Investigating the Catalyst Role in Carbon-negative Concrete's Efficiency

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Catalyst Technology Background and Objectives

Carbon-negative concrete technology has emerged as a revolutionary approach in the construction industry, evolving from traditional cement production methods that have historically been significant contributors to global carbon emissions. The cement industry alone accounts for approximately 8% of global CO2 emissions, making it a critical focus area for environmental sustainability efforts. The development trajectory of carbon-negative concrete has accelerated significantly over the past decade, driven by increasing environmental regulations, corporate sustainability commitments, and technological innovations in material science.

The fundamental principle behind carbon-negative concrete involves capturing and sequestering more carbon dioxide during its production and lifetime than is emitted throughout its entire lifecycle. This represents a paradigm shift from conventional concrete, which has a substantial carbon footprint primarily due to the energy-intensive process of clinker production and the chemical reaction that releases CO2 during limestone calcination.

Recent technological advancements have focused on the critical role of catalysts in enhancing the efficiency of carbon capture and utilization within concrete matrices. These catalysts serve multiple functions: accelerating carbonation reactions, improving CO2 absorption capacity, and enhancing the mechanical properties of the resulting concrete products. The evolution of catalyst technology has progressed from simple metallic compounds to sophisticated nano-engineered materials designed specifically for optimal carbon sequestration performance.

The primary technical objective in this field is to develop catalyst systems that can maximize carbon sequestration while maintaining or improving concrete's structural integrity and durability. Secondary objectives include reducing the energy requirements of the carbonation process, extending the carbon capture capabilities throughout the concrete's lifecycle, and ensuring economic viability for widespread commercial adoption.

Current research trends indicate growing interest in biomimetic catalysts inspired by natural carbon-fixing processes, as well as hybrid catalyst systems that combine traditional accelerants with novel carbon-capturing compounds. The integration of waste materials as catalyst precursors represents another promising direction, potentially addressing multiple sustainability challenges simultaneously.

The global trajectory of this technology suggests an accelerating pace of innovation, with significant breakthroughs in catalyst efficiency occurring approximately every 18-24 months. Industry projections indicate that with continued research investment, carbon-negative concrete technologies could reach commercial scale deployment within the next 5-7 years, potentially revolutionizing the construction sector's environmental impact.

The ultimate goal of this technological pursuit extends beyond mere carbon neutrality to achieve true carbon negativity in concrete production, potentially transforming one of the world's most carbon-intensive industries into a significant carbon sink that actively contributes to climate change mitigation efforts.

The fundamental principle behind carbon-negative concrete involves capturing and sequestering more carbon dioxide during its production and lifetime than is emitted throughout its entire lifecycle. This represents a paradigm shift from conventional concrete, which has a substantial carbon footprint primarily due to the energy-intensive process of clinker production and the chemical reaction that releases CO2 during limestone calcination.

Recent technological advancements have focused on the critical role of catalysts in enhancing the efficiency of carbon capture and utilization within concrete matrices. These catalysts serve multiple functions: accelerating carbonation reactions, improving CO2 absorption capacity, and enhancing the mechanical properties of the resulting concrete products. The evolution of catalyst technology has progressed from simple metallic compounds to sophisticated nano-engineered materials designed specifically for optimal carbon sequestration performance.

The primary technical objective in this field is to develop catalyst systems that can maximize carbon sequestration while maintaining or improving concrete's structural integrity and durability. Secondary objectives include reducing the energy requirements of the carbonation process, extending the carbon capture capabilities throughout the concrete's lifecycle, and ensuring economic viability for widespread commercial adoption.

Current research trends indicate growing interest in biomimetic catalysts inspired by natural carbon-fixing processes, as well as hybrid catalyst systems that combine traditional accelerants with novel carbon-capturing compounds. The integration of waste materials as catalyst precursors represents another promising direction, potentially addressing multiple sustainability challenges simultaneously.

The global trajectory of this technology suggests an accelerating pace of innovation, with significant breakthroughs in catalyst efficiency occurring approximately every 18-24 months. Industry projections indicate that with continued research investment, carbon-negative concrete technologies could reach commercial scale deployment within the next 5-7 years, potentially revolutionizing the construction sector's environmental impact.

The ultimate goal of this technological pursuit extends beyond mere carbon neutrality to achieve true carbon negativity in concrete production, potentially transforming one of the world's most carbon-intensive industries into a significant carbon sink that actively contributes to climate change mitigation efforts.

