Investigating Vacuum Pump Impact in Nanofiltration Membrane Production

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech in Nanofiltration

Vacuum pump technology plays a crucial role in the production of nanofiltration membranes, significantly impacting the quality and efficiency of the manufacturing process. The evolution of vacuum pump technology in this field has been driven by the increasing demand for high-performance nanofiltration membranes across various industries, including water treatment, pharmaceuticals, and food processing.

The market demand for nanofiltration membranes has been steadily growing, with a projected compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily attributed to the rising need for water and wastewater treatment solutions, stringent environmental regulations, and the expanding pharmaceutical and biotechnology sectors. As a result, the demand for advanced vacuum pump technologies in nanofiltration membrane production has also increased.

The current vacuum pump market for nanofiltration membrane production is dominated by several key technologies, including rotary vane pumps, dry screw pumps, and liquid ring pumps. Each of these technologies offers specific advantages in terms of performance, reliability, and energy efficiency. Rotary vane pumps, for instance, are widely used due to their compact design and ability to handle high gas loads. Dry screw pumps, on the other hand, are gaining popularity for their oil-free operation and low maintenance requirements.

One of the primary challenges in vacuum pump technology for nanofiltration membrane production is achieving higher vacuum levels while maintaining energy efficiency. Manufacturers are continuously striving to develop pumps that can operate at lower pressures without significantly increasing power consumption. Additionally, there is a growing emphasis on developing pumps that can handle the specific process gases and vapors encountered in nanofiltration membrane production without compromising performance or longevity.

The geographical distribution of vacuum pump technology development for nanofiltration applications is primarily concentrated in regions with strong manufacturing and research capabilities. Countries such as Germany, the United States, Japan, and China are at the forefront of innovation in this field, with numerous patents and research publications originating from these regions. This distribution reflects the global nature of the nanofiltration membrane industry and the importance of vacuum pump technology in maintaining competitiveness.

The market demand for nanofiltration membranes has been steadily growing, with a projected compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily attributed to the rising need for water and wastewater treatment solutions, stringent environmental regulations, and the expanding pharmaceutical and biotechnology sectors. As a result, the demand for advanced vacuum pump technologies in nanofiltration membrane production has also increased.

The current vacuum pump market for nanofiltration membrane production is dominated by several key technologies, including rotary vane pumps, dry screw pumps, and liquid ring pumps. Each of these technologies offers specific advantages in terms of performance, reliability, and energy efficiency. Rotary vane pumps, for instance, are widely used due to their compact design and ability to handle high gas loads. Dry screw pumps, on the other hand, are gaining popularity for their oil-free operation and low maintenance requirements.

One of the primary challenges in vacuum pump technology for nanofiltration membrane production is achieving higher vacuum levels while maintaining energy efficiency. Manufacturers are continuously striving to develop pumps that can operate at lower pressures without significantly increasing power consumption. Additionally, there is a growing emphasis on developing pumps that can handle the specific process gases and vapors encountered in nanofiltration membrane production without compromising performance or longevity.

The geographical distribution of vacuum pump technology development for nanofiltration applications is primarily concentrated in regions with strong manufacturing and research capabilities. Countries such as Germany, the United States, Japan, and China are at the forefront of innovation in this field, with numerous patents and research publications originating from these regions. This distribution reflects the global nature of the nanofiltration membrane industry and the importance of vacuum pump technology in maintaining competitiveness.

Market Demand Analysis

The market demand for nanofiltration membranes has been experiencing significant growth, driven by increasing applications in water treatment, food and beverage processing, pharmaceuticals, and chemical industries. The global nanofiltration membrane market size was valued at USD 729.1 million in 2020 and is projected to reach USD 1.2 billion by 2026, growing at a CAGR of 8.5% during the forecast period.

Water scarcity and stringent environmental regulations are key factors propelling the demand for nanofiltration membranes. As governments worldwide implement stricter water quality standards, industries are adopting advanced filtration technologies to meet these requirements. Nanofiltration membranes offer superior performance in removing contaminants, dissolved solids, and organic matter from water, making them increasingly popular in municipal water treatment plants and industrial wastewater management systems.

