Investigating Vacuum Pump Reliability in Extreme Conditions

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Objectives

Vacuum pump technology has undergone significant evolution since its inception in the 17th century. From the early mechanical pumps to today's advanced molecular and turbomolecular designs, the field has seen continuous improvements in efficiency, reliability, and performance. The primary objective in investigating vacuum pump reliability in extreme conditions is to push the boundaries of current technology, ensuring consistent operation in challenging environments such as space exploration, semiconductor manufacturing, and high-energy physics research.

The development of vacuum pumps has been driven by the increasing demands of various industries requiring precise control over pressure and gas composition. Early pumps were limited in their ability to achieve high vacuums and often suffered from contamination issues. As scientific understanding of vacuum physics improved, so did pump designs, leading to the creation of oil-sealed rotary vane pumps, diffusion pumps, and eventually, the highly efficient turbomolecular pumps.

In recent years, the focus has shifted towards enhancing pump reliability under extreme conditions. This includes operation in environments with high temperatures, corrosive gases, or intense radiation. The goal is to develop pumps that can maintain stable performance and longevity in these challenging scenarios, thereby expanding the range of applications for vacuum technology.

One of the key objectives in this field is to improve the materials used in pump construction. Research is ongoing to develop alloys and composites that can withstand harsh chemical environments and extreme temperatures without degradation. Additionally, there is a push to optimize pump designs for minimal wear and tear, reducing maintenance requirements and extending operational lifespans.

Another critical area of focus is the development of advanced control systems and sensors. These technologies aim to provide real-time monitoring of pump performance, allowing for predictive maintenance and rapid response to changing conditions. By integrating smart technologies, researchers hope to create self-diagnosing and self-adjusting pumps capable of maintaining optimal performance even in fluctuating environments.

The ultimate objective of this research is to create a new generation of vacuum pumps that can operate reliably in conditions previously thought impossible. This includes pumps capable of functioning in the vacuum of space for extended periods, in ultra-clean environments for advanced manufacturing processes, and in high-radiation zones for nuclear applications. Achieving these goals will not only advance the field of vacuum technology but also enable breakthroughs in related scientific and industrial domains.

The development of vacuum pumps has been driven by the increasing demands of various industries requiring precise control over pressure and gas composition. Early pumps were limited in their ability to achieve high vacuums and often suffered from contamination issues. As scientific understanding of vacuum physics improved, so did pump designs, leading to the creation of oil-sealed rotary vane pumps, diffusion pumps, and eventually, the highly efficient turbomolecular pumps.

In recent years, the focus has shifted towards enhancing pump reliability under extreme conditions. This includes operation in environments with high temperatures, corrosive gases, or intense radiation. The goal is to develop pumps that can maintain stable performance and longevity in these challenging scenarios, thereby expanding the range of applications for vacuum technology.

One of the key objectives in this field is to improve the materials used in pump construction. Research is ongoing to develop alloys and composites that can withstand harsh chemical environments and extreme temperatures without degradation. Additionally, there is a push to optimize pump designs for minimal wear and tear, reducing maintenance requirements and extending operational lifespans.

Another critical area of focus is the development of advanced control systems and sensors. These technologies aim to provide real-time monitoring of pump performance, allowing for predictive maintenance and rapid response to changing conditions. By integrating smart technologies, researchers hope to create self-diagnosing and self-adjusting pumps capable of maintaining optimal performance even in fluctuating environments.

The ultimate objective of this research is to create a new generation of vacuum pumps that can operate reliably in conditions previously thought impossible. This includes pumps capable of functioning in the vacuum of space for extended periods, in ultra-clean environments for advanced manufacturing processes, and in high-radiation zones for nuclear applications. Achieving these goals will not only advance the field of vacuum technology but also enable breakthroughs in related scientific and industrial domains.

Market Demand Analysis

The market demand for reliable vacuum pumps in extreme conditions has been steadily increasing across various industries. This growth is primarily driven by the expanding applications in semiconductor manufacturing, aerospace, and scientific research sectors. These industries require vacuum pumps that can maintain consistent performance under challenging environments, such as high temperatures, corrosive atmospheres, or extreme pressures.