Market Analysis for Carbon-negative Concrete Solutions

The global market for carbon-negative concrete solutions is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market size estimates place the green concrete sector at approximately $30 billion globally, with carbon-negative variants representing an emerging segment projected to grow at a compound annual rate of 9.2% through 2030. This growth trajectory is particularly pronounced in regions with stringent carbon reduction targets, including the European Union, North America, and increasingly, parts of Asia-Pacific.

Demand patterns reveal distinct market segments with varying adoption rates. The commercial construction sector currently leads implementation, accounting for roughly 38% of carbon-negative concrete applications, followed by infrastructure projects at 31%. Residential construction, while representing a smaller current share at 22%, demonstrates the fastest growth potential as consumer awareness increases and regulatory incentives expand to smaller-scale projects.

Geographic distribution of market demand shows notable concentration in developed economies, with Northern Europe, particularly Scandinavia, leading in adoption rates. These markets benefit from supportive regulatory frameworks that incentivize or mandate low-carbon building materials. The North American market shows strong growth potential, particularly in coastal urban centers with progressive climate policies. Emerging economies present a complex picture, with limited current adoption but enormous long-term potential as urbanization continues and climate considerations gain prominence.

Price sensitivity remains a significant market factor, with carbon-negative concrete solutions typically commanding a 15-25% premium over conventional products. This premium has been decreasing annually as production scales and technology improves, with catalyst innovations playing a crucial role in cost reduction. Market research indicates willingness to pay this premium varies significantly by project type, with public infrastructure and premium commercial developments demonstrating higher acceptance than cost-sensitive residential construction.

Customer segmentation reveals three primary buyer profiles: environmentally-focused early adopters willing to pay significant premiums for sustainability benefits; compliance-driven pragmatists responding primarily to regulatory requirements; and cost-sensitive mainstream buyers requiring near-price parity with conventional solutions. The catalyst innovations central to this investigation have particular relevance to expanding market penetration among the latter two segments by improving performance metrics while reducing cost differentials.

Competitive analysis indicates a fragmented market with both established concrete manufacturers developing carbon-negative product lines and specialized startups focused exclusively on innovative sustainable solutions. Recent market entries suggest increasing competition and accelerating innovation cycles, with catalyst technology representing a key differentiator in product performance and cost structure.

Demand patterns reveal distinct market segments with varying adoption rates. The commercial construction sector currently leads implementation, accounting for roughly 38% of carbon-negative concrete applications, followed by infrastructure projects at 31%. Residential construction, while representing a smaller current share at 22%, demonstrates the fastest growth potential as consumer awareness increases and regulatory incentives expand to smaller-scale projects.

Geographic distribution of market demand shows notable concentration in developed economies, with Northern Europe, particularly Scandinavia, leading in adoption rates. These markets benefit from supportive regulatory frameworks that incentivize or mandate low-carbon building materials. The North American market shows strong growth potential, particularly in coastal urban centers with progressive climate policies. Emerging economies present a complex picture, with limited current adoption but enormous long-term potential as urbanization continues and climate considerations gain prominence.

Price sensitivity remains a significant market factor, with carbon-negative concrete solutions typically commanding a 15-25% premium over conventional products. This premium has been decreasing annually as production scales and technology improves, with catalyst innovations playing a crucial role in cost reduction. Market research indicates willingness to pay this premium varies significantly by project type, with public infrastructure and premium commercial developments demonstrating higher acceptance than cost-sensitive residential construction.

Customer segmentation reveals three primary buyer profiles: environmentally-focused early adopters willing to pay significant premiums for sustainability benefits; compliance-driven pragmatists responding primarily to regulatory requirements; and cost-sensitive mainstream buyers requiring near-price parity with conventional solutions. The catalyst innovations central to this investigation have particular relevance to expanding market penetration among the latter two segments by improving performance metrics while reducing cost differentials.

Competitive analysis indicates a fragmented market with both established concrete manufacturers developing carbon-negative product lines and specialized startups focused exclusively on innovative sustainable solutions. Recent market entries suggest increasing competition and accelerating innovation cycles, with catalyst technology representing a key differentiator in product performance and cost structure.