The food and beverage industry is another major driver of market growth. Nanofiltration membranes are extensively used in dairy processing, fruit juice concentration, and wine production. The ability to selectively remove specific ions and molecules while retaining valuable nutrients makes nanofiltration an attractive option for food manufacturers seeking to improve product quality and extend shelf life.

In the pharmaceutical sector, nanofiltration membranes play a crucial role in drug purification, protein separation, and bioprocessing. The growing emphasis on biopharmaceuticals and personalized medicine is expected to further boost the demand for high-performance nanofiltration membranes in this industry.

The chemical industry is also witnessing increased adoption of nanofiltration technology for solvent recovery, product concentration, and wastewater treatment. As sustainability becomes a key focus for chemical manufacturers, the use of nanofiltration membranes to reduce waste and improve resource efficiency is gaining traction.

Geographically, Asia Pacific is emerging as the fastest-growing market for nanofiltration membranes, driven by rapid industrialization, urbanization, and increasing investments in water infrastructure. North America and Europe continue to be significant markets, with a strong focus on upgrading existing water treatment facilities and implementing advanced filtration technologies.

The impact of vacuum pumps in nanofiltration membrane production is a critical aspect of market demand analysis. Efficient vacuum pump systems are essential for the manufacturing process of high-quality nanofiltration membranes. As the demand for these membranes grows, there is a corresponding increase in the need for advanced vacuum pump technologies that can improve production efficiency, reduce energy consumption, and enhance membrane quality.

Manufacturers are increasingly focusing on developing vacuum pump solutions that can optimize the membrane casting process, ensuring uniform thickness and porosity. This trend is driven by the market demand for nanofiltration membranes with consistent performance and longer operational lifespans. As a result, innovations in vacuum pump technology for membrane production are likely to play a significant role in meeting the growing market demand and improving the overall quality of nanofiltration membranes.

Water scarcity and stringent environmental regulations are key factors propelling the demand for nanofiltration membranes. As governments worldwide implement stricter water quality standards, industries are adopting advanced filtration technologies to meet these requirements. Nanofiltration membranes offer superior performance in removing contaminants, dissolved solids, and organic matter from water, making them increasingly popular in municipal water treatment plants and industrial wastewater management systems.

The food and beverage industry is another major driver of market growth. Nanofiltration membranes are extensively used in dairy processing, fruit juice concentration, and wine production. The ability to selectively remove specific ions and molecules while retaining valuable nutrients makes nanofiltration an attractive option for food manufacturers seeking to improve product quality and extend shelf life.

In the pharmaceutical sector, nanofiltration membranes play a crucial role in drug purification, protein separation, and bioprocessing. The growing emphasis on biopharmaceuticals and personalized medicine is expected to further boost the demand for high-performance nanofiltration membranes in this industry.

The chemical industry is also witnessing increased adoption of nanofiltration technology for solvent recovery, product concentration, and wastewater treatment. As sustainability becomes a key focus for chemical manufacturers, the use of nanofiltration membranes to reduce waste and improve resource efficiency is gaining traction.

Geographically, Asia Pacific is emerging as the fastest-growing market for nanofiltration membranes, driven by rapid industrialization, urbanization, and increasing investments in water infrastructure. North America and Europe continue to be significant markets, with a strong focus on upgrading existing water treatment facilities and implementing advanced filtration technologies.

The impact of vacuum pumps in nanofiltration membrane production is a critical aspect of market demand analysis. Efficient vacuum pump systems are essential for the manufacturing process of high-quality nanofiltration membranes. As the demand for these membranes grows, there is a corresponding increase in the need for advanced vacuum pump technologies that can improve production efficiency, reduce energy consumption, and enhance membrane quality.