In the semiconductor industry, the demand for vacuum pumps capable of operating in ultra-clean environments is particularly high. As chip manufacturers continue to push the boundaries of miniaturization and complexity, the need for more advanced and reliable vacuum systems becomes critical. The global semiconductor market is projected to reach $726 billion by 2027, indicating a substantial potential for vacuum pump manufacturers catering to this sector.

The aerospace industry presents another significant market opportunity for robust vacuum pumps. With the increasing number of satellite launches and space exploration missions, there is a growing demand for vacuum pumps that can withstand the harsh conditions of space. The global space industry is expected to generate revenue of $558 billion by 2026, highlighting the potential for vacuum pump manufacturers in this sector.

Scientific research facilities, such as particle accelerators and fusion reactors, also require highly reliable vacuum pumps capable of operating under extreme conditions. These facilities often push the boundaries of physics and material science, necessitating vacuum systems that can maintain stable performance over extended periods. The global market for scientific research and development services is forecasted to reach $664.5 billion by 2025, indicating a substantial opportunity for specialized vacuum pump solutions.

The oil and gas industry represents another significant market for vacuum pumps operating in extreme conditions. Offshore drilling operations and subsea installations require vacuum systems that can withstand high pressures, corrosive environments, and temperature fluctuations. The global offshore oil and gas market is expected to reach $155 billion by 2027, presenting a considerable market for ruggedized vacuum pump solutions.

The increasing focus on environmental sustainability and energy efficiency is also driving demand for more reliable and efficient vacuum pumps. Industries are seeking solutions that can reduce energy consumption and minimize maintenance requirements, even in challenging operating conditions. This trend is expected to continue, creating opportunities for innovative vacuum pump designs that offer improved reliability and efficiency.

As industries continue to push technological boundaries and operate in more challenging environments, the demand for vacuum pumps capable of maintaining reliability in extreme conditions is expected to grow. Manufacturers who can develop and deliver robust, efficient, and adaptable vacuum pump solutions are likely to find significant market opportunities across multiple sectors in the coming years.

In the semiconductor industry, the demand for vacuum pumps capable of operating in ultra-clean environments is particularly high. As chip manufacturers continue to push the boundaries of miniaturization and complexity, the need for more advanced and reliable vacuum systems becomes critical. The global semiconductor market is projected to reach $726 billion by 2027, indicating a substantial potential for vacuum pump manufacturers catering to this sector.

The aerospace industry presents another significant market opportunity for robust vacuum pumps. With the increasing number of satellite launches and space exploration missions, there is a growing demand for vacuum pumps that can withstand the harsh conditions of space. The global space industry is expected to generate revenue of $558 billion by 2026, highlighting the potential for vacuum pump manufacturers in this sector.

Scientific research facilities, such as particle accelerators and fusion reactors, also require highly reliable vacuum pumps capable of operating under extreme conditions. These facilities often push the boundaries of physics and material science, necessitating vacuum systems that can maintain stable performance over extended periods. The global market for scientific research and development services is forecasted to reach $664.5 billion by 2025, indicating a substantial opportunity for specialized vacuum pump solutions.

The oil and gas industry represents another significant market for vacuum pumps operating in extreme conditions. Offshore drilling operations and subsea installations require vacuum systems that can withstand high pressures, corrosive environments, and temperature fluctuations. The global offshore oil and gas market is expected to reach $155 billion by 2027, presenting a considerable market for ruggedized vacuum pump solutions.

The increasing focus on environmental sustainability and energy efficiency is also driving demand for more reliable and efficient vacuum pumps. Industries are seeking solutions that can reduce energy consumption and minimize maintenance requirements, even in challenging operating conditions. This trend is expected to continue, creating opportunities for innovative vacuum pump designs that offer improved reliability and efficiency.

As industries continue to push technological boundaries and operate in more challenging environments, the demand for vacuum pumps capable of maintaining reliability in extreme conditions is expected to grow. Manufacturers who can develop and deliver robust, efficient, and adaptable vacuum pump solutions are likely to find significant market opportunities across multiple sectors in the coming years.