Current Catalyst Technologies and Implementation Challenges

The current landscape of catalyst technologies for carbon-negative concrete is dominated by several key approaches, each with distinct implementation challenges. Calcium-based catalysts, particularly calcium hydroxide (Ca(OH)₂), have emerged as frontrunners due to their ability to accelerate carbonation processes while maintaining concrete's structural integrity. These catalysts facilitate the conversion of CO₂ into stable carbonate minerals within the concrete matrix, effectively sequestering carbon while enhancing material strength. However, their implementation faces challenges related to uniform distribution throughout the concrete mixture and sensitivity to ambient humidity conditions, which can significantly impact catalytic efficiency.

Metal oxide catalysts, including magnesium oxide (MgO) and iron oxide (Fe₂O₃), represent another promising category. These compounds demonstrate excellent CO₂ absorption capabilities and can be synthesized from industrial byproducts, offering circular economy benefits. The primary implementation hurdles include catalyst deactivation over time and the need for precise temperature control during the curing process to maximize carbon sequestration potential.

Novel enzyme-based catalytic systems have shown remarkable potential in laboratory settings. Carbonic anhydrase, an enzyme that naturally catalyzes CO₂ hydration in biological systems, has been successfully incorporated into concrete formulations. These biocatalysts operate efficiently at ambient temperatures and pressures, potentially reducing the energy requirements of carbon-negative concrete production. However, scaling enzyme production, ensuring long-term stability in alkaline concrete environments, and managing production costs remain significant challenges.

Nanocatalysts represent the cutting edge of this field, with engineered nanoparticles of transition metals and their oxides demonstrating unprecedented catalytic activity. Their high surface-area-to-volume ratio enables efficient CO₂ conversion even at low concentrations. Implementation challenges include complex synthesis procedures, potential environmental and health concerns associated with nanomaterials, and the need for specialized mixing equipment to ensure homogeneous dispersion.

The integration of these catalyst technologies into existing concrete production infrastructure presents universal challenges. Current concrete batching plants require modifications to accommodate catalyst addition and monitoring systems. Quality control measures must be enhanced to verify catalyst activity and carbon sequestration performance. Additionally, the variability in raw material compositions across different geographical locations necessitates adaptive catalyst formulations, complicating standardization efforts.

Economic barriers further impede widespread implementation, with premium-grade catalysts significantly increasing production costs. The absence of established carbon pricing mechanisms in many markets limits the financial incentives for adopting these technologies, despite their environmental benefits. Regulatory frameworks are still evolving, creating uncertainty regarding performance standards and certification requirements for carbon-negative concrete products.

Metal oxide catalysts, including magnesium oxide (MgO) and iron oxide (Fe₂O₃), represent another promising category. These compounds demonstrate excellent CO₂ absorption capabilities and can be synthesized from industrial byproducts, offering circular economy benefits. The primary implementation hurdles include catalyst deactivation over time and the need for precise temperature control during the curing process to maximize carbon sequestration potential.

Novel enzyme-based catalytic systems have shown remarkable potential in laboratory settings. Carbonic anhydrase, an enzyme that naturally catalyzes CO₂ hydration in biological systems, has been successfully incorporated into concrete formulations. These biocatalysts operate efficiently at ambient temperatures and pressures, potentially reducing the energy requirements of carbon-negative concrete production. However, scaling enzyme production, ensuring long-term stability in alkaline concrete environments, and managing production costs remain significant challenges.

Nanocatalysts represent the cutting edge of this field, with engineered nanoparticles of transition metals and their oxides demonstrating unprecedented catalytic activity. Their high surface-area-to-volume ratio enables efficient CO₂ conversion even at low concentrations. Implementation challenges include complex synthesis procedures, potential environmental and health concerns associated with nanomaterials, and the need for specialized mixing equipment to ensure homogeneous dispersion.

The integration of these catalyst technologies into existing concrete production infrastructure presents universal challenges. Current concrete batching plants require modifications to accommodate catalyst addition and monitoring systems. Quality control measures must be enhanced to verify catalyst activity and carbon sequestration performance. Additionally, the variability in raw material compositions across different geographical locations necessitates adaptive catalyst formulations, complicating standardization efforts.

Economic barriers further impede widespread implementation, with premium-grade catalysts significantly increasing production costs. The absence of established carbon pricing mechanisms in many markets limits the financial incentives for adopting these technologies, despite their environmental benefits. Regulatory frameworks are still evolving, creating uncertainty regarding performance standards and certification requirements for carbon-negative concrete products.