Manufacturers are increasingly focusing on developing vacuum pump solutions that can optimize the membrane casting process, ensuring uniform thickness and porosity. This trend is driven by the market demand for nanofiltration membranes with consistent performance and longer operational lifespans. As a result, innovations in vacuum pump technology for membrane production are likely to play a significant role in meeting the growing market demand and improving the overall quality of nanofiltration membranes.

Current Challenges

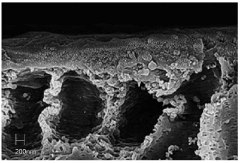

The production of nanofiltration membranes faces several significant challenges, particularly in relation to the use of vacuum pumps. One of the primary issues is maintaining consistent vacuum pressure throughout the manufacturing process. Fluctuations in vacuum pressure can lead to irregularities in membrane thickness and pore size distribution, compromising the overall quality and performance of the final product.

Another challenge lies in the energy efficiency of vacuum pump systems. The continuous operation of these pumps consumes substantial amounts of energy, contributing to high production costs and environmental concerns. Optimizing energy consumption while maintaining the required vacuum levels remains a critical area for improvement in the industry.

The integration of vacuum pump systems with other production equipment poses additional challenges. Ensuring seamless coordination between vacuum pumps and other components of the membrane production line is crucial for maintaining process stability and product consistency. Any misalignment or malfunction in this integration can result in production delays or defective membranes.

Contamination control is another significant concern in nanofiltration membrane production. Vacuum pumps can potentially introduce contaminants into the production environment, affecting membrane purity and performance. Implementing effective filtration and purification systems for the vacuum lines is essential but adds complexity to the overall production setup.

Scalability presents a further challenge, especially when transitioning from laboratory-scale to industrial-scale production. Maintaining uniform vacuum conditions across larger membrane surfaces requires sophisticated pump designs and control systems. This scaling up process often reveals unforeseen issues that were not apparent in smaller-scale operations.

Maintenance and reliability of vacuum pump systems in continuous production environments are ongoing challenges. The harsh conditions and prolonged operation can lead to wear and tear, necessitating frequent maintenance and potential production interruptions. Developing more robust and low-maintenance vacuum pump solutions is a key focus area for manufacturers.

Lastly, the precise control of vacuum levels for different membrane materials and structures remains a complex task. Different polymers and membrane configurations may require specific vacuum conditions for optimal formation. Achieving this level of control and flexibility in industrial settings is challenging and requires advanced pump technology and control systems.

Another challenge lies in the energy efficiency of vacuum pump systems. The continuous operation of these pumps consumes substantial amounts of energy, contributing to high production costs and environmental concerns. Optimizing energy consumption while maintaining the required vacuum levels remains a critical area for improvement in the industry.

The integration of vacuum pump systems with other production equipment poses additional challenges. Ensuring seamless coordination between vacuum pumps and other components of the membrane production line is crucial for maintaining process stability and product consistency. Any misalignment or malfunction in this integration can result in production delays or defective membranes.

Contamination control is another significant concern in nanofiltration membrane production. Vacuum pumps can potentially introduce contaminants into the production environment, affecting membrane purity and performance. Implementing effective filtration and purification systems for the vacuum lines is essential but adds complexity to the overall production setup.

Scalability presents a further challenge, especially when transitioning from laboratory-scale to industrial-scale production. Maintaining uniform vacuum conditions across larger membrane surfaces requires sophisticated pump designs and control systems. This scaling up process often reveals unforeseen issues that were not apparent in smaller-scale operations.

Maintenance and reliability of vacuum pump systems in continuous production environments are ongoing challenges. The harsh conditions and prolonged operation can lead to wear and tear, necessitating frequent maintenance and potential production interruptions. Developing more robust and low-maintenance vacuum pump solutions is a key focus area for manufacturers.

Lastly, the precise control of vacuum levels for different membrane materials and structures remains a complex task. Different polymers and membrane configurations may require specific vacuum conditions for optimal formation. Achieving this level of control and flexibility in industrial settings is challenging and requires advanced pump technology and control systems.