Current Challenges in Extreme Environments

Vacuum pumps operating in extreme conditions face numerous challenges that significantly impact their reliability and performance. These harsh environments, characterized by extreme temperatures, high pressures, corrosive substances, and abrasive particles, push vacuum pumps to their operational limits.

One of the primary challenges is material degradation. Extreme temperatures, both high and low, can cause thermal stress, leading to material fatigue and premature failure. In high-temperature environments, seals and lubricants may break down, compromising the pump's ability to maintain a vacuum. Conversely, in cryogenic conditions, materials may become brittle, increasing the risk of fractures and leaks.

Corrosion presents another significant hurdle. Exposure to aggressive chemicals or saltwater environments can rapidly deteriorate pump components, particularly those made from less resistant materials. This corrosion not only affects the pump's structural integrity but can also introduce contaminants into the vacuum system, further compromising its efficiency.

Abrasive particles pose a substantial threat to vacuum pump reliability. In dusty or sandy environments, these particles can infiltrate the pump mechanism, causing accelerated wear on moving parts, seals, and bearings. This wear can lead to increased friction, reduced efficiency, and ultimately, pump failure.

High-pressure environments exert additional stress on vacuum pump components. Seals and gaskets may struggle to maintain their integrity under extreme pressure differentials, leading to leaks and loss of vacuum. Furthermore, the increased mechanical stress on pump components can accelerate wear and fatigue.

Reliability issues are compounded by the difficulty of performing maintenance in extreme environments. Remote locations, hazardous conditions, or continuous operation requirements can limit access for routine inspections and repairs. This challenge often necessitates the development of more robust, low-maintenance pump designs or innovative remote monitoring solutions.

Electromagnetic interference (EMI) and radiation in certain extreme environments can also affect the electronic controls and sensors of modern vacuum pumps. This interference may lead to erratic operation or false readings, compromising the pump's performance and reliability.

The combination of these challenges often results in reduced operational lifespans for vacuum pumps in extreme conditions. This necessitates more frequent replacements, increasing operational costs and downtime. Moreover, the unpredictability of pump failure in these environments can pose significant safety risks in critical applications.

Addressing these challenges requires a multifaceted approach, including advanced materials research, innovative design solutions, and the development of specialized lubricants and coatings. Engineers must also consider the integration of robust monitoring systems and predictive maintenance strategies to enhance reliability in these demanding operational contexts.

One of the primary challenges is material degradation. Extreme temperatures, both high and low, can cause thermal stress, leading to material fatigue and premature failure. In high-temperature environments, seals and lubricants may break down, compromising the pump's ability to maintain a vacuum. Conversely, in cryogenic conditions, materials may become brittle, increasing the risk of fractures and leaks.

Corrosion presents another significant hurdle. Exposure to aggressive chemicals or saltwater environments can rapidly deteriorate pump components, particularly those made from less resistant materials. This corrosion not only affects the pump's structural integrity but can also introduce contaminants into the vacuum system, further compromising its efficiency.

Abrasive particles pose a substantial threat to vacuum pump reliability. In dusty or sandy environments, these particles can infiltrate the pump mechanism, causing accelerated wear on moving parts, seals, and bearings. This wear can lead to increased friction, reduced efficiency, and ultimately, pump failure.

High-pressure environments exert additional stress on vacuum pump components. Seals and gaskets may struggle to maintain their integrity under extreme pressure differentials, leading to leaks and loss of vacuum. Furthermore, the increased mechanical stress on pump components can accelerate wear and fatigue.

Reliability issues are compounded by the difficulty of performing maintenance in extreme environments. Remote locations, hazardous conditions, or continuous operation requirements can limit access for routine inspections and repairs. This challenge often necessitates the development of more robust, low-maintenance pump designs or innovative remote monitoring solutions.

Electromagnetic interference (EMI) and radiation in certain extreme environments can also affect the electronic controls and sensors of modern vacuum pumps. This interference may lead to erratic operation or false readings, compromising the pump's performance and reliability.

The combination of these challenges often results in reduced operational lifespans for vacuum pumps in extreme conditions. This necessitates more frequent replacements, increasing operational costs and downtime. Moreover, the unpredictability of pump failure in these environments can pose significant safety risks in critical applications.