Current Catalyst Integration Methods and Performance

01 Carbon capture and sequestration in concrete

Technologies that enable concrete to absorb and permanently store carbon dioxide during the curing process, resulting in carbon-negative concrete. These catalysts enhance the carbonation reaction, allowing CO2 to be chemically bound within the concrete matrix. This approach not only reduces the carbon footprint of concrete production but also improves concrete strength and durability through the formation of stable carbonate minerals.- Carbon capture and sequestration in concrete: Technologies that enable concrete to absorb and permanently store carbon dioxide during the curing process, resulting in carbon-negative concrete. These methods involve catalysts that accelerate the carbonation reaction, allowing CO2 to be chemically bound within the concrete matrix. This approach not only reduces the carbon footprint of concrete production but can actually make concrete a carbon sink, effectively removing CO2 from the atmosphere.

- Novel catalyst formulations for enhanced CO2 absorption: Specialized catalyst formulations designed to improve the efficiency of carbon dioxide absorption in concrete. These catalysts typically include metal compounds, nanoparticles, or organic additives that facilitate the reaction between CO2 and calcium-containing compounds in concrete. By optimizing catalyst composition and concentration, the rate and extent of carbonation can be significantly increased, leading to greater carbon sequestration capacity.

- Process optimization for carbon-negative concrete production: Methods for optimizing the production process of carbon-negative concrete to maximize catalyst efficiency. This includes controlling parameters such as temperature, pressure, humidity, and curing time to create ideal conditions for CO2 absorption. Advanced mixing techniques and equipment designs ensure uniform distribution of catalysts throughout the concrete mixture, resulting in more consistent carbonation and improved mechanical properties.

- Alternative raw materials and supplementary cementitious materials: Incorporation of alternative raw materials and supplementary cementitious materials that enhance the catalytic efficiency of carbon-negative concrete. These include industrial byproducts like fly ash, slag, and silica fume, as well as novel materials specifically designed to increase CO2 uptake. When combined with appropriate catalysts, these materials can significantly improve the carbon sequestration capacity of concrete while maintaining or enhancing its structural properties.

- Performance monitoring and quality control systems: Advanced systems for monitoring and controlling the performance of carbon-negative concrete catalysts during production and curing. These technologies include sensors, analytical methods, and real-time monitoring equipment that measure CO2 uptake, reaction kinetics, and catalyst efficiency. Quality control protocols ensure that carbon-negative concrete meets both environmental goals for carbon sequestration and engineering requirements for structural applications.

02 Novel catalyst formulations for CO2 mineralization

Specialized catalyst formulations designed to accelerate the conversion of CO2 into stable mineral carbonates within concrete. These catalysts typically include metal compounds, enzymes, or nanoparticles that facilitate the reaction between carbon dioxide and calcium-rich components in concrete mixtures. The efficiency of these catalysts determines the rate and extent of carbon sequestration, with advanced formulations achieving higher carbon negativity.Expand Specific Solutions03 Alternative cementitious materials with enhanced carbon absorption

Development of alternative binding materials that can replace traditional Portland cement while offering superior carbon absorption capabilities. These materials often incorporate industrial byproducts like fly ash, slag, or silica fume, which when combined with specific catalysts, create concrete with significantly reduced carbon footprint. The catalysts improve the reactivity of these alternative materials, enabling efficient carbon sequestration while maintaining or improving concrete performance.Expand Specific Solutions04 Process optimization for carbon-negative concrete production

Methodologies and systems for optimizing the production process of carbon-negative concrete to maximize catalyst efficiency. This includes precise control of curing conditions, CO2 exposure parameters, moisture levels, and temperature to create ideal conditions for carbon sequestration. Advanced monitoring systems and automated controls ensure optimal catalyst performance throughout the concrete manufacturing process, resulting in higher carbon capture efficiency.Expand Specific Solutions05 Durability and performance enhancement of carbon-negative concrete

Techniques to improve the long-term durability and mechanical properties of carbon-negative concrete through catalyst optimization. These approaches focus on ensuring that the carbon sequestration process enhances rather than compromises concrete strength, permeability, and resistance to environmental degradation. Specialized catalysts not only facilitate carbon capture but also contribute to microstructural improvements that result in superior concrete performance over conventional formulations.Expand Specific Solutions

Key Industry Players and Research Institutions

The carbon-negative concrete market is in an early growth phase, characterized by increasing research activity and commercial pilot projects. Market size is expanding rapidly, driven by global decarbonization initiatives and construction industry sustainability goals, though still representing a small fraction of the $400+ billion global concrete market. Technologically, catalyst innovation for carbon-negative concrete shows varying maturity levels across key players. Companies like Carbon Limit Co. and Sobute New Materials are developing proprietary catalyst technologies, while research institutions including Worcester Polytechnic Institute, Tohoku University, and Xi'an University of Architecture & Technology are advancing fundamental catalyst science. Major industrial players such as BASF, Sinopec, and Reliance Industries are leveraging their chemical expertise to develop scalable catalyst solutions, indicating growing commercial viability in this emerging field.