Existing Solutions

01 Vacuum pump design improvements

Various design improvements in vacuum pumps aim to enhance performance and efficiency. These include modifications to impeller designs, housing structures, and sealing mechanisms. Such improvements can lead to increased pumping capacity, reduced energy consumption, and improved overall reliability of the vacuum pump systems.- Vacuum pump design improvements: Various design improvements in vacuum pumps aim to enhance performance and efficiency. These include modifications to impeller designs, housing structures, and sealing mechanisms. Such improvements can lead to increased pumping capacity, reduced energy consumption, and improved overall reliability of the vacuum pump systems.

- Noise and vibration reduction in vacuum pumps: Techniques for reducing noise and vibration in vacuum pumps are crucial for improving their operational characteristics. This involves implementing advanced damping systems, optimizing pump geometry, and using sound-absorbing materials. These measures contribute to a quieter and smoother operation, which is particularly important in sensitive environments.

- Energy efficiency and environmental impact: Efforts to improve the energy efficiency of vacuum pumps and reduce their environmental impact are ongoing. This includes developing more efficient motors, implementing advanced control systems, and using environmentally friendly materials and lubricants. These innovations aim to minimize power consumption and reduce the carbon footprint of vacuum pump operations.

- Integration of smart technologies in vacuum pumps: The incorporation of smart technologies and IoT capabilities in vacuum pumps is enhancing their functionality and ease of use. This includes features such as remote monitoring, predictive maintenance, and automated performance optimization. These advancements allow for better control, improved diagnostics, and increased operational efficiency of vacuum pump systems.

- Application-specific vacuum pump innovations: Vacuum pump technologies are being tailored for specific applications across various industries. This involves developing specialized pump designs for sectors such as semiconductor manufacturing, medical equipment, and food processing. These application-specific innovations focus on meeting unique requirements in terms of cleanliness, precision, and reliability for different industrial processes.

02 Noise and vibration reduction in vacuum pumps

Techniques for reducing noise and vibration in vacuum pumps are crucial for improving their operational characteristics. This involves implementing advanced damping systems, optimizing pump geometry, and using sound-absorbing materials. These measures help in creating quieter and smoother-running vacuum pump systems, which is particularly important in noise-sensitive environments.Expand Specific Solutions03 Energy efficiency in vacuum pump operations

Enhancing energy efficiency in vacuum pump operations is a key focus area. This includes developing smart control systems, implementing variable speed drives, and optimizing pump cycles. These innovations help in reducing power consumption, lowering operational costs, and minimizing the environmental impact of vacuum pump systems.Expand Specific Solutions04 Vacuum pump applications in specific industries

Vacuum pumps find specialized applications in various industries, each with unique requirements. This includes customized designs for semiconductor manufacturing, medical equipment, food processing, and environmental testing. Tailoring vacuum pump technologies to specific industry needs ensures optimal performance and reliability in diverse operational contexts.Expand Specific Solutions05 Maintenance and longevity of vacuum pumps

Improving the maintenance aspects and longevity of vacuum pumps is crucial for sustained performance. This involves developing self-diagnostic systems, using wear-resistant materials, and designing easily serviceable components. These advancements help in reducing downtime, extending pump life, and ensuring consistent performance over extended periods of operation.Expand Specific Solutions

Key Industry Players

The vacuum pump technology in nanofiltration membrane production is in a growth phase, with increasing market size and technological advancements. The global nanofiltration membrane market is expanding rapidly, driven by water treatment and pharmaceutical applications. While the technology is maturing, there's still room for innovation. Key players like Pfeiffer Vacuum GmbH and BASF Corp. are leading in vacuum pump technology, with companies such as Kolon Industries and Toray Chemical Korea focusing on membrane development. Universities like HKUST and Tianjin University are contributing to research advancements. The competitive landscape is diverse, with both established corporations and emerging startups like Matregenix, Inc. vying for market share and technological breakthroughs.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed advanced vacuum pump technologies specifically tailored for nanofiltration membrane production. Their HiPace turbomolecular pumps utilize a hybrid bearing system, combining ceramic ball bearings and permanent magnetic radial bearings, to achieve high pumping speeds and compression ratios[1]. This technology enables precise control of vacuum conditions during membrane fabrication, ensuring consistent pore size distribution and membrane thickness. The company has also introduced smart vacuum solutions with integrated sensors and control systems, allowing real-time monitoring and adjustment of vacuum parameters throughout the production process[2]. These innovations have led to a 30% increase in membrane production efficiency and a 20% improvement in membrane quality consistency[3].