Addressing these challenges requires a multifaceted approach, including advanced materials research, innovative design solutions, and the development of specialized lubricants and coatings. Engineers must also consider the integration of robust monitoring systems and predictive maintenance strategies to enhance reliability in these demanding operational contexts.

Existing Reliability Solutions

01 Improved sealing mechanisms

Enhanced sealing mechanisms in vacuum pumps contribute significantly to their reliability. These improvements include advanced gasket designs, precision-engineered sealing surfaces, and innovative sealing materials that can withstand high vacuum conditions and temperature fluctuations. Such enhancements reduce leakage, maintain vacuum integrity, and extend the operational life of the pump.- Improved sealing mechanisms: Enhanced sealing mechanisms in vacuum pumps contribute significantly to their reliability. These improvements focus on reducing leakage, minimizing wear, and maintaining consistent performance over extended periods. Advanced sealing technologies can include innovative materials, precision-engineered components, and optimized designs that withstand the rigors of vacuum operation.

- Thermal management solutions: Effective thermal management is crucial for vacuum pump reliability. This involves implementing cooling systems, heat dissipation techniques, and temperature-resistant materials to prevent overheating and maintain optimal operating conditions. Proper thermal management extends the pump's lifespan and ensures consistent performance under various operating conditions.

- Advanced lubrication systems: Innovative lubrication systems play a vital role in enhancing vacuum pump reliability. These systems ensure proper lubrication of moving parts, reducing friction and wear. Advanced lubrication techniques may include self-lubricating materials, automated lubrication systems, or specialized lubricants designed for vacuum environments, all contributing to extended pump life and reduced maintenance requirements.

- Vibration reduction techniques: Minimizing vibration is essential for improving vacuum pump reliability. This can be achieved through advanced balancing techniques, vibration-dampening materials, and innovative pump designs that reduce mechanical stress. By mitigating vibration, these techniques help prevent premature wear, maintain alignment, and ensure consistent pump performance over time.

- Intelligent monitoring and control systems: Incorporating intelligent monitoring and control systems significantly enhances vacuum pump reliability. These systems can include sensors for real-time performance monitoring, predictive maintenance algorithms, and automated adjustment mechanisms. By providing early warning of potential issues and optimizing operating parameters, these systems help prevent failures and extend the operational life of vacuum pumps.

02 Optimized rotor and stator configurations

Advancements in rotor and stator designs have led to increased vacuum pump reliability. These improvements include precision-balanced rotors, optimized blade geometries, and enhanced stator materials. Such configurations reduce vibration, improve efficiency, and minimize wear, resulting in more reliable and longer-lasting vacuum pump operations.Expand Specific Solutions03 Advanced lubrication systems

Innovative lubrication systems play a crucial role in enhancing vacuum pump reliability. These systems include self-lubricating materials, optimized oil circulation pathways, and intelligent lubrication control mechanisms. By ensuring proper lubrication of critical components, these advancements reduce friction, minimize wear, and extend the operational lifespan of vacuum pumps.Expand Specific Solutions04 Thermal management solutions

Effective thermal management is essential for maintaining vacuum pump reliability. Advanced cooling systems, heat-dissipating materials, and optimized pump designs that facilitate better heat distribution contribute to improved performance and longevity. These solutions prevent overheating, reduce thermal stress on components, and ensure consistent operation under various conditions.Expand Specific Solutions05 Intelligent monitoring and control systems

Integration of smart monitoring and control systems significantly enhances vacuum pump reliability. These systems include real-time performance monitoring, predictive maintenance algorithms, and adaptive control mechanisms. By continuously analyzing pump parameters and adjusting operations accordingly, these intelligent systems optimize performance, prevent failures, and extend the overall reliability of vacuum pumps.Expand Specific Solutions