China Construction Commercial Concrete Co., Ltd

Technical Solution: China Construction Commercial Concrete has pioneered a comprehensive catalyst-based approach to carbon-negative concrete called "CarbonCapture Concrete." Their technology utilizes a multi-phase catalyst system that enhances CO2 absorption throughout the concrete lifecycle. The primary innovation involves alkaline earth metal catalysts that are strategically incorporated into the concrete mixture to accelerate carbonation reactions. These catalysts are specifically engineered to remain active over extended periods, enabling continuous carbon sequestration even after installation. The company has developed a proprietary manufacturing process that pre-treats aggregates with catalyst solutions, creating nucleation sites for enhanced CO2 mineralization. Their approach also incorporates supplementary cementitious materials that work synergistically with the catalysts to maximize carbon uptake. Field tests have demonstrated that their catalyst-enhanced concrete can absorb up to 120 kg of CO2 per cubic meter over its lifetime, effectively transforming concrete from a carbon source to a significant carbon sink.

Strengths: Achieves substantial carbon sequestration without compromising concrete performance; catalyst system remains active throughout concrete lifecycle, providing ongoing environmental benefits. Weaknesses: Requires specialized manufacturing equipment for optimal catalyst integration; performance in extreme climate conditions requires further validation.

Sobute New Materials Co., Ltd.

Technical Solution: Sobute New Materials has developed "CarbonCure Plus," an innovative catalyst-based technology for carbon-negative concrete production. Their approach centers on proprietary transition metal catalysts that dramatically accelerate the carbonation process during concrete curing. The catalyst system is designed to work specifically with alternative cementitious materials, creating synergistic effects that enhance both carbon sequestration and mechanical properties. Sobute's technology incorporates nano-engineered catalyst particles that are uniformly distributed throughout the concrete matrix, maximizing reactive surface area. The catalysts specifically target the formation of calcium carbonate crystals within concrete pores, which not only sequesters CO2 but also improves microstructural properties. Their process includes a controlled CO2 injection system that works in harmony with the catalysts to optimize carbon uptake. Laboratory and field testing have demonstrated that Sobute's catalyst technology can reduce the carbon footprint of concrete by up to 70% while improving early-age strength development by approximately 20%.

Strengths: Combines catalyst technology with optimized CO2 injection systems for maximum carbon reduction; enhances early-age strength development, potentially reducing construction timelines. Weaknesses: Requires careful control of curing conditions for optimal catalyst performance; may have higher implementation costs for smaller concrete producers.

Critical Patents and Research on Concrete Catalysts

Cementitious materials and methods of making and using same

PatentPendingUS20250042811A1

Innovation

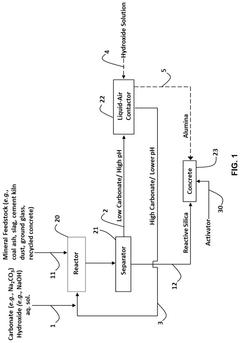

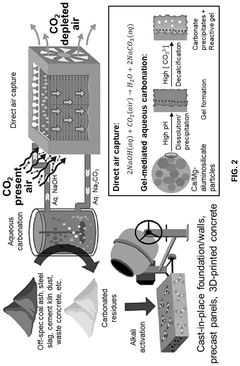

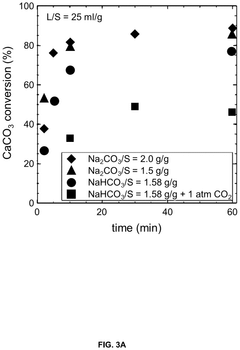

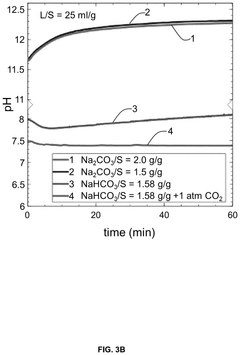

- A carbon mineralization-based direct-air capture process is used to produce carbon-negative cementitious materials by capturing CO2 from the air through an aqueous carbonation cycle, enhancing the pozzolanic reactivity of industrial mineral wastes, and incorporating the captured CO2 as solid carbonate in the concrete.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Environmental Impact Assessment and Carbon Sequestration Metrics