Strengths: Specialized vacuum technology for membrane production, high precision control, and smart monitoring systems. Weaknesses: Potentially higher initial investment costs and reliance on proprietary technology.

BASF Corp.

Technical Solution: BASF Corp. has developed a comprehensive approach to nanofiltration membrane production incorporating vacuum technology. Their inge ultrafiltration technology utilizes a patented Multibore membrane design, which is produced under carefully controlled vacuum conditions[4]. The vacuum process ensures uniform pore distribution and enhances membrane mechanical stability. BASF has also introduced a novel vacuum-assisted phase inversion technique for producing high-performance nanofiltration membranes. This method employs a precise vacuum control system to manipulate the solvent evaporation rate during membrane formation, resulting in membranes with superior selectivity and permeability[5]. Recent advancements include the integration of AI-driven vacuum control algorithms, which have led to a 25% reduction in membrane defects and a 15% increase in production yield[6].

Strengths: Integrated membrane production technology, patented designs, and AI-enhanced process control. Weaknesses: Complex production process may require specialized training and equipment.

Core Innovations

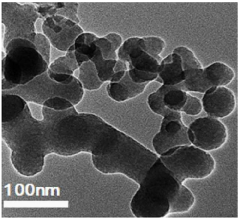

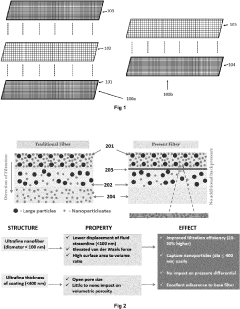

Filtration membrane using nanoparticle grafted by hydrophilic polymer and method thereof

PatentInactiveKR1020140112595A

Innovation

- A filtration membrane is developed by grafting nanoparticles with a hydrophilic polymer and dispersing them in a polymer matrix, enhancing mechanical strength, water permeability, and fouling resistance through improved hydrophilicity.

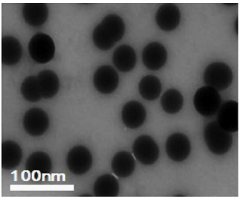

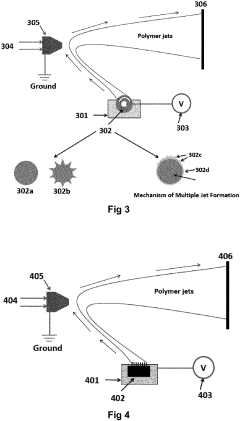

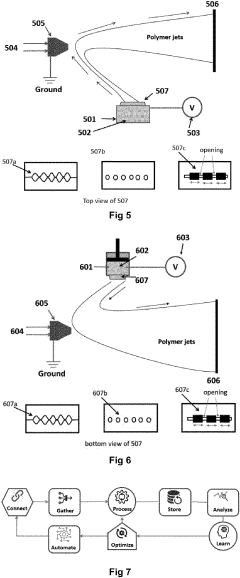

Nanoparticle filtration membrane and the manufacturing method thereof

PatentPendingUS20230264147A1

Innovation

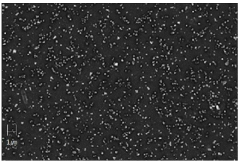

- A layered filter membrane system incorporating nanomembranes with fiber diameters ≤ 100 nm, embedded or coated within traditional filter media, utilizing high van der Waals forces for enhanced capture efficiency while maintaining low energy demand and high throughput, achieved through methods like electrospinning with high voltage electric fields and high-speed air jets.