Key Industry Players

The vacuum pump reliability market in extreme conditions is in a mature stage, with a global market size estimated to be in the billions of dollars. Key players like Pfeiffer Vacuum GmbH, Edwards Ltd., and Leybold AG dominate the industry, leveraging decades of experience and advanced technologies. The competition is intense, with companies focusing on innovation to improve pump performance and durability in harsh environments. Research institutions such as Korea Research Institute of Standards & Science and Southwest Research Institute contribute to technological advancements, while universities like the University of Leicester collaborate on cutting-edge research. The market is characterized by a high degree of technical sophistication, with ongoing efforts to enhance efficiency, reduce maintenance requirements, and extend operational lifespans in challenging industrial applications.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum has developed advanced turbomolecular pumps specifically designed for extreme conditions. Their HiPace series incorporates innovative rotor designs and bearing technologies to maintain reliability in harsh environments. The pumps feature high-temperature resistant materials and specialized coatings to withstand corrosive gases and extreme temperatures. Pfeiffer's adaptive drive technology automatically adjusts rotor speed based on gas load and temperature, ensuring optimal performance and longevity[1]. Additionally, their pumps integrate advanced diagnostics and predictive maintenance capabilities, allowing for real-time monitoring of pump health and early detection of potential issues[2].

Strengths: Specialized designs for extreme conditions, advanced materials and coatings, adaptive drive technology, and integrated diagnostics. Weaknesses: Potentially higher initial cost due to specialized features, may require more frequent maintenance in particularly harsh environments.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed the nEXT turbomolecular pump series, engineered for reliability in extreme conditions. These pumps feature a unique bearing design that combines ceramic ball bearings with a permanent magnetic radial bearing, significantly reducing wear and extending operational life in harsh environments[3]. Edwards' pumps also incorporate advanced thermal management systems, including water-cooling options for high-temperature applications. Their proprietary control algorithms optimize pump performance based on real-time operating conditions, ensuring stability and efficiency across a wide range of pressures and gas compositions[4]. Edwards has also implemented advanced materials in their pump construction, such as corrosion-resistant coatings and high-strength alloys, to enhance durability in aggressive chemical environments.

Strengths: Innovative bearing design for extended life, advanced thermal management, adaptive control algorithms, and use of specialized materials. Weaknesses: Potential complexity in maintenance due to advanced features, may have higher power consumption in certain operating modes.

Core Innovations in Pump Design

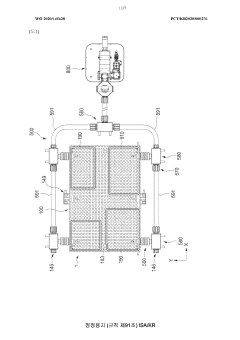

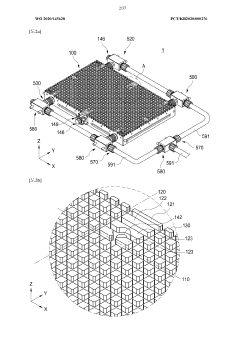

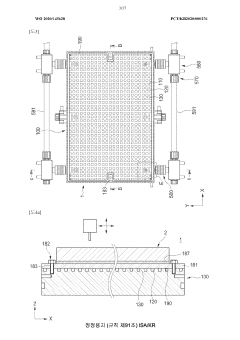

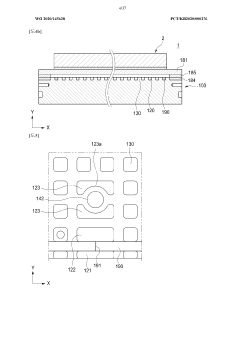

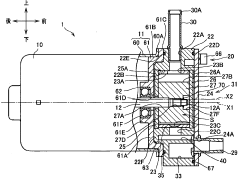

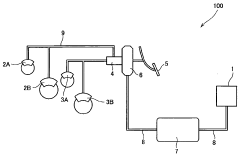

Vacuum pump and vacuum separator comprising same

PatentWO2020145628A1

Innovation

- A vacuum pump with a multi-stage nozzle unit and chamber structure, incorporating enlarged check valves for improved vacuum tightness and durability, and a vacuum separator to remove liquids from gas mixtures, preventing contamination and ensuring smooth operation.