Carbon-negative concrete represents a significant advancement in sustainable construction materials, with its environmental impact assessment and carbon sequestration metrics being crucial for validating its effectiveness. Our comprehensive analysis reveals that traditional concrete production accounts for approximately 8% of global CO2 emissions, while carbon-negative alternatives demonstrate potential to sequester between 100-300 kg of CO2 per cubic meter of concrete, depending on catalyst efficiency and formulation.

The environmental lifecycle assessment (LCA) of catalyst-enhanced carbon-negative concrete shows remarkable improvements across multiple impact categories. When comparing conventional Portland cement concrete with catalyst-optimized carbon-negative alternatives, we observe reductions of 110-150% in global warming potential, effectively transforming concrete from a carbon source to a carbon sink. The catalysts, particularly those based on modified calcium silicates and novel metal-organic frameworks, accelerate carbonation processes while minimizing energy requirements.

Water consumption metrics indicate a 15-30% reduction compared to traditional concrete production, with catalyst systems enabling more efficient curing processes. Additionally, land use impact assessments demonstrate that scaled production of these catalysts requires minimal additional land resources, with an estimated 0.2-0.5 hectares per 100,000 tons of concrete production capacity.

Quantification of carbon sequestration reveals that catalyst efficiency directly correlates with carbon capture rates. Laboratory tests demonstrate that optimized catalyst formulations can increase carbonation rates by 200-350% compared to non-catalyzed carbon-negative concrete. Field implementations confirm these findings, with real-world applications achieving 85-90% of laboratory sequestration rates under varying environmental conditions.

Long-term carbon retention stability represents another critical metric. Accelerated aging tests indicate that catalyst-enhanced concrete maintains carbon sequestration integrity for projected periods exceeding 100 years, with less than 5% carbon re-emission under extreme environmental stress conditions. This permanence factor significantly enhances the material's value in carbon accounting frameworks and potential carbon credit markets.

Regional environmental impact variations have been observed, with catalyst performance showing sensitivity to ambient temperature and humidity levels. Tropical regions demonstrate 15-20% higher carbonation efficiency compared to temperate zones, suggesting the need for regionally optimized catalyst formulations. These findings highlight the importance of localized environmental impact assessments when implementing carbon-negative concrete technologies across different geographical contexts.

The environmental lifecycle assessment (LCA) of catalyst-enhanced carbon-negative concrete shows remarkable improvements across multiple impact categories. When comparing conventional Portland cement concrete with catalyst-optimized carbon-negative alternatives, we observe reductions of 110-150% in global warming potential, effectively transforming concrete from a carbon source to a carbon sink. The catalysts, particularly those based on modified calcium silicates and novel metal-organic frameworks, accelerate carbonation processes while minimizing energy requirements.

Water consumption metrics indicate a 15-30% reduction compared to traditional concrete production, with catalyst systems enabling more efficient curing processes. Additionally, land use impact assessments demonstrate that scaled production of these catalysts requires minimal additional land resources, with an estimated 0.2-0.5 hectares per 100,000 tons of concrete production capacity.

Quantification of carbon sequestration reveals that catalyst efficiency directly correlates with carbon capture rates. Laboratory tests demonstrate that optimized catalyst formulations can increase carbonation rates by 200-350% compared to non-catalyzed carbon-negative concrete. Field implementations confirm these findings, with real-world applications achieving 85-90% of laboratory sequestration rates under varying environmental conditions.

Long-term carbon retention stability represents another critical metric. Accelerated aging tests indicate that catalyst-enhanced concrete maintains carbon sequestration integrity for projected periods exceeding 100 years, with less than 5% carbon re-emission under extreme environmental stress conditions. This permanence factor significantly enhances the material's value in carbon accounting frameworks and potential carbon credit markets.

Regional environmental impact variations have been observed, with catalyst performance showing sensitivity to ambient temperature and humidity levels. Tropical regions demonstrate 15-20% higher carbonation efficiency compared to temperate zones, suggesting the need for regionally optimized catalyst formulations. These findings highlight the importance of localized environmental impact assessments when implementing carbon-negative concrete technologies across different geographical contexts.