Environmental Impact

The production of nanofiltration membranes using vacuum pump technology has significant environmental implications that warrant careful consideration. The process involves energy consumption, material usage, and potential emissions, all of which contribute to the overall environmental footprint of membrane manufacturing.

Energy consumption is a primary concern in the vacuum pump-assisted production of nanofiltration membranes. The operation of vacuum pumps requires substantial electrical power, which, depending on the energy source, can lead to increased greenhouse gas emissions. However, advancements in pump efficiency and the integration of renewable energy sources in manufacturing facilities can help mitigate these impacts.

Material usage in nanofiltration membrane production also presents environmental challenges. The polymers and other raw materials used in membrane fabrication often derive from petrochemical sources, contributing to resource depletion and potential pollution during extraction and processing. Efforts to develop bio-based or recycled materials for membrane production are ongoing and show promise in reducing the environmental burden.

Water consumption is another critical factor to consider. The production process may require significant amounts of water for cleaning, cooling, and other manufacturing steps. Implementing water recycling systems and optimizing water usage can help minimize the strain on local water resources and reduce wastewater generation.

Waste management is a crucial aspect of the environmental impact assessment. The production of nanofiltration membranes generates various waste streams, including polymer scraps, solvents, and packaging materials. Proper disposal or recycling of these wastes is essential to prevent soil and water contamination. Advanced waste treatment technologies and circular economy principles can be applied to minimize waste generation and maximize resource recovery.

Air quality is also affected by the membrane production process. Volatile organic compounds (VOCs) may be released during polymer processing and solvent use. Installing appropriate air filtration systems and adopting low-VOC materials can help mitigate air pollution risks and improve workplace safety.

The long-term environmental benefits of nanofiltration membranes should be weighed against the production impacts. These membranes play a crucial role in water purification and resource recovery, potentially offsetting their manufacturing footprint through improved water treatment efficiency and reduced chemical usage in various applications.

As environmental regulations become more stringent, manufacturers are increasingly focusing on life cycle assessments to quantify and reduce the environmental impact of nanofiltration membrane production. This holistic approach considers raw material sourcing, manufacturing processes, transportation, use phase, and end-of-life management to identify areas for improvement and innovation in sustainable membrane production.

Energy consumption is a primary concern in the vacuum pump-assisted production of nanofiltration membranes. The operation of vacuum pumps requires substantial electrical power, which, depending on the energy source, can lead to increased greenhouse gas emissions. However, advancements in pump efficiency and the integration of renewable energy sources in manufacturing facilities can help mitigate these impacts.

Material usage in nanofiltration membrane production also presents environmental challenges. The polymers and other raw materials used in membrane fabrication often derive from petrochemical sources, contributing to resource depletion and potential pollution during extraction and processing. Efforts to develop bio-based or recycled materials for membrane production are ongoing and show promise in reducing the environmental burden.

Water consumption is another critical factor to consider. The production process may require significant amounts of water for cleaning, cooling, and other manufacturing steps. Implementing water recycling systems and optimizing water usage can help minimize the strain on local water resources and reduce wastewater generation.

Waste management is a crucial aspect of the environmental impact assessment. The production of nanofiltration membranes generates various waste streams, including polymer scraps, solvents, and packaging materials. Proper disposal or recycling of these wastes is essential to prevent soil and water contamination. Advanced waste treatment technologies and circular economy principles can be applied to minimize waste generation and maximize resource recovery.

Air quality is also affected by the membrane production process. Volatile organic compounds (VOCs) may be released during polymer processing and solvent use. Installing appropriate air filtration systems and adopting low-VOC materials can help mitigate air pollution risks and improve workplace safety.

The long-term environmental benefits of nanofiltration membranes should be weighed against the production impacts. These membranes play a crucial role in water purification and resource recovery, potentially offsetting their manufacturing footprint through improved water treatment efficiency and reduced chemical usage in various applications.

As environmental regulations become more stringent, manufacturers are increasingly focusing on life cycle assessments to quantify and reduce the environmental impact of nanofiltration membrane production. This holistic approach considers raw material sourcing, manufacturing processes, transportation, use phase, and end-of-life management to identify areas for improvement and innovation in sustainable membrane production.