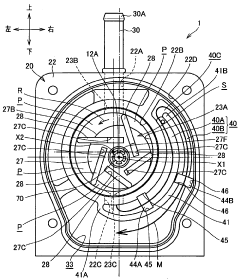

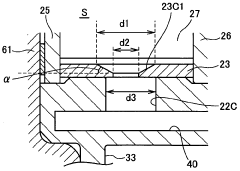

Vacuum pump

PatentWO2011126032A2

Innovation

- The vacuum pump design incorporates a folded exhaust path with an expansion chamber and sound deadening members, a thermally conductive casing for efficient heat dissipation, grooved vanes to prevent negative pressure issues, and a push nut mechanism to restrict rotor movement and prevent wear.

Material Science Advancements

Recent advancements in material science have significantly contributed to enhancing vacuum pump reliability in extreme conditions. The development of novel materials with superior properties has addressed many challenges faced by traditional vacuum pumps operating in harsh environments. One key area of progress is the creation of advanced alloys that exhibit exceptional resistance to corrosion, wear, and thermal stress. These alloys, often incorporating elements such as nickel, chromium, and molybdenum, maintain their structural integrity and performance even when exposed to aggressive chemicals, high temperatures, or abrasive particles.

Ceramic materials have also played a crucial role in improving vacuum pump reliability. Advanced ceramics, such as silicon carbide and alumina, offer excellent hardness, thermal stability, and chemical inertness. These properties make them ideal for components subjected to severe wear and corrosive environments. The integration of ceramic bearings and seals has led to extended pump lifetimes and reduced maintenance requirements, particularly in applications involving corrosive gases or high-temperature processes.

Surface engineering techniques have further enhanced the performance of vacuum pump components. Techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) allow for the application of thin, protective coatings that significantly improve wear resistance and reduce friction. Diamond-like carbon (DLC) coatings, for instance, provide exceptional hardness and low friction coefficients, extending the operational life of moving parts within the pump.

Polymer science has also contributed to vacuum pump reliability through the development of advanced elastomers and thermoplastics. These materials offer improved chemical resistance, thermal stability, and sealing properties compared to traditional rubber compounds. Fluoropolymers, such as PTFE and PEEK, have found widespread use in vacuum pump seals and gaskets due to their exceptional chemical inertness and low outgassing characteristics.

Nanostructured materials represent a frontier in material science that holds great promise for vacuum pump technology. Nanocomposites, combining nanoscale reinforcements with traditional matrix materials, can exhibit enhanced mechanical properties, thermal conductivity, and wear resistance. These materials have the potential to revolutionize pump design by allowing for lighter, stronger, and more durable components.

The integration of smart materials into vacuum pump systems is another emerging trend. Shape memory alloys and piezoelectric materials can be used to create adaptive components that respond to changes in temperature or pressure, potentially improving pump efficiency and reliability in varying operating conditions. Additionally, self-healing materials are being explored for their ability to automatically repair minor damage, potentially extending the maintenance intervals of vacuum pumps in challenging environments.

Ceramic materials have also played a crucial role in improving vacuum pump reliability. Advanced ceramics, such as silicon carbide and alumina, offer excellent hardness, thermal stability, and chemical inertness. These properties make them ideal for components subjected to severe wear and corrosive environments. The integration of ceramic bearings and seals has led to extended pump lifetimes and reduced maintenance requirements, particularly in applications involving corrosive gases or high-temperature processes.

Surface engineering techniques have further enhanced the performance of vacuum pump components. Techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) allow for the application of thin, protective coatings that significantly improve wear resistance and reduce friction. Diamond-like carbon (DLC) coatings, for instance, provide exceptional hardness and low friction coefficients, extending the operational life of moving parts within the pump.

Polymer science has also contributed to vacuum pump reliability through the development of advanced elastomers and thermoplastics. These materials offer improved chemical resistance, thermal stability, and sealing properties compared to traditional rubber compounds. Fluoropolymers, such as PTFE and PEEK, have found widespread use in vacuum pump seals and gaskets due to their exceptional chemical inertness and low outgassing characteristics.

Nanostructured materials represent a frontier in material science that holds great promise for vacuum pump technology. Nanocomposites, combining nanoscale reinforcements with traditional matrix materials, can exhibit enhanced mechanical properties, thermal conductivity, and wear resistance. These materials have the potential to revolutionize pump design by allowing for lighter, stronger, and more durable components.