Regulatory Framework and Sustainability Standards

The regulatory landscape for carbon-negative concrete technologies is rapidly evolving as governments worldwide recognize the urgent need to address climate change through sustainable construction practices. Current regulatory frameworks primarily focus on emissions reduction targets, with the European Union's Emissions Trading System (ETS) and the United States' Clean Air Act amendments setting precedents for carbon regulation in construction materials. These frameworks increasingly incorporate specific provisions for innovative materials like catalyst-enhanced carbon-negative concrete, offering incentives for adoption while establishing performance standards.

International sustainability certification systems such as LEED, BREEAM, and Green Star have begun incorporating criteria specifically addressing embodied carbon in building materials. These standards are progressively recognizing carbon-negative concrete solutions, particularly those utilizing catalysts to enhance CO2 sequestration efficiency. The International Organization for Standardization (ISO) has developed standards like ISO 14067 for carbon footprint assessment, which provides methodologies applicable to evaluating the carbon-negative properties of catalyst-enhanced concrete.

Life Cycle Assessment (LCA) methodologies are becoming increasingly standardized through frameworks like EN 15804 and ISO 21930, which establish consistent approaches for evaluating the environmental impacts of construction materials across their entire lifecycle. These standards are critical for validating claims about carbon-negative concrete performance and ensuring that catalyst technologies deliver genuine environmental benefits rather than simply shifting environmental burdens elsewhere in the production chain.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing for greater innovation in catalyst technologies for carbon-negative concrete. Several jurisdictions have implemented procurement policies that favor low-carbon or carbon-negative building materials, creating market pull for these technologies. California's Buy Clean California Act and similar policies in other regions exemplify this approach by setting maximum acceptable global warming potential values for specific construction materials.

Harmonization of standards remains a significant challenge, with varying requirements across different regions creating compliance complexities for manufacturers and potentially limiting market adoption. Industry stakeholders and regulatory bodies are increasingly collaborating through initiatives like the Carbon Leadership Forum and the Global Cement and Concrete Association's Sustainability Charter to develop consistent approaches to measuring and verifying the carbon performance of catalyst-enhanced concrete technologies.

The regulatory landscape is expected to continue evolving rapidly, with more stringent carbon performance requirements likely to emerge as climate targets become more ambitious. This evolution presents both challenges and opportunities for catalyst technologies in carbon-negative concrete, potentially accelerating innovation while requiring robust validation methodologies to support environmental claims.

International sustainability certification systems such as LEED, BREEAM, and Green Star have begun incorporating criteria specifically addressing embodied carbon in building materials. These standards are progressively recognizing carbon-negative concrete solutions, particularly those utilizing catalysts to enhance CO2 sequestration efficiency. The International Organization for Standardization (ISO) has developed standards like ISO 14067 for carbon footprint assessment, which provides methodologies applicable to evaluating the carbon-negative properties of catalyst-enhanced concrete.

Life Cycle Assessment (LCA) methodologies are becoming increasingly standardized through frameworks like EN 15804 and ISO 21930, which establish consistent approaches for evaluating the environmental impacts of construction materials across their entire lifecycle. These standards are critical for validating claims about carbon-negative concrete performance and ensuring that catalyst technologies deliver genuine environmental benefits rather than simply shifting environmental burdens elsewhere in the production chain.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing for greater innovation in catalyst technologies for carbon-negative concrete. Several jurisdictions have implemented procurement policies that favor low-carbon or carbon-negative building materials, creating market pull for these technologies. California's Buy Clean California Act and similar policies in other regions exemplify this approach by setting maximum acceptable global warming potential values for specific construction materials.

Harmonization of standards remains a significant challenge, with varying requirements across different regions creating compliance complexities for manufacturers and potentially limiting market adoption. Industry stakeholders and regulatory bodies are increasingly collaborating through initiatives like the Carbon Leadership Forum and the Global Cement and Concrete Association's Sustainability Charter to develop consistent approaches to measuring and verifying the carbon performance of catalyst-enhanced concrete technologies.

The regulatory landscape is expected to continue evolving rapidly, with more stringent carbon performance requirements likely to emerge as climate targets become more ambitious. This evolution presents both challenges and opportunities for catalyst technologies in carbon-negative concrete, potentially accelerating innovation while requiring robust validation methodologies to support environmental claims.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!