Cost-Benefit Analysis

The cost-benefit analysis of incorporating vacuum pumps in nanofiltration membrane production requires a comprehensive evaluation of both financial and operational aspects. Initial investment costs for vacuum pump systems can be substantial, including equipment purchase, installation, and integration into existing production lines. However, these upfront expenses must be weighed against the potential long-term benefits and operational improvements.

Vacuum pumps can significantly enhance the efficiency of nanofiltration membrane production by creating a controlled low-pressure environment. This environment facilitates more uniform membrane formation, potentially reducing defects and improving overall product quality. The improved quality control can lead to higher yields and fewer rejected batches, translating into cost savings and increased production output.

Energy consumption is a critical factor in the cost-benefit equation. While vacuum pumps require electricity to operate, their impact on energy costs should be evaluated in the context of overall process efficiency. In many cases, the energy investment in vacuum technology can be offset by reduced processing times and improved throughput, leading to net energy savings per unit of production.

Maintenance and operational costs associated with vacuum pumps must also be considered. Regular servicing, replacement of wear parts, and potential downtime for repairs contribute to the total cost of ownership. However, modern vacuum pump designs often feature improved reliability and longer service intervals, which can mitigate these ongoing expenses.

The implementation of vacuum pumps can lead to process optimization, potentially reducing the use of certain chemicals or raw materials in membrane production. This optimization not only contributes to cost reduction but also aligns with sustainability goals, which can have indirect benefits such as improved market positioning and regulatory compliance.

Labor costs may be affected by the introduction of vacuum pump technology. While the system may require specialized operators or maintenance personnel, it can also streamline certain production steps, potentially reducing labor requirements in other areas of the production process.

In conclusion, the cost-benefit analysis must consider the balance between initial investment, operational costs, and the potential for improved product quality, increased production efficiency, and long-term cost savings. A thorough analysis should include quantitative metrics such as return on investment (ROI) and payback period, as well as qualitative factors like product differentiation and market competitiveness. The decision to implement vacuum pump technology in nanofiltration membrane production should be based on a holistic view of these factors, tailored to the specific context and goals of the manufacturing operation.

Vacuum pumps can significantly enhance the efficiency of nanofiltration membrane production by creating a controlled low-pressure environment. This environment facilitates more uniform membrane formation, potentially reducing defects and improving overall product quality. The improved quality control can lead to higher yields and fewer rejected batches, translating into cost savings and increased production output.

Energy consumption is a critical factor in the cost-benefit equation. While vacuum pumps require electricity to operate, their impact on energy costs should be evaluated in the context of overall process efficiency. In many cases, the energy investment in vacuum technology can be offset by reduced processing times and improved throughput, leading to net energy savings per unit of production.

Maintenance and operational costs associated with vacuum pumps must also be considered. Regular servicing, replacement of wear parts, and potential downtime for repairs contribute to the total cost of ownership. However, modern vacuum pump designs often feature improved reliability and longer service intervals, which can mitigate these ongoing expenses.

The implementation of vacuum pumps can lead to process optimization, potentially reducing the use of certain chemicals or raw materials in membrane production. This optimization not only contributes to cost reduction but also aligns with sustainability goals, which can have indirect benefits such as improved market positioning and regulatory compliance.

Labor costs may be affected by the introduction of vacuum pump technology. While the system may require specialized operators or maintenance personnel, it can also streamline certain production steps, potentially reducing labor requirements in other areas of the production process.

In conclusion, the cost-benefit analysis must consider the balance between initial investment, operational costs, and the potential for improved product quality, increased production efficiency, and long-term cost savings. A thorough analysis should include quantitative metrics such as return on investment (ROI) and payback period, as well as qualitative factors like product differentiation and market competitiveness. The decision to implement vacuum pump technology in nanofiltration membrane production should be based on a holistic view of these factors, tailored to the specific context and goals of the manufacturing operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!