The integration of smart materials into vacuum pump systems is another emerging trend. Shape memory alloys and piezoelectric materials can be used to create adaptive components that respond to changes in temperature or pressure, potentially improving pump efficiency and reliability in varying operating conditions. Additionally, self-healing materials are being explored for their ability to automatically repair minor damage, potentially extending the maintenance intervals of vacuum pumps in challenging environments.

Environmental Impact Assessment

The environmental impact of vacuum pump reliability in extreme conditions is a critical consideration for industries operating in challenging environments. The use of vacuum pumps in harsh conditions can lead to increased energy consumption, heightened emissions, and potential environmental hazards if not properly managed.

Extreme conditions, such as high temperatures, corrosive atmospheres, or extreme pressures, can significantly affect the performance and longevity of vacuum pumps. When these pumps fail or operate inefficiently, they consume more energy, leading to increased carbon emissions and higher operational costs. This energy inefficiency not only impacts the environment but also contributes to the depletion of non-renewable resources.

Furthermore, vacuum pump failures in extreme conditions can result in the release of harmful substances into the environment. For instance, in chemical processing or oil and gas industries, pump malfunctions may lead to leaks of hazardous materials, potentially contaminating soil, water, or air. Such incidents can have severe consequences for local ecosystems and human health.

The disposal of vacuum pumps and their components also presents environmental challenges. Pumps exposed to extreme conditions may degrade more rapidly, necessitating more frequent replacements. This increased turnover contributes to electronic waste and the consumption of raw materials for manufacturing replacement parts.

To mitigate these environmental impacts, industries are focusing on developing more resilient and efficient vacuum pump technologies. Advanced materials and coatings are being explored to enhance pump durability in extreme conditions, reducing the frequency of replacements and associated waste. Additionally, smart monitoring systems are being implemented to optimize pump performance, minimizing energy consumption and preventing catastrophic failures that could lead to environmental contamination.

Efforts are also being made to improve the recyclability and eco-friendly disposal of vacuum pump components. This includes the use of more sustainable materials and the implementation of take-back programs to ensure proper recycling of used pumps and parts.

In conclusion, the environmental impact assessment of vacuum pump reliability in extreme conditions highlights the need for continuous innovation in pump technology. By improving reliability, efficiency, and sustainability, industries can significantly reduce their environmental footprint while operating in challenging environments. This assessment underscores the importance of considering environmental factors in the development and deployment of vacuum pump technologies for extreme conditions.

Extreme conditions, such as high temperatures, corrosive atmospheres, or extreme pressures, can significantly affect the performance and longevity of vacuum pumps. When these pumps fail or operate inefficiently, they consume more energy, leading to increased carbon emissions and higher operational costs. This energy inefficiency not only impacts the environment but also contributes to the depletion of non-renewable resources.

Furthermore, vacuum pump failures in extreme conditions can result in the release of harmful substances into the environment. For instance, in chemical processing or oil and gas industries, pump malfunctions may lead to leaks of hazardous materials, potentially contaminating soil, water, or air. Such incidents can have severe consequences for local ecosystems and human health.

The disposal of vacuum pumps and their components also presents environmental challenges. Pumps exposed to extreme conditions may degrade more rapidly, necessitating more frequent replacements. This increased turnover contributes to electronic waste and the consumption of raw materials for manufacturing replacement parts.

To mitigate these environmental impacts, industries are focusing on developing more resilient and efficient vacuum pump technologies. Advanced materials and coatings are being explored to enhance pump durability in extreme conditions, reducing the frequency of replacements and associated waste. Additionally, smart monitoring systems are being implemented to optimize pump performance, minimizing energy consumption and preventing catastrophic failures that could lead to environmental contamination.

Efforts are also being made to improve the recyclability and eco-friendly disposal of vacuum pump components. This includes the use of more sustainable materials and the implementation of take-back programs to ensure proper recycling of used pumps and parts.

In conclusion, the environmental impact assessment of vacuum pump reliability in extreme conditions highlights the need for continuous innovation in pump technology. By improving reliability, efficiency, and sustainability, industries can significantly reduce their environmental footprint while operating in challenging environments. This assessment underscores the importance of considering environmental factors in the development and deployment of vacuum pump technologies for extreme conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!