements for battery disposal and recycling.

Manufacturers must implement robust quality management systems to ensure consistent compliance with these regulations. This includes maintaining detailed documentation of design processes, risk assessments, and performance testing results. Regular audits and inspections by regulatory bodies are common to verify ongoing compliance.

Specific performance metrics for AGM batteries in healthcare applications must be carefully monitored and documented to meet regulatory requirements. These metrics may include cycle life, capacity retention, self-discharge rates, and safety parameters such as thermal stability and short-circuit protection. Manufacturers must demonstrate that their batteries meet or exceed the specified performance criteria throughout the expected life of the medical device.

Regulatory compliance also extends to the labeling and packaging of AGM batteries used in healthcare applications. Clear and accurate information regarding battery specifications, usage instructions, and safety precautions must be provided to end-users in accordance with regulatory guidelines.

One of the primary regulatory bodies overseeing medical devices in the United States is the Food and Drug Administration (FDA). The FDA's Center for Devices and Radiological Health (CDRH) is responsible for regulating medical devices, including those powered by AGM batteries. Manufacturers must adhere to the FDA's Quality System Regulation (QSR) and obtain necessary clearances or approvals before marketing their devices.

In Europe, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) set the standards for medical devices. These regulations require manufacturers to demonstrate the safety and performance of their devices, including the battery components. Compliance with these regulations involves rigorous testing and documentation processes.

International standards such as IEC 60601-1 for medical electrical equipment safety and IEC 62133 for secondary cells and batteries safety are crucial for AGM batteries in healthcare applications. These standards outline specific requirements for battery performance, safety features, and testing procedures.

Environmental regulations also play a role in AGM battery compliance. The European Union's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous materials in electrical and electronic equipment, including batteries. Similarly, the Battery Directive (2006/66/EC) sets requirements for battery disposal and recycling.

Manufacturers must implement robust quality management systems to ensure consistent compliance with these regulations. This includes maintaining detailed documentation of design processes, risk assessments, and performance testing results. Regular audits and inspections by regulatory bodies are common to verify ongoing compliance.

Specific performance metrics for AGM batteries in healthcare applications must be carefully monitored and documented to meet regulatory requirements. These metrics may include cycle life, capacity retention, self-discharge rates, and safety parameters such as thermal stability and short-circuit protection. Manufacturers must demonstrate that their batteries meet or exceed the specified performance criteria throughout the expected life of the medical device.

Regulatory compliance also extends to the labeling and packaging of AGM batteries used in healthcare applications. Clear and accurate information regarding battery specifications, usage instructions, and safety precautions must be provided to end-users in accordance with regulatory guidelines.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) batteries in healthcare applications is a critical consideration as the healthcare sector increasingly adopts these power solutions. AGM batteries offer several environmental advantages over traditional lead-acid batteries, particularly in terms of reduced emissions and improved recyclability.

AGM batteries are sealed, which significantly reduces the risk of acid spills and hydrogen gas emissions during operation. This characteristic is particularly important in healthcare settings, where maintaining a clean and safe environment is paramount. The reduced emissions contribute to better indoor air quality, benefiting both patients and healthcare professionals.

In terms of energy efficiency, AGM batteries generally outperform flooded lead-acid batteries. They have lower internal resistance, which allows for more efficient charging and discharging cycles. This improved efficiency translates to reduced energy consumption over the battery's lifetime, indirectly lowering the carbon footprint associated with power generation for battery charging.

The lifespan of AGM batteries is typically longer than that of traditional lead-acid batteries when used in healthcare applications. This extended service life means fewer battery replacements are needed over time, reducing the overall environmental impact associated with battery production, transportation, and disposal.

Recyclability is another significant environmental advantage of AGM batteries. The materials used in these batteries, including lead, plastic, and glass mat, are highly recyclable. Many manufacturers have established recycling programs, ensuring that a high percentage of the battery components can be recovered and reused. This closed-loop approach minimizes waste and reduces the demand for raw materials in new battery production.

However, it is important to note that the production of AGM batteries still involves the use of lead, which is a toxic material. While the sealed design mitigates risks during use, proper handling and disposal procedures are crucial to prevent environmental contamination. Healthcare facilities must adhere to strict protocols for battery management and partner with certified recycling facilities to ensure environmentally responsible end-of-life treatment.

The use of AGM batteries in healthcare applications also indirectly contributes to environmental sustainability by supporting the reliability of medical equipment. By providing stable power to critical devices, AGM batteries help reduce the need for energy-intensive backup systems and minimize the risk of equipment failure, which could lead to waste of medical supplies or increased resource consumption.

As healthcare facilities increasingly focus on sustainability, the choice of AGM batteries aligns with broader environmental goals. Their improved performance characteristics, coupled with lower maintenance requirements, support the sector's efforts to reduce its overall environmental footprint while maintaining high standards of patient care and operational efficiency.

AGM batteries are sealed, which significantly reduces the risk of acid spills and hydrogen gas emissions during operation. This characteristic is particularly important in healthcare settings, where maintaining a clean and safe environment is paramount. The reduced emissions contribute to better indoor air quality, benefiting both patients and healthcare professionals.

In terms of energy efficiency, AGM batteries generally outperform flooded lead-acid batteries. They have lower internal resistance, which allows for more efficient charging and discharging cycles. This improved efficiency translates to reduced energy consumption over the battery's lifetime, indirectly lowering the carbon footprint associated with power generation for battery charging.

The lifespan of AGM batteries is typically longer than that of traditional lead-acid batteries when used in healthcare applications. This extended service life means fewer battery replacements are needed over time, reducing the overall environmental impact associated with battery production, transportation, and disposal.

Recyclability is another significant environmental advantage of AGM batteries. The materials used in these batteries, including lead, plastic, and glass mat, are highly recyclable. Many manufacturers have established recycling programs, ensuring that a high percentage of the battery components can be recovered and reused. This closed-loop approach minimizes waste and reduces the demand for raw materials in new battery production.

However, it is important to note that the production of AGM batteries still involves the use of lead, which is a toxic material. While the sealed design mitigates risks during use, proper handling and disposal procedures are crucial to prevent environmental contamination. Healthcare facilities must adhere to strict protocols for battery management and partner with certified recycling facilities to ensure environmentally responsible end-of-life treatment.

The use of AGM batteries in healthcare applications also indirectly contributes to environmental sustainability by supporting the reliability of medical equipment. By providing stable power to critical devices, AGM batteries help reduce the need for energy-intensive backup systems and minimize the risk of equipment failure, which could lead to waste of medical supplies or increased resource consumption.

As healthcare facilities increasingly focus on sustainability, the choice of AGM batteries aligns with broader environmental goals. Their improved performance characteristics, coupled with lower maintenance requirements, support the sector's efforts to reduce its overall environmental footprint while maintaining high standards of patient care and operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!